Technical Contents

Engineering Guide: Casting Vs Moulding

Engineering Insight: Casting vs Moulding in High-End Metal Manufacturing

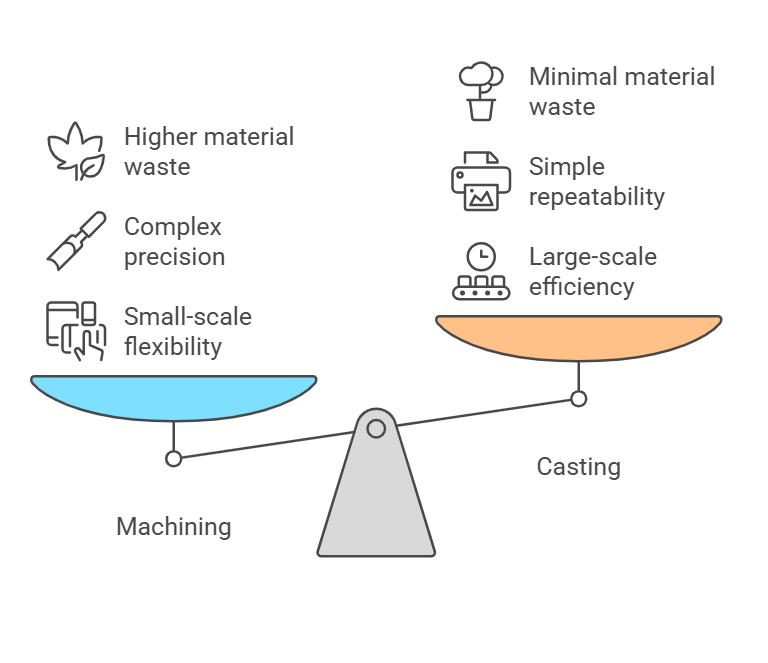

In the realm of custom metal manufacturing, the distinction between casting and moulding is not merely semantic—it defines the precision, scalability, and structural integrity of the final component. At Wuxi Lead Precision Machinery, we approach both processes with a rigorous engineering mindset, understanding that the choice between casting and moulding directly impacts performance in mission-critical applications.

Casting involves pouring molten metal into a mold cavity, where it solidifies into the desired shape. This method is particularly effective for producing complex geometries in materials such as aluminum, steel, and specialty alloys. Investment casting and die casting are two widely used techniques, each offering distinct advantages in dimensional accuracy and surface finish. At Lead Precision, we specialize in high-pressure die casting and precision investment casting, enabling us to deliver parts with tolerances as tight as ±0.05 mm—essential for aerospace, military, and high-performance automotive systems.

Moulding, often associated with polymers, also applies to metal injection moulding (MIM), where fine metal powders are mixed with a binder and injected into a mold. While MIM excels in producing small, intricate components at scale, it is limited in material strength and part size compared to traditional casting. For large-scale, load-bearing components used in defense systems or Olympic-grade sporting equipment, casting remains the superior choice due to its mechanical robustness and material versatility.

Precision is not an optional attribute in our industry—it is a requirement. A deviation of even a few microns can compromise the functionality of a part operating under extreme stress or temperature. Our CNC-integrated post-processing systems ensure that every cast component meets strict geometric dimensioning and tolerancing (GD&T) standards. This level of control is why Wuxi Lead has been entrusted to manufacture precision parts for Olympic athletic equipment and specialized components for military-grade hardware.

Our engineering team evaluates each project based on material properties, production volume, mechanical requirements, and environmental conditions. Whether selecting casting for its strength and scalability or moulding for its repeatability in miniaturized parts, we prioritize long-term reliability and performance.

