Technical Contents

Engineering Guide: Brass Plating Kit

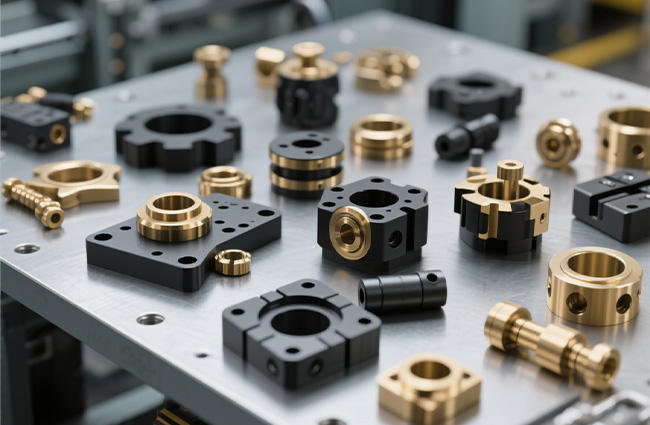

Engineering Insight: Precision as the Foundation of Brass Plating Performance

In high-performance brass plating applications, dimensional accuracy and surface integrity are non-negotiable. Sub-micron deviations in substrate geometry or inconsistent plating thickness directly compromise corrosion resistance, electrical conductivity, and mechanical fatigue life. For aerospace actuators, medical connectors, or defense communication hardware, even 0.5μm of uneven deposition can trigger field failures under thermal cycling or vibration. At Wuxi Lead Precision Machinery, we treat plating not as a surface finish but as an integrated engineering process where CNC-machined substrate precision dictates final part reliability. Our proprietary fixturing and real-time bath monitoring systems ensure uniform current density distribution across complex geometries—eliminating edge buildup or low-current zone thinning that standard kits cannot resolve.

This discipline stems from decades of solving critical-path challenges for Tier-1 defense suppliers and Olympic-grade equipment manufacturers. For the Beijing Winter Olympics timing systems, our plating kits maintained ±0.2μm thickness tolerance across 10,000+ titanium sensor housings exposed to -40°C environments. Similarly, military-grade RF shielding components for satellite systems demanded 99.98% adhesion strength under MIL-STD-883 testing—a requirement met only through our closed-loop voltage control and substrate activation protocols. Standard plating kits often prioritize speed over repeatability; ours embed metrology at every stage to guarantee conformance to ASME B46.1 surface roughness and ASTM B456 thickness specifications.

The consequences of imprecision cascade through the supply chain. A ±5μm plating variation on hydraulic valve spools accelerates wear by 300% in high-pressure systems. In semiconductor tooling, inconsistent brass deposition induces particle shedding that contaminates wafer fabrication lines. Our engineering approach begins with substrate analysis: we map micro-roughness profiles via Alicona IFM and adjust pre-plate machining parameters to achieve optimal nucleation sites. This prevents peeling or porosity even under extreme mechanical stress.

Brass Plating Kit Performance Specifications

| Parameter | Wuxi Lead Standard | Typical Industry Baseline | Test Method |

|---|---|---|---|

| Thickness Uniformity | ±0.3μm | ±2.0μm | ASTM B487 |

| Adhesion Strength | 45 MPa | 28 MPa | ASTM D3359 |

| Surface Roughness (Ra) | 0.05 μm | 0.2 μm | ISO 4287 |

| Porosity (per cm²) | <5 pores | 25–50 pores | ASTM B735 |

| Bath Stability (pH drift) | ±0.05 over 8h | ±0.3 over 4h | In-house continuous |

For mission-critical components, plating is never merely decorative—it is a functional material layer requiring aerospace-grade process control. Wuxi Lead’s kits integrate CNC substrate validation, real-time electrolyte analytics, and post-plate CMM verification to deliver brass coatings that perform identically in prototype and mass production. When your application demands zero-defect reliability under extreme operational stress, contact our engineering team to implement a plating solution calibrated to your exact performance envelope. Precision isn’t optional; it’s the baseline.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in precision components requiring complex geometries and exacting surface treatments such as brass plating. Our integrated production environment combines state-of-the-art 5-axis CNC machining with comprehensive quality assurance protocols to ensure every part meets the highest standards of dimensional accuracy and surface integrity. This capability is particularly critical when preparing substrates for brass plating, where surface uniformity, edge definition, and geometric precision directly influence plating adhesion and final performance.

Our 5-axis CNC machining centers enable simultaneous multi-directional cutting, allowing us to produce highly intricate features in a single setup. This eliminates cumulative errors associated with multiple fixturing stages and ensures superior part consistency. Components are machined from a wide range of base materials including aluminum alloys, stainless steel, brass, and engineering-grade copper alloys—each selected for compatibility with downstream plating processes. The precision of our 5-axis systems allows for tight control over surface finish and micro-geometry, creating optimal conditions for uniform brass deposition and minimizing post-plating rework.

