Technical Contents

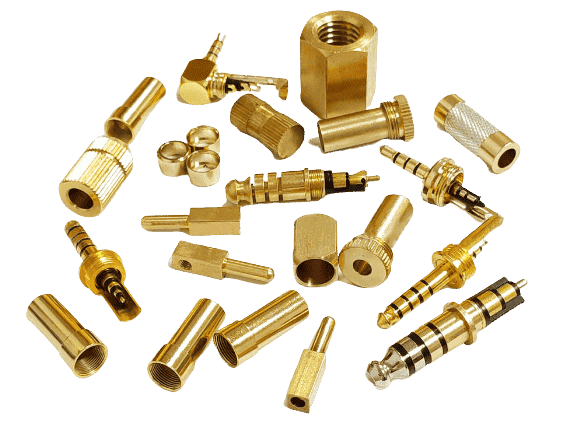

Engineering Guide: Brass Tap Employment

Engineering Insight: Precision Imperatives in Brass Tapping Operations

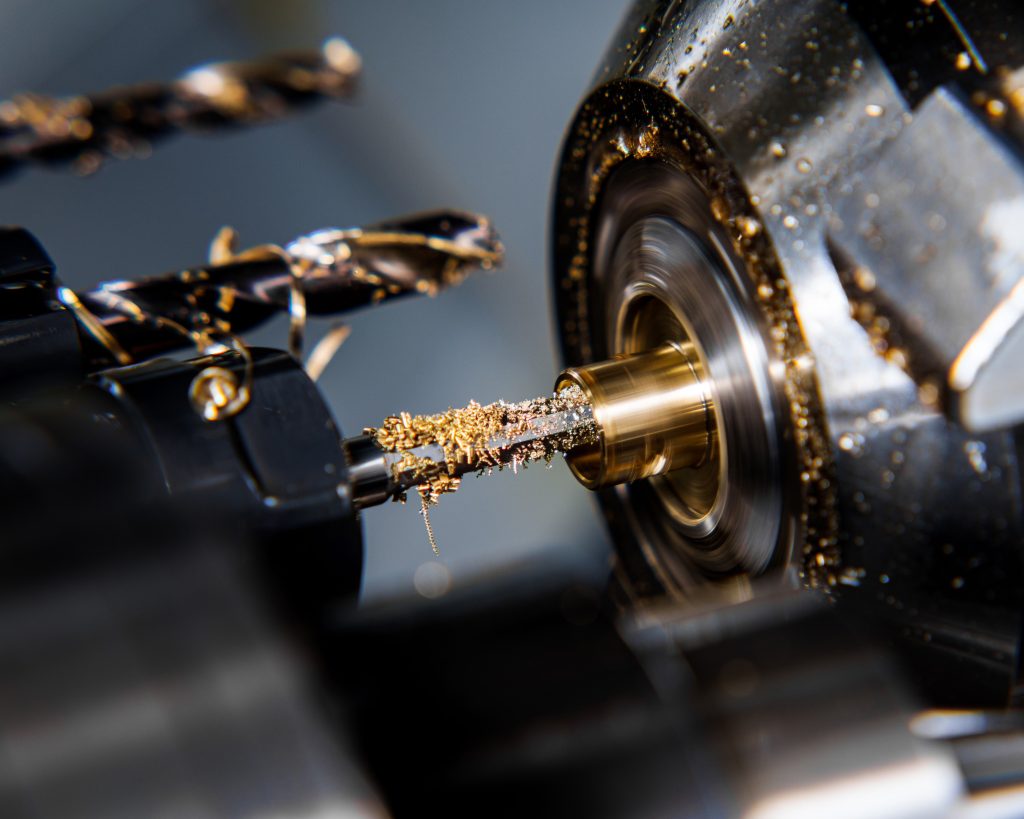

Brass tapping demands exacting process control far beyond standard threading applications. As a soft yet stringy material, brass exhibits unique challenges including rapid work hardening, chip evacuation difficulties, and susceptibility to galling. Even minor deviations in tap geometry alignment or feed synchronization induce chatter, thread tearing, or catastrophic tap breakage—compromising part integrity and escalating production costs. At Wuxi Lead Precision Machinery, we treat brass tapping not as a routine operation but as a precision science requiring integrated engineering oversight. Our CNC cells implement real-time spindle load monitoring and adaptive feed algorithms to maintain optimal torque thresholds, preventing the micro-vibrations that degrade thread accuracy in materials like C36000 free-cutting brass.

