Technical Contents

Engineering Guide: Cheapest 3D Printing Service

Engineering Insight Precision Over Price in Mission-Critical Additive Manufacturing

The term “cheapest 3D printing service” carries significant risk in high-stakes metal manufacturing. While initial cost is a factor, true value is defined by dimensional accuracy, material integrity, and process repeatability – elements where compromise directly threatens component functionality and safety. In aerospace, defense, and precision industrial applications, tolerances measured in microns determine whether a part succeeds or catastrophically fails. Selecting a provider based solely on the lowest quote often results in costly rework, project delays, and unacceptable field failures. Precision is not a luxury; it is the non-negotiable foundation of reliable additive manufacturing for critical systems.

At Wuxi Lead Precision Machinery, we understand that precision begins with rigorous process control. Our industrial-grade metal additive systems operate within tightly monitored environmental parameters, utilizing certified aerospace-grade powders and in-situ monitoring to ensure layer consistency. Post-processing protocols, including stress-relieving, precision heat treatment, and multi-axis CNC finishing, are equally critical to achieving final specifications. This integrated approach guarantees parts meet exacting functional requirements, not just nominal geometry. The consequences of inadequate precision are severe. A turbine blade with surface roughness exceeding Ra 1.6µm suffers accelerated erosion. Hydraulic manifolds with internal channel deviations beyond ±0.02mm induce flow turbulence and pressure loss. These are not theoretical concerns but documented failure modes in demanding operational environments.

Our direct experience supplying components for Olympic infrastructure and Tier-1 military programs underscores this reality. For the Beijing Winter Olympics, we produced custom titanium components for ice resurfacing systems where thermal stability and wear resistance were paramount – failures would have disrupted global events. Similarly, precision hydraulic fittings for naval vessel systems demanded absolute leak-proof integrity under extreme pressure cycles, a requirement met only through our stringent adherence to AS9100 and MIL-STD quality frameworks. These projects demanded first-article perfection; there was no margin for “cheapest” iterations.

The table below illustrates the critical performance gap between basic additive services and precision-grade manufacturing essential for mission-critical applications.

| Parameter | Entry-Level Service Typical Capability | Wuxi Lead Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.1mm to ±0.2mm | ±0.02mm to ±0.05mm |

| Surface Roughness (As-Built) | Ra 12µm to 25µm | Ra 4µm to 8µm |

| Material Certification | Limited or Generic | Full Mill Certificates (AMS, ASTM) |

| In-Process Monitoring | Basic Layer Imaging | Real-Time Melt Pool Analysis |

| Post-Processing | Minimal or Outsourced | Integrated CNC Finishing & NDT |

True cost efficiency emerges from first-article success, extended service life, and elimination of field failures. When human safety, system uptime, or global event continuity is at stake, precision engineering is the only viable strategy. Wuxi Lead Precision Machinery delivers the certified accuracy and reliability demanded by the world’s most challenging applications – where performance is non-negotiable and value is measured in mission success.

