Technical Contents

Engineering Guide: Brass Tools For Injection Molding

Engineering Insight Precision Imperatives in Brass Injection Molding Tools

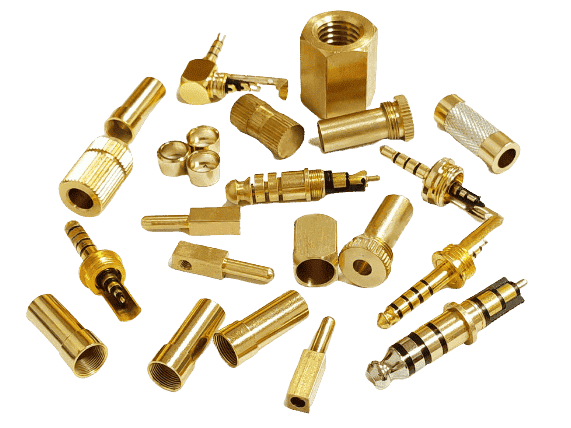

Brass tools for injection molding represent a critical intersection of material science and micron-level manufacturing execution. While brass alloys like C36000 offer inherent advantages—superior thermal conductivity for rapid heat dissipation, excellent corrosion resistance against aggressive polymers, and inherent lubricity reducing wear—the ultimate performance hinges entirely on precision engineering. Sub-micron deviations in cavity geometry, core alignment, or cooling channel placement directly translate to part warpage, inconsistent shrinkage, surface defects, and premature tool failure. In high-value sectors like medical device housings, optical components, or aerospace connectors, where tolerances often reside below ±0.025mm, the margin for error is nonexistent. Precision isn’t merely desirable; it is the non-negotiable foundation for part consistency, extended tool life, and operational cost efficiency. Cycle times and part quality are intrinsically linked to the thermal management precision achievable only through exacting tool fabrication.

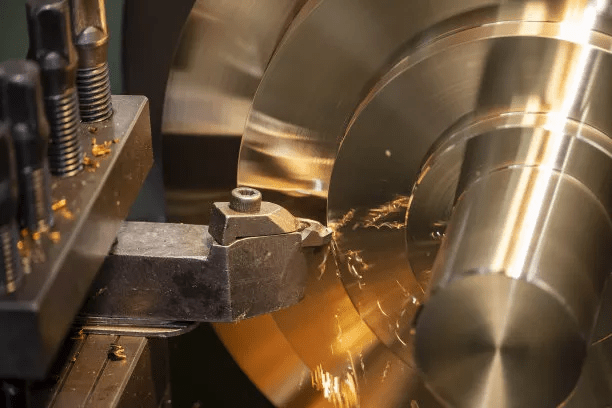

Wuxi Lead Precision Machinery operates at this exacting threshold. Our CNC machining centers, calibrated to sub-micron repeatability, transform brass billets into mission-critical molding tools where thermal gradients and mechanical stresses are meticulously controlled. This capability is rigorously proven through demanding applications. We engineered brass core inserts for precision optical lens molds deployed in Olympic-standard sports timing systems, where thermal stability directly impacted nanosecond measurement accuracy. Similarly, our brass manifold tools for military-grade polymer components undergo stringent validation for dimensional stability under extreme thermal cycling—a requirement where failure is not an option. These projects demand not only adherence to ISO 2768-mK geometric tolerances but often exceed them, achieving positional accuracies of ±0.002mm and surface finishes below Ra 0.2µm on critical sealing surfaces. Such results stem from integrated processes: multi-axis simultaneous milling eliminating cumulative errors, in-process probing for real-time compensation, and stress-relieved material sourcing to prevent post-machining distortion.

