Technical Contents

Engineering Guide: Carbon Fiber 3D Printing Service

Engineering Insight Precision in Carbon Fiber 3D Printing Services

Achieving true precision in carbon fiber 3D printing is non-negotiable for mission-critical industrial applications. Unlike standard polymer printing, the integration of continuous or chopped carbon fibers introduces complex material behavior demanding exceptional process control. Fiber alignment, resin curing kinetics, and thermal management during deposition directly impact part strength, dimensional stability, and surface integrity. Microscopic layer inconsistencies or fiber misalignment can propagate into catastrophic failure points under load, particularly in aerospace, defense, or high-performance sporting goods. This necessitates engineering-grade systems operating within tightly controlled environmental parameters, far beyond the capabilities of desktop or general-purpose industrial printers. Precision here transcends mere geometric accuracy; it encompasses consistent fiber distribution, minimized void content, and predictable mechanical properties throughout the printed structure. Without this level of control, the theoretical advantages of carbon fiber composites – high strength-to-weight ratio, stiffness, fatigue resistance – remain unrealized in practice.

Wuxi Lead Precision Machinery leverages its deep heritage in ultra-precision CNC metal manufacturing to address these exacting demands. Our experience delivering components for Olympic athletic equipment and certified military subsystems instilled an uncompromising culture of metrology and process validation. We apply identical rigor to carbon fiber additive processes. This means implementing closed-loop environmental monitoring within build chambers, utilizing aerospace-grade resins with traceable material lots, and employing in-situ laser scanning for real-time layer verification. Our engineering team, fluent in both composite science and precision metal fabrication, understands how printed carbon fiber structures must interface seamlessly with machined metallic components in final assemblies. This holistic view ensures the printed part meets not only its standalone specifications but also integrates flawlessly within the larger mechanical system, avoiding costly assembly issues or performance compromises.

The following table outlines key precision metrics achievable within our controlled carbon fiber 3D printing service environment, reflecting the standards required for demanding industrial integration.

| Parameter | Typical Achievable Range | Measurement Standard | Critical Impact |

|---|---|---|---|

| Layer Resolution (Z) | 50 – 150 microns | ISO 2768-mK | Surface finish, fine feature definition |

| Dimensional Accuracy | ±0.05% (min ±0.1 mm) | ISO 2768-mK / AS9100 Rev D | Assembly fit, tolerance stack-up control |

| Fiber Alignment Tolerance | ±2 degrees | Internal Optical Analysis | Predictable mechanical properties |

| Interlayer Bond Strength | >95% of bulk material | ASTM D2344 | Structural integrity, delamination risk |

| Build Volume Precision | ±0.15 mm over 300mm | Laser Tracker Verification | Large part consistency, scalability |

This precision is validated daily through our work. Components we produce undergo the same stringent non-destructive testing and first-article inspection protocols as our metal parts, proven in applications where failure is not an option – from lightweight structural elements in specialized military unmanned systems to performance-critical frames in Olympic-level competition equipment. Partnering with a provider possessing this depth of precision engineering discipline ensures your carbon fiber 3D printed components deliver on the promise of the material, integrated reliably within your high-value assemblies.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to support high-performance applications across aerospace, automotive, medical, and industrial sectors. At the core of our precision fabrication services is a fully integrated 5-axis CNC machining platform, enabling complex geometries and tight-tolerance components that meet the most demanding design specifications. Our 5-axis technology provides simultaneous multi-directional cutting, reducing setup times and part handling while improving accuracy and surface finish. This capability is essential for producing intricate components used in carbon fiber 3D printing systems, where alignment, rigidity, and thermal stability are critical.

Our machining centers operate with high-speed spindles and dynamic tool compensation, ensuring micron-level precision across a wide range of materials, including aluminum alloys, titanium, stainless steel, and high-strength composites. Each machine is monitored in real time using advanced process control systems to maintain consistency and minimize variability during production runs. Tool wear detection, adaptive cutting strategies, and automated calibration routines further enhance repeatability and quality.

