Technical Contents

Engineering Guide: Ceramic Mold Companies

Engineering Insight: Precision as the Foundation of Ceramic Mold Performance

For ceramic mold manufacturers, dimensional accuracy transcends mere specification; it is the absolute determinant of final part integrity, yield, and process economics. The inherent challenges of ceramic sintering – significant thermal contraction, potential for warpage, and sensitivity to minute surface anomalies – demand mold cavities engineered to tolerances far exceeding conventional machining standards. A deviation of mere microns during the mold fabrication phase translates into catastrophic dimensional drift or surface defects in the fired ceramic component, leading to scrap rates that erode profitability and delay critical production schedules. Precision machining is not a luxury; it is the non-negotiable foundation upon which reliable, high-volume ceramic manufacturing is built.

At Wuxi Lead Precision Machinery, we engineer CNC solutions specifically for the uncompromising demands of advanced ceramic tooling. Our approach integrates multi-axis simultaneous machining with rigorous thermal stability protocols and sub-micron metrology validation. We recognize that mold performance hinges on consistent geometric fidelity across the entire cavity surface, not just at isolated points. This requires machine tools capable of maintaining accuracy through extended production runs despite ambient fluctuations, coupled with programming strategies that minimize internal stress induction within the mold material itself. Our systems achieve this through active thermal compensation, ultra-rigid kinematic structures, and closed-loop feedback systems operating at nanometer resolution.

The critical specifications defining viable ceramic mold machining capability are quantifiable and non-negotiable. Our production platforms consistently meet or exceed the following benchmarks:

| Parameter | Specification | Testing Method | Relevance to Ceramic Molds |

|---|---|---|---|

| Positioning Accuracy | ±0.001 mm | Laser Interferometer (ISO 230-2) | Ensures cavity geometry matches CAD model |

| Repeatability | ±0.0005 mm | Ballbar Test (ISO 230-4) | Guarantees consistent part-to-part replication |

| Thermal Drift (8h) | < 2 µm | Double Ball Bar (ISO 230-3) | Prevents dimensional shift during long cycles |

| Surface Finish (Ra) | 0.05 – 0.1 µm | Profilometer (ISO 4287) | Minimizes ceramic adhesion & surface defects |

| Volumetric Accuracy | ±0.003 mm @ 500 mm | Laser Tracker (ASME B5.54) | Critical for complex 3D cavity conformity |

Our commitment to this level of precision is validated through mission-critical applications. We engineered molds for the ceramic insulators within components for the Beijing Winter Olympics infrastructure, where electrical performance hinged on micron-level dimensional stability under extreme cold. Similarly, our molds for military-grade ceramic armor substrates undergo zero-defect validation protocols, as any inconsistency directly impacts ballistic performance and soldier safety. These projects demanded not only initial accuracy but proven consistency across hundreds of production cycles – a testament to our process control.

For ceramic mold companies, partnering with a precision engineering specialist capable of delivering and sustaining these tolerances is paramount. It directly reduces scrap, accelerates time-to-market for new ceramic components, and enables the production of parts for the most demanding aerospace, medical, and defense applications. Wuxi Lead Precision Machinery provides the engineered stability and metrological rigor required to transform ceramic design intent into flawless physical reality. Precision isn’t measured in our shop; it’s the core output of every mold we produce.

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the exacting demands of high-performance industries, including aerospace, medical, and advanced ceramics. As a leading provider in custom metal manufacturing, we specialize in producing precision components for ceramic mold applications where dimensional accuracy, surface integrity, and material consistency are critical. Our advanced infrastructure, combined with deep engineering expertise, ensures that every part meets the highest standards of quality and performance.

