Technical Contents

Engineering Guide: Clear Injection Molded Plastics

Engineering Insight: Precision Imperatives in Clear Injection Molded Plastics

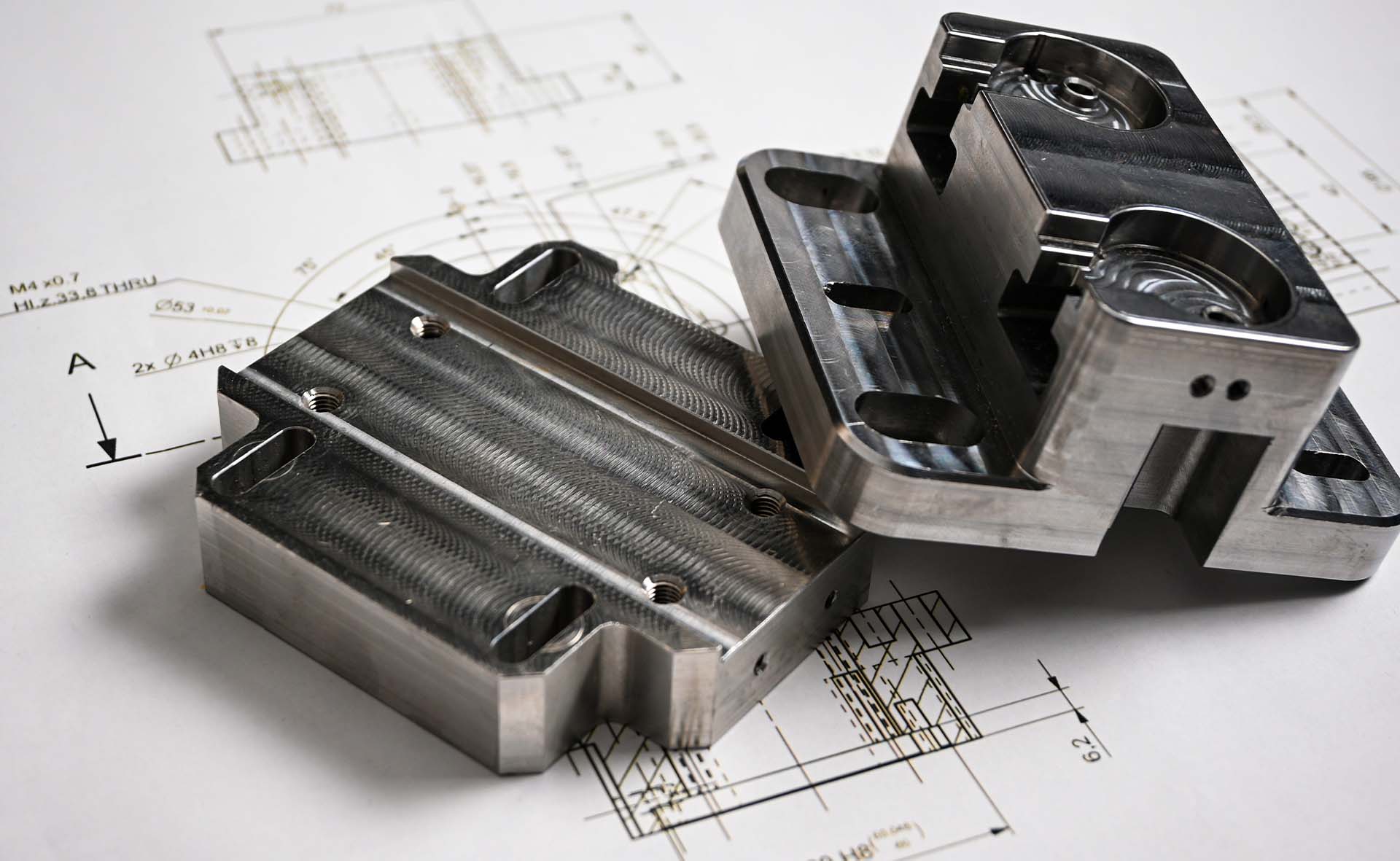

Achieving optical clarity in injection molded plastics transcends basic molding competence. It demands micron-level precision at every stage, where deviations invisible to the naked eye manifest as unacceptable haze, distortion, or internal stresses in the final part. The critical factor determining success is the quality and precision of the metal tooling itself. Imperfections in the mold cavity surface finish, minute thermal variations across the mold, or inadequate venting directly translate into light-scattering defects within the polymer. Standard molding tolerances are insufficient; true optical clarity requires holding dimensional stability and surface integrity far beyond typical industrial standards. This necessitates advanced CNC machining capabilities applied to mold construction, ensuring perfect thermal management, absolute geometric accuracy, and mirror-like finishes that replicate flawlessly onto the plastic substrate.