Quality assurance is embedded into every stage of the manufacturing process. All critical components undergo comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing full 3D metrology validation. Our CMM systems are programmed to inspect geometric dimensioning and tolerancing (GD&T) features, ensuring compliance with ASME Y14.5 and ISO 1101 standards. Data from each inspection is documented and traceable, supporting full quality reporting for audits and certifications.

We maintain strict environmental controls in our metrology lab to eliminate thermal drift, ensuring measurement stability down to ±0.5 μm. In addition to CMM inspection, we utilize optical comparators, surface roughness testers, and laser alignment tools to verify dimensional integrity and surface quality. All inspection equipment is calibrated annually per ISO 9001 protocols, with internal checks performed weekly.

The following table outlines our standard and achievable tolerances across key manufacturing parameters:

| Feature Type | Standard Tolerance | Achievable Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Angular Dimensions | ±0.1° | ±0.05° | Verified via CMM |

| Positional Tolerance | ±0.02 mm | ±0.008 mm | GD&T compliant |

| Surface Roughness (Ra) | 3.2 μm | 0.4 μm | Machined finish |

| Flatness | 0.02 mm | 0.005 mm | Per 100 mm² |

| Repeatability (Batch) | ±0.01 mm | ±0.003 mm | Statistical process control applied |

These capabilities enable Wuxi Lead Precision Machinery to produce critical subsystems for carbon fiber 3D printing platforms, including heated build chambers, kinematic mounts, extrusion guides, and structural frames. Our engineering team collaborates directly with clients to optimize designs for manufacturability, ensuring performance, durability, and seamless integration.

Material & Finish Options

Material Selection for Precision Metal Components in Advanced Manufacturing

Understanding material properties is critical when integrating carbon fiber composite structures with precision metal components. While carbon fiber 3D printing excels for lightweight polymer-based prototypes and end-use parts, high-stress, high-temperature, or safety-critical applications demand engineered metals. Wuxi Lead Precision Machinery specializes in CNC-machined metal solutions that complement additive processes, ensuring structural integrity and performance where composites reach their limits. Selecting the optimal metal alloy directly impacts part longevity, weight, corrosion resistance, and cost-effectiveness in demanding industrial environments.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and excellent machinability. They are ideal for aerospace brackets, drone frames, and automotive fixtures requiring weight reduction without sacrificing rigidity. Steel variants like 4140 and 304 stainless provide superior hardness, wear resistance, and structural stability for tooling, hydraulic components, and heavy machinery parts subjected to high loads. For extreme conditions, titanium Grade 5 (Ti-6Al-4V) delivers unparalleled corrosion resistance, biocompatibility, and strength at elevated temperatures, making it indispensable for medical implants, aerospace actuators, and marine hardware. Each material presents distinct trade-offs in cost, machinability, and environmental resilience that must align with your functional requirements.

Key mechanical properties guide informed selection. The following table compares critical specifications for common aerospace and industrial alloys:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 570 | 505 | 2.81 | Moderate | Aircraft fittings, high-stress mounts |

| Steel 4140 | 655 | 415 | 7.85 | Low (requires coating) | Shafts, gears, tooling fixtures |

| Stainless 304 | 515 | 205 | 8.00 | High | Food processing, chemical pumps |

| Titanium Ti-6Al-4V | 900 | 830 | 4.43 | Exceptional | Aircraft engine parts, medical implants |

Surface finishing significantly enhances performance and aesthetics. Anodizing is the premier post-processing solution for aluminum components, creating a durable, non-conductive oxide layer that improves wear resistance and allows for color coding. Type II (sulfuric acid) anodizing provides standard corrosion protection, while Type III (hardcoat) delivers extreme surface hardness for moving parts. Wuxi Lead Precision Machinery implements MIL-A-8625 compliant anodizing with precise thickness control (5–25 µm), ensuring dimensional stability and adhesion for secondary processes like painting or bonding. This is particularly vital when mating machined aluminum housings to carbon fiber assemblies, preventing galvanic corrosion and ensuring seamless integration.

