Technical Contents

Engineering Guide: Brushed Stainless Steel Sheet Metal

Engineering Insight: Brushed Stainless Steel Sheet Metal

In high-end sheet metal fabrication, brushed stainless steel is more than a material choice—it is a statement of precision, durability, and aesthetic integrity. At Wuxi Lead Precision Machinery, we understand that the performance of brushed stainless steel components hinges not only on material quality but on the exacting standards of engineering and manufacturing processes. This finish, characterized by its uniform, directional grain, serves both functional and visual purposes, making it a preferred selection in industries where reliability and appearance are equally critical.

The brushing process involves mechanically abrading the surface of stainless steel with abrasive belts or brushes to create a satin finish that resists fingerprints and masks minor scratches. However, achieving a consistent grain across large panels or complex geometries demands advanced toolpath control, stable feed rates, and calibrated abrasive media. Variations in pressure or speed can result in mottling or streaking, compromising both the visual uniformity and the protective oxide layer beneath. Precision in this context is not optional; it is foundational.

At Lead Precision, our CNC-controlled brushing systems ensure repeatable surface finishes across batches, maintaining exact alignment with design specifications. Our engineering team leverages decades of experience in tight-tolerance fabrication, gained through critical projects including components for Olympic-standard facilities and military-grade enclosures. These applications demand not only corrosion resistance and structural integrity but also compliance with stringent surface quality standards—requirements we meet through process discipline and advanced metrology.

Beyond aesthetics, the brushed finish plays a role in functional performance. A properly finished surface minimizes light reflectivity, making it ideal for control panels, medical enclosures, and transportation interiors. Additionally, the texture enhances grip and tactile feedback in high-use environments. When paired with 304 or 316 stainless steel grades, brushed finishes deliver long-term resilience in harsh conditions, from coastal installations to industrial processing plants.

Our fabrication capabilities extend beyond surface treatment. We integrate brushing into a comprehensive workflow that includes laser cutting, precision bending, robotic welding, and in-house quality inspection. This vertical integration ensures that every dimension, edge, and surface meets the exacting demands of high-performance applications.

Below are key specifications for brushed stainless steel sheet metal as processed at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Grades | AISI 304, 304L, 316, 316L |

| Thickness Range | 0.5 mm – 6.0 mm |

| Standard Sheet Sizes | 1000×2000 mm, 1219×2438 mm, 1500×3000 mm |

| Surface Finish | #4 Architectural Brush (180–220 grit) |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2°, ±0.1 mm linear |

| Coating Protection | Anti-scratch PE film (standard) |

| Quality Standards | ISO 9001:2015, MIL-STD-810 (military projects) |

At Wuxi Lead Precision Machinery, we treat every brushed stainless steel component as a convergence of engineering rigor and surface science. Our commitment to precision ensures that each part performs reliably, looks consistently refined, and meets the elevated expectations of global industrial clients.

Precision Specs & Tolerances

Precision Machining Capabilities for Brushed Stainless Steel Fabrication

Wuxi Lead Precision Machinery delivers exceptional technical execution for brushed stainless steel sheet metal components, leveraging advanced manufacturing infrastructure to meet the stringent demands of aerospace, medical, and high-end industrial applications. Our core strength lies in the seamless integration of multi-axis machining with rigorous quality control, specifically optimized for the unique challenges of maintaining surface integrity on brushed finishes while achieving micron-level accuracy. This capability ensures final parts not only meet exact dimensional requirements but also preserve the critical aesthetic and functional properties of the brushed stainless substrate.

