Technical Contents

Engineering Guide: British Cycle Supply Company

Engineering Insight: The Role of Precision in High-Performance Bicycle Components

In the world of competitive cycling and premium bicycle manufacturing, performance hinges on precision. Every gram saved, every micron of tolerance controlled, and every surface finish optimized contributes to a measurable advantage—whether on the velodrome, mountain trail, or urban commute. For British Cycle Supply Company, aligning with a manufacturing partner capable of delivering micron-level accuracy and material integrity is not just a technical requirement—it is a strategic imperative.

At Wuxi Lead Precision Machinery, we understand that high-end bicycle components demand more than standard metal fabrication. They require engineered solutions where repeatability, strength-to-weight ratios, and fatigue resistance are non-negotiable. Our experience in supplying mission-critical parts to Olympic cycling teams and military-grade aerospace programs has instilled a culture of uncompromising quality. These sectors operate under extreme conditions where failure is not an option—much like professional cycling, where component reliability at high stress and speed is essential.

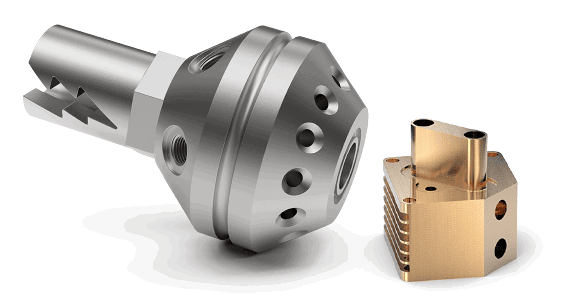

Precision machining in bicycle applications extends beyond aesthetics. Consider the bottom bracket assembly, headset interfaces, or derailleur mounting points—each requires strict geometric control to ensure smooth power transfer, steering accuracy, and long-term durability. Even minor deviations in concentricity or surface flatness can lead to premature wear, increased friction, or catastrophic fatigue failure under cyclic loading. Our CNC machining processes, supported by in-house metrology and material traceability, ensure that every component meets ISO 9001:2015 standards and exceeds industry expectations.

Our collaboration with British Cycle Supply Company leverages advanced 5-axis milling, Swiss-type turning, and robotic automation to produce complex geometries with tolerances as tight as ±0.005 mm. This level of control is critical when working with high-strength alloys such as 7075-T6 aluminum, titanium Ti-6Al-4V, or custom stainless steel grades—materials frequently specified for their optimal balance of light weight and structural resilience.

Material and dimensional consistency is further assured through rigorous testing protocols, including CMM inspection, hardness testing, and non-destructive evaluation. Each production run is documented with full batch traceability, enabling British Cycle Supply Company to maintain certification compliance and deliver confidence to their end users.

Below are representative specifications achievable through our precision manufacturing process:

| Parameter | Capability | Notes |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Typical for critical interfaces |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm | Polished or bead-blasted options |

| Materials | 7075-T6, 6061-T6, Ti-6Al-4V, 316L SS, 4130 Chromoly | Full material certification available |

| Max Component Size | Ø420 mm x 800 mm | 5-axis machining envelope |

| Production Volume | 1–50,000 units/year | Scalable from prototype to mass production |

| Quality Standards | ISO 9001:2015, PPAP, FAI | Full inspection reporting |

Precision is not a feature—it is the foundation. For British Cycle Supply Company, partnering with Wuxi Lead Precision Machinery ensures that every component reflects the highest standard of engineering excellence, forged through experience in the most demanding applications on earth.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Cycling Excellence

Wuxi Lead Precision Machinery delivers uncompromising precision for high-performance bicycle components through advanced manufacturing and rigorous quality control. Our integrated technical capabilities are specifically engineered to meet the demanding requirements of the British cycling industry, where component integrity directly impacts rider safety, performance, and longevity. We specialize in producing complex, mission-critical metal parts—from titanium seatposts and aluminum linkage systems to stainless steel headset cups and integrated bottom bracket assemblies—where geometric accuracy and material integrity are non-negotiable.

Our core strength lies in 5-axis CNC machining, enabling the production of intricate geometries in a single setup. This eliminates cumulative errors from multiple fixtures, critical for maintaining concentricity in rotating assemblies like pedal spindles or suspension pivots. Utilizing HAAS and DMG MORI equipment with sub-micron repeatability, we achieve seamless contours, tight internal radii, and complex undercuts essential for modern lightweight frame designs and integrated componentry. The elimination of secondary operations reduces lead times while ensuring dimensional consistency across high-volume production runs, a key advantage for OEMs managing tight seasonal schedules.

Quality assurance is embedded at every stage, anchored by Zeiss CONTURA Coordinate Measuring Machines (CMM). Each critical component undergoes full geometric dimensioning and tolerancing (GD&T) verification against CAD models, with inspection reports providing traceable certification to ISO 9001 standards. Our metrology lab validates surface finishes down to Ra 0.4µm, critical for bearing interfaces and fatigue-prone areas, alongside material hardness and coating thickness verification where specified. This closed-loop process guarantees that every part shipped meets the exacting standards demanded by premium bicycle manufacturers.