The performance envelope of brass molding tools is defined by specific, measurable parameters achievable through advanced precision manufacturing. Key specifications we consistently deliver include:

| Critical Performance Parameter | Typical Value Range | Relevance to Injection Molding |

|---|---|---|

| Thermal Conductivity (C36000) | 115-125 W/m·K | Enables 15-20% faster cycle times vs. standard steels |

| Hardness (Temper H02-H04) | 100-140 HB | Balances machinability with wear resistance for core/cavity |

| Geometric Tolerance (GD&T) | ±0.002mm to ±0.005mm | Ensures part dimensional stability and assembly fit |

| Surface Roughness (Critical Areas) | Ra 0.1µm to Ra 0.4µm | Prevents part sticking and ensures optical surface quality |

| Cooling Channel Positional Accuracy | ±0.01mm | Guarantees uniform thermal management and minimizes warpage |

Achieving these specifications requires moving beyond standard machining practices. It demands a systems approach where material certification, thermal stability protocols, and metrology validation are inseparable from the CNC programming and cutting strategy. At Lead Precision, this integrated precision philosophy—forged in Olympic and defense applications—ensures brass molding tools deliver not just function, but predictable, high-yield production for the most demanding polymer components. The cost of imprecision in this domain manifests as scrap, downtime, and compromised product integrity; the investment in true precision engineering delivers measurable ROI through process stability and part excellence.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-performance brass tools for injection molding applications. Our in-house production infrastructure is built around precision engineering, repeatable quality, and rapid turnaround, enabling us to support global OEMs and tier-one suppliers with mission-critical components. At the core of our machining capacity is a full suite of 5-axis CNC machining centers, which provide the flexibility and accuracy required for complex geometries typical in mold tooling. These systems allow simultaneous multi-axis movement, ensuring tight tolerances, superior surface finishes, and reduced setup times compared to conventional 3-axis platforms. This capability is particularly critical when producing brass components with intricate cooling channels, threaded inserts, or fine detail features that directly impact mold performance and part consistency.

All brass tooling components are machined from high-quality, lead-free or leaded brass alloys—including C36000, C37700, and CuZn15—as specified by client requirements. Material selection is optimized for machinability, thermal conductivity, and wear resistance, ensuring long service life under repetitive molding cycles. Our machining protocols are supported by advanced fixturing, high-resolution tool monitoring, and adaptive cutting strategies that minimize thermal deformation and maximize dimensional stability. Each operation is programmed using industry-leading CAM software, with toolpaths optimized for surface integrity and feature accuracy.

Quality assurance is fully integrated into our manufacturing workflow. Every brass component undergoes comprehensive inspection using a Zeiss DuraMax and CONTURA series Coordinate Measuring Machine (CMM), enabling micron-level verification of critical dimensions, geometric tolerances, and form accuracy. Our CMM inspection routines are aligned with ISO 10360 standards and include full first-article inspection reports (FAIR) and production batch sampling as required. Dimensional data is traceable and archived for full production lot accountability.

The following table outlines the standard technical specifications achievable across our brass tooling production line

| Specification | Capability |

|---|---|

| Machining Process | 5-Axis CNC Milling and Turning |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positional Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finishes available) |

| Dimensional Tolerance (Standard) | ±0.01 mm |

| Dimensional Tolerance (Tight) | ±0.005 mm |

| Geometric Tolerances (Flatness, True Position) | ≤ 0.01 mm per ISO 2768-mK |

| Inspection Equipment | Zeiss CMM, Optical Comparators, Micrometers, Calipers |

| Material Compliance | RoHS, REACH (upon request) |

Our technical capabilities are reinforced by a quality management system compliant with ISO 9001:2015 standards, ensuring consistent performance across prototype, bridge, and full-scale production runs. Wuxi Lead Precision Machinery is equipped to support high-mix, low-volume tooling demands with the same rigor applied to high-volume manufacturing, making us a trusted partner in precision brass component development for injection molding systems.

Material & Finish Options

Material Selection for Injection Molding Tools: Precision Engineering for Brass Components

Selecting the optimal material for injection molding tools is critical when producing brass components. While brass itself is the common molded material due to its excellent machinability and corrosion resistance, the tooling must withstand significant thermal cycling, mechanical stress, and abrasive wear from the molten metal. Brass is unsuitable for tool construction; its low hardness and thermal stability lead to rapid deformation and failure under molding pressures and temperatures. Instead, precision tooling requires high-performance metals engineered for durability and thermal management. At Wuxi Lead Precision Machinery, we guide clients through this critical decision based on production volume, part complexity, and required surface finish.

