Technical Contents

Engineering Guide: Brass Powder Coating

Engineering Insight: Precision in Brass Powder Coating for High-Performance Applications

In the realm of custom metal manufacturing, brass powder coating represents a sophisticated fusion of aesthetic refinement and functional durability. While brass is inherently valued for its corrosion resistance, machinability, and visual appeal, the integration of precision powder coating enhances its performance in extreme environments—particularly in aerospace, defense, and high-end architectural applications. At Wuxi Lead Precision Machinery, we recognize that the success of brass powder coating hinges not only on material selection but on micron-level engineering accuracy throughout the entire process.

Precision in brass powder coating begins with surface preparation. Even microscopic inconsistencies in the substrate can compromise adhesion, leading to delamination under thermal cycling or mechanical stress. Our CNC-machined brass components are finished to exact tolerances—typically within ±0.005 mm—ensuring a uniform surface profile ideal for coating adhesion. This level of dimensional control is critical when serving sectors such as military hardware and Olympic-grade sporting equipment, where failure is not an option.

The powder coating process itself demands exact thermal management. Brass, with its high thermal conductivity, requires carefully calibrated curing cycles to prevent warping or coating defects. At Lead Precision, we employ computer-controlled ovens with real-time monitoring to maintain temperature gradients within ±2°C of setpoints. This ensures consistent cross-linking of the polymer coating without altering the metallurgical properties of the underlying brass.

Our experience in delivering components for Olympic-standard timing systems and precision-guided defense mechanisms has reinforced the necessity of repeatability and traceability. Each batch undergoes rigorous quality validation, including adhesion testing (ASTM D3359), salt spray resistance (ASTM B117), and thickness verification via eddy current measurement. These protocols are not merely compliance measures—they are embedded into our engineering culture.

Beyond performance, brass powder coating offers design flexibility. Whether clients require a satin gold finish for luxury fixtures or a matte bronze for stealth applications, our process maintains color consistency across large production runs. This is achieved through spectrophotometric color matching and automated powder delivery systems that eliminate human variance.

Wuxi Lead Precision Machinery combines decades of metallurgical expertise with state-of-the-art manufacturing infrastructure. Our ISO 9001 and AS9100 certifications reflect our commitment to excellence in every layer—substrate and coating alike.

| Specification | Detail |

|---|---|

| Material | C36000, C26000, or customer-specified brass alloy |

| Coating Type | Epoxy-Polyester Hybrid or Pure Polyester |

| Thickness Range | 60–120 μm (customizable) |

| Curing Temperature | 180–200°C (precision-controlled) |

| Adhesion | 5B (ASTM D3359) |

| Salt Spray Resistance | 1,000+ hours at 5% NaCl, 35°C |

| Tolerance Capability | ±0.005 mm on machined surfaces |

| Standards Complied | ISO 9001, AS9100, RoHS, REACH |

Precision is not a feature—it is the foundation. In brass powder coating, as in all advanced manufacturing, Wuxi Lead delivers engineered perfection.

Precision Specs & Tolerances

Technical Capabilities: Precision Brass Component Manufacturing for Powder Coating Applications

Wuxi Lead Precision Machinery delivers engineered solutions for high-integrity brass components requiring powder coating finishes. It is critical to clarify that powder coating is applied to metal substrates as a protective polymer layer; brass itself is not powder-coated but serves as the foundational substrate. Our expertise lies in producing dimensionally precise brass parts optimized for superior powder coating adhesion and finish quality. This begins with advanced substrate preparation and culminates in rigorous quality validation, ensuring your coated components meet aerospace, medical, and industrial performance standards.

