Technical Contents

Engineering Guide: Central Machine And Fabrication

Engineering Insight: Central Machine and Fabrication

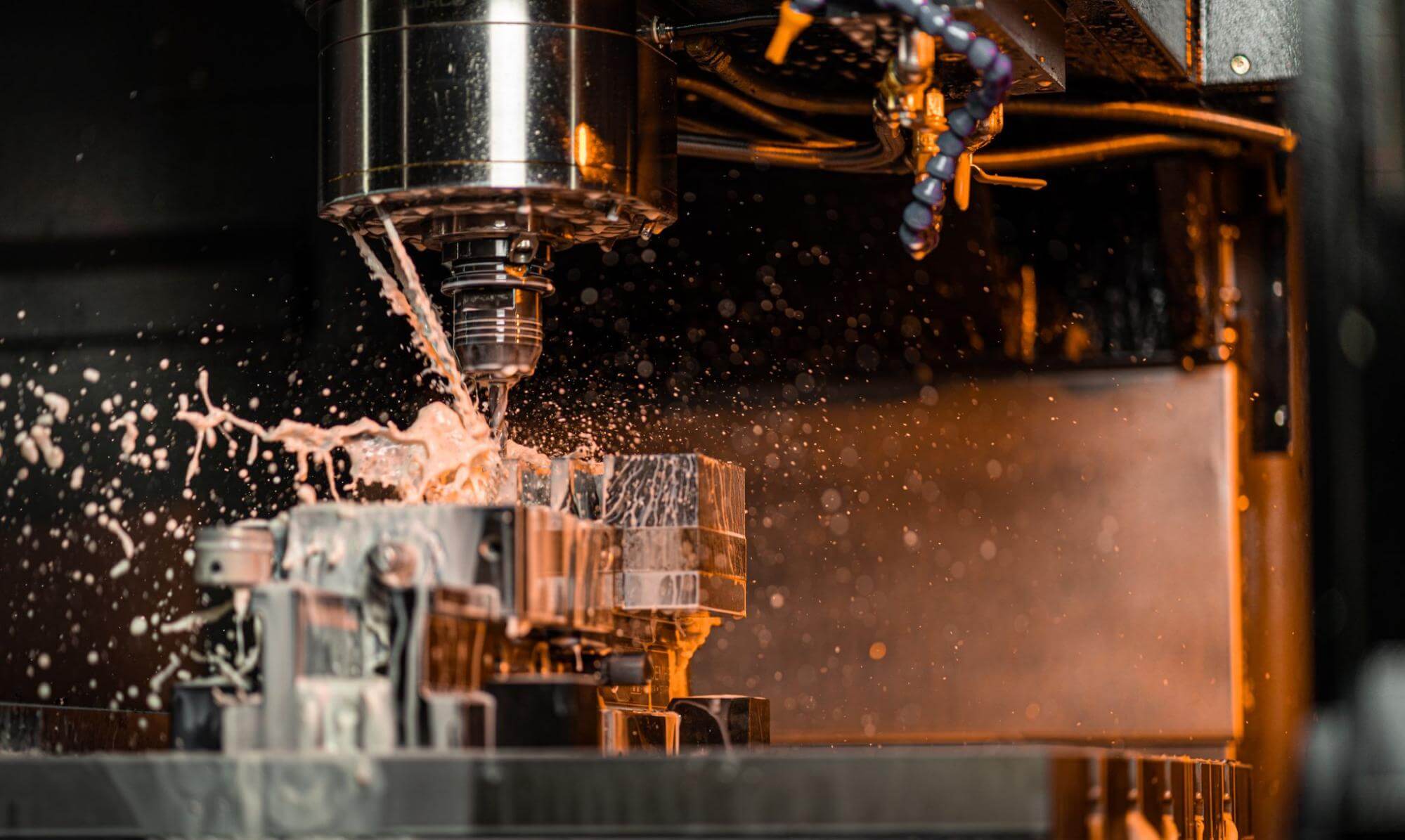

In the realm of sheet metal fabrication, the concept of a central machine—often a multi-functional, high-precision CNC system—serves as the backbone of modern production efficiency. At Wuxi Lead Precision Machinery, we define the central machine not merely by its physical presence on the shop floor, but by its role as the nucleus of accuracy, repeatability, and integrated workflow. This centrality is achieved through advanced motion control, real-time feedback systems, and seamless integration with upstream and downstream processes, ensuring that every bend, cut, and form adheres to exacting tolerances.

