Technical Contents

Engineering Guide: Clear Plastic Injection Molding

Engineering Insight: Clear Plastic Injection Molding – The Role of Precision in Optical Clarity and Performance

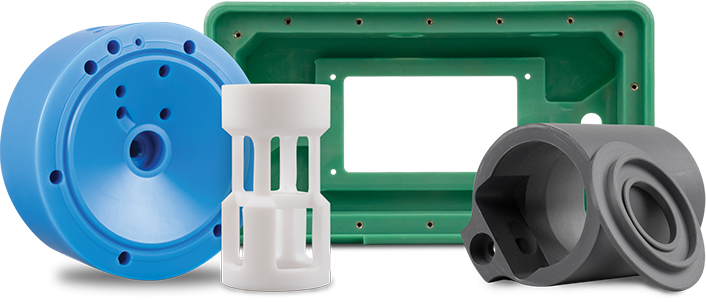

In the realm of high-end manufacturing, clear plastic injection molding stands apart as a discipline where optical clarity, dimensional accuracy, and material consistency converge. Unlike opaque or pigmented resins, transparent polymers such as polycarbonate, PMMA (acrylic), and COP/COC reveal every imperfection—flow lines, sink marks, or microscopic surface defects—making precision not merely desirable but mandatory. At Wuxi Lead Precision Machinery, we approach clear plastic molding with the same rigor applied to our custom metal components for aerospace, defense, and Olympic-standard equipment, where failure is not an option.