The polymer flow dynamics during injection are exceptionally sensitive for clear resins like optical-grade polycarbonate (PC) or polymethyl methacrylate (PMMA). Any inconsistency in mold temperature control, injection speed, or pressure profile induces internal stresses or flow lines that compromise transparency. Precision-engineered cooling channels, machined with exacting tolerances using multi-axis CNC technology, are non-negotiable for uniform heat extraction. Similarly, venting must be meticulously calculated and placed to prevent trapped gas without causing material flash – a single micron-scale gap miscalculation can create visible defects. Material selection and drying protocols further compound the precision requirement, as moisture or contamination instantly degrades optical properties.

Wuxi Lead Precision Machinery’s deep expertise in ultra-precision metal manufacturing, forged through demanding projects including components for Olympic timing systems and specialized military optics housings, directly addresses these challenges. These applications demanded absolute zero-defect performance under rigorous environmental testing, where optical clarity was mission-critical. Our experience proves that achieving flawless transparency requires treating the mold not merely as a tool, but as a high-precision optical instrument crafted from metal. This philosophy drives our approach to every clear molding project.

The table below outlines key specifications where precision metal manufacturing directly enables optical clarity:

| Critical Parameter | Standard Industrial Tolerance | Precision Requirement for Optical Clarity | Impact on Clarity |

|---|---|---|---|

| Mold Cavity Surface Finish | Ra 0.2 – 0.4 μm | Ra ≤ 0.025 μm (Mirror Polish) | Eliminates surface scatter; direct replication onto part surface |

| Mold Dimensional Tolerance | ±0.05 – 0.10 mm | ±0.005 – 0.010 mm | Prevents warpage, sink marks, and geometric distortion affecting light transmission |

| Cooling Channel Accuracy | ±0.10 mm | ±0.02 mm | Ensures uniform thermal profile; eliminates stress-induced birefringence |

| Vent Depth Tolerance | ±0.01 mm | ±0.002 mm | Prevents gas traps (haze) without causing flash |

| Material Compatibility | General Purpose Resins | Certified Optical Grade PC, PMMA, COP | Inherent low birefringence and purity; requires precise drying (≤ 0.02% moisture) |

At Wuxi Lead Precision Machinery, our foundation in high-tolerance metal fabrication for the most exacting sectors provides the essential bedrock for mastering clear injection molding. We understand that clarity is not an outcome of the molding press alone, but the direct result of precision-engineered metal tooling and process control. This capability ensures our clients receive components meeting the stringent optical and dimensional demands of medical devices, advanced optics, and premium consumer applications.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered solutions for high-performance applications requiring clear injection molded plastics, leveraging advanced custom metal manufacturing capabilities. Our expertise lies in producing complex, optically clear components that meet stringent dimensional and surface quality standards. Central to our process is the integration of 5-axis CNC machining, which enables the fabrication of highly intricate mold tooling with superior accuracy and surface finish—critical for achieving clarity in injection molded plastic parts.

Our 5-axis CNC machining centers operate with simultaneous multi-axis motion, allowing for continuous tool engagement and access to complex geometries without the need for multiple setups. This level of precision ensures that mold cavities and cores are machined to exact specifications, minimizing parting lines, knit lines, and other defects that can compromise optical clarity. The result is a mold capable of consistently producing transparent components with minimal post-processing, ideal for industries such as medical devices, consumer electronics, automotive lighting, and optical instrumentation.

To maintain the highest level of quality, every mold and finished component undergoes rigorous inspection using coordinate measuring machine (CMM) technology. Our CMM systems provide full 3D metrology, enabling traceable, micron-level verification of critical dimensions, flatness, roundness, and profile tolerances. This inspection process is integrated into both the mold validation phase and ongoing production runs, ensuring long-term process stability and part-to-part consistency.

We specialize in materials suitable for clear molding, including polycarbonate (PC), cyclic olefin copolymer (COC), polymethyl methacrylate (PMMA), and other optically transparent resins. Our engineering team works closely with clients to optimize mold design for uniform wall thickness, proper gate placement, and controlled cooling—factors that directly influence clarity, warpage, and internal stress in the final part.

