Technical Contents

Engineering Guide: Casting And Machining

Engineering Insight: Casting and Machining – The Foundation of Precision Manufacturing

In the world of custom metal manufacturing, the integration of casting and machining processes defines the boundary between standard production and true engineering excellence. At Wuxi Lead Precision Machinery, we understand that precision is not merely a target—it is a requirement embedded in every stage of development, from raw casting to final machining. Our decades of experience in serving high-demand sectors—including Olympic-grade sports equipment and mission-critical military components—underscore our commitment to dimensional accuracy, material integrity, and long-term reliability.

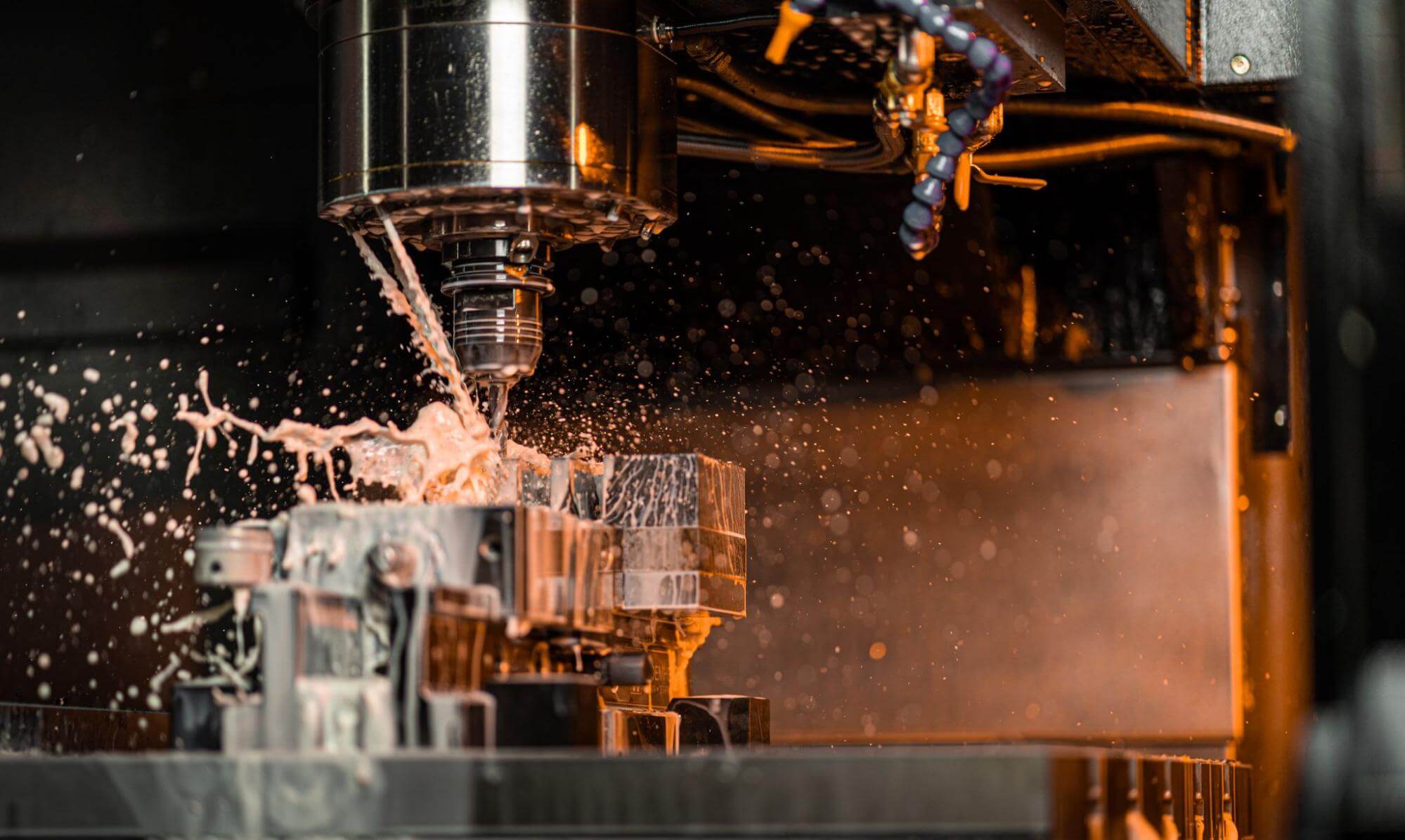

Casting forms the initial geometry of a component, establishing its foundational structure. However, even the most advanced casting techniques produce parts with inherent tolerances that are insufficient for high-performance applications. This is where precision machining becomes indispensable. By removing material with micron-level accuracy, CNC machining transforms cast near-net shapes into fully functional components that meet exact design specifications. The synergy between casting and machining allows for complex geometries, optimized weight, and superior mechanical properties—critical in aerospace, defense, and high-end industrial systems.

