Technical Contents

Engineering Guide: Casting Vs Machining

Precision as the Decisive Factor in Casting Versus Machining Selection

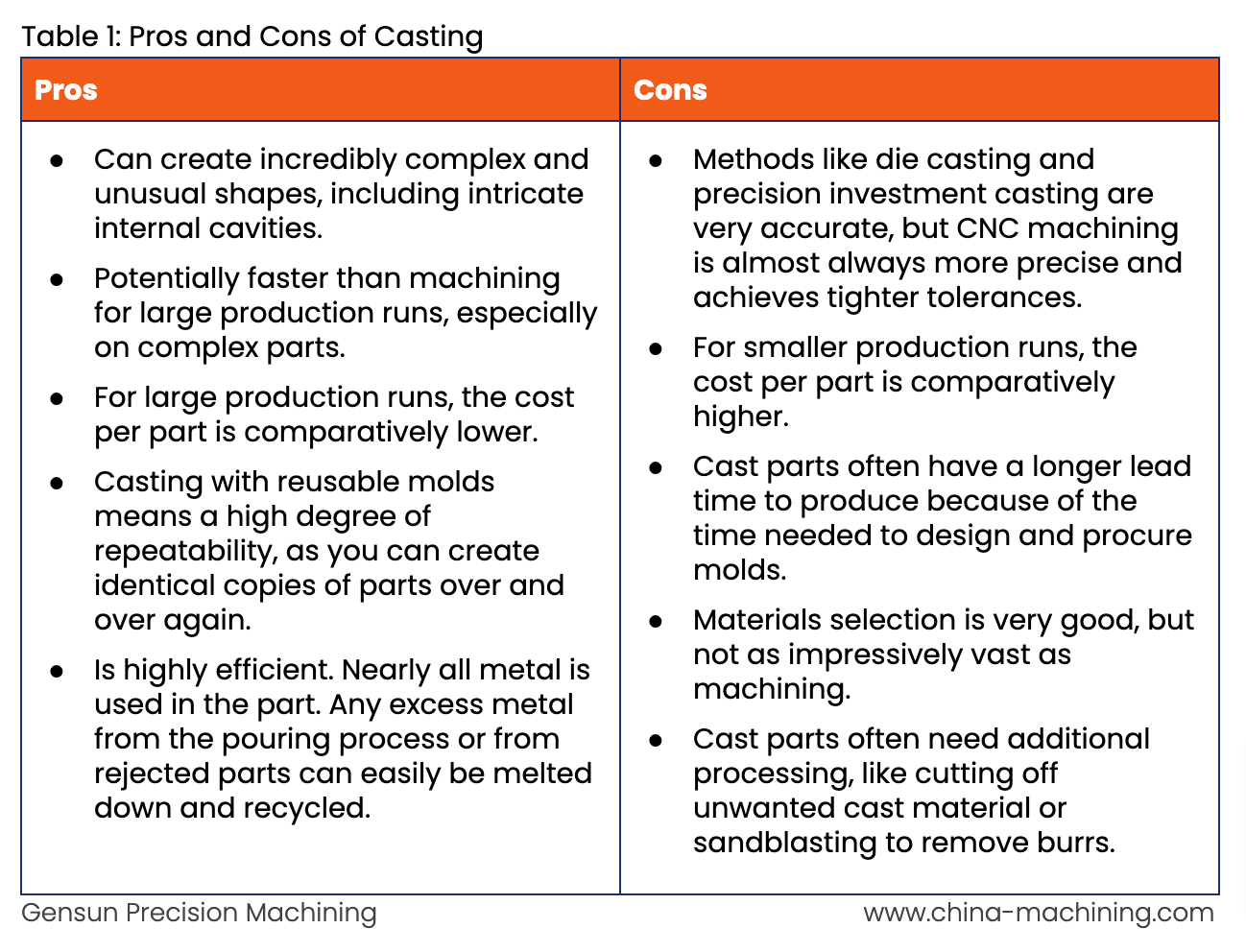

Selecting between casting and machining is not merely a cost exercise; it is a fundamental engineering decision where precision dictates suitability for mission-critical applications. While casting excels in producing complex geometries and large volumes with inherent material savings, its dimensional accuracy and surface integrity are inherently constrained by mold fidelity, thermal contraction, and post-cast finishing limitations. Machining, particularly advanced CNC milling and turning, achieves superior dimensional repeatability and surface finishes by removing material from a solid billet or near-net shape preform. This subtractive process eliminates variables inherent in molten metal solidification, making it indispensable when tolerances fall below ±0.05mm or surface roughness requirements demand Ra values under 0.8µm. For sectors like aerospace, defense, and high-performance medical devices, where component failure is not an option, the precision deficit of even the most refined casting process becomes unacceptable. The margin for error vanishes; only machining guarantees the geometric integrity and fatigue resistance required under extreme operational stresses.

