Technical Contents

Engineering Guide: C1018 Cold Rolled Steel

Engineering Insight: C1018 Cold Rolled Steel – The Precision Imperative

In high-integrity custom metal manufacturing, C1018 cold rolled steel is a foundational material prized for its excellent machinability, weldability, and consistent surface finish. However, its widespread use across demanding sectors like aerospace, defense, and precision instrumentation underscores a critical reality: achieving the required performance hinges entirely on rigorous dimensional control and process precision. C1018 cold rolled steel possesses inherently good mechanical properties, but its low carbon content (approximately 0.15-0.20%) means it lacks the hardenability of higher-carbon alloys. This characteristic places immense emphasis on the accuracy of the cold rolling process and subsequent machining operations. Any deviation in thickness, flatness, or straightness introduced during rolling propagates directly into the final component, potentially compromising fit, function, and assembly integrity in high-tolerance assemblies. For applications demanding seamless integration or critical load paths, even micron-level variations become unacceptable failure points.

The cold rolling process itself is where foundational precision is established. Controlled reduction of hot rolled coil under ambient conditions imparts superior surface quality and tighter dimensional tolerances compared to hot rolled alternatives. Yet, achieving true high-end consistency requires more than standard industry practices. It demands sophisticated process monitoring, precise roll gap control, and stringent thermal management to minimize residual stresses and ensure uniform material properties throughout the coil. These factors directly influence machining stability, tool life, and the final part’s geometric accuracy during CNC operations. Variations in material consistency can lead to chatter, dimensional drift, or surface imperfections, significantly impacting yield rates and escalating production costs for complex components.

Wuxi Lead Precision Machinery leverages decades of specialized experience in transforming C1018 cold rolled steel into mission-critical components where failure is not an option. Our deep understanding of this material’s behavior informs every stage, from strategic material sourcing with certified mills to our proprietary CNC machining protocols. We implement real-time in-process gauging and adaptive machining strategies specifically calibrated for C1018’s characteristics, ensuring geometric tolerances are maintained within microns, even on intricate geometries. This unwavering commitment to precision is validated by our track record supplying components for Olympic-standard sporting equipment requiring flawless dynamic performance and critical subsystems for military applications where reliability under extreme conditions is paramount. Material consistency is non-negotiable; our processes are engineered to extract the maximum potential from every billet.

The following table details key mechanical properties and standard tolerances achievable with high-quality C1018 cold rolled steel, reflecting the baseline upon which precision manufacturing builds.

| Property | Typical Value/Range | Industry Standard Tolerance (Thickness) |

|---|---|---|

| Carbon Content (C) | 0.15% – 0.20% | ASTM A568 / A1008: ±0.005″ (0.127mm) |

| Yield Strength (min) | 32,000 psi (220 MPa) | Precision Grade: ±0.002″ (0.051mm) |

| Tensile Strength | 53,000 – 63,000 psi | Lead Precision Capability: ±0.001″ (0.025mm) |

| Elongation in 2″ (min) | 20% | |

| Surface Finish (Typical) | Bright, Smooth | |

| Machinability Rating | 70% (Excellent) |

Precision in C1018 cold rolled steel manufacturing transcends mere specification adherence; it is the engineering discipline that transforms a versatile material into a reliable, high-performance solution. At Wuxi Lead, we treat dimensional accuracy as the core deliverable, applying our Olympic and military-proven expertise to ensure your C1018 components meet the most exacting functional and reliability requirements, batch after batch. The cost of imprecision in critical applications is far too high; our process guarantees it is never a factor.

Precision Specs & Tolerances

Advanced Machining Capabilities for c1018 Cold Rolled Steel at Wuxi Lead Precision Machinery