At Lead Precision, our engineering team leverages proprietary process controls to minimize distortion during both casting solidification and post-cast machining. We utilize vacuum-assisted die casting and precision sand casting methods tailored to alloy type and end-use environment. These castings are then transferred to our in-house 3-, 4-, and 5-axis CNC machining centers, where tight tolerances and fine surface finishes are achieved consistently. Our quality assurance protocols include CMM inspection, metallurgical analysis, and first-article reporting, ensuring every component meets or exceeds international standards.

Our work on Olympic-level components—where fractions of a millimeter impact athletic performance—and ruggedized military hardware—where failure is not an option—demonstrates our mastery in balancing precision with durability. These projects demand not only technical capability but also deep material science understanding and process traceability, which are core to our manufacturing philosophy.

Below are representative specifications achievable through our integrated casting and machining workflow:

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.025 mm (machined surfaces) |

| Surface Finish (Ra) | As low as 0.4 µm (machined) |

| Maximum Part Weight | Up to 100 kg (aluminum and steel alloys) |

| Casting Methods | Die casting, sand casting, investment casting |

| Machining Centers | 5-axis CNC, high-speed milling |

| Materials Supported | Aluminum alloys, stainless steel, cast iron, bronze |

| Quality Standards | ISO 9001:2015, AS9100, MIL-STD-1312 |

Precision in casting and machining is not an incremental advantage—it is the cornerstone of performance, safety, and innovation. At Wuxi Lead Precision Machinery, we combine advanced technology with battle-tested experience to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities: Integrated Casting and Precision Machining

Wuxi Lead Precision Machinery delivers end-to-end solutions for mission-critical metal components, uniquely integrating advanced casting processes with state-of-the-art CNC machining. Our facility bridges the gap between near-net-shape casting and micron-level precision, eliminating supply chain fragmentation for aerospace, medical, and energy sector clients. We specialize in transforming complex castings—produced via investment, sand, or die-casting—into fully finished parts meeting the most stringent geometric and functional requirements. This vertical integration ensures dimensional stability, reduces lead times by up to 40%, and guarantees traceability from raw material to final inspection.

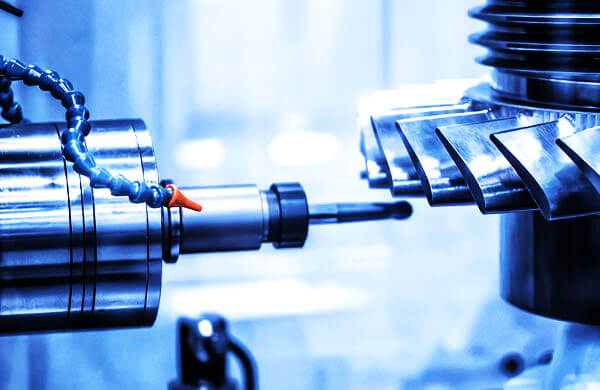

Our machining capabilities are anchored by a dedicated fleet of 5-axis CNC machining centers, including DMG MORI CTX beta 2500 and Makino D200Z systems. These platforms enable simultaneous multi-axis contouring of intricate geometries—such as turbine blades, orthopedic implants, and hydraulic manifolds—with sub-micron repeatability. High-speed spindles (up to 24,000 RPM) and dynamic toolpath optimization allow efficient material removal while maintaining surface integrity on challenging alloys like Inconel 718, Ti-6Al-4V, and high-silicon aluminum. All equipment operates under strict thermal compensation protocols, ensuring consistent accuracy across extended production runs.