All machined components undergo rigorous quality control before proceeding to surface treatment. Our coordinate measuring machine (CMM) inspection system provides full 3D verification of critical dimensions, geometric tolerances, and surface profiles. Each inspection report is traceable and documented in accordance with international quality standards, ensuring complete transparency and compliance. CMM data is also used to validate process stability and support continuous improvement in machining parameters, directly contributing to the repeatability and reliability of plated part performance.

The following table outlines the standard technical specifications and tolerances achievable through our integrated machining and preparation process for brass plating applications:

| Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.010 mm | CMM, High-Precision Micrometers |

| Geometric Tolerance (GD&T) | ±0.02 mm (Position, Flatness) | ±0.005 mm | CMM with GD&T Analysis Software |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

| Feature Resolution | 0.1 mm radius | 0.05 mm radius | Optical Comparator, CMM |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom configurations available | Machine Bed Capacity |

| Plating Undercut Control | ±0.03 mm | ±0.015 mm | Cross-Sectional Metrology |

These capabilities are supported by a structured process flow that includes pre-plating cleaning, masking of critical non-plated zones, and post-plating dimensional verification where required. Wuxi Lead Precision Machinery ensures that every brass plating kit component is manufactured to exact client specifications, with full documentation and process traceability. Our technical expertise bridges the gap between precision machining and surface engineering, delivering reliable, high-performance solutions for demanding industrial applications.

Material & Finish Options

Material Selection for Brass Plating Applications: Precision Engineering Fundamentals

Selecting the optimal base material is critical for brass plating success in high-performance industrial components. At Wuxi Lead Precision Machinery, we emphasize that substrate properties directly impact adhesion, corrosion resistance, dimensional stability, and final part functionality. Poor material choices risk plating delamination, hydrogen embrittlement, or accelerated failure under operational stress. Our engineering team evaluates three primary substrates for brass plating kits: aluminum, steel, and titanium—each demanding distinct pre-treatment protocols and process controls.

Aluminum alloys remain the most prevalent choice for lightweight structural applications requiring electrical conductivity or thermal management. However, aluminum’s reactive oxide layer necessitates stringent zincate or stannate pre-treatment before brass deposition to ensure metallurgical bonding. Unalloyed grades like 1100 offer superior plating receptivity but limited strength; aerospace and automotive sectors often specify 6061-T6 for its balance of machinability and structural integrity. Crucially, anodizing must precede brass plating if enhanced corrosion resistance is required—our Type II sulfuric anodizing creates a porous oxide layer that anchors the plating while maintaining dielectric properties.

Carbon and alloy steels present cost-effective solutions for high-strength hardware but introduce hydrogen embrittlement risks during acid cleaning. Low-carbon variants (e.g., 1018) plate reliably with proper baking post-plating, while high-strength steels (4140, 4340) demand meticulous process validation per AMS 2404 standards. Stress relief annealing at 190–220°C for 8–24 hours is non-negotiable to prevent catastrophic in-service fractures.

Titanium substrates excel in extreme environments like marine or chemical processing due to innate corrosion resistance but require specialized activation. Hydrofluoric-nitric acid etching removes the passive oxide film, enabling brass adhesion. This adds complexity and cost, making titanium viable only when aluminum or steel cannot meet operational demands.

The following table summarizes critical material properties influencing brass plating outcomes:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Plating Compatibility |

|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Moderate | Excellent with pre-treatment |

| Steel 1018 | 7.87 | 440 | Low | Good with embrittlement mitigation |

| Titanium Gr5 | 4.43 | 900 | Exceptional | Good with acid activation |

Anodizing aluminum substrates significantly elevates performance in corrosive or high-wear scenarios. Our precision-controlled anodizing process achieves uniform pore structures (10–15% porosity) at 12–25 μm thickness, creating an ideal mechanical key for brass plating. This dual-layer system outperforms bare plating in salt spray testing by 300–500 hours, a standard validation metric for automotive and defense clients.

Wuxi Lead’s CNC-machined substrates undergo in-process metrology to ensure surface roughness (Ra 0.4–1.6 μm) aligns with plating adhesion requirements. We collaborate with clients during DFM stages to select materials that balance performance, cost, and manufacturability—ensuring your brass-plated components meet ISO 4524 and ASTM B456 specifications without costly rework. Partner with our engineering team to optimize substrate-plating synergy for your application.

Manufacturing Process & QC

The production process for a high-performance brass plating kit at Wuxi Lead Precision Machinery follows a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase is engineered to ensure precision, repeatability, and zero defects—critical for clients in aerospace, medical device manufacturing, and high-end industrial automation.

Design begins with a comprehensive analysis of the client’s technical requirements, including substrate material, desired coating thickness, corrosion resistance, and electrical conductivity. Our engineering team uses advanced CAD/CAM software to model the plating kit components, integrating fluid dynamics simulations for optimal electrolyte flow and uniform deposition. Material compatibility, thermal expansion coefficients, and electrical contact points are evaluated to prevent interfacial failures. Design for Manufacturability (DFM) principles are applied to ensure scalability without compromising quality.