Wuxi Lead Precision Machinery routinely operates at this precision frontier. Our CNC machining centers consistently deliver micron-level tolerances for components deployed in environments demanding absolute reliability. This capability is validated through stringent qualification for projects including structural elements for the Beijing Winter Olympics infrastructure and critical subsystems for classified military platforms, where dimensional conformity directly impacts safety and mission success. These applications underscore a core principle: when the functional performance, longevity, or safety of a component hinges on exact geometry and flawless surface metallurgy, machining is the non-negotiable solution. Casting may form the starting point for some high-value parts, but the final precision-critical features must be machined.

The following table outlines key comparative specifications highlighting the precision divergence:

| Parameter | Casting (Precision Investment) | CNC Machining (Wuxi Lead Standard) |

|---|---|---|

| Typical Tolerance Range | ±0.10mm to ±0.25mm | ±0.005mm to ±0.025mm |

| Surface Finish (Ra) | 1.6µm to 6.3µm | 0.4µm to 1.6µm |

| Material Utilization | High (Near-Net Shape) | Moderate to Low |

| Lead Time (Complex Part) | Moderate | Longer (Per Part) |

| Best Application | Complex Geometry, Low Stress | High Stress, Critical Interfaces, Sealing Surfaces |

Understanding these precision thresholds is paramount. Wuxi Lead Precision Machinery leverages over 15 years of experience in ultra-precision CNC manufacturing to transform demanding engineering specifications into reality. Our ISO 9001 and AS9100 certified processes, combined with in-house metrology using Zeiss CMMs, ensure every machined component meets the exacting standards required by Olympic committees and defense prime contractors. When your application demands guaranteed dimensional stability and surface perfection under load, machining is not just a process choice—it is the engineering imperative. Contact our applications engineering team to discuss how our precision machining capabilities solve your most challenging component requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions, combining precision engineering with state-of-the-art production technologies. Our core capabilities in machining provide a critical advantage over traditional casting methods, particularly in applications requiring tight tolerances, superior surface finishes, and complex geometries. While casting serves a purpose in high-volume, near-net-shape production, our 5-axis CNC machining processes are optimized for high-integrity components used in aerospace, medical, energy, and industrial automation sectors where performance and reliability are non-negotiable.

Our facility is equipped with a full suite of 5-axis CNC machining centers, enabling multi-directional cutting with exceptional accuracy and reduced setup times. This technology allows us to machine intricate 3D contours and internal features in a single setup, minimizing human error and ensuring repeatability across production runs. Unlike cast parts, which may contain porosity, inclusions, or inconsistent wall thicknesses, machined components are derived from fully dense, certified raw materials—ensuring uniform mechanical properties and structural integrity throughout the part.

We specialize in machining a wide range of materials, including aerospace-grade aluminum alloys, titanium, stainless steel, Inconel, and high-performance engineering plastics. This versatility, combined with our technical expertise, allows us to produce mission-critical components that meet the most stringent industry standards. From rapid prototyping to low-to-mid volume production, our machining capabilities support clients who demand precision, consistency, and compliance.

Quality assurance is embedded into every stage of our manufacturing process. All critical dimensions are verified using a Coordinate Measuring Machine (CMM), ensuring full traceability and adherence to customer specifications. Our inspection protocols follow ISO 9001 standards, and we provide comprehensive first-article inspection (FAI) reports and production-level QC documentation upon request. This level of scrutiny is particularly vital when replacing cast components with machined equivalents, as it ensures functional interchangeability and long-term performance in demanding environments.

The table below outlines the typical machining tolerances we achieve across various feature types, reflecting our commitment to precision and consistency.

