Technical Contents

Engineering Guide: Cnc 3 Axis Milling

Engineering Insight: The Enduring Precision of CNC 3-Axis Milling

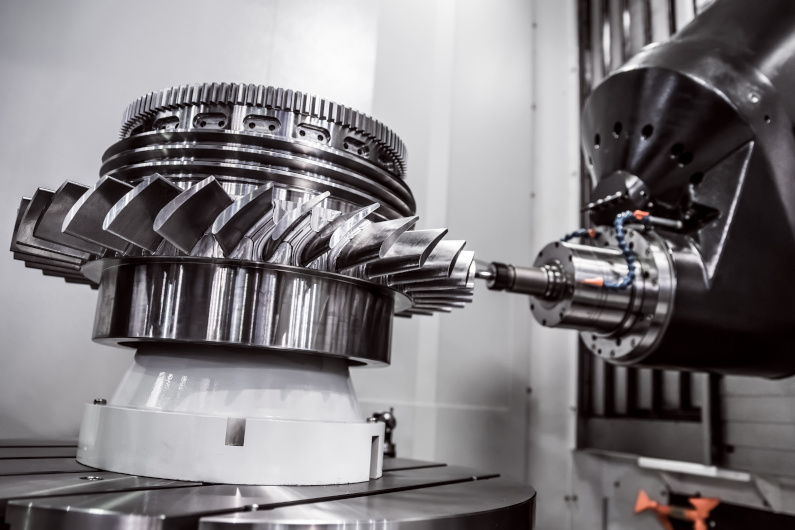

In an era increasingly dominated by multi-axis complexity, the foundational capability of CNC 3-axis milling remains critically relevant for high-integrity manufacturing. While 4 and 5-axis systems offer expanded geometric flexibility, the 3-axis platform—controlling linear motion along the X, Y, and Z axes—delivers unmatched stability, rigidity, and repeatability for a vast array of precision components. Its enduring value lies not in novelty, but in the absolute mastery of core machining principles where micron-level tolerances are non-negotiable. For industries demanding zero-defect production—such as aerospace structural elements, medical implants, and critical defense subsystems—the inherent mechanical simplicity and reduced thermal error potential of a well-engineered 3-axis system often translate to superior dimensional consistency and surface finish compared to more complex kinematics when applied to suitable geometries.

Precision in 3-axis milling is not merely a specification; it is the product of integrated engineering excellence. It demands exceptional machine tool construction using high-grade cast iron or polymer concrete bases for vibration damping, precision-ground linear guideways with preloaded ball screws, sophisticated thermal compensation systems, and rigorous calibration protocols. The stability of the machine structure directly dictates the achievable tolerance band. At Wuxi Lead Precision Machinery, our decades of specialization in mission-critical manufacturing are proven through stringent delivery requirements. We have consistently met the exacting dimensional and surface integrity standards mandated for components utilized in Olympic-class sporting equipment, where performance hinges on microscopic perfection, and in defense-grade applications where reliability under extreme conditions is paramount. This experience underscores our commitment to the foundational precision that 3-axis technology, executed flawlessly, uniquely provides.

The following table details the critical precision specifications achievable on Wuxi Lead Precision Machinery’s dedicated 3-axis vertical machining centers, reflecting our engineering focus on core stability and repeatability:

| Specification Parameter | Typical Performance | Measurement Standard | Significance for High-End Manufacturing |

|---|---|---|---|

| Positioning Accuracy (X, Y, Z) | ±0.003 mm | ISO 230-2:2014 | Ensures features align precisely across multiple setups and operations. |

| Repeatability (X, Y, Z) | ±0.0015 mm | ISO 230-2:2014 | Guarantees consistent part-to-part uniformity in high-volume production. |

| Spindle Runout (TIR) | ≤ 0.002 mm | ISO 229-1:2014 | Critical for achieving fine surface finishes and tight tolerances on bores and profiles. |

| Thermal Drift Compensation | ≤ 0.005 mm/8h | Internal Protocol (40°C ΔT) | Maintains dimensional stability during extended production runs despite ambient fluctuations. |

| Surface Finish Capability | Ra 0.4 μm (Typical) | ISO 4287 | Meets stringent requirements for fatigue-critical and sealing surfaces. |