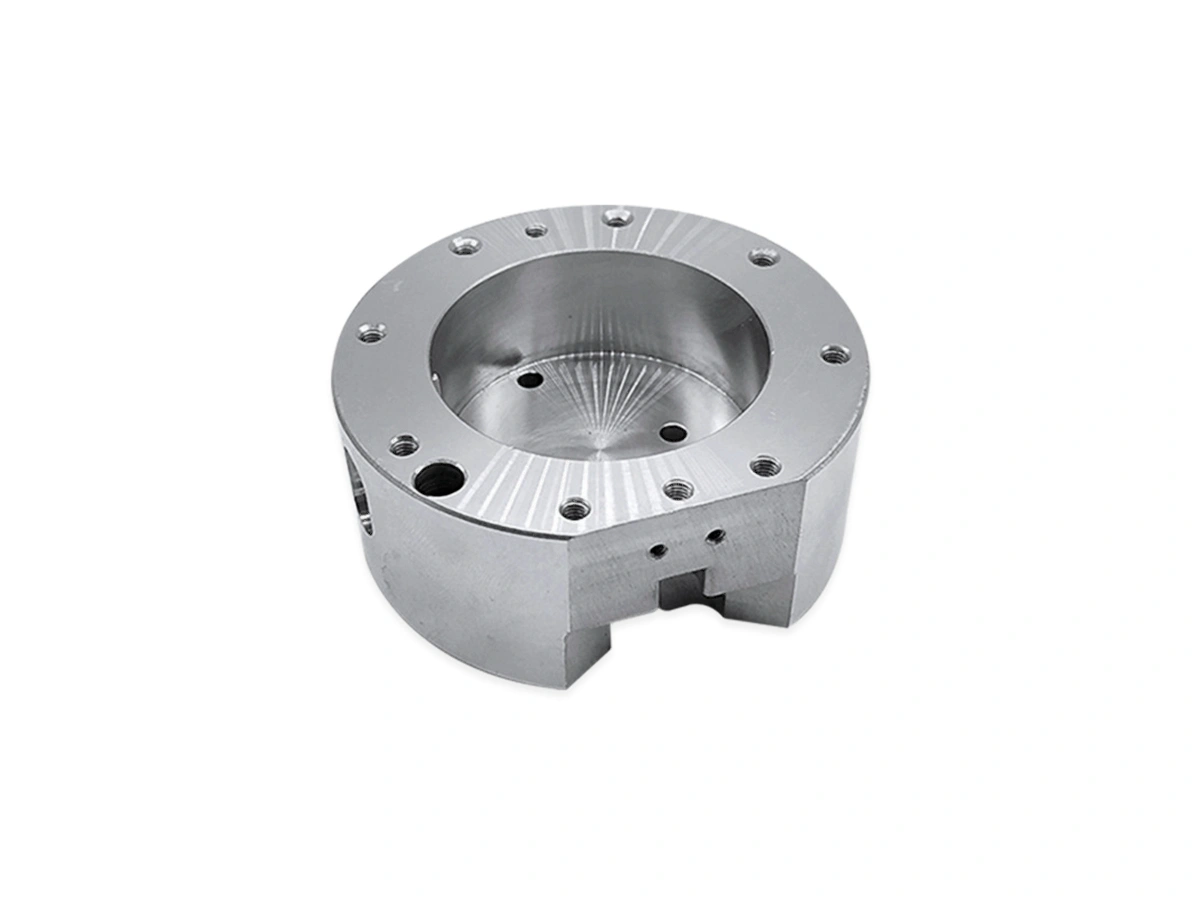

At Wuxi Lead Precision Machinery, we specialize in high-precision custom manufacturing of components using c1018 cold rolled steel, a material known for its excellent machinability, uniform grain structure, and dimensional stability. Our technical capabilities are built around state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with superior accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, significantly reducing setup time and increasing repeatability, which is critical for high-tolerance parts used in aerospace, automation, and precision instrumentation.

Our 5-axis CNC platforms are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems. This ensures consistent material removal rates and surface integrity across both prototyping and large-volume production runs. The integration of advanced CAM software allows for optimized toolpaths, minimizing cycle times while maintaining tight tolerances on intricate features such as undercuts, contours, and deep cavities.

Quality control is embedded into every stage of our manufacturing process. All c1018 steel components undergo comprehensive inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM). This high-accuracy metrology system provides full 3D verification of critical dimensions, geometric tolerances, and surface profiles in compliance with ISO 1101 and ASME Y14.5 standards. Our inspection reports include detailed GD&T analysis, ensuring full traceability and conformance to customer engineering drawings.

We maintain strict material traceability for all c1018 cold rolled steel stock, verifying chemical composition and mechanical properties prior to machining. Our facility adheres to ISO 9001:2015 quality management protocols, and our technicians are trained in lean manufacturing principles to minimize waste and maximize throughput without compromising precision.

The following table outlines the standard machining tolerances achievable on c1018 cold rolled steel using our 5-axis CNC systems and verified through CMM inspection:

| Feature Type | Standard Tolerance | Precision Tolerance (Optional) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | CMM, Micrometer |

| Hole Diameter | ±0.020 mm | ±0.008 mm | CMM, Pin Gauge |

| Positional Tolerance | ±0.030 mm | ±0.012 mm | CMM (GD&T) |

| Flatness | 0.03 mm/m | 0.01 mm/m | CMM, Surface Plate |

| Surface Roughness (Ra) | 3.2 μm | 0.8 μm (polished) | Surface Roughness Tester |

| Angular Features | ±0.1° | ±0.05° | CMM, Optical Comparator |

All tolerances are achievable on parts up to 600 mm in length, with extended capacity available upon request. Wuxi Lead Precision Machinery delivers engineered solutions where precision, reliability, and repeatability are non-negotiable.