Choosing the right metal and finish requires balancing performance demands with production efficiency. Wuxi Lead Precision Machinery leverages decades of CNC expertise to optimize material selection, machining parameters, and surface treatments for your specific application. We collaborate closely with clients to transform carbon fiber composite designs into fully integrated systems where metal components deliver the reliability and precision that additive manufacturing alone cannot achieve. Contact our engineering team to discuss material certifications, lead times, and finishing specifications for your next high-performance project.

Manufacturing Process & QC

Design Phase: Precision Engineering for Carbon Fiber 3D Printing

At Wuxi Lead Precision Machinery, the production journey for carbon fiber 3D printed components begins with an intensive design phase rooted in engineering excellence. Our in-house design team collaborates closely with clients to analyze functional requirements, environmental conditions, and load-bearing demands. Utilizing advanced CAD software such as SolidWorks and Siemens NX, we develop high-fidelity 3D models optimized for additive manufacturing. Special attention is given to material anisotropy, layer adhesion, and structural reinforcement to ensure mechanical performance matches or exceeds traditional metal counterparts. Finite Element Analysis (FEA) is conducted to simulate stress distribution and thermal behavior, enabling preemptive design corrections. This digital-first approach ensures manufacturability while minimizing downstream risks.

Prototyping: Validating Performance and Fit

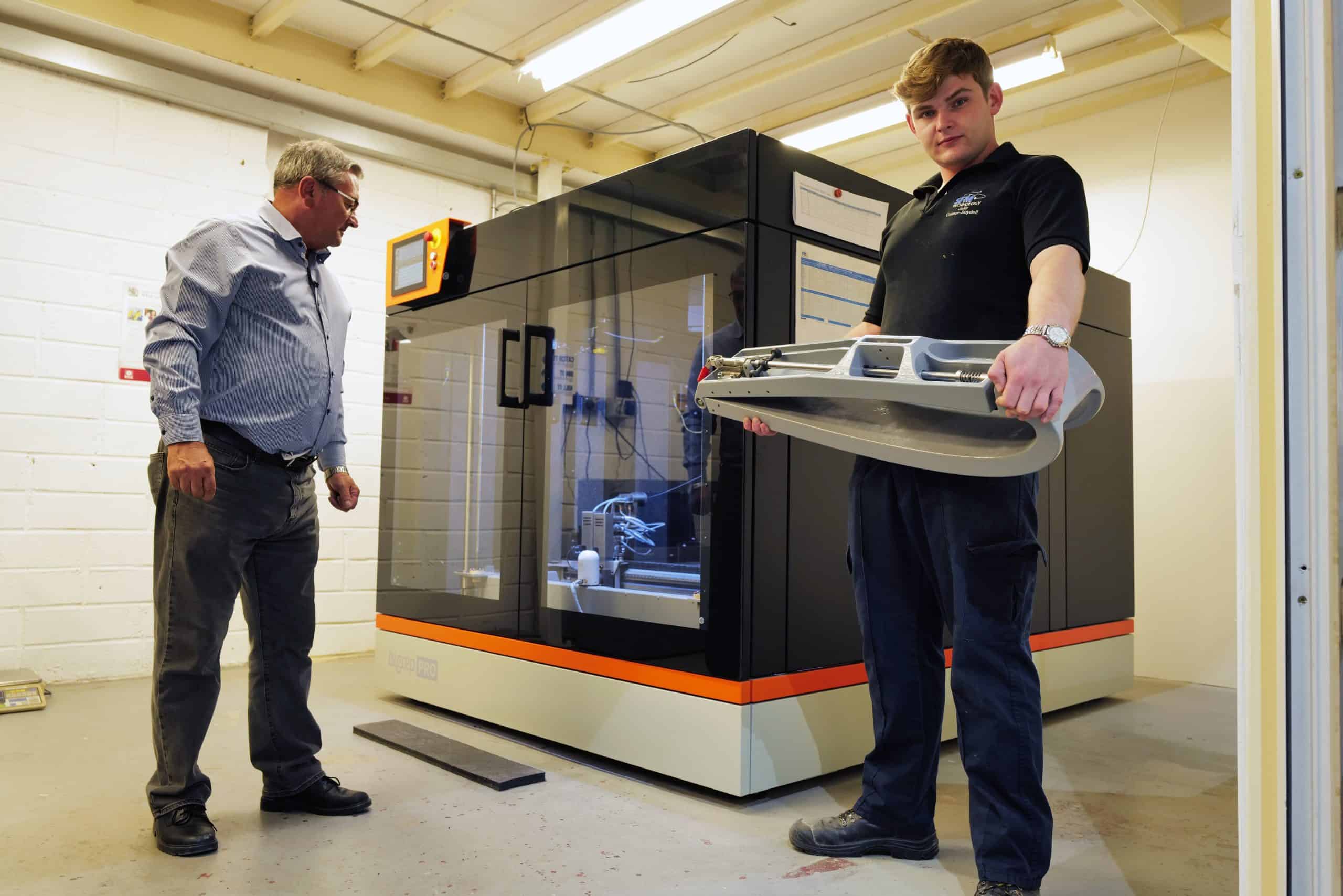

Once the design is finalized, we transition into the prototyping stage, where functional samples are produced using industrial-grade carbon fiber-reinforced 3D printing systems. Employing continuous or chopped carbon fiber filament with thermoplastic matrices such as PEEK, PEKK, or nylon-based polymers, our Stratasys and Markforged-integrated platforms deliver high-strength, dimensionally accurate prototypes. These prototypes undergo rigorous physical testing, including tensile strength, impact resistance, and thermal cycling, to validate performance under real-world conditions. Dimensional inspection is performed using coordinate measuring machines (CMM) and laser scanning to ensure geometric accuracy within ±0.1 mm. Client feedback is incorporated at this stage, allowing for iterative refinement before committing to full-scale production. This phase is critical for achieving zero defects, as it uncovers potential design or process flaws early.