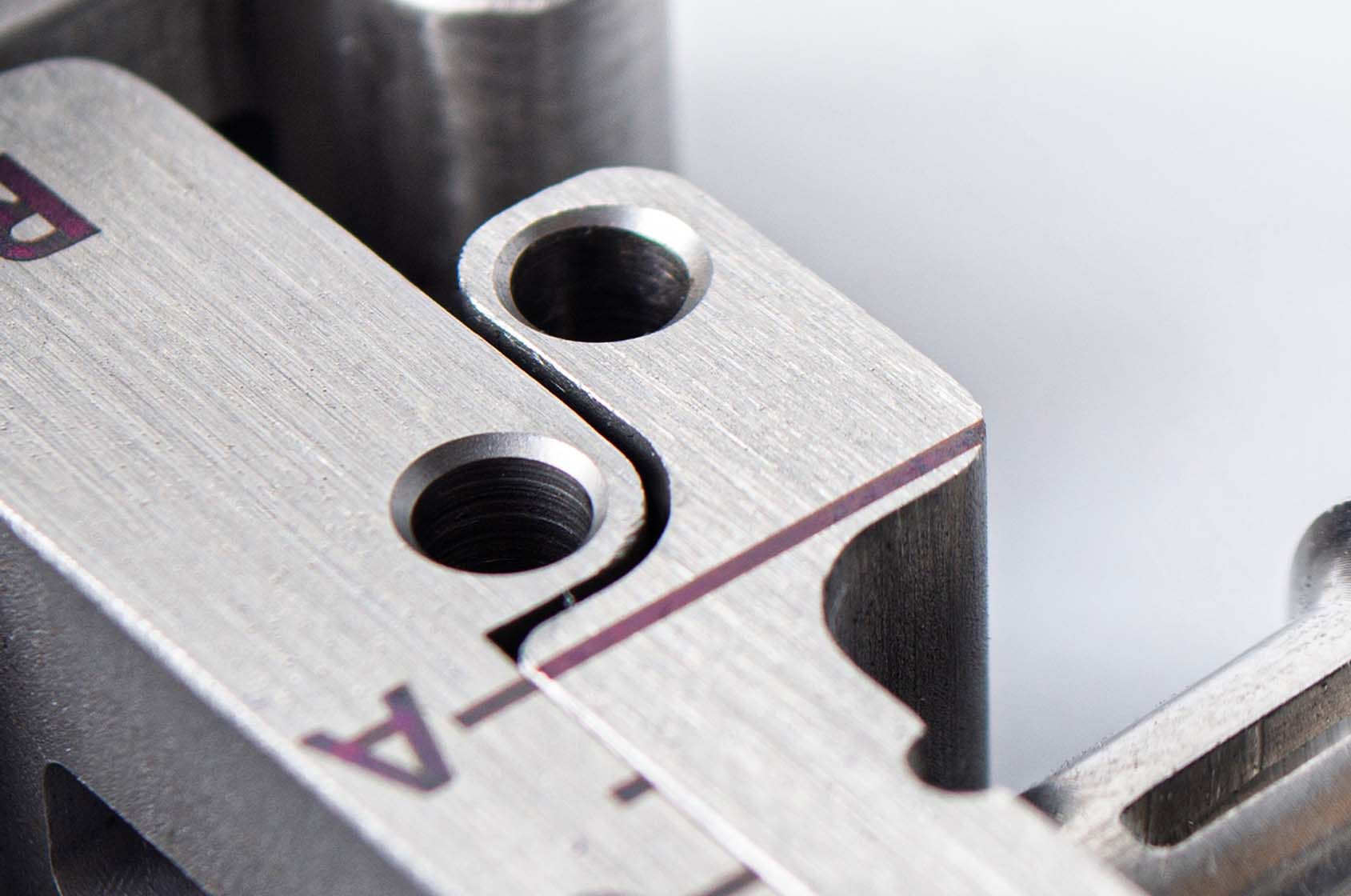

Our flagship 5-axis CNC milling and turning centers form the backbone of this precision capability. These machines enable the complete machining of complex geometries in a single setup, significantly reducing the potential for cumulative error inherent in multiple fixturing operations. For brushed stainless steel sheets, this is paramount; minimizing handling and repositioning directly protects the delicate surface finish from scratches, dents, or inconsistencies introduced during secondary operations. Advanced toolpath strategies and specialized tooling are employed to manage heat generation and cutting forces, preventing thermal distortion or work hardening of the stainless material which could compromise both dimensional stability and the uniformity of the brushed texture. This integrated approach ensures features such as intricate cutouts, precision-formed bends, tight-tolerance holes, and complex 3D contours are achieved without sacrificing the specified surface aesthetic.

Quality Assurance Protocol

Dimensional verification is non-negotiable. Every critical brushed stainless steel component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM systems, calibrated to ISO 17025 standards, provide full 3D geometric validation against the original CAD model. This process captures not only basic dimensional conformance but also critical form, position, and surface profile deviations that impact fit, function, and appearance. Inspection reports are fully traceable, linking measured data points directly to customer drawings and material certifications, providing complete transparency and assurance for regulated industries. This systematic QC protocol guarantees that the final part’s brushed finish remains pristine and consistent, meeting both functional tolerances and visual specifications.