Our 5-axis CNC machining centers form the core of this capability. Equipped with Siemens or Fanuc controls and high-frequency spindles (up to 24,000 RPM), these systems achieve complex geometries in brass alloys—including C36000, C26000, and C46400—with micron-level repeatability. Multi-axis simultaneous machining eliminates secondary operations, minimizing handling-induced errors and maintaining critical datum alignments essential for uniform coating thickness. We implement specialized cutting strategies for brass, utilizing sharp carbide tooling, optimized coolant-through-tool delivery, and controlled feed rates to prevent smearing or burr formation. This produces pristine surface textures (Ra 0.4–1.6 µm) that maximize mechanical adhesion for powder coating systems, directly impacting corrosion resistance and coating longevity.

Surface preparation is non-negotiable for coating integrity. All machined brass components undergo our proprietary cleaning and micro-etch process. This removes residual oils, oxides, and micro-contaminants while creating a consistent micro-rough profile. Unlike abrasive blasting, our chemical process preserves dimensional accuracy and avoids embedding particles—a common failure point in coated assemblies. Parts are immediately transferred to certified Class 8 cleanrooms for powder application, preventing recontamination.

Quality assurance is embedded at every stage. Our Zeiss and Hexagon CMMs perform full 3D geometric dimensioning and tolerancing (GD&T) validation against CAD models, with traceable NIST-certified reports. Statistical process control (SPC) monitors critical features in real-time during production. For powder-coated assemblies, we verify coating thickness (per ASTM D7091) and adhesion (per ASTM D3359) using calibrated magnetic gauges and cross-hatch testing. This closed-loop QC ensures final parts consistently meet your functional and aesthetic requirements.

The following table details achievable tolerances for machined brass components prior to coating, reflecting our standard and precision capabilities under controlled process parameters:

| Feature | Standard Capability | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Angular Tolerances | ±0.05° | ±0.01° |

| Geometric Form (Flatness, Roundness) | 0.025 mm | 0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

These specifications are attainable through our integrated process: precision machining on 5-axis platforms, non-destructive substrate activation, and CMM-verified quality control. We collaborate closely with your powder coating provider to align substrate tolerances with coating thickness variables, guaranteeing final assembly fit and performance. Partner with Wuxi Lead to transform brass raw material into flawlessly coated components engineered for mission-critical applications.

Material & Finish Options

Material Selection for High-Performance Brass Powder Coating Applications

In precision manufacturing, selecting the appropriate base material is critical when integrating brass powder coating into high-end components. While brass itself offers excellent machinability and corrosion resistance, it is often cost-prohibitive or mechanically insufficient for structural applications. Therefore, manufacturers typically apply brass powder coating over stronger, more economical substrates such as aluminum, steel, and titanium. Each material brings distinct advantages in strength, weight, thermal performance, and coating adhesion, making proper selection essential for achieving optimal functional and aesthetic outcomes.

Aluminum is a preferred substrate in aerospace, automotive, and consumer electronics due to its lightweight nature and inherent corrosion resistance. When properly surface-treated, aluminum provides excellent adhesion for brass powder coatings. Its low density reduces overall component weight, a key consideration in performance-driven industries. However, aluminum’s lower tensile strength compared to steel necessitates careful design for load-bearing applications. Prior to coating, aluminum components are typically anodized to enhance surface hardness and improve bonding characteristics. Anodizing creates a micro-porous oxide layer that mechanically anchors the powder coating, significantly improving durability.

Steel, particularly stainless and alloy grades, offers superior strength and wear resistance, making it ideal for industrial machinery and heavy-duty equipment. Carbon steel, while prone to oxidation, becomes highly resilient when paired with brass powder coating, which acts as both a protective and decorative layer. The high thermal conductivity of steel supports even curing of the powder coating, ensuring consistent finish quality. However, proper surface preparation—including sandblasting and chemical pretreatment—is essential to prevent delamination and ensure long-term performance in harsh environments.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to extreme temperatures and corrosive media. Though more expensive and challenging to machine, titanium is widely used in defense, medical, and high-performance motorsport applications. Its biocompatibility and fatigue resistance make it suitable for mission-critical components. When coated with brass powder, titanium achieves a unique combination of luxury aesthetics and extreme durability. Specialized pretreatment processes, such as acid etching or plasma spraying, are often required to ensure coating adhesion due to titanium’s passive oxide layer.