Quality control is non-negotiable. Every component undergoes comprehensive inspection via Zeiss CONTURA CMM systems equipped with 0.0001 mm resolution probes and PC-DMIS software. We perform full 3D scanning, GD&T validation, and first-article reporting per AS9102 or customer-specific standards. In-process checks at critical stages prevent deviation accumulation, while our ISO 17025-accredited lab validates material properties and coating adherence. This closed-loop methodology ensures zero escapes and full compliance with NADCAP or FDA mandates.

The following table details our standard and achievable tolerance benchmarks for machined cast components:

| Feature | Standard Tolerance | Tight Tolerance Capability | Measurement Standard |

|---|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm | ISO 2768-mK |

| Geometric (GD&T) | ±0.1 mm | ±0.01 mm | ASME Y14.5-2018 |

| Surface Roughness (Ra) | 3.2 μm | 0.4 μm | ISO 4287 |

| Positional Accuracy | ±0.03 mm | ±0.002 mm | VDI/VDE 2617 |

| Angular Deviation | ±0.1° | ±0.005° | ISO 1101 |

These capabilities are validated through continuous investment in metrology and process engineering. We do not merely meet specifications—we redefine feasibility for high-complexity metal components. Partner with Wuxi Lead to convert your most demanding casting-to-machining challenges into production-ready realities, backed by rigorous data and uncompromising accountability.

Material & Finish Options

Material selection is a critical step in custom metal manufacturing, directly influencing performance, durability, and cost-effectiveness of the final component. At Wuxi Lead Precision Machinery, we specialize in precision casting and machining of high-performance metals, with aluminum, steel, and titanium being the most widely used materials across aerospace, automotive, medical, and industrial applications. Each material offers distinct mechanical and thermal properties, making them suitable for specific operational environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly ideal for lightweight structural components where weight reduction is crucial without sacrificing performance. Common aluminum alloys used in casting and machining include 6061, 7075, and A380, each offering tailored characteristics for high-stress or high-temperature environments. Due to its conductivity and low density, aluminum is frequently selected for heat sinks, housings, and aerospace brackets.

Steel remains the backbone of heavy-duty applications due to its superior strength, wear resistance, and affordability. We utilize a range of carbon and alloy steels—such as 4140, 1018, and 4340—engineered for high tensile strength and impact resistance. Steel components are commonly found in tooling, shafts, and structural frames where load-bearing capacity is paramount. While heavier than aluminum, steel’s durability and ease of heat treatment make it indispensable in demanding mechanical systems.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, especially in saline or high-temperature environments. Grade 5 (Ti-6Al-4V) is the most widely used titanium alloy in aerospace and medical implants due to its biocompatibility and ability to maintain integrity under extreme conditions. Though more challenging to machine and more costly, titanium’s long-term reliability justifies its use in mission-critical applications.

Surface finishing further enhances material performance, with anodizing being a key process for aluminum components. Anodizing increases surface hardness, improves corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly applied based on functional requirements, with Type III offering thicker, more durable coatings for industrial use.

The following table outlines key mechanical properties of commonly used materials in our casting and machining operations:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Common Applications | Typical Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 276 | 2.70 | Aerospace, automotive parts | Anodizing, powder coating |

| Steel 4140 | 655 | 415 | 7.85 | Shafts, tooling, gears | Zinc plating, passivation |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | Aircraft components, implants | Anodizing, bead blasting |

Selecting the right material and finish requires a comprehensive understanding of operational demands. At Wuxi Lead Precision Machinery, we collaborate closely with engineers and designers to ensure optimal material pairing and finishing processes, delivering components that meet the highest standards in precision and reliability.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Precision Casting & Machining Production Process

At Wuxi Lead Precision Machinery, our integrated casting and machining workflow eliminates defects before they occur. We enforce rigorous controls across Design, Prototyping, and Mass Production to deliver zero-defect components for aerospace, medical, and energy sectors. This closed-loop methodology ensures dimensional stability, material integrity, and full traceability from digital blueprint to finished part.

Design Phase: Engineering for Zero Defects

Our engineers collaborate with clients to optimize part geometry for both casting feasibility and CNC machinability. Using advanced simulation software, we predict thermal distortion in casting and toolpath stresses in machining, adjusting wall thicknesses and draft angles proactively. Critical tolerances (±0.005mm) are validated against ASME Y14.5 GD&T standards, while material selection aligns with ASTM/AMS specifications. Every design undergoes Design Failure Mode and Effects Analysis (DFMEA) to preempt risks, ensuring manufacturability without compromise.