The following table details our standard achievable tolerances for brushed stainless steel sheet metal fabrication, reflecting the combined capability of our 5-axis CNC machining and CMM inspection systems. These values represent typical production capabilities for materials like 304 and 316 stainless steel in thicknesses ranging from 0.5mm to 10.0mm.

| Feature | Capability | Standard Reference |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ISO 2768-mK |

| Angular Tolerance | ±0.1° | ISO 2768-mK |

| Positional Tolerance | ±0.03 mm | ISO 1101 |

| Flatness Tolerance | 0.05 mm per 100 mm | ISO 2768-fine |

| Surface Roughness (Ra) | 0.8 – 1.6 μm | ASME B46.1 |

| Brushed Finish Uniformity | Consistent across entire surface | Customer Spec / ISO 15730 |

This technical capability, combining sophisticated 5-axis machining with metrology-grade inspection, positions Wuxi Lead Precision Machinery as a trusted partner for OEMs requiring flawless brushed stainless steel components where precision, surface quality, and absolute reliability are mission-critical. We translate complex design intent into physically perfect parts, consistently.

Material & Finish Options

When selecting materials for precision sheet metal fabrication, particularly for applications requiring durability, corrosion resistance, and aesthetic consistency, brushed stainless steel stands out as a premier choice. At Wuxi Lead Precision Machinery, we specialize in high-tolerance fabrication processes that leverage the intrinsic advantages of stainless steel, aluminum, and titanium—each offering distinct performance characteristics tailored to industrial, medical, and architectural applications.

Stainless steel, especially grades 304 and 316, is widely preferred for its excellent strength-to-weight ratio, resistance to oxidation, and long-term durability in harsh environments. The brushed finish not only enhances visual appeal by minimizing fingerprint visibility and surface glare but also provides a uniform texture that conceals minor scratches and imperfections. This makes brushed stainless steel ideal for enclosures, control panels, and high-end equipment housings where both function and appearance are critical.

Aluminum, particularly 5052 and 6061 alloys, offers a lightweight alternative with good machinability and corrosion resistance. While naturally softer than stainless steel, aluminum can be enhanced through anodizing—a controlled electrochemical process that thickens the oxide layer on the surface. Anodized aluminum exhibits improved wear resistance, electrical insulation, and color stability when dyed, making it suitable for outdoor applications and consumer-facing components. However, for environments with high mechanical stress or exposure to chlorides, stainless steel remains superior.

Titanium, though more costly and challenging to process, delivers exceptional strength-to-density performance and unparalleled resistance to extreme temperatures and corrosive media. It is typically reserved for aerospace, defense, and medical implant applications where material failure is not an option. Due to its reactivity during machining, titanium requires specialized tooling and slow processing speeds, which we manage with our precision CNC systems and experienced engineering team.

Below is a comparative overview of key material properties relevant to sheet metal fabrication:

| Material | Common Grades | Thickness Range (mm) | Tensile Strength (MPa) | Corrosion Resistance | Typical Surface Finish |

|---|---|---|---|---|---|

| Stainless Steel | 304, 316 | 0.5 – 6.0 | 515 – 620 | Excellent | Brushed, Satin, Mirror |

| Aluminum | 5052, 6061 | 0.4 – 5.0 | 190 – 310 | Good (with anodizing) | Anodized, Mill, Powder Coated |

| Titanium | Grade 2, Grade 5 | 0.8 – 4.0 | 345 – 860 | Outstanding | Matte, Bead Blasted, Polished |

At Wuxi Lead, we integrate material science with advanced fabrication techniques—including laser cutting, CNC bending, and robotic welding—to ensure dimensional accuracy and finish consistency. Our engineering team collaborates closely with clients to match material and finish selections with functional requirements, environmental exposure, and lifecycle expectations. Whether you require the sleek professionalism of brushed stainless steel or the lightweight resilience of anodized aluminum, our solutions are engineered for performance and precision.

Manufacturing Process & QC

Design Phase: Precision Engineering Foundation

The production journey for brushed stainless steel sheet metal begins with meticulous digital design. At Wuxi Lead Precision Machinery, our engineering team utilizes advanced CAD/CAM software to translate client specifications into manufacturable models. Critical parameters including grain direction, surface finish consistency, and edge treatment are rigorously defined to meet architectural or industrial application standards. Finite element analysis validates structural integrity under operational loads, while manufacturability checks prevent downstream errors. This phase establishes geometric tolerances as tight as ±0.05mm and confirms compatibility with our laser cutting, bending, and brushing systems. Design sign-off requires explicit approval of surface roughness parameters and grain alignment to ensure aesthetic uniformity across all panels.