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm | Up to 300 mm |

| Hole Diameter | ±0.025 mm | ±0.005 mm | Reamed/precision bored |

| Positional Tolerance | ±0.05 mm | ±0.01 mm | Relative to datum |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As machined or polished |

| Flatness | 0.05 mm | 0.01 mm | Over 100 mm surface |

| Angular Features | ±0.1° | ±0.05° | Verified via CMM |

By leveraging 5-axis CNC technology and rigorous quality control, Wuxi Lead Precision Machinery offers a manufacturing solution that surpasses the limitations of casting in performance-critical applications. Our technical capabilities ensure that every component meets exacting design requirements, delivering reliability, longevity, and operational superiority.

Material & Finish Options

Material Selection Fundamentals for Casting and Machining

Selecting the optimal material is critical when choosing between casting and machining processes. Each metal responds differently to manufacturing methods, impacting final part performance, cost, and lead time. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your application’s mechanical, environmental, and precision requirements. Aluminum, steel, and titanium dominate high-end manufacturing, but their suitability varies significantly based on process constraints and operational demands.

Aluminum excels in both casting and machining due to its low density, high thermal conductivity, and excellent corrosion resistance. Cast aluminum alloys like A356 are ideal for complex geometries in automotive or aerospace housings, offering good fluidity and minimal shrinkage. For machined components requiring tight tolerances—such as hydraulic manifolds or drone frames—6061-T6 or 7075-T6 aluminum provides superior strength and machinability. Anodizing is highly recommended for machined aluminum parts, enhancing surface hardness and corrosion resistance while allowing color coding for assembly. Note that anodizing adds dimensional considerations; we advise final machining before finishing to maintain critical tolerances.

Steel remains indispensable for high-strength, wear-resistant applications. Cast steel (e.g., ASTM A216 WCB) suits large structural components like valve bodies, where impact resistance is paramount. However, for precision-machined parts—gears, shafts, or medical instruments—alloy steels like 4140 or 17-4 PH deliver exceptional fatigue strength and heat treatability. Machining steel demands rigid CNC setups to manage thermal deformation, a capability our facility ensures through dynamic toolpath optimization. Unlike aluminum, steel typically requires plating (e.g., zinc-nickel) or powder coating for corrosion protection, not anodizing.

Titanium (Grade 5 Ti-6Al-4V) is reserved for extreme environments, such as aerospace or marine components, where strength-to-weight ratio and corrosion resistance are non-negotiable. Its poor castability often makes machining the preferred method despite high tool wear and slow cycle times. Titanium’s biocompatibility also drives its use in medical implants. Anodizing titanium is possible for cosmetic or mild corrosion enhancement, but specialized processes like plasma electrolytic oxidation (PEO) are more effective for engineering applications.

Key Material Properties Comparison

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Primary Process Fit |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Excellent | 8/10 | Machining (Complex parts) |

| Steel 4140 | 7.85 | 655 | Moderate | 5/10 | Machining (High-strength) |

| Cast A356 | 2.68 | 260 | Good | N/A | Casting (Thin-walled) |

| Ti-6Al-4V | 4.43 | 900 | Exceptional | 2/10 | Machining (Critical loads) |

Anodizing as a Strategic Finish

Anodizing is exclusively viable for aluminum and significantly extends part life in corrosive or high-wear scenarios. Type II (sulfuric acid) anodizing offers standard protection for general industrial use, while Type III (hardcoat) achieves 50-70 µm thickness for aerospace or military specifications. Our integrated finishing line ensures uniform coating without dimensional drift, critical for assemblies with ±0.005mm tolerances. Always specify anodizing requirements early—we optimize machining allowances to accommodate the 5-10µm per surface growth inherent in the process.

Material selection must balance process economics with functional longevity. Wuxi Lead’s engineering team collaborates to match your performance needs with the most efficient manufacturing route, whether leveraging casting for volume or precision machining for mission-critical components.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, every manufacturing journey begins with a rigorous design phase, where engineering precision meets functional intent. Our team collaborates closely with clients to translate conceptual requirements into detailed 3D CAD models and technical drawings. Utilizing advanced simulation software, we analyze structural integrity, thermal behavior, and material performance under operational conditions. This ensures that both casting and machining routes are evaluated for optimal manufacturability, cost-efficiency, and long-term reliability. Design for Manufacturability (DFM) principles are applied early to eliminate potential flaws, reduce complexity, and ensure compliance with international quality standards such as ISO 9001 and IATF 16949.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototyping—a critical step in our zero-defect philosophy. For casting applications, we produce sample parts using investment, die, or sand casting methods, depending on material and volume requirements. For high-precision components, CNC machining prototypes are fabricated to validate tight tolerances and surface finishes. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and metallurgical analysis to verify dimensional accuracy and material properties. Functional testing, including stress, fatigue, and fit checks, ensures the part performs as intended in real-world conditions. Client feedback is integrated at this stage to refine the design before committing to mass production, minimizing risk and rework.