Precision in fabrication is not a luxury—it is a necessity. As industries such as aerospace, defense, and high-end industrial equipment demand tighter specifications, the margin for error diminishes to microns. Components must fit perfectly in complex assemblies, often under extreme operational conditions. The central machine, therefore, must deliver consistent geometric accuracy across thousands of cycles. At Lead Precision, our engineering philosophy revolves around deterministic manufacturing: every output is predictable, traceable, and compliant with the highest quality standards.

Our experience in delivering mission-critical components for Olympic infrastructure projects and military-grade applications has reinforced the imperative of precision. In these environments, failure is not an option. For example, structural elements used in Olympic venues required not only aesthetic perfection but also load-bearing accuracy under dynamic stress. Similarly, military enclosures and mounting systems demanded electromagnetic shielding integrity, which can only be achieved through precise forming and tight seam tolerances. These projects were executed on our central fabrication platforms, where laser cutting, automated bending cells, and robotic handling operated in synchrony under a unified control architecture.

The integration of such systems allows for adaptive correction—using in-process metrology to adjust tool paths in real time. This closed-loop precision ensures that material variance, thermal drift, and tool wear do not compromise final part quality. Moreover, our machines are engineered with rigid cast-iron frames, linear guideways, and high-resolution encoders to maintain positional accuracy over extended operational cycles.

Below are key performance specifications that define our central fabrication platforms:

| Specification | Value | Application Impact |

|---|---|---|

| Positioning Accuracy | ±0.01 mm | Ensures alignment in multi-stage forming |

| Repeatability | ±0.005 mm | Critical for batch consistency in military specs |

| Laser Cutting Precision | ±0.02 mm | Enables fine feature definition in thin-gauge alloys |

| Max Bending Force | 300 tons | Supports high-strength steel forming up to 12 mm |

| Control System | Siemens 840D Solution Line | Enables real-time diagnostics and process integration |

At Wuxi Lead Precision Machinery, our decades of refinement in central machine engineering have positioned us as a trusted partner in high-stakes fabrication. Precision is not just measured in numbers—it is proven in performance, under pressure, and in the field.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication at Scale

Wuxi Lead Precision Machinery delivers uncompromising accuracy and complexity in sheet metal fabrication, engineered for demanding aerospace, medical, and industrial applications. Our core strength lies in integrating advanced multi-axis CNC technology with rigorous metrology protocols, ensuring every component meets the strictest global specifications. This integrated approach eliminates process gaps, reduces lead times, and guarantees dimensional integrity from raw material to finished part.

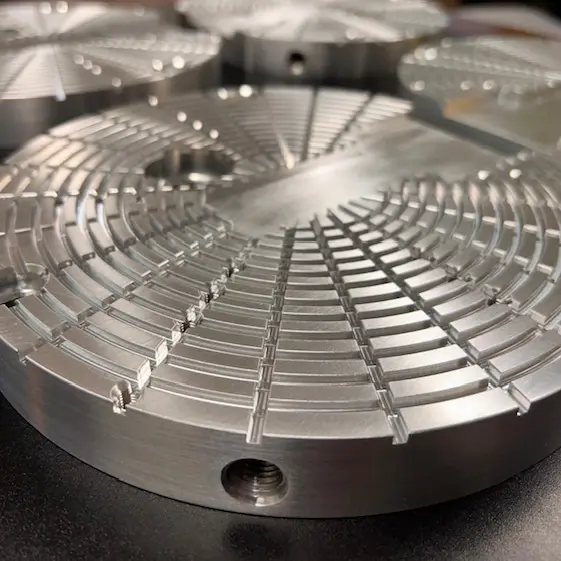

Central to our capability is a modern fleet of high-torque 5-axis CNC machining centers. These systems perform simultaneous 5-axis interpolation, enabling the precise fabrication of intricate geometries—such as compound curves, deep cavities, and undercuts—in a single setup. This eliminates cumulative errors inherent in multi-stage operations, significantly improving positional accuracy and surface finish. Our machines handle a wide spectrum of sheet materials, including stainless steel (304, 316), aluminum alloys (5052, 6061, 7075), titanium, and specialty alloys, with thicknesses ranging from 0.5mm to 12.7mm. The elimination of secondary operations not only enhances precision but also optimizes cost efficiency for complex components, a critical advantage in high-value manufacturing.

Quality assurance is non-negotiable. Every critical dimension undergoes verification using state-of-the-art Coordinate Measuring Machines (CMM) operating under ISO 10360-2 standards. Our CMMs feature tactile and optical probes, achieving measurement repeatability down to 0.0002 inches (0.005mm). This metrology backbone validates geometric dimensioning and tolerancing (GD&T), surface profiles, and critical feature relationships against client CAD models. All inspection data is digitally recorded and traceable, providing comprehensive quality documentation for full production lot traceability and audit compliance. This systematic verification ensures conformance to AS9100, ISO 13485, and customer-specific quality management systems.