Below is a comparative overview of key specifications between die casting and metal injection moulding:

| Parameter | Die Casting | Metal Injection Moulding (MIM) |

|---|---|---|

| Typical Materials | Aluminum, Zinc, Magnesium, Copper Alloys | Stainless Steel, Tool Steels, Cobalt Alloys |

| Dimensional Tolerance | ±0.05 mm to ±0.1 mm | ±0.1 mm to ±0.3 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 1.6 – 6.3 µm |

| Part Size Range | 10 g – 20 kg | 0.1 g – 250 g |

| Production Volume | High | Very High |

| Secondary Machining | Often required | Minimal |

| Mechanical Strength | High | Moderate to High |

| Ideal Applications | Automotive, Aerospace, Defense | Medical, Electronics, Small Gears |

At Wuxi Lead Precision Machinery, our expertise in casting technologies—backed by ISO-certified quality systems and decades of applied engineering—ensures that every component we produce meets the highest standards of precision and performance.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration for Cast and Molded Components

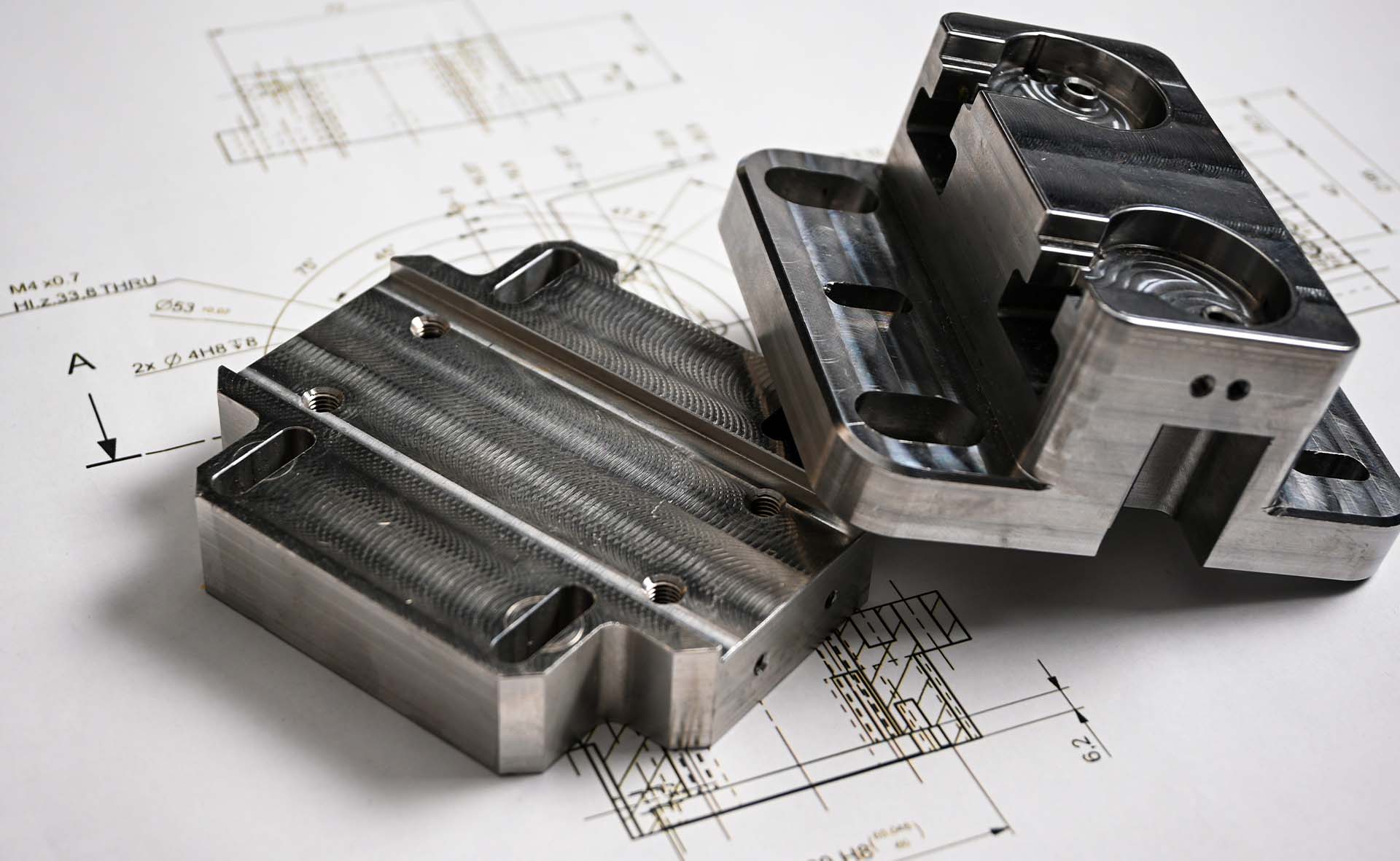

At Wuxi Lead Precision Machinery, we address the critical precision gap inherent in cast and molded metal components through advanced secondary machining. While casting and molding excel at creating complex near-net shapes, achieving tight tolerances and refined surface finishes for mission-critical applications demands integrated CNC expertise. Our facility bridges this gap, transforming rough castings or molded parts into fully functional, high-integrity components meeting aerospace, medical, and energy sector standards.

Our core strength lies in 5-axis CNC machining, specifically optimized for post-processing cast and molded geometries. We utilize DMG MORI and Makino platforms with sub-micron positioning accuracy and high-speed spindles (up to 24,000 RPM). This capability is essential for machining intricate internal passages, undercuts, and organic shapes common in investment cast turbine blades or pressure-molded hydraulic manifolds—features impossible to achieve with 3-axis systems alone. Simultaneous 5-axis interpolation ensures minimal fixturing, preserving critical datum relationships and eliminating cumulative error from multiple setups. Material removal strategies are tailored to challenging alloys like Inconel 718, Ti-6Al-4V, and high-silicon aluminum castings, mitigating thermal distortion and tool wear.