The consequences of imprecise tap employment extend beyond scrap rates. In aerospace hydraulic fittings or medical instrumentation, thread inconsistencies cause seal failures under pressure, leading to systemic risks. Military-spec connectors we manufactured for satellite deployment mechanisms required threads held to ISO 2768-mK tolerances (±0.05mm pitch diameter), where a single micron deviation would trigger mission-critical leaks. Similarly, our Olympic-standard timing system components demanded flawless thread engagement to ensure nanosecond synchronization across 10,000+ assembly points. These projects underscore why brass tapping success hinges on three non-negotiable factors: geometric precision in tap grinding, thermal stability during cutting, and material-specific parameter optimization.

Empirical data confirms that standard tapping parameters fail consistently with brass. Our process engineers developed proprietary speed/feed matrices validated across 12,000+ production runs. Key differentiators include reduced surface speeds to minimize heat buildup and precisely calculated chip thinning ratios to prevent clogging. Below outlines critical parameter comparisons:

| Parameter | Standard Brass Tapping | Lead Precision Protocol | Impact of Deviation |

|---|---|---|---|

| Cutting Speed | 30-40 m/min | 18-22 m/min | >25 m/min induces work hardening |

| Feed Rate | 0.15 mm/rev | 0.08-0.10 mm/rev | Excess feed causes thread tearing |

| Coolant Pressure | 20-30 bar | 50-60 bar (through-spindle) | Inadequate pressure traps chips |

| Tap Point Angle | 8°-10° | 3°-5° (brass-specific) | Steeper angles increase breakout |

Material science informs every adjustment. For instance, our C36000 brass runs use cobalt-HSS taps with TiN coatings and polished flutes to reduce friction coefficients by 37% versus uncoated tools—data derived from metallurgical analysis of chip morphology. This level of rigor transformed yield rates for a German automotive client from 68% to 99.2% on transmission valve bodies.

Wuxi Lead’s approach integrates Olympic-grade metrology with military-grade process validation. Every tap run undergoes pre-production simulation in Siemens NX, followed by post-process 3D thread scanning using Zeiss CONTURA systems. When your application demands threads that perform under extreme cyclic loads or vacuum environments, precision isn’t optional—it’s the foundation of reliability. Contact our engineering team to discuss brass-specific tap protocols validated in mission-critical deployments.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Brass Component Manufacturing

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most demanding requirements in custom brass component production. Specializing in high-precision machining for critical industrial applications, we leverage state-of-the-art 5-axis CNC machining centers to deliver complex geometries with exceptional accuracy and surface finish. Our facility is equipped with multi-axis milling and turning systems capable of simultaneous five-axis motion, enabling us to machine intricate brass parts in a single setup. This reduces cumulative errors, improves part consistency, and significantly shortens lead times compared to conventional 3-axis methods.

Our 5-axis CNC platforms are optimized for brass alloys, including C36000, C37700, and other lead-free variants, ensuring optimal chip evacuation, tool life, and dimensional stability. Advanced toolpath strategies such as high-speed machining (HSM) and dynamic contouring allow for efficient material removal while maintaining tight tolerances across multi-faceted components. This capability is particularly critical for sectors such as aerospace, medical instrumentation, and high-performance fluid control systems, where brass taps and fittings must perform under extreme conditions.

Quality assurance is fully integrated into our manufacturing workflow. Every production run undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing traceable, three-dimensional verification of critical dimensions. Our CMM system is calibrated to ISO 10360 standards and operates in a temperature-controlled metrology lab to eliminate thermal drift. In addition to first-article inspection, we perform in-process and final inspections to ensure compliance with customer specifications and international standards such as ISO 2768 and ASME Y14.5.

We maintain full documentation for all inspection routines, including GD&T reports, point-cloud analysis, and 3D deviation mapping, which are provided with each shipment. This level of traceability ensures complete transparency and supports our customers’ compliance needs in regulated industries.

The following table outlines our standard machining capabilities and achievable tolerances for brass components:

| Parameter | Capability |

|---|---|

| Maximum Work Envelope (5-axis) | 800 mm × 600 mm × 500 mm |

| Spindle Speed | Up to 24,000 rpm |

| Positioning Accuracy (X, Y, Z) | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance (per ISO 2768-m) | ±0.05 mm (up to 30 mm) |

| Geometric Tolerance (Flatness, Perpendicularity) | 0.01 mm / 100 mm |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish available) |

| Minimum Feature Size | 0.5 mm (drilling and milling) |

| CMM Measurement Uncertainty | ±0.0015 mm (k=2) |

Our technical capabilities are reinforced by a team of experienced CNC programmers, process engineers, and quality technicians who collaborate to optimize every stage of production. From prototype development to high-volume manufacturing, Wuxi Lead Precision Machinery delivers precision, reliability, and technical excellence in every brass component we produce.