Aluminum alloys, particularly 7075-T6, offer superior thermal conductivity, enabling faster cycle times for low to medium volume production of brass parts. This material is cost-effective for prototyping and short runs but lacks the hardness for extended use with abrasive brass alloys, typically yielding molds with 10,000 to 50,000 shots. Tool steel variants like H13 and S7 dominate high-volume brass molding. H13 provides an excellent balance of toughness, thermal fatigue resistance, and ease of heat treatment, supporting mold lives exceeding 500,000 shots with proper maintenance. For extremely abrasive brass formulations or ultra-high-volume applications demanding maximum wear resistance, premium tool steels such as M2 or specialized P20 modifications are essential, though at higher initial cost and longer machining times. Titanium alloys, while offering exceptional strength-to-weight ratio and corrosion resistance, are rarely cost-justified for standard brass molding tools due to machining complexity and cost; their primary niche remains specialized aerospace applications.

Surface finishing, particularly hard anodizing, significantly enhances aluminum tool performance. This electrochemical process creates a dense, wear-resistant aluminum oxide layer, improving surface hardness up to 60-70 HRC and providing better release for brass components. However, anodizing is not applicable to steel tools; nitriding or specialized PVD coatings like TiN are the standard surface treatments for steel molds to achieve similar wear and release benefits. The choice between base material and finish must align with your specific brass alloy composition and production targets.

Key material properties for brass injection molding tools are summarized below:

| Material | Hardness Range (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Brass) | Primary Application Context |

|---|---|---|---|---|

| Aluminum 7075-T6 | 45-50 (As Machined) | 130 | 10,000 – 50,000 shots | Prototypes, low-volume production |

| Tool Steel H13 | 48-52 (Heat Treated) | 35 | 100,000 – 500,000+ shots | Medium to high-volume production |

| Tool Steel M2 | 62-65 (Heat Treated) | 24 | 500,000+ shots | High-volume, abrasive brass alloys |

| Titanium Alloys | 35-40 (As Machined) | 7 | Specialized applications | Niche aerospace components |

Material selection directly impacts tool longevity, part quality consistency, and overall production economics for brass molding. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise and metallurgical knowledge to match the optimal material and surface treatment to your specific brass component requirements. Contact our engineering team for a detailed analysis of your application to ensure maximum tool performance and return on investment.

Manufacturing Process & QC

The production process for brass tools in injection molding at Wuxi Lead Precision Machinery follows a disciplined, end-to-end methodology designed to ensure precision, performance, and zero defects. This process integrates advanced engineering with rigorous quality control across three core phases: Design, Prototyping, and Mass Production.

Design begins with a detailed analysis of the customer’s technical specifications, including part geometry, material flow dynamics, and thermal requirements. Our engineering team utilizes 3D CAD software and mold flow simulation tools to optimize gate placement, cooling channels, and ejection systems specific to brass tool applications. Special attention is given to thermal conductivity and wear resistance, as brass tools are often selected for their superior heat dissipation in high-cycle molding environments. Finite element analysis (FEA) is applied to predict stress distribution and prevent premature tool failure. The final design is validated through a formal design review involving cross-functional teams, ensuring compliance with ISO 9001 standards and customer-specific requirements.

Prototyping follows design approval and serves as a critical validation step. A fully functional prototype is manufactured using CNC precision milling and EDM processes, replicating the exact geometry and tolerances of the final tool. This prototype undergoes a series of performance tests, including dry runs, pressure cycling, and first-article inspection. Dimensional accuracy is verified using coordinate measuring machines (CMM), ensuring tolerances are held within ±0.002 mm. Any deviations are addressed through iterative refinement, with feedback looped directly into the digital model. This phase not only confirms functional integrity but also validates cycle time, part quality, and ease of maintenance.