Quality control is non-negotiable. Every component undergoes rigorous validation via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with VAST gold probes and CALYPSO software. Our CMM cells perform full 3D geometric dimensioning and tolerancing (GD&T) analysis, including complex profile, position, and runout checks on freeform surfaces. This data is directly correlated to the original CAD model, providing actionable feedback for process refinement. Statistical Process Control (SPC) monitoring ensures capability indices (Cp/Cpk) consistently exceed 1.67 for critical features.

The following table details achievable tolerances for machined cast and molded components under controlled production conditions. These values reflect our standard capability; tighter tolerances are attainable for qualified critical features through dedicated process validation.

| Material Category | Feature Type | Standard Tolerance Range | Surface Finish (Ra) |

|---|---|---|---|

| Aluminum Alloys (A356, 6061) | Bore Diameters | ±0.005 mm to ±0.015 mm | 0.4 µm to 0.8 µm |

| Flatness | 0.010 mm per 100 mm | ||

| Profile of Surface | ±0.010 mm | ||

| Steel Alloys (4140, 17-4PH) | Positional Tolerance | ±0.010 mm | 0.8 µm to 1.6 µm |

| Thread Pitch Diameter | ±0.020 mm | ||

| Angularity | 0.020 mm per 100 mm | ||

| Superalloys (Inconel 718) | Complex Contours | ±0.015 mm | 1.6 µm to 3.2 µm |

| Hole Location | ±0.012 mm | ||

| Runout | 0.015 mm |

This precision integration capability eliminates costly hand-fitting and rework downstream. By controlling the entire value stream—from collaborating on casting/molding design for machinability to final CMM-certified delivery—we ensure components meet the stringent functional requirements of high-performance systems. Partner with Wuxi Lead to convert your cast or molded near-net shapes into reliably precise, ready-to-assemble components.

Material & Finish Options

Material Selection in Casting vs Moulding: Aluminum, Steel, and Titanium for High-Precision Applications

In custom metal manufacturing, the choice between casting and moulding processes is closely tied to material properties and performance requirements. At Wuxi Lead Precision Machinery, we guide clients through selecting the optimal combination of material and process based on mechanical demands, environmental exposure, and finish requirements. Among the most widely used materials in high-end industrial applications are aluminum, steel, and titanium—each offering distinct advantages depending on the application.