Prototyping: Validation Before Scale

Following design validation, we produce physical prototypes using the exact production tooling and materials. Each prototype undergoes metrology-grade verification against the CAD model using CMM and optical comparators. The brushing process is calibrated on sample coupons to achieve the specified satin finish without directional inconsistencies or surface scratches. Clients receive prototypes with documented surface roughness measurements and dimensional reports. This stage identifies hidden fabrication challenges—such as springback in bending or heat-affected zones near cut edges—allowing adjustments before mass production. Only when prototypes pass 100% of functional and aesthetic criteria do we proceed, eliminating costly revisions during scale-up.

Mass Production: Zero Defects Execution

Our mass production leverages integrated CNC workflows with real-time quality gates. Laser cutting operates under inert gas shielding to prevent oxidation, while robotic bending cells apply adaptive force compensation for angular precision. The brushing line uses synchronized abrasive belts with automated tension control, maintaining Ra 0.8–1.6μm across all sheets. Every component undergoes inline inspection: vision systems scan for surface defects, and ultrasonic testers verify material integrity. Statistical process control monitors critical dimensions, triggering automatic machine recalibration if deviations approach tolerance limits. Final assembly includes passivation per ASTM A967 and 100% helium leak testing for sealed enclosures. This closed-loop system ensures zero non-conforming parts reach clients.

Critical Production Specifications

| Parameter | Standard Specification | Wuxi Lead Precision Tolerance |

|————————-|————————|—————————–|

| Material Grades | AISI 304, 316L | Mill-certified with COA |

| Thickness Range | 0.5mm – 6.0mm | ±0.03mm (≤3mm) / ±0.05mm (>3mm) |

| Surface Roughness (Ra) | 0.8μm – 1.6μm | ±0.1μm consistency |

| Flatness Tolerance | Per ASTM A480 | ≤0.15mm per 300mm |

| Bend Angle Accuracy | ±0.5° | ±0.25° |

| Zero Defects Protocol | 100% inline inspection | 0 PPM defect rate guarantee |

This integrated approach—from digital design validation through prototype refinement to closed-loop mass production—ensures brushed stainless steel components meet the highest functional and aesthetic demands. Wuxi Lead’s commitment to zero defects transforms precision engineering into your strategic advantage.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Brushed Stainless Steel Sheet Metal Fabrication

When precision, durability, and aesthetic quality are non-negotiable, global manufacturers turn to Wuxi Lead Precision Machinery for engineered excellence in brushed stainless steel sheet metal fabrication. As a leading provider in high-tolerance sheet metal solutions, we combine advanced CNC technology, rigorous quality control, and decades of industrial experience to deliver components that meet the most demanding specifications. Whether your application is in medical equipment, aerospace systems, food processing, or architectural design, our capabilities are tailored to ensure performance, consistency, and long-term reliability.

Our facility in Wuxi, China, operates under strict ISO 9001 standards, with state-of-the-art laser cutting, CNC bending, TIG and MIG welding, and automated surface finishing systems. Each brushed stainless steel sheet is processed with controlled grain alignment, uniform texture, and minimal surface distortion—critical for both functional integrity and visual appeal. We specialize in low to high-volume production runs, offering rapid prototyping, material certification, and full traceability for every batch.

We understand that your supply chain depends on partners who deliver more than just parts—they deliver confidence. At Wuxi Lead Precision Machinery, our engineering team collaborates directly with clients to optimize designs for manufacturability, reduce material waste, and accelerate time-to-market. From initial concept review to final inspection, we maintain open communication and real-time project tracking to ensure seamless integration with your production schedule.

Our commitment to quality is matched only by our responsiveness. With a dedicated export department and experience shipping to North America, Europe, and Southeast Asia, we manage logistics with precision, ensuring on-time delivery and full compliance with international standards.

Below are key technical specifications for our brushed stainless steel fabrication services:

| Specification | Details |

|---|---|

| Material Grades | 304, 304L, 316, 316L, 430 (custom grades available) |

| Thickness Range | 0.5 mm – 6.0 mm |

| Standard Finishes | #4 Brush (uni-directional), 180–320 grit |

| Tolerance (Cutting) | ±0.1 mm |

| Tolerance (Bending) | ±0.2° |

| Max Working Area | 1500 mm × 3000 mm |

| Surface Protection | Anti-scratch film (standard) |

| Certifications | ISO 9001:2015, Material Test Reports (MTRs) available |

Partnering with Wuxi Lead Precision Machinery means choosing a manufacturer that treats your project as a strategic priority. We don’t just meet standards—we set them.

For technical inquiries, project consultations, or to request a quote, contact us today at [email protected]. Let our team help you achieve flawless results in every brushed stainless steel component you require.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.