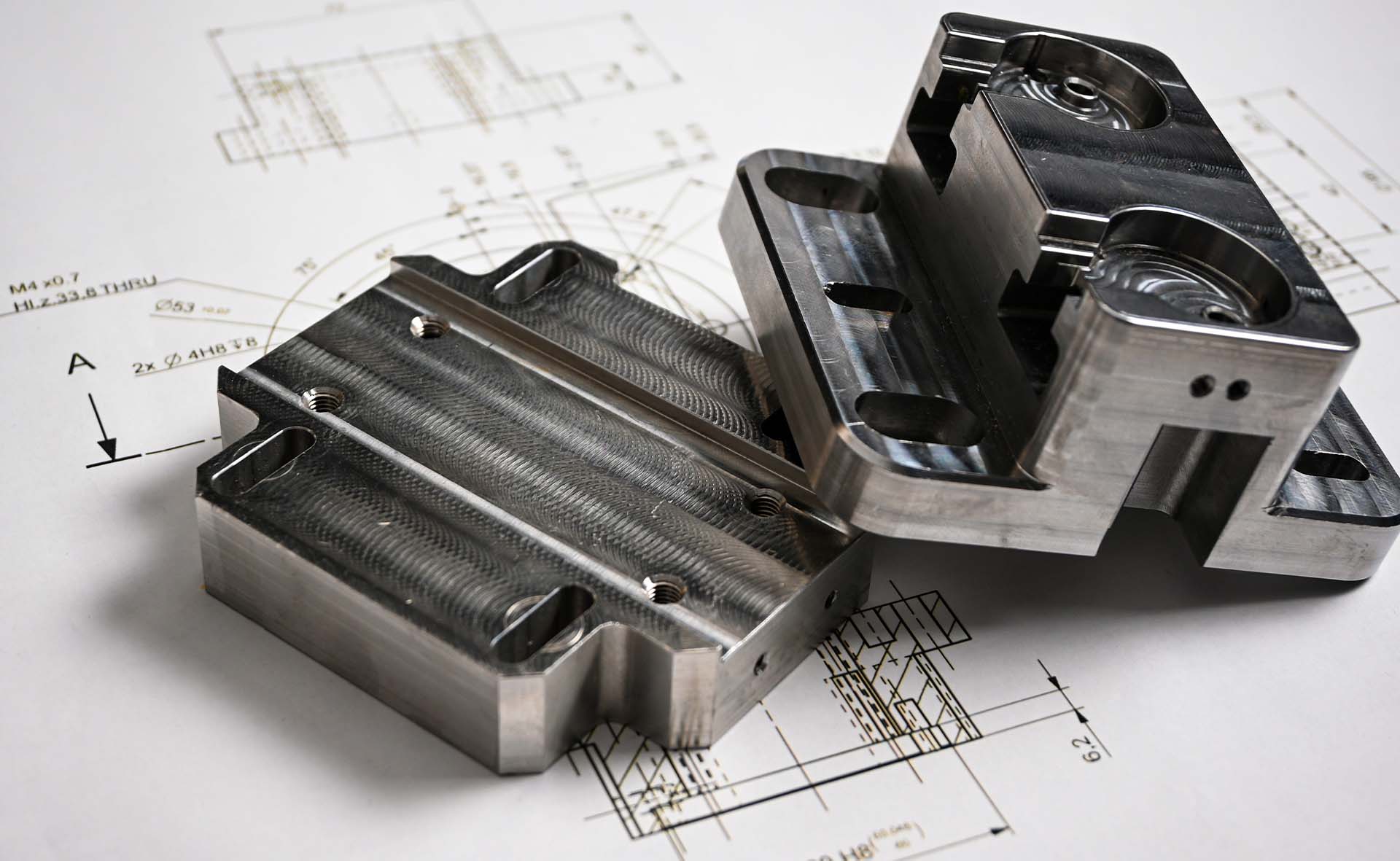

The foundation of successful clear molding lies in precision engineering at every stage: mold design, material handling, process control, and post-processing. Even minor deviations in wall thickness or cooling rates can result in birefringence, warpage, or haze—compromising both aesthetics and functionality. Our molds, machined using Swiss-grade CNC systems and inspected to ±0.002 mm tolerances, are engineered with balanced runner systems, optimized gate geometry, and conformal cooling channels. These features ensure uniform melt flow and thermal management, critical for maintaining clarity and minimizing internal stress.

Material selection is equally vital. Hygroscopic resins like polycarbonate must be dried to below 0.02% moisture content; any residual moisture leads to splay marks and reduced transparency. Our cleanroom-compatible drying and feeding systems maintain strict environmental controls, ensuring material integrity from hopper to cavity. Additionally, we employ high-resolution in-mold sensors and closed-loop pressure control to monitor cavity filling in real time, adjusting injection profiles dynamically to compensate for viscosity fluctuations.

Wuxi Lead’s experience in mission-critical applications directly informs our approach to clear molding. Components we’ve produced for military-grade optics and Olympic timing systems demand not only visual perfection but also repeatability across thousands of cycles. This heritage enables us to deliver molded parts that meet ISO 13485, MIL-STD, and other stringent standards, even in complex geometries.

The following table outlines key specifications and capabilities for our clear plastic injection molding process:

| Parameter | Specification |

|---|---|

| Material Compatibility | PC, PMMA, COP, COC, PS, PETG |

| Mold Tolerance | ±0.002 mm |

| Part Weight Range | 0.1 g – 500 g |

| Clarity (Haze, ASTM D1003) | <1.5% (typical for PMMA/PC) |

| Injection Pressure Control | ±1 bar precision with real-time feedback |

| Drying Conditions | 80–120°C, dew point < -40°C, RH < 5% |

| Cleanroom Class | ISO 7 (Class 10,000) available |

| Secondary Operations | UV coating, plasma treatment, laser marking |

In industries where transparency equates to trust—medical devices, sensor housings, display components—only the highest standard of precision molding suffices. Wuxi Lead Precision Machinery leverages decades of metal and polymer expertise to deliver clarity not just in material, but in performance, consistency, and engineering excellence.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Components for Clear Plastic Injection Molding

While Wuxi Lead Precision Machinery does not produce plastic components directly, our core expertise in ultra-precision custom metal manufacturing is fundamental to enabling high-quality clear plastic injection molding. We specialize in fabricating the critical metal tooling components—mold cores, cavities, inserts, and precision runners—that determine the optical clarity, dimensional accuracy, and surface finish of the final plastic part. Superior mold performance begins with exceptional metal part quality, which is where our advanced capabilities deliver decisive value.

Our foundation is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems provide the simultaneous multi-directional control essential for producing the complex, seamless geometries required in optical-grade molds. We machine hardened tool steels, aluminum alloys, and specialty materials to exacting standards, achieving intricate contours, mirror-finish surfaces, and micron-level feature placement without secondary operations. This capability eliminates parting lines, knit lines, and stress points in the mold that would otherwise manifest as visual defects or structural weaknesses in transparent plastic parts like lenses, light guides, or medical housings.