Material & Finish Options

Material Selection for Precision Brass Components: Aluminum, Steel, and Titanium Considerations

Selecting the optimal base material for brass component integration is a critical engineering decision impacting performance, manufacturability, and lifecycle cost. At Wuxi Lead Precision Machinery, our CNC expertise reveals that aluminum, steel, and titanium each present distinct advantages and challenges when employed alongside brass elements in high-precision assemblies. Understanding these nuances ensures robust functionality and cost efficiency in demanding applications like fluid control systems, aerospace fittings, and industrial instrumentation.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer an exceptional strength-to-weight ratio and inherent corrosion resistance, making them ideal for weight-sensitive applications where brass inserts or bushings are required. Their excellent thermal and electrical conductivity complements brass components effectively. However, aluminum’s lower hardness compared to steel necessitates careful CNC parameter optimization to prevent galling during brass thread engagement. Machinability is generally very good, but thermal management during high-speed milling of complex geometries near brass interfaces is paramount to maintain dimensional stability. Anodizing provides superior surface protection and wear resistance for aluminum sections, creating a durable, electrically insulating layer that significantly enhances component longevity without affecting adjacent brass parts.

Steel, especially 303 stainless and 17-4 PH, delivers superior strength, hardness, and wear resistance essential for high-pressure or high-torque brass tap applications. Its thermal expansion characteristics are closer to brass than aluminum, reducing stress risks in temperature-varying environments. The primary challenge lies in its significantly lower machinability compared to aluminum, requiring rigid CNC setups, specialized tooling, and controlled feeds/speeds to achieve the tight tolerances demanded around brass features without work hardening. While anodizing is not applicable to steel, alternative finishes like passivation, electropolishing, or precision plating (e.g., nickel) are essential for corrosion protection and maintaining interface integrity with brass.

Titanium alloys (e.g., Grade 5 Ti-6Al-4V) provide the ultimate in strength-to-weight ratio and exceptional corrosion resistance, crucial for extreme environments. However, its low thermal conductivity and high chemical reactivity pose significant machining hurdles. Titanium generates intense heat at the tool interface and readily welds to cutting tools, demanding ultra-precise CNC control, specialized coated carbide tooling, and aggressive coolant strategies – especially critical when machining near dissimilar brass components to avoid thermal distortion. Machinability is notably poor, increasing production time and cost substantially. Anodizing is ineffective; alternative surface treatments like laser texturing or specialized plasma electrolytic oxidation are required for wear enhancement.

Material compatibility with brass dictates finish selection. Anodizing is exclusively viable for aluminum sections, providing critical wear and corrosion resistance. Steel requires non-electrolytic finishes like passivation, while titanium needs advanced treatments. The following table summarizes key comparative properties:

| Material | Key Properties | Machinability Rating (Relative) | Common Applications with Brass | Finish Compatibility |

|---|---|---|---|---|

| Aluminum | Low density, good conductivity | Excellent (1.0) | Lightweight housings, brackets, fittings | Anodizing (Hard/Type III) |

| Steel (Stainless) | High strength, hardness, wear | Moderate (0.6) | High-pressure valves, structural fittings | Passivation, Plating |

| Titanium | Highest strength/weight, corrosion | Poor (0.3-0.5) | Aerospace, marine critical components | Laser Texturing, PEO |

Wuxi Lead Precision Machinery leverages decades of CNC process mastery to navigate these material complexities. We advise selecting aluminum for optimal balance of performance and cost when anodizing is beneficial, steel for maximum durability in standard environments, and titanium only when its unique properties justify the significant machining challenges. Our engineering team collaborates closely with clients to determine the precise material and finish strategy ensuring seamless brass integration and peak component performance.

Manufacturing Process & QC

Design: Precision Engineering at the Core

At Wuxi Lead Precision Machinery, the journey of brass tap employment begins with meticulous design engineering. Our in-house team of CNC specialists and mechanical engineers collaborates closely with clients to translate functional requirements into manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Mastercam, we develop 3D models that define critical dimensions, thread profiles, torque tolerances, and surface finish requirements. Each design undergoes rigorous simulation for stress distribution, thermal behavior, and thread engagement to ensure optimal performance in real-world applications. Design for manufacturability (DFM) principles are applied from the outset to eliminate inefficiencies and preempt potential production flaws. All technical drawings are ISO-compliant and include full GD&T (Geometric Dimensioning and Tolerancing) callouts to ensure unambiguous interpretation during production.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to low-volume prototyping using high-precision CNC turning and milling centers. These prototypes are machined from the same brass alloys—typically C3604 or C3771—that will be used in mass production, ensuring material consistency. Each prototype undergoes comprehensive metrological inspection using coordinate measuring machines (CMM), optical comparators, and thread gauges to verify dimensional accuracy down to ±0.005 mm. Functional testing includes thread fit assessment, torque resistance, and corrosion resistance under controlled environments. Client feedback is integrated at this stage, allowing for rapid design iterations without impacting the production timeline. This phase is critical in achieving zero defects, as it uncovers potential flaws before tooling and process parameters are locked in.