Precision Specs & Tolerances

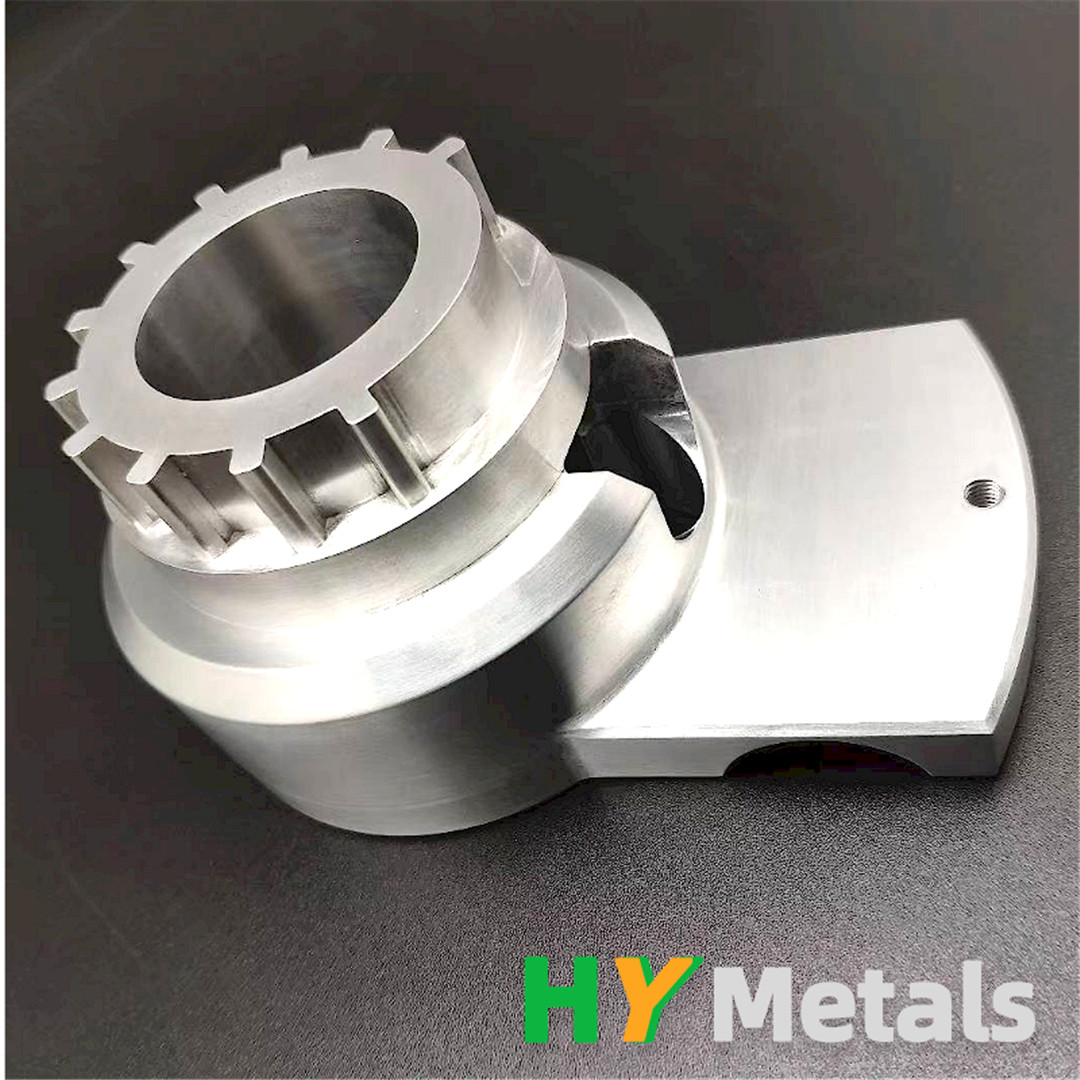

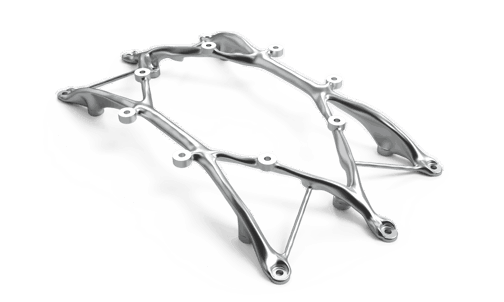

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored for high-performance industries including aerospace, medical, automotive, and industrial automation. At the core of our technical capabilities is a fully integrated 5-axis CNC machining platform, enabling us to produce complex, high-precision metal components with exceptional accuracy and surface finish. Our 5-axis machining centers allow simultaneous movement across all five axes, providing unparalleled flexibility in contouring and multi-faceted part geometries that are unattainable with conventional 3-axis systems. This capability significantly reduces setup time, enhances dimensional consistency, and supports the production of monolithic components that would otherwise require multiple operations or assemblies.

Our facility is equipped with state-of-the-art CNC machines from leading global manufacturers, operating under strict environmental controls to ensure thermal stability and machining repeatability. We specialize in working with a wide range of engineering metals, including aluminum alloys, stainless steels, titanium, Inconel, and tool steels, supporting both prototyping and high-volume production runs. Advanced tooling systems, high-speed spindles, and real-time tool wear monitoring ensure consistent part quality and extended tool life, minimizing downtime and maximizing throughput.

Quality assurance is embedded at every stage of the manufacturing process. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM) with tactile and optical probing systems. This allows for full geometric dimensioning and tolerancing (GD&T) verification, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Our CMM inspection process is supported by calibrated metrology equipment, including surface roughness testers, micrometers, and optical comparators, enabling traceable and repeatable quality control.

We maintain strict adherence to international quality standards, with documented inspection reports provided for every production batch. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance specifications, minimizing cost and lead time without compromising performance.