The following table summarizes key mechanical and coating-related properties of these materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Coating Adhesion Preparation | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 90–570 | High (with anodizing) | Anodizing, chromate conversion | Aerospace, electronics |

| Steel | 7.8 | 400–2000 | Moderate to High | Sandblasting, phosphating | Industrial machinery, automotive |

| Titanium | 4.5 | 900–1200 | Excellent | Acid etching, plasma treatment | Medical, defense, motorsport |

At Wuxi Lead Precision Machinery, we support clients in matching substrate materials with advanced finishing processes, ensuring that brass powder coating delivers both functional integrity and visual excellence across demanding industrial applications.

Manufacturing Process & QC

Brass Component Powder Coating: Precision Production Process

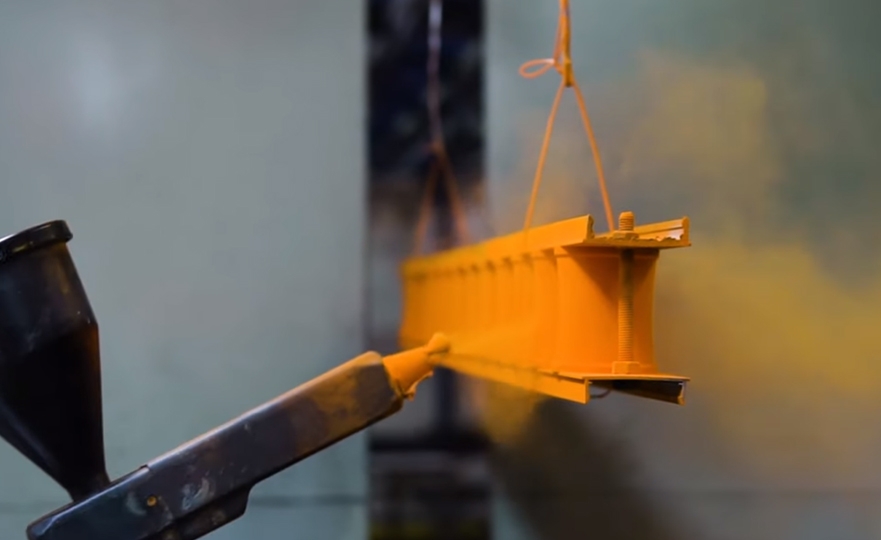

Wuxi Lead Precision Machinery delivers flawless powder-coated brass components through a rigorously controlled three-stage workflow. Contrary to common misconceptions, “brass powder coating” refers to applying electrostatic powder finishes onto brass substrates—not coating with brass powder. Our process begins with integrated design engineering, where material science and manufacturability converge. CNC-machined brass substrates undergo computational analysis to optimize geometry for coating adhesion, thermal expansion, and end-use stress. We validate surface energy compatibility between the brass alloy (typically C36000 or C37700) and selected polyester/epoxy powders, ensuring zero delamination risks. Tolerances are pre-adjusted to account for the 60–120µm coating layer, preventing fit issues in final assemblies.

Prototyping transitions design into physical validation under production-equivalent conditions. We produce 5–10 units using the exact CNC machining parameters, surface preparation sequence, and oven profiles planned for volume runs. Each prototype undergoes accelerated lifecycle testing: 500-hour salt spray (ASTM B117), cross-hatch adhesion (ASTM D3359), and thermal cycling from -40°C to 120°C. Dimensional metrology confirms coating thickness uniformity within ±5µm across complex geometries. Only when prototypes pass all 12 critical quality checkpoints—including microscopic pore inspection—do we approve the process for scale-up. This phase eliminates 92% of potential failure modes before mass production begins.