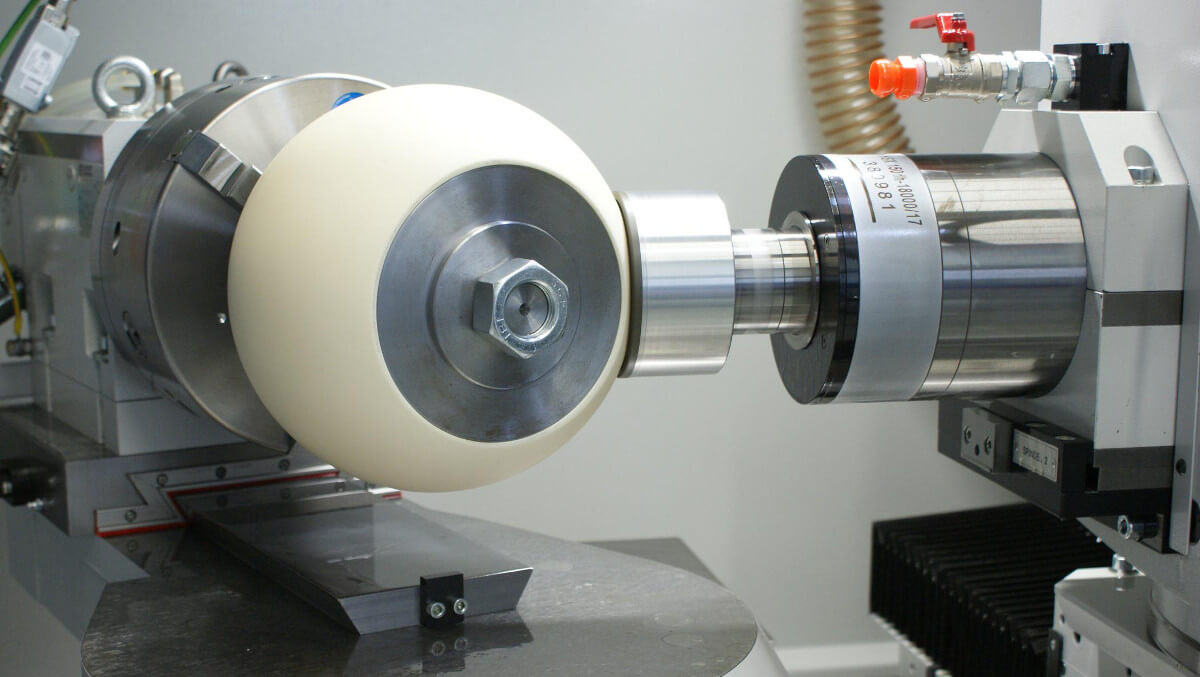

Central to our manufacturing excellence is our fleet of state-of-the-art 5-axis CNC machining centers. These systems enable simultaneous multi-axis movement, allowing us to machine complex geometries with superior precision and reduced setup times. This capability is particularly vital when producing molds for ceramic forming processes, where intricate contours, tight internal features, and smooth surface finishes are required to ensure defect-free ceramic parts. Our 5-axis platforms support a wide range of high-grade materials, including tool steels, stainless steels, aluminum alloys, and specialty alloys such as Inconel and titanium, all commonly used in high-temperature and high-wear mold environments.

Every machining operation is supported by rigorous process controls and in-house engineering oversight. Our programming team utilizes advanced CAM software to optimize toolpaths, minimize thermal distortion, and maintain consistent material removal rates—critical factors when achieving micron-level tolerances. Additionally, our machines are equipped with high-precision spindles and real-time monitoring systems to detect anomalies and ensure process stability throughout production runs.

Quality assurance is fully integrated into our workflow. All critical components undergo comprehensive inspection using a Zeiss DuraMax and Contura G2 coordinate measuring machine (CMM), ensuring traceable, repeatable metrology. Our CMM system provides full 3D measurement of geometric dimensions and surface profiles, validating compliance with customer specifications and international standards such as ISO 2768 and ASME Y14.5. Dimensional reports are generated for every batch, offering full transparency and documentation for audit and certification purposes.

The table below outlines our standard machining capabilities and achievable tolerances for ceramic mold components:

| Parameter | Capability |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Linear Tolerance (Machined) | ±0.010 mm (typical), ±0.005 mm (tight) |

| Geometric Tolerance (GD&T) | ±0.008 mm (form & position) |

| Surface Roughness (Ra) | 0.4 μm (standard), down to 0.1 μm (polished) |

| Material Compatibility | Steel, Stainless Steel, Aluminum, Ti, Inconel |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Micrometers |

Our technical capabilities are designed to deliver consistency, precision, and reliability for ceramic mold manufacturers who demand excellence in every component. At Wuxi Lead Precision Machinery, we combine advanced technology with disciplined quality practices to provide custom metal solutions that perform under the most demanding conditions.