The following table outlines our standard machining tolerances and surface finish capabilities under controlled production conditions.

| Feature | Standard Tolerance | Precision Tolerance (Optional) | Notes |

|---|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.01 mm | ±0.005 mm | Measured via CMM |

| Linear Dimensions (100–500 mm) | ±0.02 mm | ±0.01 mm | Calibrated environment |

| Hole Diameter | ±0.01 mm | ±0.005 mm | Reamed or precision bored |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | GD&T compliant |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm | Verified with CMM |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished) | As-machined or post-processed |

| Angular Features | ±0.1° | ±0.05° | 5-axis simultaneous control |

Our technical capabilities are reinforced by a culture of precision engineering and continuous process improvement. Wuxi Lead Precision Machinery is committed to delivering metal components that meet the most demanding performance and reliability requirements in mission-critical applications.

Material & Finish Options

Material Selection for Cost-Effective Precision Metal 3D Printing

Selecting the optimal material is paramount when sourcing a cost-effective metal 3D printing service. True value extends beyond the initial quote; it encompasses part performance, longevity, post-processing requirements, and total lifecycle cost. At Wuxi Lead Precision Machinery, we guide clients toward materials that deliver the best balance of functionality and economic efficiency for demanding industrial applications. Choosing an inappropriate alloy to chase the absolute lowest print cost often leads to higher expenses through premature failure, excessive finishing, or redesign.

Aluminum alloys, particularly 6061 and 7075, offer an excellent strength-to-weight ratio and superior machinability, making them ideal for aerospace brackets, automotive components, and consumer electronics housings where weight savings are critical. Aluminum 6061 provides good corrosion resistance and weldability at a moderate cost, while 7075 delivers significantly higher strength for highly stressed parts, albeit at a premium. Steel variants like 316L stainless steel are the benchmark for corrosion resistance in marine or chemical environments and offer good strength for medical implants or fluid handling systems. For applications demanding the ultimate in strength-to-weight ratio and extreme temperature resistance, Titanium Grade 5 (Ti-6Al-4V) is unmatched, essential for critical aerospace and biomedical components, though its raw material and processing costs are higher. The initial material cost is only one factor; machining time, required heat treatment, and surface finish complexity significantly impact the final delivered price.

Material properties directly influence manufacturability and cost. The following table provides key comparative specifications for common high-performance alloys:

| Material | Density (g/cm³) | Yield Strength (MPa) | Corrosion Resistance | Typical Applications | Relative Cost Factor |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 276 | Good | Enclosures, brackets, drones | 1.0x |

| Aluminum 7075 | 2.8 | 503 | Fair | High-stress aerospace parts | 1.4x |

| Stainless 316L | 8.0 | 290 | Excellent | Marine, medical, chemical | 1.8x |

| Titanium Ti-6Al-4V | 4.4 | 880 | Excellent | Aerospace, biomedical implants | 3.5x+ |

Surface finish, particularly anodizing for aluminum, is not merely cosmetic but a critical performance enhancer and cost mitigator. Hard anodizing (Type III) creates a thick, wear-resistant, electrically insulating oxide layer that significantly extends part life in abrasive environments, reducing replacement frequency. While adding a processing step, it often eliminates the need for secondary protective coatings or more expensive base materials. Decorative anodizing (Type II) provides enhanced corrosion resistance and aesthetic options for visible components. Selecting the correct anodizing type and thickness specification upfront prevents costly rework and ensures the part meets functional requirements without over-engineering the finish.

Wuxi Lead Precision Machinery leverages deep material science expertise to match your application’s exact mechanical, environmental, and budgetary demands. We analyze total cost of ownership, not just the print price, ensuring your investment yields reliable, high-performance parts. Contact our engineering team to optimize your material and finish selection for genuine cost efficiency.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, our production process for custom metal manufacturing is engineered for precision, repeatability, and zero-defect delivery. We integrate advanced 3D printing technologies with stringent quality controls to ensure every component meets the highest industrial standards. Our end-to-end workflow spans from initial design through prototyping to full-scale mass production, all optimized for performance and cost-efficiency.

The process begins with collaborative design engineering. Our technical team works directly with client CAD models, conducting detailed design for manufacturability (DFM) analysis. This stage ensures optimal material selection, structural integrity, and geometric feasibility while minimizing waste and production risk. We specialize in high-performance alloys such as titanium, stainless steel, Inconel, and aluminum, tailored to application requirements including aerospace, medical, and energy sectors.

Once the design is validated, we proceed to prototyping using our state-of-the-art metal additive manufacturing systems. This phase allows rapid physical verification of form, fit, and function. Each prototype is subjected to comprehensive metrology inspection using coordinate measuring machines (CMM) and 3D scanning to confirm dimensional accuracy within ±0.02 mm. Iterative adjustments are made if necessary, ensuring the final design is production-ready with no compromise on quality.