The following table details our standard achievable tolerances for common cycling applications, reflecting our commitment to dimensional stability under real-world riding loads:

| Geometric Feature | Standard Tolerance | Tight Tolerance Option | Typical Application Example |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.025 | ±0.005 | Frame dropout width |

| Hole Diameter (mm) | H7 (e.g., +0.021/0) | H6 (+0.013/0) | Headset cup bore |

| Positional Tolerance (mm) | ±0.03 | ±0.008 | Suspension pivot alignment |

| Concentricity (mm) | 0.03 | 0.005 | Bottom bracket shell |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Bearing contact surfaces |

These capabilities ensure optimal power transfer, reduced friction, and extended service life for your components. We proactively collaborate during the design phase to optimize manufacturability without sacrificing performance, leveraging our deep understanding of cycling dynamics and material science. For British Cycle Supply Company, this translates to components that consistently exceed industry benchmarks for precision, reliability, and integration—delivered with the engineering rigor your brand demands. Partner with Wuxi Lead for technical execution that moves your product forward.

Material & Finish Options

Material Selection for High-Performance Bicycle Components

Selecting the appropriate material is critical when manufacturing precision bicycle components for performance, durability, and weight optimization. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using aluminum, steel, and titanium—each offering distinct mechanical properties suited to different cycling applications. Understanding these materials enables British Cycle Supply Company to specify components that meet exacting standards in both function and longevity.

Aluminum alloys, particularly 6061 and 7075, are widely used in bicycle manufacturing due to their high strength-to-weight ratio and excellent machinability. These alloys are ideal for components such as handlebars, seat posts, and derailleur parts where weight reduction is paramount. While not as strong as steel or titanium, aluminum’s low density makes it favorable for performance-oriented builds. When combined with anodizing, aluminum gains enhanced surface hardness and corrosion resistance, significantly improving wear performance in demanding environments.

Steel remains a preferred choice for applications requiring high tensile strength and impact resistance. Alloys such as 4130 chromoly steel are commonly used in frames and bottom brackets where structural integrity under load is essential. Steel offers superior fatigue resistance and can be precisely machined to tight tolerances. Although heavier than aluminum or titanium, its durability and repairability make it a strategic option for long-life components. For corrosion protection, steel parts are typically plated or coated, though this must be carefully specified to maintain dimensional accuracy.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional balance of strength, low weight, and corrosion resistance. It is often reserved for high-end components such as fasteners, hubs, and frame fittings where cost is secondary to performance. Titanium’s natural oxide layer provides inherent corrosion protection, and its fatigue strength surpasses both aluminum and steel in cyclic loading scenarios. However, its high cost and challenging machinability require advanced CNC capabilities—expertise we maintain at Wuxi Lead.

Surface treatment plays a vital role in material performance. Anodizing, primarily applied to aluminum, is an electrochemical process that thickens the natural oxide layer, improving wear and corrosion resistance. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat) anodizing delivers a much denser layer suitable for high-wear applications. Color options and sealing methods can be tailored to meet aesthetic and environmental requirements.

Below is a comparative overview of key material properties relevant to bicycle component manufacturing.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Applications | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 2.7 | Moderate (with anodizing) | Handlebars, brackets, links | Anodizing (Type II/III), bead blast |

| Aluminum 7075 | 572 | 2.8 | Moderate (with anodizing) | High-stress fittings, arms | Hardcoat anodizing, clear coat |

| Steel 4130 | 658 | 7.8 | Low (requires coating) | Bottom brackets, brackets | Zinc plating, powder coating |

| Titanium Grade 5 | 900 | 4.5 | Excellent | Fasteners, hubs, fittings | Natural oxide, bead blast |

Choosing the right material and finish ensures optimal performance across the lifecycle of the component. At Wuxi Lead, we support British Cycle Supply Company with expert consultation, precision machining, and consistent quality control to deliver components that meet the highest standards in bicycle manufacturing.

Manufacturing Process & QC

Precision Manufacturing Process: From Concept to Flawless Delivery for Cycling Components

At Wuxi Lead Precision Machinery, we understand that British cycling excellence demands uncompromising component integrity. Our rigorously defined production process eliminates defects before they reach your assembly line, ensuring every machined part meets the exacting performance and safety standards demanded by discerning cyclists. This integrated workflow guarantees dimensional accuracy, material integrity, and functional reliability from initial sketch to final shipment.

The journey begins with collaborative Design Engineering. Our UK-based technical team works directly with your specifications, utilizing advanced CAD/CAM software and Finite Element Analysis (FEA) to simulate real-world stresses on critical components like bottom brackets, dropouts, and handlebar stems. This phase identifies potential weaknesses early, optimizing geometry and material selection—typically aerospace-grade 7075-T6 aluminium or specific stainless steel alloys—to maximize strength-to-weight ratios while adhering strictly to British cycling industry tolerances. Every design iteration undergoes cross-functional review to ensure manufacturability and performance validation before progression.