The following table outlines our standard technical capabilities and achievable tolerances:

| Parameter | Specification |

|---|---|

| Machining Tolerance (5-axis CNC) | ±0.005 mm |

| Surface Roughness (mold cavity) | Ra 0.025 µm (mirror finish achievable) |

| CMM Measurement Accuracy | ±0.001 mm |

| Mold Base Materials | P20, H13, S136, 420 Stainless Steel |

| Compatible Plastics | PC, PMMA, COC, COP, PS (optical grade) |

| Minimum Wall Thickness (clear molding) | 0.3 mm |

| Typical Lead Time (mold development) | 4–8 weeks, depending on complexity |

At Wuxi Lead Precision Machinery, we combine advanced manufacturing technology with disciplined quality control to deliver molds and components that meet the exacting demands of clear injection molding. Our end-to-end process ensures optical clarity, dimensional precision, and long-term reliability for high-value applications.

Material & Finish Options

Material Selection for Optical-Grade Injection Molding Tooling

For optical-grade plastic components requiring exceptional clarity—such as lenses, light guides, or medical housings—the mold material directly dictates part quality, cycle efficiency, and tool longevity. At Wuxi Lead Precision Machinery, we engineer molds where thermal management, surface replication, and chemical resistance are non-negotiable. Aluminum and tool steel dominate this space; titanium is impractical due to cost and inadequate thermal properties for high-volume production. Aluminum enables rapid prototyping and low-volume runs with superior heat dissipation, while hardened steel delivers wear resistance for million-plus cavity lifespans. Material choice must align with resin chemistry, part geometry, and production volume to avoid defects like sink marks, haze, or surface pitting.

Critical properties include thermal conductivity for uniform cooling, hardness to resist abrasive fillers, and corrosion resistance against halogenated or hygroscopic plastics. Anodizing aluminum molds is essential—it seals porosity, prevents resin adhesion, and extends service life by 3–5× versus untreated surfaces. For steel molds, nitriding or chrome plating often supplements hardness, but anodizing remains exclusive to aluminum substrates. Below is a comparative specification guide for common mold materials in optical applications:

| Material | Thermal Conductivity (W/m·K) | Hardness (Typical) | Corrosion Resistance | Best Application Context |

|---|---|---|---|---|

| Aluminum 7075-T6 | 130 | 150 HB | Low (Requires Anodizing) | Prototypes, low-volume production (<10k cycles), complex cooling |

| P20 Tool Steel | 28–36 | 28–32 HRC | Moderate | Medium-volume production (100k+ cycles), abrasive resins |

| H13 Tool Steel | 28–34 | 48–52 HRC | Good | High-volume production (500k+ cycles), high-temperature resins |

Anodizing aluminum molds to 25–50μm thickness with Type III (hard coat) processes is mandatory for optical clarity. This finish minimizes micro-porosity that traps release agents or degrades surface finish, ensuring Ra values below 0.05μm for pristine light transmission. Steel molds prioritize polishability—optical cavities require diamond polishing to SPI-A1 standards—but lack aluminum’s thermal agility. For polycarbonate or PMMA molding, aluminum’s conductivity reduces cycle times by 20–30% versus steel, though steel remains indispensable for glass-filled or flame-retardant formulations.

Wuxi Lead integrates material science with CNC precision to optimize your tooling. Our engineers assess resin thermal profiles, part tolerances, and volume demands to prescribe the ideal material-finish pairing. This eliminates costly trial-and-error, ensuring your optical plastics achieve >92% light transmission from the first shot. Partner with us to transform material constraints into competitive advantage.

Manufacturing Process & QC

Design: Precision Engineering for Optical Clarity and Structural Integrity

The production of clear injection molded plastics begins with a rigorous design phase, where engineering precision meets material science. At Wuxi Lead Precision Machinery, our design team leverages advanced CAD/CAM software and finite element analysis (FEA) to simulate flow dynamics, cooling behavior, and stress distribution within the mold cavity. This ensures optimal wall thickness, gate placement, and venting—critical factors in achieving optical clarity without sink marks, flow lines, or internal stresses. We collaborate closely with clients to refine part geometry, select the appropriate transparent resin—such as polycarbonate, PMMA, or COP—and integrate features that enhance manufacturability while maintaining aesthetic and functional requirements. Mold design includes mirror-finish cavity surfaces (typically polished to SPI A1 or ISO 2000 N3 standards), conformal cooling channels, and tight tolerance control to prevent warpage and birefringence.