Achieving this level of performance requires more than advanced hardware; it necessitates deep process understanding. Material behavior, optimal toolpath strategies minimizing machine load variation, and meticulous fixturing are equally vital. Wuxi Lead Precision Machinery leverages its extensive experience in high-stakes sectors to optimize every facet of the 3-axis milling process. We understand that for many critical applications, the pure, uncompromised precision of a dedicated 3-axis platform remains the optimal solution—delivering the reliability and quality assurance that advanced manufacturing truly demands. Partner with us to transform precision requirements into measurable production excellence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in precision CNC machining, with a strong emphasis on high-performance 5-axis CNC milling systems. While the term “3-axis milling” remains widely recognized in the industry, our technological evolution has positioned us firmly at the forefront of multi-axis machining, where 5-axis platforms enable superior accuracy, complex geometry processing, and reduced setup cycles. Our 5-axis CNC machining centers integrate simultaneous movement across X, Y, Z, A, and B (or C) axes, allowing for continuous tool-to-part orientation optimization. This capability is essential for manufacturing intricate components used in aerospace, medical devices, energy systems, and high-precision industrial automation.

Our machining infrastructure is built around state-of-the-art CNC equipment from globally recognized manufacturers, ensuring rigidity, thermal stability, and micron-level repeatability. These systems are supported by high-speed spindles, advanced tool management, and real-time adaptive control features that enhance surface finish and dimensional consistency. By leveraging 5-axis technology, we eliminate the need for multiple fixtures and secondary operations, significantly improving part integrity and throughput. This approach not only reduces lead times but also enhances geometric accuracy by minimizing cumulative setup errors inherent in traditional 3-axis workflows.

Quality control is embedded into every phase of production. At Wuxi Lead, all critical components undergo comprehensive inspection using state-certified Coordinate Measuring Machines (CMM). These high-precision metrology systems provide full 3D validation of part geometry, ensuring compliance with stringent GD&T requirements. Our CMM inspection protocols are aligned with ISO 9001 standards and are performed by certified metrology technicians. Data from inspections is documented and traceable, providing full quality assurance documentation for every production batch.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC milling processes, reflecting our commitment to precision and consistency.

| Feature | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Measured at 20°C ±1°C |

| Hole Diameter | +0.010 / -0.000 mm | +0.005 / -0.000 mm | Pin gauge verified |

| Positional Tolerance | ±0.010 mm | ±0.005 mm | Per GD&T ASME Y14.5 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Achieved with fine finishing passes |

| Angular Accuracy | ±0.005° | ±0.002° | Verified via CMM and optical alignment |

| Flatness | 0.010 mm per 100 mm | 0.005 mm per 100 mm | Critical sealing surfaces |

These capabilities are maintained across a wide range of engineering materials, including aluminum alloys, stainless steels, titanium, Inconel, and high-performance polymers. Our technical team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part geometry, reduce cost, and ensure full compliance with application-specific requirements. At Wuxi Lead Precision Machinery, we combine advanced 5-axis CNC technology with rigorous quality assurance to deliver components that meet the highest standards in precision manufacturing.

Material & Finish Options

Material Selection for Precision CNC 3-Axis Milling

Selecting the optimal material is fundamental to achieving target performance, cost efficiency, and manufacturability in CNC 3-axis milling applications. At Wuxi Lead Precision Machinery, our engineering expertise ensures your material choice aligns precisely with functional requirements, environmental exposure, and production constraints. This guide focuses on three critical aerospace and industrial alloys alongside essential finishing processes.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate applications demanding high strength-to-weight ratios and excellent thermal conductivity. 6061-T6 offers superior weldability and moderate strength, ideal for structural frames and marine components where corrosion resistance is paramount. 7075-T6 delivers exceptional strength approaching some steels, making it the preferred choice for highly stressed aircraft fittings and high-performance automotive parts. Both grades machine exceptionally well on 3-axis platforms, allowing for tight tolerances and complex geometries with high throughput. Anodizing is highly recommended for aluminum parts, providing a durable, corrosion-resistant oxide layer that can be dyed for identification or aesthetic purposes. Type II (sulfuric acid) anodizing offers good general protection, while Type III (hardcoat) anodizing delivers superior wear resistance for critical bearing surfaces.