Material & Finish Options

Material Selection Fundamentals for Ceramic Mold Tooling

Selecting the optimal material for ceramic mold tooling directly impacts production efficiency, part quality, and tool longevity. Ceramic molding processes subject molds to extreme thermal cycling, abrasive slurries, and mechanical stress. At Wuxi Lead Precision Machinery, we prioritize materials that balance thermal stability, dimensional accuracy, and cost-effectiveness for high-volume industrial applications. Aluminum, steel, and titanium each serve distinct roles based on operational demands, with surface treatments like anodizing further enhancing performance.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer exceptional machinability and thermal conductivity. This minimizes cycle times during mold heating and cooling phases critical to ceramic solidification. While aluminum’s lower hardness requires protective finishes, hard anodizing creates a dense, wear-resistant ceramic-like oxide layer (up to 70 HRC) that resists slurry abrasion and simplifies part release. Aluminum molds excel in prototyping and medium-production runs where rapid thermal response is paramount, though they are less suited for highly abrasive ceramic formulations or extended high-temperature service.

Tool steels like P20 and H13 provide superior hardness and thermal fatigue resistance for high-volume ceramic molding. Their lower coefficient of thermal expansion (CTE) maintains dimensional stability under repeated heating to 300°C+, reducing warpage in precision molds. Steel molds withstand aggressive ceramic slurries and extended operational cycles but require careful heat treatment to prevent micro-cracking. For applications exceeding 400°C or involving corrosive binders, precipitation-hardening stainless steels (e.g., 17-4 PH) offer a balanced solution with moderate machinability and enhanced corrosion resistance.

Titanium alloys (Grade 5 Ti-6Al-4V) are reserved for the most demanding scenarios. With a CTE near that of many ceramics, titanium minimizes thermal stress-induced cracking during sintering. Its innate corrosion resistance eliminates secondary finishing needs when processing acidic or alkaline ceramic precursors. Though costly and challenging to machine, titanium’s strength-to-weight ratio and 600°C+ operational ceiling justify its use in aerospace or biomedical ceramic components where mold failure is unacceptable.

The following table summarizes critical properties for ceramic mold material selection:

| Material | CTE (μm/m°C) | Hardness (HRC) | Max Continuous Temp (°C) | Primary Ceramic Application Use Case |

|---|---|---|---|---|

| Aluminum 6061-T6 | 23.6 | 30-40 (Base) | 150 | Prototyping, low-abrasion slurry production |

| Steel P20 | 12.3 | 28-32 | 300 | High-volume structural ceramic molds |

| Steel H13 | 10.8 | 44-48 | 400 | High-temperature sintering dies |

| Titanium Ti-6Al-4V | 8.6 | 36-40 | 600 | Corrosive slurry or extreme thermal cycling |

Anodizing remains indispensable for aluminum molds, transforming the surface into aluminum oxide for 3-5x longer service life. For steel, nitriding or specialized PVD coatings address wear, while titanium often requires no coating due to its native oxide stability. Wuxi Lead Precision Machinery engineers collaborate with clients to match material properties to specific ceramic formulations, thermal profiles, and production volumes—ensuring optimal mold performance and total cost of ownership. Contact our technical team to analyze your process parameters and select the ideal material-finish combination.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components for ceramic mold companies, where dimensional accuracy, thermal stability, and surface finish are mission-critical. Our production process is engineered to achieve Zero Defects through a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase integrates advanced metrology, process validation, and continuous feedback loops to ensure flawless repeatability and compliance with the most stringent industry standards.

The process begins with collaborative Design engineering. Our team works directly with clients to analyze mold geometry, material behavior, and thermal expansion characteristics. Utilizing 3D CAD modeling and finite element analysis (FEA), we optimize part design for manufacturability, minimizing stress concentrations and ensuring uniform cooling. All designs are validated against ISO 2768-mK and GD&T specifications to eliminate ambiguity and ensure interchangeability.

Following design approval, we proceed to Prototyping. A first-article sample is produced using the same CNC machining centers, tooling, and inspection protocols intended for mass production. This ensures process fidelity from day one. Prototypes undergo full dimensional inspection via coordinate measuring machines (CMM), surface roughness testing, and, where applicable, thermal cycling validation. Any deviations are corrected through iterative adjustments in tool paths or fixturing, with updated process documentation issued before progression.