Prototyping: Validating Clarity, Fit, and Function

Once the mold is fabricated from high-grade steel or aluminum with precision CNC machining and EDM processes, we proceed to prototyping. A small batch of 10–50 parts is produced under near-mass-production conditions. These prototypes undergo comprehensive evaluation, including visual inspection under controlled lighting for haze, bubbles, and surface defects, as well as metrological verification using coordinate measuring machines (CMM). We conduct functional testing for light transmission, dimensional accuracy, and mechanical performance. Any micro-defects or optical inconsistencies are traced back to process parameters—such as injection speed, packing pressure, or mold temperature—and corrected before full-scale production. This iterative validation ensures that the final design is robust, repeatable, and ready for zero-defect manufacturing.

Mass Production: Consistency Through Automation and Real-Time Monitoring

With design and prototyping confirmed, we transition to high-volume production on state-of-the-art electric or hybrid injection molding machines. These systems offer precise control over injection profiles, minimizing shear-induced stress that can compromise clarity. Production runs are executed in ISO Class 8 cleanroom environments when required, with desiccant drying of raw materials to prevent moisture-related splay or haze. Automated in-line inspection systems, including machine vision cameras and laser gauging, monitor each part for dimensional deviation and surface quality. Data from each cycle is logged and analyzed for statistical process control (SPC), enabling real-time adjustments and full traceability. Our zero-defect philosophy is enforced through preventive maintenance schedules, operator training, and a closed-loop corrective action (CAPA) system.

Typical Process Specifications

| Parameter | Specification |

|---|---|

| Material Options | Polycarbonate, PMMA, COP, COC |

| Mold Surface Finish | SPI A1 (Mirror Polish), Ra < 0.05 µm |

| Dimensional Tolerance | ±0.025 mm (standard), down to ±0.01 mm |

| Optical Clarity (Haze) | <1% (per ASTM D1003) |

| Light Transmission | Up to 92% (depending on material) |

| Production Environment | Cleanroom Class 8 (optional) |

| Cycle Time Optimization | 15–60 seconds (part-dependent) |

| Quality Control | 100% visual + automated inspection, SPC |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers clear injection molded plastic components with uncompromised quality and zero-defect reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Optical Clarity

Achieving optical-grade clarity in injection molded plastics demands more than advanced polymers—it requires micron-level precision in metal tooling. At Wuxi Lead Precision Machinery, we engineer the foundational metal components that transform demanding optical specifications into flawless production reality. Our CNC-machined molds eliminate surface defects, refractive inconsistencies, and internal stresses that plague inferior tooling, ensuring your lenses, light guides, or medical housings meet stringent transmission and aesthetic standards.

As a vertically integrated custom metal manufacturer in Wuxi, China, we control every variable from raw material sourcing to final inspection. Our 5-axis milling centers achieve sub-micron tolerances on cavity surfaces, while proprietary thermal management systems maintain uniform cooling critical for distortion-free parts. Unlike generic mold makers, we treat optical plastics as a metallurgical challenge: optimizing steel hardness, polish consistency, and venting geometry to prevent haze, splay, or weld lines. This precision-first approach reduces scrap rates by 30–50% and accelerates qualification for aerospace, medical, and consumer electronics applications.

Our technical capabilities directly address the root causes of clarity failure:

| Parameter | Specification | Impact on Plastic Clarity |

|---|---|---|

| Cavity Surface Finish | ≤ 0.02 μm Ra (SPI A1) | Eliminates micro-haze and light scattering |

| Thermal Uniformity | ±0.5°C across cavity | Prevents internal stress and warpage |

| Parting Line Precision | ≤ 0.005 mm mismatch | Avoids flash-induced optical distortion |

| Vent Depth Tolerance | ±0.001 mm | Ensures complete cavity filling without burns |

This rigor extends beyond machining. We collaborate during your design phase to optimize gate placement, draft angles, and ejection systems—factors often overlooked but critical for maintaining surface integrity in clear resins like PMMA, PC, or COP. Our engineers leverage moldflow analysis validated against actual metal tooling performance, not theoretical models, to predict and resolve clarity risks before cut steel.

When your project demands zero-defect transparency, partner with a manufacturer that speaks the language of optics and metallurgy fluently. Wuxi Lead Precision Machinery delivers the repeatable tooling foundation that turns ambitious clear-plastic designs into high-yield production. Contact our engineering team to specify your optical requirements, material constraints, and volume needs. Initiate your project with precision partners who understand that clarity begins in the metal.

Email [email protected] with your application details and target specifications. Our CNC specialists will respond within 24 hours with a feasibility assessment and timeline. Trust Lead Precision to machine the unseen foundation of your visible success.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.