Rigorous quality control is non-negotiable for optical applications. Every critical metal component undergoes comprehensive inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols verify dimensional conformity against the master CAD model across all axes, validating complex profiles, hole patterns, and critical datum relationships. Surface texture analysis ensures the required roughness for optimal plastic release and clarity. This first-article and in-process inspection guarantees mold components meet the stringent tolerances necessary to prevent common clear molding failures such as haze, distortion, or dimensional instability in the plastic part.

The table below defines the precision levels we consistently achieve on mold-critical metal features. These tolerances directly translate to reduced scrap rates, extended mold life, and superior optical performance in your clear plastic production.

| Feature Type | Tolerance Range | Measurement Method | Application Context |

|---|---|---|---|

| Critical Dimensions | ±0.005 mm | CMM | Lens curvature, sealing surfaces |

| Surface Roughness (Ra) | 0.05 – 0.20 µm | Profilometer | Optical surfaces, cavity finishes |

| Flatness/Parallelism | 0.003 mm per 100 mm | CMM/Optical Flat | Parting lines, core/cavity alignment |

| Hole Position | ±0.008 mm | CMM | Ejector pins, cooling channels |

| Geometric Controls | 0.010 mm (Total Runout) | CMM | Rotational symmetry, concentricity |

This level of metal component precision ensures your injection molding process achieves consistent fill, minimal internal stress, and exceptional light transmission. Partnering with Wuxi Lead means your mold tooling starts with the highest fidelity metal foundation, directly enabling the production of flawless clear plastic components at scale. We machine the precision that makes your optics perfect.

Material & Finish Options

Material Selection for High-Precision Clear Plastic Injection Molding Components

In the production of clear plastic injection molded parts, the performance and longevity of the mold are directly influenced by the choice of mold material and surface finish. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for high-precision tooling, ensuring optimal clarity, dimensional stability, and cycle efficiency in transparent plastic applications. The selection between aluminum, steel, and titanium—alongside appropriate surface treatments such as anodizing—must be guided by production volume, part complexity, and environmental exposure.

Aluminum is often the preferred choice for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. Its ability to dissipate heat quickly reduces cycle times, which is critical in maintaining consistency during molding of sensitive clear resins such as polycarbonate or PMMA. While not as hard as steel, modern high-grade aluminum alloys offer sufficient durability for thousands of cycles when properly treated.

Steel, particularly hardened tool steels like P20 or H13, remains the standard for high-volume production runs. Its superior hardness and wear resistance ensure long-term dimensional accuracy and surface integrity, essential for optical-grade clarity. Stainless steel variants further enhance corrosion resistance, a key factor when processing hygroscopic or abrasive plastics that may degrade under moisture or cause tool erosion over time.

Titanium, though less common in standard mold construction, offers exceptional strength-to-density ratio and corrosion resistance. Its use is typically reserved for specialized inserts or components exposed to extreme conditions, such as high-temperature resins or aggressive chemical environments. While more costly and challenging to machine, titanium’s longevity in corrosive or high-stress zones can justify its application in critical mold areas.

Surface finish plays an equally vital role in clear plastic molding. Imperfections in the mold surface are directly transferred to the final part, compromising transparency and aesthetics. Anodizing is a widely used electrochemical process, particularly for aluminum molds. It increases surface hardness, improves wear resistance, and enhances corrosion protection. Type II (sulfuric acid) anodizing provides a clear or dyed oxide layer suitable for most molding applications, while Type III (hardcoat) anodizing delivers thicker, more durable coatings for extended service life.

Below is a comparative overview of key material properties relevant to mold performance in clear plastic injection molding.

| Material | Hardness (HB) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 150 | 130 | Moderate (improved with anodizing) | Prototyping, low-volume production |

| P20 Steel | 280–320 | 30 | Low (unless stainless) | Medium-to-high volume production |

| H13 Steel | 230–260 | 35 | Moderate | High-temperature, high-wear molding |

| Titanium Grade 5 | 330 | 7 | Excellent | Specialized inserts, corrosive environments |

At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver molds that meet the stringent demands of optical and medical-grade plastic components. Our expertise ensures that every material and finish selection aligns with your production goals, quality standards, and cost-efficiency targets.

Manufacturing Process & QC

Precision Execution: The Zero-Defect Pathway in Clear Plastic Injection Molding

Achieving optical clarity in injection molded plastic demands absolute precision at every stage. At Wuxi Lead Precision Machinery, our expertise lies not in molding plastics directly, but in engineering the ultra-precision metal molds and tooling that make flawless clear parts possible. We partner with leading plastic manufacturers to ensure the foundational metal components meet the exacting demands of high-end optical applications. Our process rigorously follows a Design-Prototyping-Mass Production sequence, engineered for zero defects from inception.