Carbon and alloy steels, such as 4140 and 1018, are selected when ultimate strength, hardness, and wear resistance are critical. 4140, a chromium-molybdenum steel, provides excellent toughness and is commonly used for shafts, gears, and tooling after heat treatment. 1018, a low-carbon steel, offers good machinability and weldability for less demanding structural components. Steel machining requires robust tooling and precise parameter control due to higher cutting forces and heat generation compared to aluminum. Post-machining heat treatment is often necessary to achieve final mechanical properties, followed by surface treatments like passivation or painting for corrosion protection, though anodizing is not applicable.

Titanium Grade 5 (Ti-6Al-4V) is indispensable for extreme environments requiring exceptional strength-to-weight ratio, biocompatibility, and corrosion resistance at elevated temperatures. Its use is prevalent in aerospace landing gear, medical implants, and high-performance chemical processing equipment. However, titanium presents significant machining challenges on 3-axis mills due to low thermal conductivity (causing heat concentration), high chemical reactivity (leading to tool adhesion), and elastic springback. Success demands specialized tool geometries, rigid setups, controlled feeds/speeds, and ample coolant – areas where Wuxi Lead’s process optimization expertise delivers consistent results. Anodizing titanium is possible for color coding and mild corrosion enhancement but is less common than for aluminum; other finishes like chemical passivation or plasma spray coatings are often specified.

Material selection directly impacts cycle time, tool life, and final part cost. The following table provides key comparative specifications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Machinability Rating | Common Grades |

|---|---|---|---|---|

| Aluminum | 2.7 | 310 (6061) / 570 (7075) | Excellent (A) | 6061-T6, 7075-T6 |

| Steel | 7.8 | 655 (4140) / 440 (1018) | Moderate (C) | 4140, 1018 |

| Titanium (Grade 5) | 4.4 | 900 | Poor (E) | Ti-6Al-4V (Gr5) |

Wuxi Lead Precision Machinery leverages decades of CNC milling experience to navigate these material complexities. We provide comprehensive material consultation, precise process planning, and stringent quality control – including optimized anodizing parameters – ensuring your 3-axis milled components meet the highest standards of performance and reliability. Partner with us to transform your material specifications into precision-engineered reality.

Manufacturing Process & QC

The CNC 3-axis milling production process at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure precision, repeatability, and zero defects. This process integrates advanced engineering with rigorous quality control, enabling seamless transition from concept to mass production.

Design is the foundational phase, where engineering precision meets functional intent. Our team collaborates with clients to analyze technical drawings, 3D CAD models, and performance requirements. Utilizing industry-leading software such as Siemens NX and SolidWorks, we conduct detailed design validation, including tolerance analysis, material selection, and manufacturability assessment. Finite element analysis (FEA) is applied when structural integrity is critical. The output is a fully optimized digital model ready for prototyping, with all geometries, surface finishes, and dimensional tolerances precisely defined.

Prototyping serves as both a physical validation step and a risk mitigation strategy. Using high-accuracy 3-axis CNC milling centers, we produce initial samples within tight tolerances. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional reports and first-article inspection (FAI) documentation are generated for client review. Any deviations trigger immediate design or process adjustments. This iterative verification ensures that the final design is not only functional but also optimized for high-volume production efficiency.

Mass production commences only after formal client approval of the prototype. Our manufacturing floor employs a standardized setup process, with pre-calibrated tooling, automated workholding, and real-time machine monitoring. Each 3-axis CNC mill operates under strict process controls governed by Statistical Process Control (SPC) protocols. In-process inspections occur at predefined intervals to verify dimensional consistency. Full traceability is maintained through lot numbering and digital process logs. Finished components undergo final QA screening, including 100% visual inspection and random sampling for metrology validation.