Material & Finish Options

Material Selection Guide: C1018 Cold Rolled Steel for Precision Components

C1018 cold rolled steel represents a cornerstone material for high-volume, precision-turned and milled components demanding excellent machinability, dimensional stability, and cost efficiency. As a low-carbon steel (0.15-0.20% carbon), its primary advantage lies in the cold rolling process which refines the grain structure, significantly improving surface finish, straightness, and dimensional accuracy over hot-rolled equivalents. This makes C1018 CR ideal for shafts, pins, spindles, fasteners, and hydraulic components where tight tolerances and smooth surface finishes are critical. Its balanced composition provides good weldability and formability for secondary operations, while maintaining sufficient strength for non-structural applications. While not suitable for high-stress or extreme corrosion environments without protective coatings, C1018 CR delivers exceptional value where machinability, consistency, and surface quality are paramount.

Key mechanical and processing properties define C1018 CR’s application scope. The cold working process inherently increases strength compared to hot-rolled material but maintains the ductility necessary for complex geometries. Its low carbon content minimizes hardening during welding, reducing cracking risk. Crucially, the smooth, scale-free surface achieved through cold rolling provides an optimal base for subsequent finishing processes like plating, painting, or passivation, ensuring superior adhesion and final appearance. Machinability is rated highly (approximately 70% relative to B1112 free-machining steel), allowing for high-speed CNC operations, excellent chip control, and extended tool life – directly impacting production efficiency and cost per part.

C1018 Cold Rolled Steel Key Specifications

| Property | Typical Value | Significance for Precision Manufacturing |

|---|---|---|

| Carbon Content | 0.15% – 0.20% | Optimized balance for weldability & machinability |

| Yield Strength | 370 MPa (53.7 ksi) min | Adequate for non-structural precision components |

| Tensile Strength | 440 MPa (63.8 ksi) min | Provides reliable mechanical performance |

| Elongation (in 2″) | 15% min | Sufficient ductility for bending/forming ops |

| Hardness (Brinell) | 121 HB max | Ensures good machinability and tool life |

| Machinability Rating | 70% (Relative to B1112 = 100%) | High efficiency in CNC turning/milling processes |

When comparing core materials, C1018 CR occupies a distinct niche. Aluminum alloys (e.g., 6061-T6) offer significant weight savings and natural corrosion resistance but at higher material cost and lower stiffness; they excel in aerospace and portable equipment. Titanium (e.g., Grade 5) provides unparalleled strength-to-weight ratio and extreme corrosion resistance but commands a substantial premium and presents significant machining challenges; it is reserved for critical aerospace or medical applications. C1018 CR delivers the optimal blend of affordability, ease of machining, and consistent dimensional quality for high-volume industrial parts where ultimate strength or weight savings are not primary drivers. Note that anodizing is specific to aluminum; C1018 steel requires alternative finishes like zinc plating, black oxide, or painting for corrosion protection.

At Wuxi Lead Precision Machinery, we leverage deep expertise in C1018 CR processing. Our CNC centers utilize optimized toolpaths, specialized carbide grades, and stringent process controls to maximize surface integrity and dimensional repeatability directly from the machine, minimizing secondary finishing needs. We rigorously source material meeting ASTM A519 standards and implement in-process inspections to ensure every bar meets the tight tolerance demands of precision assemblies. Partner with us to transform C1018 cold rolled steel into high-performance, cost-optimized components for your demanding applications.

Manufacturing Process & QC

The production process for components fabricated from C1018 cold rolled steel at Wuxi Lead Precision Machinery follows a disciplined, closed-loop methodology designed to ensure precision, consistency, and zero defects across all manufacturing stages. This process integrates advanced engineering controls, rigorous validation protocols, and real-time quality monitoring from initial design through to mass production.

Design begins with a detailed engineering review, where our team analyzes customer specifications, functional requirements, and environmental conditions. Using C1018 cold rolled steel, we leverage its excellent machinability, uniform grain structure, and dimensional stability to optimize part geometry and tolerance allocation. Finite element analysis (FEA) and geometric dimensioning and tolerancing (GD&T) are applied to simulate performance under operational loads, ensuring long-term reliability. Design for manufacturability (DFM) principles are strictly followed to eliminate unnecessary complexity and reduce potential failure modes before any material is cut.