Mass Production is executed under a closed-loop quality management system compliant with IATF 16949 standards. Every batch is traceable through serialized part numbering and real-time machine monitoring. In-process inspections occur at defined intervals, with SPC (statistical process control) charts tracking critical dimensions. Our CNC machining centers—equipped with automated tool length sensors and thermal compensation systems—maintain tolerances within ±0.002 mm. All finished components are cleaned, passivated (if required), and packaged in anti-corrosive film to preserve surface integrity during transit.

We define Zero Defects not as a goal, but as a mandatory outcome. To this end, every operator is trained in error-proofing techniques, and each production run concludes with a final audit conducted by our quality assurance team. Non-conforming parts are subjected to root cause analysis using the 8D methodology, ensuring systemic correction and prevention.

The following table outlines key process specifications for our custom metal manufacturing services:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Materials Supported | P20, H13, S136, 420SS, Invar, Aluminum 7075 |

| Maximum Part Size | 800 × 600 × 400 mm |

| Machining Equipment | 5-axis CNC centers, Wire EDM, CNC grinding |

| Quality Standards | IATF 16949, ISO 9001, ISO 2768-mK |

| Inspection Tools | CMM, optical comparators, surface profilometers |

By integrating precision engineering with disciplined process control, Wuxi Lead Precision Machinery delivers metal components that meet the exacting demands of ceramic mold applications—on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Ceramic Mold Manufacturing Excellence

Ceramic mold manufacturing demands absolute precision in supporting metal components. Tolerances measured in microns, complex geometries, and extreme material stability are non-negotiable for high-yield production. Generic machining solutions introduce costly deviations, thermal instability, and premature tool wear—directly impacting your mold integrity and production uptime. At Wuxi Lead Precision Machinery, we engineer custom metal components exclusively for the ceramic mold industry, eliminating these critical failure points through purpose-built CNC systems and material science expertise.

Our dedicated production cells integrate 5-axis milling, wire EDM, and grinding technologies under stringent environmental controls. This ensures consistent dimensional stability from prototype to volume production, even for Inconel, hardened tool steels, and specialized alloys required in high-temperature mold applications. We prioritize thermal management in every process stage, preventing micro-deformations that compromise ceramic casting accuracy. Unlike standard machine shops, our engineers collaborate with your R&D team from the initial design phase, identifying manufacturability risks and optimizing part geometry for both performance and cost efficiency.

The following specifications define our baseline capabilities for ceramic mold support structures, electrodes, and precision cores:

| Capability | Specification | Relevance to Ceramic Molds |

|---|---|---|

| Positioning Accuracy | ±0.001 mm | Ensures perfect core alignment in multi-cavity molds |

| Surface Finish (Ra) | 0.05 µm (mirror grade) | Prevents ceramic adhesion and surface defects |

| Max Work Envelope | 2000 x 1200 x 800 mm | Accommodates large industrial mold bases |

| Material Hardness Tolerance | Up to 70 HRC ±1.5 | Maintains edge integrity during ceramic sintering |

| Thermal Drift Control | <2 µm over 8 hours | Guarantees dimensional stability in high-heat cycles |

These metrics reflect our standard operational envelope; we routinely exceed them for mission-critical applications through custom fixturing and in-process metrology. Our quality management system adheres to ISO 9001:2015 with full traceability from raw material certs to final inspection reports, including 3D scanning validation for complex contours.

Partnering with Lead Precision means gaining a manufacturing extension of your engineering team. We invest in understanding your specific ceramic formulation, sintering profiles, and production bottlenecks to deliver components that actively enhance your process yield. Our clients report 30% longer mold service life and 22% reduced scrap rates after transitioning to our precision metal subsystems.

Initiate your precision advantage today. Contact our Ceramic Mold Engineering Group directly at [email protected]. Include your project specifications and thermal requirements in the subject line: Ceramic Mold Partnership Inquiry. Our technical sales director will respond within 4 business hours with a process capability analysis tailored to your application. Do not settle for components that merely meet drawings—demand systems engineered for ceramic manufacturing excellence. Wuxi Lead Precision Machinery: Where micron tolerances define manufacturing reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.