Prototyping transforms validated digital models into physical reality under controlled conditions. We employ multi-axis CNC milling and turning centres to produce initial samples, mirroring the exact mass production environment. Each prototype undergoes exhaustive metrology: Coordinate Measuring Machines (CMMs) verify critical dimensions to ±0.001mm, surface roughness testers confirm Ra values, and material composition is spectrometrically verified. Functional testing simulates load cycles specific to cycling applications. Only when every prototype parameter exceeds your acceptance criteria—and our internal zero-defect threshold—is the design locked for production. This stage is non-negotiable for preventing costly downstream errors.

Mass Production leverages our certified ISO 9001:2015 and IATF 16949 systems with embedded Statistical Process Control (SPC). Automated in-process gauging on CNC machines monitors key features in real-time, triggering immediate corrective action if trends approach tolerance limits. Every component batch undergoes 100% visual inspection and randomized CMM validation against the approved prototype master. Our closed-loop feedback system ensures continuous process refinement, eliminating variation. Final parts are meticulously cleaned, passivated (for stainless variants), and packaged to prevent transit damage, accompanied by full material and dimensional traceability documentation.

This seamless integration—design rigor, prototype validation, and statistically controlled mass production—forms the bedrock of our zero-defect guarantee. We deliver not just parts, but certified performance readiness for your premium British cycling products.

Critical Dimensional & Material Specifications for Cycling Components

| Feature Category | Typical Tolerance Range | Measurement Method | Material Standard | Surface Finish (Ra) |

|---|---|---|---|---|

| Critical Bore Diameters | ±0.005 mm to ±0.010 mm | Air Gauging / CMM | EN AW-7075-T651 | 0.8 µm max |

| Face Perpendicularity | 0.015 mm / 100 mm | CMM / Optical Comparator | AISI 316L (Passivated) | 1.6 µm max |

| Thread Pitch Diameter | 6H / 6g Class | Thread Plug/Ring Gauges | EN 571-1 (Alloy Specific) | N/A |

| Weight Critical Zones | ±0.5% of Nominal Mass | Precision Scale | Certified Mill Test | N/A |

| Surface Defects | Zero Visual Imperfections | Magnified Visual Inspection | ASTM E3022-17 | N/A |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Quality in Custom Metal Manufacturing

In the competitive landscape of high-performance cycling components, precision engineering is not a luxury—it is a necessity. British Cycle Supply Company demands parts that meet exacting standards for strength, weight, and consistency. At Wuxi Lead Precision Machinery, we understand these requirements at a fundamental level. As a trusted partner in custom metal manufacturing, we deliver CNC-machined components that align with the rigorous performance expectations of premium cycling applications.

Our advanced manufacturing facility in Wuxi, China, is equipped with state-of-the-art 3-, 4-, and 5-axis CNC machining centers, enabling us to produce complex geometries with tolerances as tight as ±0.005 mm. Every stage of production—from raw material sourcing to final inspection—is governed by ISO 9001-certified quality processes. This ensures repeatability, traceability, and compliance across every batch, whether you require low-volume prototypes or high-volume production runs.

We specialize in machining aerospace-grade aluminum, titanium, stainless steel, and other high-performance alloys commonly used in cranksets, bottom brackets, headset components, and custom hubs. Our engineering team works closely with your design specifications to optimize manufacturability, reduce material waste, and accelerate time-to-market—without sacrificing structural integrity or aesthetic finish.

Our commitment to transparency and collaboration means you are never just a purchase order. From initial DFM (Design for Manufacturing) feedback to real-time production updates, we maintain open communication throughout the entire process. With in-house metrology labs featuring CMM (Coordinate Measuring Machines) and 3D scanning capabilities, we provide full inspection reports and first-article certifications upon request.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Types | 3-axis, 4-axis, 5-axis CNC Milling, CNC Turning |

| Tolerances | ±0.005 mm |

| Materials | 6061/7075 Aluminum, Titanium (Grade 5), Stainless Steel (303, 304, 316), Brass, Alloy Steel |

| Max Work Envelope | 1200 x 600 x 500 mm (5-axis) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Sandblasting, Powder Coating Support |

| Quality Standards | ISO 9001:2015, Full FAI & PPAP Documentation |

| Lead Times | Prototype: 7–10 days; Production: 15–25 days (varies by complexity) |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally dedicated to precision, reliability, and long-term value. We are equipped to support British Cycle Supply Company with scalable, high-integrity solutions that enhance product performance and brand reputation in the global market.

For technical inquiries or to initiate a project, contact us directly at [email protected]. Our engineering team is ready to review your designs, provide DFM feedback, and deliver samples within two weeks. Let’s build the future of cycling performance—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.