Prototyping serves as the critical validation phase. A small batch of components is produced using the same tooling, fixtures, and CNC equipment intended for full-scale production. This ensures process fidelity and enables direct performance comparison. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM), surface roughness testers, and optical comparators. Dimensional accuracy, surface finish, and material integrity are verified against design intent. Any deviations trigger immediate root cause analysis and corrective action, with design or process adjustments implemented before progression.

Upon successful prototype approval, the process transitions to mass production under a fully documented control plan. Our CNC machining centers—equipped with automated tool measurement, in-process probing, and real-time spindle monitoring—maintain tight tolerances and detect anomalies at the earliest stage. Every production run is supported by first-article inspection reports (FAIR), statistical process control (SPC) charts, and batch traceability records. 100% critical dimension checks are performed on high-risk features, while non-destructive testing (NDT) methods such as ultrasonic or magnetic particle inspection are employed when required.

Throughout the production cycle, environmental controls, tool wear compensation algorithms, and operator training protocols are synchronized to minimize variability. Our ISO 9001-certified quality management system enforces traceability from raw material certification to final packaging, ensuring full compliance with aerospace, automotive, and industrial equipment standards.

Key mechanical and physical properties of C1018 cold rolled steel utilized in this process are summarized below:

| Property | Value | Test Standard |

|---|---|---|

| Tensile Strength | 440–550 MPa | ASTM A370 |

| Yield Strength | 320–380 MPa | ASTM A370 |

| Elongation at 2″ | 15% min | ASTM A370 |

| Hardness (Brinell) | 121–131 HB | ASTM E10 |

| Carbon Content | 0.18% | ASTM E108 |

| Surface Finish (Typical) | 0.8–1.6 µm Ra | ISO 4287 |

By integrating precision engineering, iterative validation, and systematic quality assurance, Wuxi Lead Precision Machinery delivers defect-free C1018 cold rolled steel components at scale, meeting the most demanding industrial requirements.

Why Choose Wuxi Lead Precision

Elevate Your Precision Manufacturing with Certified C1018 Cold Rolled Steel

When your application demands uncompromising dimensional stability and superior machinability in low-carbon steel, generic C1018 supply chains introduce unacceptable risk. At Wuxi Lead Precision Machinery, we engineer success from the molecular level upward. Our ISO 9001:2015-certified facility in Wuxi, China, specializes in end-to-end control of C1018 cold rolled steel—from certified mill sourcing to final CNC-machined component. Unlike commodity suppliers, we implement rigorous in-house material verification and process validation to eliminate batch variance. This ensures your hydraulic manifolds, automotive brackets, or precision shafts meet aerospace and medical tolerances consistently. Our proprietary stress-relief protocols prevent warpage during machining, while optimized toolpaths maximize yield on this responsive alloy.

Material integrity defines performance in high-cycle applications. We subject all C1018 stock to real-time spectrographic analysis and mechanical testing before it enters our 5-axis milling centers. The table below details our guaranteed baseline specifications for cold rolled C1018, exceeding ASTM A519 standards through our closed-loop production system.

| Property | Typical Value | Our Guaranteed Tolerance |

|---|---|---|

| Tensile Strength | 55-70 ksi | ±3 ksi |

| Yield Strength | 40-50 ksi | ±2 ksi |

| Elongation (2″) | 15-25% min | +3% buffer |

| Hardness (HRB) | 65-75 | ±2 points |

| Thickness Tolerance | Per ASTM A595 | +25% tighter |

| Surface Roughness (Ra) | 32-64 μin after CNC | ≤40 μin |

This precision stems from our integration of material science and manufacturing execution. Our engineers collaborate with your team during DFM analysis to identify hidden risks in your C1018 applications—such as microstructural inconsistencies affecting thread integrity or residual stress in thin-walled geometries. We then deploy adaptive machining strategies using Renishaw probes and thermal compensation systems to counter environmental variables. The result is zero scrap rates on complex components where competitors face 8-12% waste.

Partnering with Lead Precision means accessing China-based manufacturing without compromising quality governance. Our facility operates under U.S. and EU quality frameworks, with full traceability from heat number to finished part. When your next project requires C1018 components that perform identically across 10,000 units, our process-controlled environment delivers. Do not risk project timelines with suppliers who treat steel as a commodity.

Contact our engineering team today at [email protected] to receive a material certification package specific to your C1018 application. Include your dimensional drawings and volume requirements for a guaranteed 48-hour feasibility assessment. Let us prove why global Tier 1 manufacturers trust Lead Precision for mission-critical cold rolled steel components—where precision isn’t promised, it’s engineered.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.