Mass Production: Scalable Precision with Zero Defects

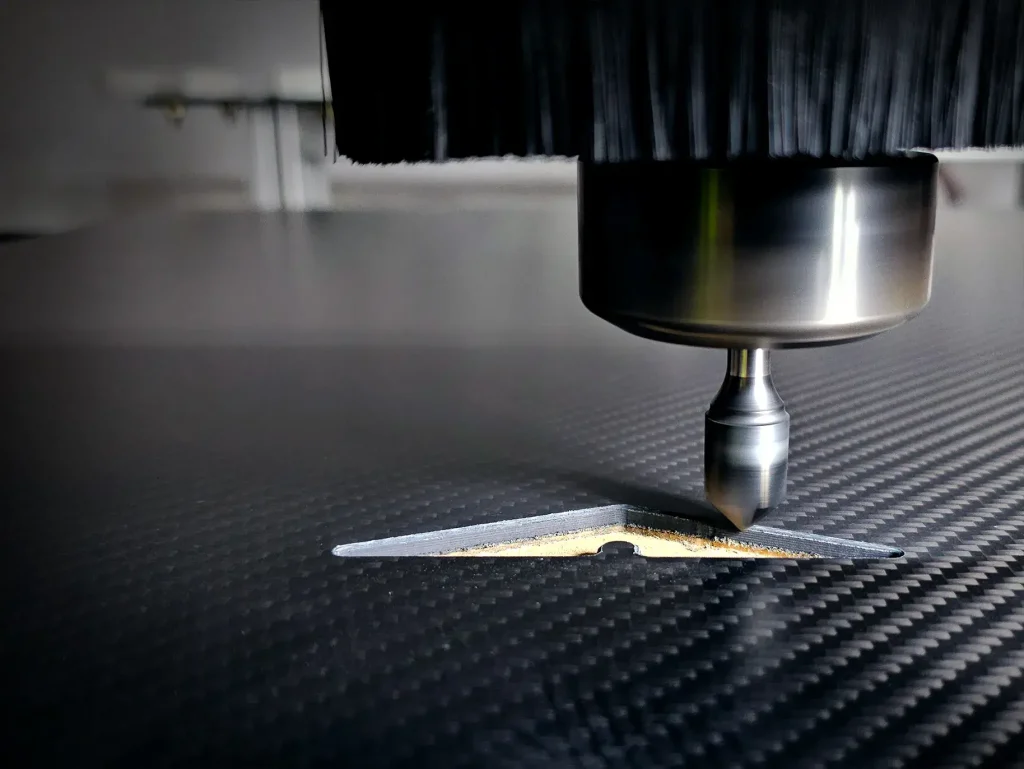

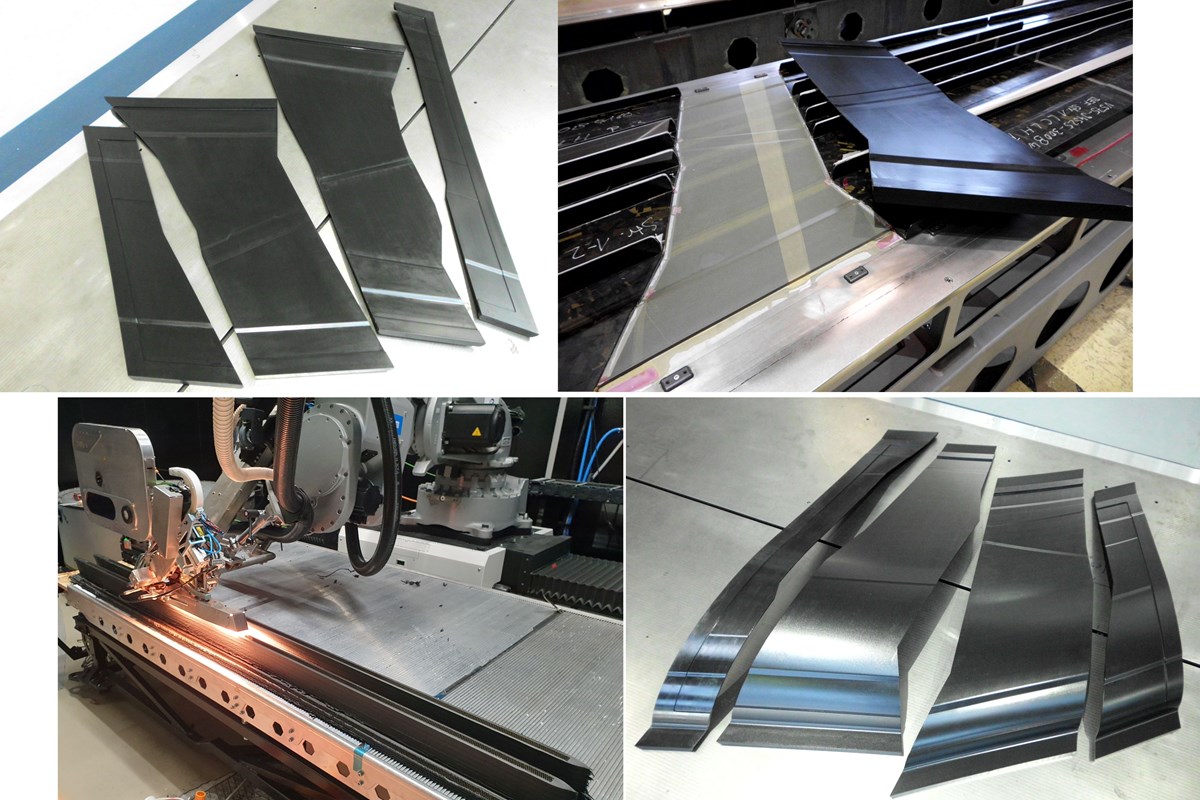

With prototype approval, Wuxi Lead initiates mass production under a fully documented quality management system compliant with ISO 9001 standards. Our automated 3D printing cells operate under controlled environmental conditions to maintain consistency in layer bonding and part integrity. Each build is monitored in real time using sensor-based anomaly detection systems that track temperature, humidity, and extrusion performance. Post-processing—including CNC trimming, surface finishing, and heat treatment—is performed with tight tolerance control to meet aerospace, automotive, or industrial equipment specifications. Every component undergoes 100% visual and dimensional inspection, supported by non-destructive testing (NDT) when required. Traceability is ensured through serialized part marking and digital production logs.