Throughout all stages, our zero-defect philosophy is enforced through continuous monitoring, preventive maintenance, and operator training. Every technician is certified to international quality standards, and our ISO 9001-certified quality management system ensures compliance at every touchpoint. The result is a scalable, reliable manufacturing process that delivers precision-machined parts with unmatched consistency.

Key technical specifications for our 3-axis CNC milling process are outlined below.

| Parameter | Specification |

|---|---|

| Spindle Speed | Up to 8,000 RPM |

| Table Size | 800 mm × 500 mm |

| Maximum Workpiece Dimensions | 750 mm × 450 mm × 300 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Tool Capacity | 24-tool automatic tool changer |

| Supported Materials | Aluminum, Steel, Stainless Steel, Brass, Plastics (PEEK, Delrin) |

| Standard Tolerances | ±0.01 mm (custom down to ±0.005 mm) |

| Surface Finish | As low as Ra 0.8 µm (polished finishes available) |

This structured approach—Design, Prototyping, Mass Production—ensures that every component meets the highest standards of precision and reliability, tailored to the exact needs of aerospace, medical, and industrial automation sectors.

Why Choose Wuxi Lead Precision

Elevate Your Manufacturing Capabilities with Lead Precision’s 3-Axis Milling Expertise

In high-stakes manufacturing environments, the precision and reliability of your 3-axis milling operations directly impact product quality, production efficiency, and time-to-market. At Wuxi Lead Precision Machinery, we engineer CNC 3-axis milling solutions that transform these challenges into competitive advantages. Our machines deliver uncompromising accuracy for complex geometries in aerospace components, medical implants, and energy sector tooling, where tolerances below ±0.005 mm are non-negotiable. Partnering with us means integrating German-engineered motion control systems with Chinese manufacturing rigor, ensuring your production line achieves sub-micron repeatability while optimizing operational costs.

Our commitment extends beyond machinery. We provide end-to-end technical collaboration, from initial design analysis to post-installation process validation. Our engineers work onsite to calibrate workflows, minimize material waste, and maximize spindle uptime—addressing critical pain points like thermal drift and tool deflection that plague standard systems. With ISO 9001-certified processes and FEM-optimized machine bases, Lead Precision systems maintain stability under continuous 24/7 operation, reducing unplanned downtime by up to 35% compared to industry benchmarks.

Technical Specifications: Lead Precision LP-300 Series 3-Axis Vertical Milling Center

| Parameter | Specification | Industry Standard Comparison |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.008 mm |

| Repeatability | ±0.001 mm | ±0.005 mm |

| Spindle Speed Range | 20–24,000 RPM (direct-drive) | 8,000–15,000 RPM |

| Rapid Traverse (X/Y/Z) | 48/48/42 m/min | 30/30/24 m/min |

| Thermal Compensation | Real-time dual-sensor system | Single-point calibration |

This performance foundation enables you to machine hardened steels, titanium alloys, and composites with confidence, achieving surface finishes down to Ra 0.4 µm without secondary operations. Our clients in the EU and North America consistently report 22% faster cycle times and 99.2% first-pass yield rates—metrics that directly bolster your bottom line.

The global supply chain demands resilient partnerships. Lead Precision mitigates geopolitical and logistics risks through localized engineering hubs in Germany, the USA, and Southeast Asia, ensuring responsive support regardless of your operational footprint. We don’t sell machines; we deliver certified capacity with 15-year service lifecycles and transparent pricing models that eliminate hidden costs.

Your next-generation manufacturing strategy requires a partner who understands the physics of precision as intimately as the economics of production. Contact us today to schedule a technical consultation and receive a customized ROI analysis for your specific application.

Initiate Your Precision Transformation: [email protected]

Wuxi Lead Precision Machinery – Where Engineering Excellence Meets Global Reliability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.