Aluminum is a preferred choice in casting and die-casting due to its excellent strength-to-weight ratio, corrosion resistance, and thermal conductivity. It is particularly effective in aerospace, automotive, and consumer electronics where weight reduction is critical. When paired with anodizing, aluminum achieves enhanced surface hardness and wear resistance, making it suitable for both structural and aesthetic components. Anodized finishes also allow for color coding and improved adhesion for paint primers.

Steel, especially in investment casting and precision moulding, delivers superior strength, durability, and resistance to high stress and temperature. Alloy steels and stainless variants are commonly used in heavy machinery, oil and gas equipment, and medical devices requiring sterilization. While steel does not anodize like aluminum, it benefits from alternative surface treatments such as passivation, plating, or powder coating. Its high density and melting point make steel less suitable for high-volume die-casting but ideal for low-volume, high-integrity castings.

Titanium stands out for applications demanding extreme performance. With exceptional corrosion resistance, high strength-to-density ratio, and biocompatibility, titanium is frequently used in aerospace components, medical implants, and marine systems. Although challenging to cast due to its reactivity at high temperatures, advanced vacuum casting techniques enable precise titanium part production. Surface finishing for titanium typically involves acid etching or thermal oxidation, as it does not support conventional anodizing in the same way as aluminum—though specialized electrochemical treatments can yield protective oxide layers.

The decision between casting and moulding further influences material compatibility. Die-casting is highly efficient for aluminum and zinc alloys but less viable for steel and titanium. Investment casting accommodates all three materials, offering tight tolerances and complex geometries. Moulding, particularly in the context of metal injection moulding (MIM), excels with small, intricate steel and titanium parts, though with limitations in size and section thickness.

Below is a comparative overview of key material properties and process compatibility:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Processes | Surface Treatment Options | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 200–400 | Die-casting, Sand Casting | Anodizing, Powder Coating | Aerospace, Automotive, Electronics |

| Steel | 7.8 | 400–1000 | Investment Casting, MIM | Passivation, Plating, Coating | Industrial Machinery, Medical |

| Titanium | 4.5 | 900–1200 | Vacuum Casting, MIM | Thermal Oxidation, Etching | Aerospace, Medical Implants, Marine |

Selecting the right material and process requires a systems-level understanding of operational demands. At Wuxi Lead Precision Machinery, we combine metallurgical expertise with advanced manufacturing capabilities to deliver precision-engineered solutions tailored to your application.

Manufacturing Process & QC

Precision Metal Manufacturing: From Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production sequence for casting and moulding processes, engineered to eliminate defects before they reach the production floor. Our methodology begins with collaborative Design Engineering, where cross-functional teams analyze part geometry, material properties, and functional requirements using advanced simulation software. Finite Element Analysis (FEA) predicts thermal stresses, flow dynamics, and potential porosity in casting, while moulding designs undergo gate placement and cooling channel optimization. This phase ensures dimensional stability and structural integrity are validated digitally, reducing physical iterations by 70%. Critical tolerances are locked early, with all features aligned to ISO 2768-mK standards or client-specific GD&T callouts.

Prototyping transitions digital models into tangible validation. We deploy rapid tooling for sand casting or soft aluminium moulds for low-pressure die casting, producing 5–10 functional units for comprehensive testing. Every prototype undergoes non-destructive testing (NDT) via X-ray for internal voids and CMM inspection for geometric conformity. For moulding processes like investment casting, wax patterns are laser-scanned against CAD models to confirm ±0.05mm accuracy. Material certifications and mechanical property reports are generated per ASTM or EN standards. Client sign-off requires zero deviations in first-article inspection (FAI) reports, with failure modes documented and resolved before tooling release.