The following table outlines key process parameters for our carbon fiber 3D printing service:

| Parameter | Specification |

|---|---|

| Material Options | Carbon fiber-reinforced PEEK, PEKK, Nylon |

| Layer Resolution | 50–200 microns |

| Dimensional Accuracy | ±0.1 mm |

| Build Envelope | Up to 360 × 360 × 360 mm |

| Tensile Strength | Up to 800 MPa (depending on material) |

| Surface Finish | As-printed, sanded, or machined to request |

| Lead Time (Prototype) | 5–7 days |

| Lead Time (Mass Production) | 10–20 days (scalable to 10,000+ units) |

Through seamless integration of design intelligence, iterative validation, and disciplined manufacturing execution, Wuxi Lead delivers carbon fiber 3D printed components with uncompromising quality—ensuring zero defects and full client confidence.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Carbon Fiber Components

Wuxi Lead Precision Machinery delivers more than carbon fiber 3D printing; we provide engineered additive manufacturing solutions integrated with decades of precision metal fabrication expertise. For high-stakes industries like aerospace, medical device manufacturing, and advanced robotics, component failure is not an option. Our service bridges the gap between rapid prototyping and certified production, ensuring your carbon fiber parts meet rigorous functional and regulatory demands from concept to final assembly. We understand that material properties, geometric complexity, and environmental resilience are non-negotiable factors in your design process. Our engineering team collaborates directly with your R&D staff to optimize part geometry for additive manufacturing, select the optimal carbon fiber composite matrix (including PEEK-CF, PEKK-CF, and nylon-CF variants), and implement stringent in-process validation protocols. This integrated approach eliminates the trial-and-error phase common with standard printing services, accelerating time-to-market while guaranteeing repeatability.

Our facility operates under ISO 9001:2015 standards with dedicated climate-controlled printing cells and post-processing capabilities including precision machining, surface finishing, and non-destructive testing. We specialize in producing complex, lightweight structural components that withstand extreme thermal cycles, chemical exposure, and high mechanical loads – capabilities essential for next-generation applications where traditional metals reach performance limits. The table below outlines our core technical specifications, reflecting the industrial-grade precision demanded by Tier 1 suppliers and OEMs.

| Parameter | Specification | Application Impact |

|---|---|---|

| Build Volume | 500 x 500 x 400 mm | Accommodates large-scale structural parts |

| Layer Resolution | 50 – 200 microns | Balances surface finish and build speed |

| Tensile Strength | Up to 850 MPa (PEEK-CF) | Matches or exceeds many metal alloys |

| Thermal Resistance | Continuous use to 250°C (PEEK-CF) | Suitable for high-temp aerospace components |

| Dimensional Accuracy | ±0.1% (min ±0.05 mm) | Enables direct assembly with metal systems |

| Material Options | PEEK-CF, PEKK-CF, Nylon-CF, ULTEM | Meets flammability and biocompatibility reqs |

Choosing Lead Precision means partnering with a manufacturer that treats your project as a shared engineering challenge. We do not operate as a print farm but as an extension of your technical team, providing full material traceability, first-article inspection reports (FAIR), and production part approval process (PPAP) documentation. Our hybrid manufacturing environment – where carbon fiber printing seamlessly integrates with CNC milling, turning, and sheet metal fabrication – ensures your composite components interface perfectly with surrounding metal assemblies, eliminating costly redesigns and supply chain fragmentation.

For projects demanding uncompromising quality in carbon fiber additive manufacturing, initiate a technical consultation with our engineering team. Contact us at [email protected] to submit your CAD files and discuss how our certified processes can de-risk your next-generation product development. Specify your industry, application requirements, and target tolerances to receive a detailed capability assessment within 24 business hours. Let Lead Precision transform your carbon fiber design intent into certified, production-ready reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.