Our commitment to precision is quantified in the achievable tolerances across standard fabrication processes. The following table details our typical capabilities under controlled production conditions:

| Material Type | Thickness Range | Feature Tolerance | Hole Position Tolerance | Flatness Tolerance |

|---|---|---|---|---|

| Stainless Steel | 0.5mm – 6.0mm | ±0.05mm | ±0.03mm | 0.1mm per 100mm |

| Aluminum Alloys | 0.5mm – 8.0mm | ±0.05mm | ±0.03mm | 0.1mm per 100mm |

| Titanium | 0.8mm – 6.0mm | ±0.05mm | ±0.03mm | 0.1mm per 100mm |

| Carbon Steel | 1.0mm – 12.7mm | ±0.08mm | ±0.05mm | 0.15mm per 100mm |

These capabilities translate directly into client value: reduced assembly errors, minimized scrap rates, and accelerated time-to-market for mission-critical components. Wuxi Lead Precision Machinery operates at the intersection of advanced machine capability and disciplined quality control, providing the technical foundation for reliable, high-performance sheet metal solutions. We partner with engineering teams to transform complex designs into reality, where tolerances are not targets but guaranteed outcomes.

Material & Finish Options

Material Selection in Sheet Metal Fabrication: A Precision Engineering Guide

Selecting the appropriate material is a foundational step in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we recognize that high-end manufacturing demands materials engineered to meet exacting standards across mechanical, thermal, and environmental conditions. Among the most widely used materials in precision fabrication are aluminum, steel, and titanium—each offering distinct advantages tailored to specific industrial applications.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, transportation, and electronics enclosures where weight reduction and thermal management are critical. Its natural oxide layer provides inherent protection against environmental degradation, though further enhancement is achievable through surface treatments such as anodizing. Aluminum’s machinability and weldability make it a preferred choice for complex geometries and high-volume production.

Steel, particularly low-carbon and stainless variants, is valued for its superior strength, structural integrity, and cost-effectiveness. Mild steel is commonly used in industrial enclosures, frames, and machinery components requiring high mechanical resilience. Stainless steel, especially grades 304 and 316, offers exceptional resistance to corrosion and high temperatures, making it suitable for medical devices, food processing equipment, and marine applications. While heavier than aluminum, steel’s versatility and availability ensure its continued dominance in heavy-duty fabrication.

Titanium, though more costly, delivers unmatched performance in extreme environments. With a strength-to-density ratio exceeding that of many steels and outstanding resistance to corrosion—even in saline and acidic conditions—titanium is the material of choice for aerospace, defense, and high-performance automotive sectors. Its biocompatibility also makes it indispensable in medical implant manufacturing. Despite challenges in machining and forming due to work hardening, titanium’s long-term reliability justifies its use in mission-critical components.

Surface finishing plays a pivotal role in enhancing both functional and aesthetic properties. Anodizing, primarily applied to aluminum, is an electrochemical process that thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and adhesion for paint or primers. It also allows for color coding through dye integration, supporting both branding and functional identification in assemblies. Hard anodizing (Type III) is used in applications requiring extreme surface durability, such as hydraulic components and military hardware.

The following table summarizes key mechanical and fabrication properties of these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Aerospace, Electronics | Anodizing, Powder Coating |

| Mild Steel | 7.85 | 400–550 | Moderate | Industrial Frames, Enclosures | Painting, Galvanizing |

| Stainless Steel 304 | 8.0 | 505–760 | Very High | Medical, Food Processing | Passivation, Polishing |

| Titanium Gr 5 | 4.43 | 880–900 | Exceptional | Aerospace, Defense | Anodizing, Bead Blasting |

At Wuxi Lead Precision Machinery, we support clients in aligning material and finish selection with application requirements, ensuring every fabricated component meets the highest standards of performance and reliability.

Manufacturing Process & QC

Sheet Metal Fabrication: Precision Production Process with Zero Defects Commitment

Wuxi Lead Precision Machinery executes a rigorously controlled sheet metal fabrication workflow designed to eliminate defects before they occur. Our process begins with collaborative engineering during the Design phase. We integrate advanced CAD/CAM software with deep manufacturing expertise to perform comprehensive Design for Manufacturability (DFM) analysis. This critical step identifies potential fabrication conflicts—such as problematic bend radii, material grain direction issues, or tooling interference—while the design is still malleable. We apply Geometric Dimensioning and Tolerancing (GD&T) principles from inception, ensuring every feature specification aligns with achievable process capabilities and the client’s functional requirements. Early virtual prototyping via CNC simulation software validates toolpaths and detects collisions, preventing costly physical errors later. This proactive design scrutiny minimizes rework and establishes the foundation for zero non-conformances.