Mass production is initiated only after prototype sign-off and process capability certification. Our automated manufacturing cells, equipped with high-speed CNC machines and real-time monitoring systems, ensure consistent output. Each brass tool is machined from certified raw materials, with full traceability from batch to finished product. In-process inspections occur at every major stage—rough machining, finishing, assembly, and surface treatment—ensuring adherence to specifications. Final quality verification includes hardness testing, surface roughness measurement, and functional testing under simulated production conditions.

Throughout the entire production cycle, Wuxi Lead applies a zero-defect philosophy. Non-conformance is mitigated through statistical process control (SPC), root cause analysis, and operator certification programs. Every tool is delivered with a comprehensive quality dossier, including inspection reports, material certifications, and maintenance guidelines.

The table below outlines key specifications for our brass injection molding tools:

| Parameter | Specification |

|---|---|

| Material | High-grade brass (CuZn39Pb3) |

| Tolerance | ±0.002 mm |

| Surface Roughness (Ra) | ≤0.4 µm |

| Hardness | 85–95 HRB |

| Tool Life | 500,000+ cycles (typical) |

| Cooling Efficiency | 20–30% faster than steel molds |

| Lead Time (Mass Production) | 4–6 weeks (after prototype approval) |

This structured, quality-driven approach ensures that every brass tool we produce meets the highest standards of reliability and performance in demanding injection molding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Brass Injection Molding Solutions

Selecting the right manufacturing partner for brass injection molding tools demands more than standard capability. It requires deep material science expertise, precision engineering rigor, and unwavering commitment to your production timeline. At Wuxi Lead Precision Machinery, we specialize exclusively in high-tolerance brass tooling for demanding industries including automotive transmission systems, medical fluid handling, and aerospace hydraulic components. Our CNC engineering team possesses 15+ years of focused experience machining brass alloys under stringent thermal and dimensional constraints, ensuring your molds deliver consistent part quality across millions of cycles.

Brass presents unique challenges: its thermal conductivity requires specialized cooling channel design, while its machinability demands exact spindle speed and feed rate calibration to prevent galling or surface defects. We address these through proprietary machining protocols developed with leading global brass suppliers. Every tool undergoes rigorous thermal stress simulation and in-process metrology checks using Zeiss coordinate measuring machines, guaranteeing cavity-to-core alignment within microns. This precision directly translates to reduced cycle times, minimized flash, and extended tool life for your production floor.

Beyond technical execution, we mitigate your supply chain risks. Our integrated facility in Wuxi houses 28 CNC machining centers dedicated to non-ferrous alloys, eliminating third-party dependencies. Real-time production tracking and dedicated logistics coordination ensure on-time delivery—even for complex multi-cavity brass molds requiring sub-5µm surface finishes. We treat your project timeline as critical path, not a target date.

The table below summarizes our brass-specific technical capabilities for injection molding tools:

| Specification | Capability Range | Industry Standard Comparison |

|---|---|---|

| Material Grades | C36000, C37700, C69300, Custom Alloys | Broader alloy selection |

| Tolerance Range | ±0.002 mm (critical dimensions) | Typical: ±0.005 mm |

| Surface Finish (Cavity) | Ra 0.2 µm to Ra 0.8 µm | Typical: Ra 0.4 µm min |

| Lead Time (Complex) | 15–20 working days | Industry avg: 25–35 days |

| Thermal Conductivity | Validated 220 W/m·K performance | Critical for cooling efficiency |

Your brass molding project cannot afford compromises in dimensional stability or thermal management. Wuxi Lead Precision Machinery delivers engineered solutions where material science meets manufacturing excellence. We transform your design intent into production-ready tools that outperform expectations and outlast competitors’ offerings.

Resolve your brass molding challenges with a partner who speaks the language of precision engineering. Contact our technical sales team directly at [email protected] to discuss your specific requirements. Include your target tolerances, material grade, and production volume for a tailored capability assessment within 24 business hours. Let us prove why global leaders trust Lead Precision for mission-critical brass tooling. Your next-generation mold starts with an engineered conversation.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.