Mass Production integrates closed-loop quality control. Hard tooling for permanent mould casting or gravity die casting is manufactured using 5-axis CNC machining with sub-micron repeatability. Real-time process monitoring tracks melt temperature, injection speed, and cooling rates, with SPC charts triggering automatic machine adjustments if parameters drift beyond ±0.5% of setpoints. Every 50th part undergoes 100% automated optical inspection (AOI), while batch sampling follows ANSI/ASQ Z1.4 Level II. Our zero-defect mandate is enforced through poka-yoke systems: moulding cells reject parts with surface defects via vision systems, and casting lines isolate units with density variations through inline ultrasonic testing. Full traceability—linking each component to melt batch, machine settings, and operator logs—ensures root-cause analysis takes under 4 hours if non-conformities arise.

The following table summarizes key process capabilities for critical applications:

| Parameter | Casting (Gravity Die) | Moulding (Investment) |

|---|---|---|

| Tolerance Capability | ±0.10 mm | ±0.02 mm |

| Material Range | Aluminum, Zinc Alloys | Stainless Steel, Superalloys |

| Surface Finish (Ra) | 3.2–6.3 µm | 1.6–3.2 µm |

| Tooling Lead Time | 8–12 weeks | 10–14 weeks |

| Max Part Weight | 50 kg | 25 kg |

Defect elimination is not aspirational at Wuxi Lead—it is engineered into every stage. By fusing predictive design, empirical prototyping validation, and autonomous production controls, we deliver 99.98% first-pass yield rates for aerospace, medical, and energy sector clients. Contact our engineering team to implement this zero-defect framework for your next precision metal component.

Why Choose Wuxi Lead Precision

When it comes to precision metal manufacturing, the decision between casting and moulding is not merely a matter of process selection—it’s a strategic choice that impacts product performance, production scalability, and long-term cost efficiency. At Wuxi Lead Precision Machinery, we understand the technical and economic nuances that define high-end manufacturing. With over 15 years of specialized expertise in custom metal solutions, we bridge the gap between design intent and industrial execution.

Our engineering team works closely with clients to determine whether investment casting, die casting, or precision moulding best suits their application. Whether you’re producing complex aerospace components, high-strength automotive parts, or durable industrial equipment, our advanced facilities in Wuxi, China, are equipped to deliver tight-tolerance, high-repeatability results. We leverage state-of-the-art simulation software, in-house tooling design, and rigorous quality control protocols to ensure every component meets international standards, including ISO 9001 and IATF 16949.

Partnering with Wuxi Lead Precision Machinery means more than outsourcing production—it means gaining a technical collaborator. From material selection and prototyping to full-scale manufacturing and logistics, we offer end-to-end support tailored to your industry’s demands. Our vertical integration allows for faster turnaround times, reduced lead cycles, and greater control over quality and consistency. Whether your project requires small-batch precision or high-volume output, our scalable systems adapt seamlessly.

Below is a comparison of key capabilities that define our casting and moulding services:

| Feature | Investment Casting | Die Casting | Precision Moulding |

|---|---|---|---|

| Material Options | Stainless Steel, Carbon Steel, Alloy Steel | Aluminum, Zinc, Magnesium | Thermoplastics, Engineering Polymers |

| Tolerance Range | ±0.076 mm | ±0.1 mm | ±0.05 mm |

| Surface Finish (Ra) | 1.6 – 3.2 µm | 0.8 – 6.3 µm | 0.4 – 1.6 µm |

| Typical Applications | Aerospace, Medical, Turbines | Automotive, Industrial Housings | Electrical Enclosures, Consumer Devices |

| Tooling Lead Time | 4–6 weeks | 6–8 weeks | 3–5 weeks |

| Production Volume Suitability | Low to Medium | Medium to High | High |

We specialize in applications where failure is not an option. Our clients trust us to deliver components that perform under extreme conditions—high pressure, thermal cycling, corrosive environments—because we validate every process with metallurgical analysis, dimensional inspection, and non-destructive testing.

If you are evaluating casting versus moulding for your next project, let our engineers provide a technical assessment tailored to your specifications. We offer free design for manufacturability (DFM) reviews and rapid prototyping services to accelerate your time to market.

Contact us today at [email protected] to initiate a conversation with our precision manufacturing team. At Wuxi Lead Precision Machinery, we don’t just produce parts—we engineer performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.