Prototyping transitions validated designs into tangible verification. We produce functional prototypes using the exact production-grade materials and intended CNC processes—laser cutting, precision bending, welding, and finishing. Each prototype undergoes exhaustive metrology using calibrated Coordinate Measuring Machines (CMM) and optical comparators, comparing every critical dimension against the original CAD model and GD&T callouts. This phase is not merely a form check; it validates structural integrity, assembly fit, and surface finish under real-world conditions. Client sign-off on prototype performance and dimensional accuracy is mandatory before proceeding, confirming that the manufacturing process parameters are locked and proven capable.

Mass Production leverages the validated process through stringent statistical process control (SPC). Every machine—Amada CNC press brakes, Bystronic laser cutters, automated welding cells—operates under real-time monitoring. Key process parameters (bend angles, laser power, weld penetration) are continuously tracked against control limits established during prototyping. Our integrated quality management system triggers immediate alerts for any parameter drift, halting production before out-of-specification parts are generated. Final inspection employs automated vision systems for surface defects and random CMM verification of critical features, ensuring sustained conformance. This closed-loop system guarantees consistent output meeting the highest precision standards.

The following table summarizes our core production capabilities and quality metrics for critical sheet metal components:

| Specification Category | Performance Standard | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.05 mm | CMM, Optical Comparator |

| Geometric Tolerance (GD&T) | Full ASME Y14.5 Compliance | CMM, Laser Tracker |

| Process Capability (Cpk) | ≥ 1.67 (Critical Features) | Statistical Process Control Data |

| Defect Rate (PPM) | ≤ 50 PPM | Final Inspection Records |

| Material Traceability | Full Lot/Batch Certification | ERP System Documentation |

This integrated approach—where design validation, prototype rigor, and statistically controlled mass production converge—ensures zero defects are not an aspiration but a measurable outcome. Wuxi Lead Precision Machinery delivers consistent, high-integrity sheet metal components that meet the exacting demands of aerospace, medical, and advanced industrial applications, directly reducing our clients’ total cost of non-conformance.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Sheet Metal Fabrication Excellence

In the competitive landscape of industrial manufacturing, precision, reliability, and speed are not just advantages—they are necessities. At Wuxi Lead Precision Machinery, we understand the demands of high-volume, high-accuracy sheet metal fabrication. As a leading provider based in Wuxi, China, we specialize in delivering end-to-end fabrication solutions that combine advanced CNC technology, rigorous quality control, and decades of engineering expertise. When you partner with us, you’re not just sourcing components—you’re aligning with a team committed to elevating your production standards.

Our facility is equipped with state-of-the-art fiber laser cutting systems, high-tonnage press brakes, and automated bending cells, enabling us to handle complex geometries with tight tolerances. From prototype development to full-scale production runs, we maintain consistency across batches, ensuring your parts meet exact specifications every time. Whether you require mild steel, stainless steel, aluminum, or specialty alloys, our material processing capabilities support a wide range of thicknesses and finishes tailored to your application.

We serve industries where precision is non-negotiable—automotive, energy, telecommunications, and industrial equipment—delivering components that perform under real-world conditions. Our quality management system adheres to ISO 9001 standards, with in-process inspections and final QA protocols that minimize defects and maximize yield. Every part is traceable, documented, and delivered on schedule.

Below are key technical specifications that define our fabrication capabilities:

| Specification | Capability |

|---|---|

| Laser Cutting Thickness Range | 0.5 mm – 25 mm |

| Maximum Laser Cutting Area | 1500 mm × 3000 mm |

| Press Brake Tonnage | Up to 300 tons |

| Bending Length | Up to 3200 mm |

| Minimum Bending Radius | 0.8 mm (material-dependent) |

| Tolerance Accuracy | ±0.1 mm |

| Supported Materials | Mild Steel, Stainless Steel (304, 316), Aluminum (5052, 6061), Galvanized Steel |

| Secondary Operations | Welding (MIG/TIG), Surface Treatment (Powder Coating, Anodizing, Plating), Assembly |

Our engineering team works closely with clients to optimize designs for manufacturability, reducing waste and lowering total cost of ownership. We offer DFM analysis, rapid prototyping, and just-in-time delivery options to support agile supply chains.

Choosing the right fabrication partner is a strategic decision. At Wuxi Lead Precision Machinery, we don’t just meet expectations—we set new benchmarks in precision and service. Let us become an extension of your manufacturing capability.

Contact us today at [email protected] to discuss your next project. Let’s build precision together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.