The journey begins with collaborative design engineering. We translate complex optical requirements—minimizing birefringence, eliminating flow lines, ensuring uniform wall thickness—into precise mold geometry. Advanced simulation software models polymer flow, cooling dynamics, and potential stress points within the cavity and core inserts. This phase is critical; microscopic imperfections in the mold steel surface or cooling channel layout directly translate to visible defects in the final clear part. Our engineers work hand-in-hand with your design team to optimize gate location, venting, and ejection systems specifically for clarity-critical resins like PMMA or PC.

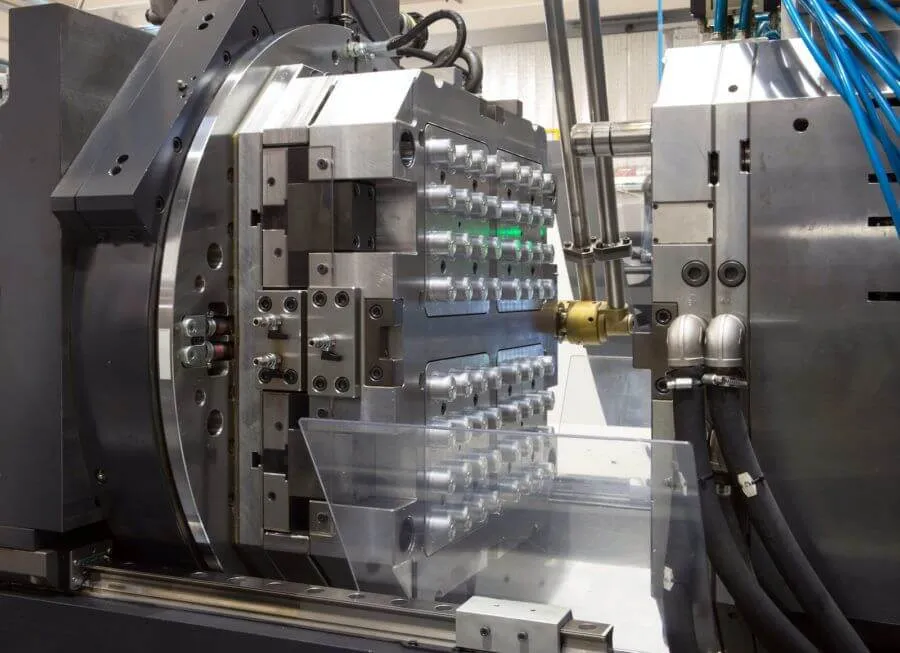

Prototyping utilizes production-intent molds machined from hardened tool steel on our state-of-the-art 5-axis CNC platforms. This is not a soft tool exercise. We produce functional prototypes under actual production parameters to validate optical performance, dimensional stability, and cycle time. Each prototype undergoes rigorous metrology, including interferometry and surface roughness analysis, against the original optical specifications. Any deviation triggers immediate mold steel correction—polishing, texturing adjustment, or cooling circuit modification—before committing to full production. This stage eliminates theoretical risks, proving the mold’s capability for zero-defect output.

Mass production leverages the perfected metal mold system. Zero defects are non-negotiable, achieved through absolute control of the metal mold’s performance. Our molds incorporate proprietary thermal management systems and cavity pressure monitoring integrated directly into the steel. Consistent melt temperature, precise injection speed, and uniform cooling across the entire cavity surface are maintained within microns. The table below details the critical mold performance specifications enabling optical perfection.

| Critical Parameter | Target Specification | Measurement Method | Impact on Clear Part Quality |

|---|---|---|---|

| Cavity Surface Finish (Ra) | ≤ 0.02 μm | Atomic Force Microscopy | Eliminates haze, surface scatter |

| Cooling Channel Uniformity | ΔT ≤ ±0.5°C | Infrared Thermography | Prevents internal stress, distortion |

| Cavity Pressure Control | ±0.5% of setpoint | Integrated Piezoelectric | Ensures consistent molecular alignment |

| Mold Alignment (TIR) | ≤ 2 μm | Laser Alignment System | Prevents flash, knit lines at parting line |

| Thermal Stability (10k cycles) | Δ Dimension ≤ 5 μm | CMM with Temp Chamber | Guarantees long-term dimensional accuracy |