Mass Production: Consistency Through Automation and Control

With prototype approval, we transition to full-scale production on automated CNC lathes and multi-axis machining centers. Our facility employs real-time process monitoring systems that track spindle load, tool wear, and dimensional drift, enabling predictive maintenance and instant correction. Each brass tap is machined under controlled environmental conditions to minimize thermal deformation. In-process inspections occur at defined intervals, and final quality audits are conducted on 100% of critical dimensions for high-tolerance components. Our ISO 9001-certified quality management system ensures traceability from raw material batch to finished product, with full documentation available upon request.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Standards | C3604, C3771, CW614N, Custom Alloys |

| Dimensional Tolerance | ±0.005 mm (standard), ±0.002 mm (tight) |

| Surface Finish | Ra 0.4 μm to Ra 1.6 μm |

| Thread Accuracy | ISO 6157-1, Class 4h to 6g |

| Production Capacity | Up to 50,000 units/month |

| Lead Time (Mass Production) | 15–25 days after prototype approval |

| Quality Certification | ISO 9001:2015, Full PPAP Documentation |

Through integrated design validation, precision prototyping, and tightly controlled mass production, Wuxi Lead ensures every brass tap meets the highest standards of reliability and performance—delivering true zero-defect manufacturing for demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Brass Component Excellence

In the demanding landscape of precision brass component manufacturing, selecting a partner capable of delivering consistent quality, technical mastery, and responsive execution is non-negotiable. Wuxi Lead Precision Machinery stands as your definitive solution for high-integrity brass parts where dimensional accuracy, material integrity, and on-time delivery directly impact your product performance and market reputation. We specialize in transforming complex brass alloy specifications—from free-machining C36000 to high-strength naval brass—into mission-critical components for fluid control, electrical systems, and industrial automation. Our ISO 9001-certified facility integrates advanced CNC Swiss machining, multi-spindle turning, and precision milling with rigorous in-process metrology, ensuring every part meets the exacting standards demanded by aerospace, medical, and automotive sectors.

Our technical capabilities are engineered specifically for the unique challenges of brass machining, including optimal chip control, thermal management, and surface finish consistency. The table below outlines our core brass production specifications, reflecting our commitment to exceeding industry benchmarks.

| Specification Parameter | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.0127 mm (±0.0005″) |

| Surface Roughness (Ra) | 0.4 µm (16 µin) achievable | 1.6 µm (63 µin) typical |

| Maximum Part Diameter | Ø 42 mm (1.65″) | Ø 25 mm (1.0″) |

| Minimum Wall Thickness | 0.3 mm (0.012″) | 0.5 mm (0.020″) |

| Annual Production Capacity | 2.5+ million precision components | Varies by complexity |

| Material Certification | Full MTR traceability per order | Basic certification common |

Beyond technical prowess, we eliminate the friction inherent in global sourcing. Our engineering team collaborates directly with your design phase to optimize manufacturability, reduce lead times, and prevent costly iterations. Real-time production tracking, dedicated quality documentation portals, and proactive communication ensure complete supply chain transparency. Unlike commodity-focused suppliers, we treat your project as a strategic extension of your engineering objectives—protecting your brand through zero-defect processes and rapid corrective action. This partnership model has enabled clients to reduce component failure rates by up to 78% while accelerating time-to-market for next-generation assemblies.

The cost of substandard brass components extends far beyond initial procurement—field failures, recalls, and reputational damage carry exponential consequences. Partnering with Wuxi Lead Precision Machinery mitigates these risks through engineered reliability. We invest in your success with scalable capacity, metallurgical expertise, and a culture where precision isn’t a claim but a measurable outcome. Contact us today to discuss your specific brass component requirements and receive a detailed capability assessment within 24 hours. Elevate your supply chain with a partner who delivers certainty in every micron.

Initiate your precision brass manufacturing partnership now. Email [email protected] with your project specifications and engineering requirements. Our technical sales team will respond within one business day with a tailored production plan, feasibility analysis, and competitive quotation—no obligation. Trust Wuxi Lead Precision Machinery to transform your brass component challenges into a precision-engineered advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.