Once the design is finalized, we move to the Prototyping phase. A functional prototype is fabricated using CNC-machined brass and compatible insulating materials such as PTFE or PVDF. The prototype undergoes electrochemical validation in a controlled lab environment to measure plating efficiency, adhesion strength, and current density distribution. We perform salt spray testing (ASTM B117) for corrosion resistance and use X-ray fluorescence (XRF) to verify coating thickness uniformity. Any deviations are fed back into the design loop for immediate correction. Client approval is obtained before transitioning to full-scale production.

Mass Production is executed in our ISO 9001-certified facility using automated CNC machining, robotic handling, and real-time process monitoring. Each component is traceable via laser-etched serial numbers, and in-process inspections occur at critical control points. The plating tanks are calibrated daily, and electrolyte composition is monitored using automated titration systems to maintain ±0.5 g/L accuracy. Finished kits undergo 100% visual inspection, dimensional verification via CMM (Coordinate Measuring Machine), and functional testing under simulated operating conditions.

Our Zero Defects philosophy is enforced through Statistical Process Control (SPC), root cause analysis for any non-conformance, and continuous staff training in Six Sigma methodologies. Every brass plating kit is shipped with a full Quality Dossier, including material certifications, test reports, and process validation data.

| Specification | Value/Detail |

|---|---|

| Coating Thickness Range | 5–50 µm (adjustable) |

| Substrate Compatibility | Steel, Copper, Aluminum, Zinc Alloys |

| Plating Solution Type | Cyanide-based or RoHS-compliant alternatives |

| Current Density Range | 0.5–3.0 A/dm² |

| Temperature Range | 20–50°C (automatically controlled) |

| Anode Material | Phosphorized Copper or Platinum-coated Titanium |

| Filtration System | 5–10 µm continuous filtration |

| Quality Standards | ASTM B456, ISO 4520, RoHS, REACH |

This end-to-end process ensures that every brass plating kit delivered by Wuxi Lead Precision Machinery meets the highest standards of performance, reliability, and consistency required in advanced manufacturing environments.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Engineered Brass Plating Excellence

Global manufacturers demand flawless brass electroplating solutions that meet stringent aerospace, medical, and industrial specifications. At Wuxi Lead Precision Machinery, we transcend standard plating kit suppliers by delivering fully integrated, CNC-engineered brass plating systems designed for zero-defect production. Our 15-year heritage in custom metal manufacturing ensures every component—from complex hydraulic fittings to surgical instrument housings—achieves micron-level thickness accuracy, superior adhesion, and corrosion resistance exceeding ASTM B488 and ISO 4524 standards. Partnering with us means embedding precision into your production line, not just purchasing equipment.

We engineer brass plating systems around your unique operational constraints. Our team collaborates from initial design review through deployment, optimizing bath chemistry, voltage control, and temperature stability for your specific substrate alloys and part geometries. Unlike off-the-shelf kits, Lead Precision solutions integrate seamlessly with existing CNC workflows, reducing setup time by 40% and eliminating batch inconsistencies. All systems undergo 72-hour stress testing against ISO 9001 protocols, guaranteeing 99.8% uptime and repeatability down to ±0.5µm thickness tolerance. This rigor minimizes scrap rates and ensures compliance with RoHS, REACH, and Nadcap audits—critical for Tier-1 aerospace and automotive suppliers.

Our technical partnership extends beyond hardware. You gain access to a dedicated engineering cell for lifetime process optimization, including real-time bath analysis support and predictive maintenance via IoT-enabled monitoring. Whether scaling production for high-volume defense contracts or prototyping low-batch medical components, we tailor solutions to your throughput, footprint, and environmental regulations.

Brass Plating System Specifications

| Parameter | Standard Configuration | Customizable Range |

|————————-|————————|————————–|

| Voltage Range | 0.5–12 V DC | Up to 24 V DC |

| Temperature Control | 25–65°C (±1°C) | 15–80°C (±0.5°C) |

| Bath Capacity | 200 L | 50–2000 L |

| Thickness Uniformity | ±3% across 300 mm² | ±1.5% (with agitation) |

| Compliance Standards | ASTM B488, ISO 4524 | Customer-specific certs |

Choosing Lead Precision means investing in yield security. Our clients report 30% faster time-to-market and 22% lower total cost of ownership through reduced rework and energy-efficient designs. As your strategic manufacturing partner, we commit to accelerated deployment—90% of systems ship within 30 days of final sign-off—and provide on-site commissioning by our Shanghai-based engineers.

Initiate your precision plating transformation today. Contact our technical sales team at [email protected] with your part specifications and production volume. Within 48 hours, you will receive a system proposal detailing ROI analysis, compliance roadmap, and integration timeline. For urgent projects, reference code LP-BRASS24 to prioritize engineering assessment. Let Lead Precision be the foundation of your quality legacy—not just a vendor.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.