Wuxi Lead’s commitment is to deliver the metal foundation—the mold—that makes zero-defect clear plastic injection molding achievable. We validate every production mold through stringent optical and dimensional testing protocols before shipment. Partner with us to transform demanding optical designs into consistently perfect, high-volume reality. Contact our engineering team for mold validation specifications tailored to your clarity-critical application.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for unmatched expertise in clear plastic injection molding and custom metal manufacturing. As a trusted leader in high-precision industrial solutions, we specialize in delivering engineered components and systems that meet the most demanding specifications. Our advanced manufacturing capabilities, combined with decades of experience in mold design, CNC machining, and injection molding, ensure that every project—no matter how complex—is executed with precision, consistency, and reliability.

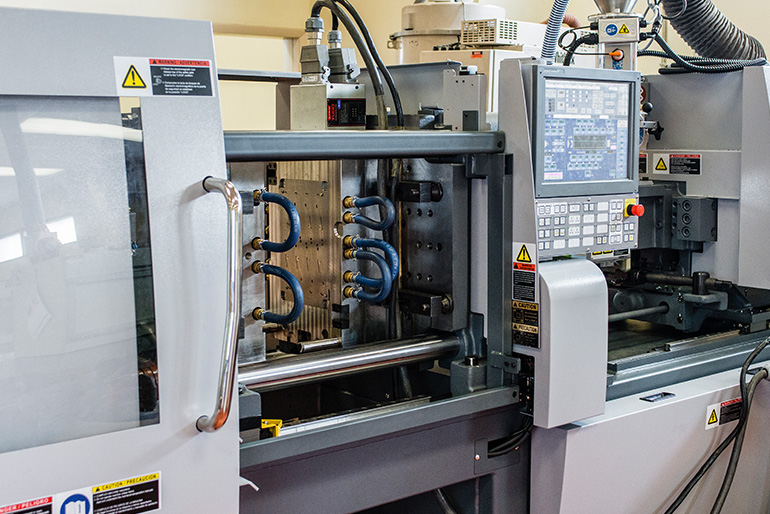

Clear plastic injection molding requires exceptional control over material flow, temperature, and mold surface finish to achieve optical clarity, dimensional accuracy, and structural integrity. At Lead Precision, we utilize state-of-the-art all-electric injection molding machines, climate-controlled production environments, and Class 10,000 cleanroom facilities to eliminate contamination and ensure flawless transparency. Our engineering team works closely with clients from concept to production, offering mold flow analysis, material selection guidance, and rapid prototyping to accelerate time-to-market.

Our facility in Wuxi, China, is equipped with integrated custom metal manufacturing capabilities, enabling us to produce high-precision molds and supporting components in-house. This vertical integration reduces lead times, improves quality control, and allows for seamless coordination between mold fabrication and plastic part production. Whether you require medical-grade transparent housings, optical lenses, or high-volume consumer components, we deliver solutions that meet international standards including ISO 13485, ISO 9001, and RoHS compliance.

We serve industries where clarity, precision, and reliability are non-negotiable—medical devices, automotive lighting, consumer electronics, and industrial instrumentation. Every project is backed by rigorous quality assurance protocols, including in-process inspections, first-article testing, and full traceability of materials and process parameters.

Below are key technical specifications that define our clear plastic injection molding capabilities:

| Specification | Detail |

|---|---|

| Clamping Force Range | 50 to 1,200 tons |

| Shot Weight Accuracy | ±0.1% |

| Mold Tolerance | ±0.002 mm |

| Surface Finish | SPI-SPE (optical grade), mirror polish available |

| Materials Supported | PMMA (acrylic), PC (polycarbonate), COP, COC, PS, cyclic olefin polymers |

| Cleanroom Class | ISO Class 7 (10,000) |

| Secondary Operations | Ultrasonic welding, laser marking, assembly, metrology |

| Quality Standards | ISO 9001, ISO 13485, RoHS, REACH |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally committed to engineering excellence, operational transparency, and long-term collaboration. We don’t just produce parts—we deliver precision-engineered solutions tailored to your application.

For expert support in clear plastic injection molding and integrated metal manufacturing, contact us today. Reach out to our engineering team at [email protected] to discuss your project requirements, request a quote, or schedule a virtual factory audit. Let Lead Precision be your trusted partner in precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.