Prototyping: Validation at Micro-Volume Scale

Prototypes are produced using the exact production tooling and materials—not 3D printing—to replicate mass production physics. We conduct First Article Inspection (FAI) per AS9102, measuring 100% of critical features with CMM, optical comparators, and X-ray fluorescence for material composition. Dimensional data is compared against simulation outputs; deviations trigger immediate process recalibration. This phase validates thermal compensation algorithms for CNC machines and solidification models for casting, confirming the process window achieves Cpk >1.67 before scaling.

Mass Production: Sustained Precision at Scale

Serial production leverages automated in-process gauging and SPC control. Each casting undergoes real-time X-ray inspection for porosity, while CNC machining employs touch-probe systems for on-the-fly tool wear compensation. Every component is serialized; material certificates, process parameters, and inspection data are blockchain-logged for full traceability. Our 5-axis machining cells maintain ±0.002mm positional accuracy through continuous thermal monitoring, and statistical process control charts trigger automatic line halts if trends approach tolerance limits—eliminating downstream rework.

Core Production Capabilities

| Parameter | Casting Capability | Machining Capability |

|---|---|---|

| Material Range | Aluminum, Titanium, Inconel, Cast Iron | All alloys + exotic metals |

| Tolerance Precision | ±0.1mm (net shape) | ±0.005mm (critical features) |

| Max Part Size | 1,200mm x 800mm x 600mm | 1,500mm x 1,000mm x 800mm |

| Volume Capacity | 1–10,000 units | 1–50,000 units |

| Key Certifications | ISO 9001, IATF 16949 | AS9100, NADCAP |

This end-to-end discipline—where design insights feed prototyping, and prototype data hardens production—ensures every component meets mission-critical requirements. Wuxi Lead transforms complex metal manufacturing into a predictable, defect-free outcome. Partner with us to convert engineering intent into flawless reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Casting and Machining Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, custom metal manufacturing services tailored to the exacting demands of global industries. From aerospace and automotive to energy and industrial automation, our integrated casting and machining capabilities ensure your components meet the highest standards of performance, durability, and dimensional accuracy. When you choose to partner with us, you’re not just sourcing parts—you’re gaining a strategic manufacturing ally with deep technical expertise, rigorous quality control, and a relentless commitment to on-time delivery.

Our advanced production ecosystem combines state-of-the-art foundry technologies with multi-axis CNC machining centers, enabling seamless transition from raw casting to finished component—all under one roof. This vertical integration reduces lead times, enhances consistency, and gives you full traceability from material sourcing to final inspection. Whether you require low-volume prototypes or high-volume production runs, our team of engineering specialists collaborates closely with your design and procurement teams to optimize manufacturability, reduce cost, and accelerate time-to-market.

We support a wide range of materials, including aluminum alloys, ductile iron, stainless steel, and specialty alloys, ensuring compatibility with demanding operational environments. Our foundry processes include die casting, gravity casting, and sand casting, each selected based on your part’s geometry, mechanical requirements, and production volume. These castings are then precision-machined using 3-axis, 4-axis, and 5-axis CNC systems, achieving tolerances down to ±0.005 mm and surface finishes below Ra 0.8 µm.

Quality is embedded in every step. Our facility is ISO 9001:2015 certified, and we employ comprehensive in-process and final inspections using CMMs, optical comparators, and metallurgical testing equipment. Every component is validated against your technical specifications, ensuring compliance with international standards and industry-specific requirements.

Below are key specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Surface Finish | As low as Ra 0.8 µm |

| Maximum Work Envelope (5-axis) | 1,200 × 800 × 750 mm |

| Minimum Feature Size | 0.5 mm |

| Materials Supported | Aluminum, Cast Iron, Stainless Steel, Brass, Alloy Steel |

| Annual Production Capacity | Up to 2,000 tons of precision castings |

| Quality Standards | ISO 9001:2015, Full Material Traceability, FAI Reports |

Partnering with Wuxi Lead Precision Machinery means access to a scalable, responsive, and technically agile manufacturing partner based in China with global reach. We understand the complexities of international supply chains and are equipped to manage logistics, customs compliance, and just-in-time delivery to support your operational continuity.

Start your next project with confidence. Contact us today at [email protected] to discuss your casting and machining requirements. Let our engineering team help you turn precision into performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.