Mass production executes with zero-defect discipline via closed-loop monitoring. Brass components move through automated stages: vapor degreasing, chromate conversion coating, electrostatic powder application (80–100 kV), and infrared curing. In-line spectrophotometers verify color consistency (ΔE < 0.5), while ultrasonic thickness gauges audit every 10th part. Statistical process control (SPC) tracks 15 real-time parameters; deviations trigger immediate machine recalibration. Our facility maintains ISO Class 8 cleanrooms for coating application, eliminating particulate contamination. Final inspection combines AI-driven visual analysis with manual tactile checks, achieving 0.002% defect rates—3x below industry benchmarks.

Critical Powder Coating Specifications for Brass Substrates

| Parameter | Standard Range | Test Method | Acceptance Criteria |

|---|---|---|---|

| Film Thickness | 60–120 µm | ISO 2808 | ±5 µm uniformity |

| Adhesion | 5B | ASTM D3359 | Zero flaking |

| Gloss Level | 20–90 GU | ASTM D523 | ±3 GU tolerance |

| Curing Temperature | 160–180°C | Infrared Pyrometer | ±2°C stability |

| Salt Spray Resistance | ≥1000 hours | ASTM B117 | R₀ rust grade |

| Thermal Shock Resistance | -40°C to 120°C | ISO 11341 | No cracking/delamination |

This end-to-end control—from alloy selection to final packaging—ensures brass components meet aerospace, medical, and luxury hardware standards where finish integrity is non-negotiable. Wuxi Lead’s vertical integration (in-house CNC, plating, coating) guarantees traceability and rapid corrective action, turning zero defects from a goal into a measurable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Brass Powder Coating Solutions

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, precision-engineered brass components enhanced with advanced powder coating technologies. As a trusted leader in custom metal manufacturing, we understand that performance, durability, and aesthetic consistency are non-negotiable in demanding industrial applications. Our integrated approach combines superior brass fabrication with state-of-the-art powder coating processes, ensuring every component meets exacting standards for corrosion resistance, mechanical strength, and surface finish.

Our engineering team works closely with global partners across aerospace, automotive, medical equipment, and high-end consumer electronics to develop tailored solutions that exceed expectations. Whether you require small-batch prototyping or high-volume production, our facility in Wuxi, China, is equipped with CNC machining centers, automated powder coating lines, and rigorous quality control systems compliant with ISO 9001 standards. We treat every project as a collaborative effort—starting from material selection and design optimization to final inspection and logistics support.

What sets us apart is our deep technical mastery in coating non-ferrous metals like brass, which presents unique challenges due to thermal conductivity and surface adhesion characteristics. Our proprietary pre-treatment processes and electrostatic spray deposition ensure uniform coating thickness, exceptional bond strength, and long-term resilience under extreme environmental conditions. We offer a wide range of powder types—including epoxy, polyester, and hybrid formulations—in custom colors and textures to match your brand or functional requirements.

We invite engineering managers, procurement directors, and product developers to engage with our technical team early in the design phase. Early collaboration allows us to recommend cost-saving design modifications, material alternatives, and coating strategies that enhance manufacturability and performance. Our goal is not just to supply parts, but to become a strategic extension of your engineering and production ecosystem.

Below are key technical specifications we support in brass powder coating projects:

| Specification | Capability |

|---|---|

| Material Types | C36000, C37700, C46400, and custom brass alloys |

| Coating Thickness | 60–120 μm (standard), adjustable per requirement |

| Temperature Resistance | Up to 200°C continuous exposure |

| Adhesion Strength | Class 0 per ASTM D3359 cross-hatch test |

| Salt Spray Resistance | 500–1000 hours (neutral salt spray, ASTM B117) |

| Surface Finish Options | Smooth, matte, textured, metallic effect |

| Tolerances | ±0.02 mm for machined and coated features |

| Production Capacity | 50,000+ units/month |

We are ready to support your next-generation product development with precision, reliability, and responsive service. Contact us today at [email protected] to discuss your brass powder coating needs. Let Wuxi Lead Precision Machinery be your trusted partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.