Mass Production: Scalable Precision with Zero Defects

With prototype approval, we transition seamlessly into mass production, leveraging automated casting lines and high-speed CNC machining centers equipped with real-time monitoring systems. Our facility in Wuxi integrates lean manufacturing practices and Statistical Process Control (SPC) to maintain consistency across thousands of parts. Every casting is inspected for porosity, shrinkage, and surface integrity, while machined components are verified for geometric accuracy down to ±0.005 mm. In-process inspections, first-article checks, and final audits are standard. Traceability is ensured through batch numbering and digital quality records, enabling full audit trails for aerospace, automotive, and medical clients.

The table below outlines key process capabilities for both casting and machining at Wuxi Lead Precision Machinery.

| Parameter | Casting Process | Machining Process |

|---|---|---|

| Tolerance Range | ±0.1 mm – ±0.3 mm | ±0.005 mm – ±0.02 mm |

| Surface Finish (Ra) | 3.2 – 12.5 µm | 0.8 – 3.2 µm |

| Materials | Aluminum, Zinc, Stainless Steel | Aluminum, Steel, Titanium, Brass |

| Lead Time (Prototype) | 10–20 days | 7–14 days |

| Production Volume | 100 – 100,000+ units | 1 – 10,000+ units |

| Quality Standards | ISO 9001, IATF 16949 | ISO 9001, AS9100, IATF 16949 |

Through disciplined execution across design, prototyping, and mass production, Wuxi Lead Precision Machinery delivers defect-free metal components tailored to the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Precision Manufacturing Decisions Demand Expert Partnership

Selecting between casting and machining is never a theoretical exercise—it determines your product’s performance, cost structure, and time-to-market. At Wuxi Lead Precision Machinery, we move beyond generic comparisons to solve your specific engineering challenges. With 15 years of深耕 in aerospace, medical, and defense manufacturing, we’ve mastered the art of matching processes to mission-critical requirements. Our engineers don’t just follow blueprints; we interrogate them. Where does casting introduce hidden porosity risks for your hydraulic manifold? When does 5-axis machining eliminate costly secondary operations for your turbine blade? We deliver answers grounded in 200+ CNC centers and ISO 9001-certified quality systems operating under zero-defect culture.

Technical Clarity Through Data-Driven Analysis

| Process | Best For | Lead Precision Edge |

|---|---|---|

| Investment Casting | Complex geometries, low-volume prototypes | ±0.1mm tolerance control; 40% faster iteration cycles |

| CNC Machining | Tight-tolerance components (±0.005mm), hardened materials | In-house material testing; 99.2% first-pass yield rate |

| Hybrid Approach | High-stress assemblies requiring both complexity and precision | Seamless transition from cast preform to finished part |

This isn’t academic theory. Last quarter, we rescued a medical device client’s spinal implant project by switching from sand casting to our precision-machined titanium solution—eliminating $220K in scrap costs while meeting FDA fatigue specifications. Your application demands this level of contextual expertise. Generic suppliers quote tolerances; we engineer reliability.

Why Global Leaders Trust Our Partnership Model

We integrate into your development lifecycle as a co-engineering extension—not a transactional vendor. Our APQP framework begins with DFMEA workshops to de-risk your design before metal touches machine. When a European aerospace client faced turbine housing warpage, our team recalibrated their entire thermal treatment sequence, achieving Cpk >1.67 on critical diameters. This depth of collaboration stems from 78 certified engineers holding AS9100 and NADCAP credentials, not sales promises.

Your Next Step: Precision Engineered for Action

Stop navigating process trade-offs alone. Send your CAD file and target specifications to [email protected] with subject line “Casting vs Machining Analysis Request.” Within 24 business hours, you’ll receive:

A detailed manufacturability report highlighting cost/tolerance/lead time impacts

A recommended process flow with failure-mode mitigation strategies

Direct access to our lead applications engineer for technical dialogue

Wuxi Lead doesn’t sell machines—we deliver solved problems. Since 2008, we’ve reduced client NRE costs by 33% on average through precision process selection. Your component’s integrity starts with the right partner. Contact us today to transform manufacturing uncertainty into engineered certainty. Precision isn’t optional; it’s our contract with you.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.