Upon client approval, we transition seamlessly into mass production. Our factory utilizes a fleet of industrial-grade metal 3D printers with full process traceability, inert gas-controlled environments, and in-situ layer monitoring to prevent defects. Each build undergoes real-time anomaly detection, ensuring consistency across batches. Post-processing—including heat treatment, stress relieving, CNC machining, and surface finishing—is performed in-house under ISO 9001-certified procedures.

Quality assurance is embedded at every stage. We implement first-article inspection (FAI), statistical process control (SPC), and 100% visual and dimensional inspection for critical features. Our zero-defect philosophy is enforced through automated reporting and non-conformance tracking, guaranteeing full accountability and continuous improvement.

The following table outlines key production specifications and capabilities:

| Parameter | Specification |

|---|---|

| Material Options | Ti6Al4V, 316L, Inconel 718, AlSi10Mg, CoCr |

| Build Volume (Max) | 250 x 250 x 325 mm |

| Layer Thickness | 20–60 µm |

| Dimensional Accuracy | ±0.02 mm |

| Surface Roughness (As-Built) | Ra 10–15 µm |

| Post-Processing | Heat Treatment, CNC Machining, Polishing, HIP |

| Quality Standards | ISO 9001, AS9100, First Article Inspection |

| Lead Time (Prototype) | 7–10 days |

| Lead Time (Mass Production) | 15–25 days (scalable batches) |

From concept to final part, Wuxi Lead Precision Machinery delivers unmatched precision and reliability in custom metal manufacturing. Our integrated approach ensures that every component not only meets but exceeds the demands of high-stakes industrial applications.

Why Choose Wuxi Lead Precision

Reframe Your Metal Additive Strategy: Beyond the “Cheapest” Myth

Pursuing the absolute lowest price in metal 3D printing often leads to hidden costs: failed builds, compromised material integrity, extended lead times, and non-conforming parts that disrupt your production flow. At Wuxi Lead Precision Machinery, we engineer value, not just components. Our ISO 9001-certified metal additive manufacturing services deliver aerospace-grade precision and repeatability, ensuring your investment translates directly into functional, reliable parts that meet stringent industry specifications. We eliminate the false economy of cheap printing through rigorous process control, certified materials, and engineering expertise embedded in every build.

True cost efficiency stems from first-time-right production. Our integrated workflow begins with expert design for additive manufacturing (DfAM) consultation to optimize part geometry, reduce material waste, and ensure structural integrity. We utilize state-of-the-art EOS and SLM systems with full in-process monitoring, coupled with metallurgical validation and post-processing capabilities including HIP, precision machining, and surface finishing—all under one roof. This vertically integrated approach guarantees dimensional accuracy, mechanical properties, and surface quality that cheaper services cannot replicate, preventing costly downstream rework or scrap.

The table below details the precision standards underpinning our value-driven service model. These specifications are not optional extras; they are foundational to every project we undertake, ensuring your parts perform as intended in critical applications.

| Parameter | Specification | Industry Impact |

|---|---|---|

| Build Volume | 500 x 500 x 500 mm (EOS M 400-4) | Enables large, complex single-piece components |

| Layer Resolution | 20–50 μm | Achieves fine features and smooth surface finish |

| Material Certification | AMS, ASTM, ISO certified stock + full MTR | Guarantees material traceability & properties |

| Dimensional Accuracy | ±0.05 mm per 100 mm | Reduces post-machining needs, saving time/cost |

| Post-Processing | In-house HIP, CNC, polishing, anodizing | Ensures final part meets functional requirements |

Partnering with Lead Precision means gaining a strategic manufacturing ally, not just a vendor. Our engineering team collaborates with you from concept through certification, providing build simulation, process parameter optimization, and comprehensive inspection reports (including CT scanning and mechanical testing). This proactive partnership mitigates risk, accelerates time-to-market, and delivers predictable outcomes—transforming additive manufacturing from a cost center into a competitive advantage.

Stop paying for suboptimal geometries, inconsistent density, or delayed deliveries disguised as “low cost.” Demand the precision engineering that protects your reputation and bottom line. Contact our additive manufacturing specialists today to discuss your project requirements and receive a transparent, value-based quotation. Email [email protected] with your part specifications and timeline. Let us demonstrate how true cost efficiency in metal 3D printing is built on uncompromising quality, not the lowest headline price. Your precision-engineered future starts with a single, strategic partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.