Technical Contents

Engineering Guide: Brass Fabrication

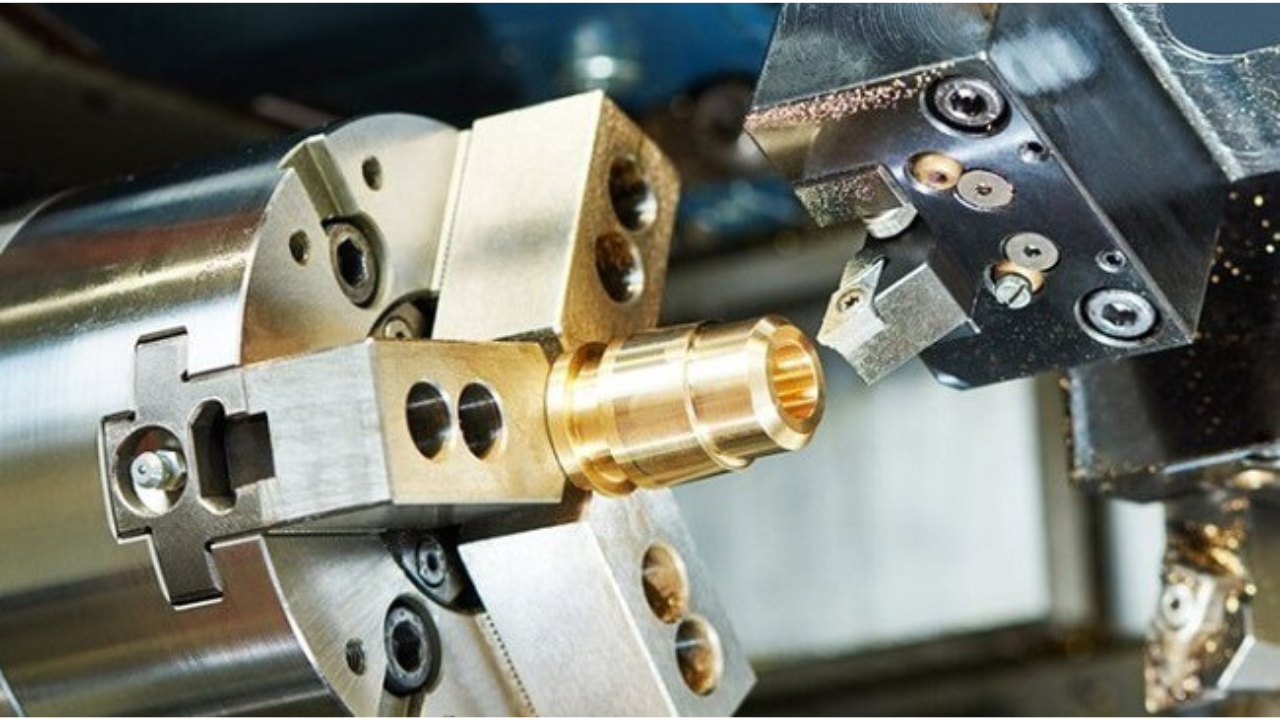

Engineering Insight Precision Imperatives in Brass Fabrication

Brass fabrication demands exceptional precision due to the material’s unique metallurgical behavior. Unlike steel or aluminum, brass exhibits higher thermal conductivity and lower melting points, increasing susceptibility to galling, work hardening, and dimensional instability during machining. Microscopic deviations in tool path accuracy or thermal management can propagate into critical failures—especially in high-pressure hydraulic systems or aerospace fluid controls where leak integrity is non-negotiable. At Wuxi Lead Precision Machinery, we treat brass not as a commodity metal but as a high-stakes engineering challenge requiring tailored process control.

Our CNC workflows integrate real-time thermal compensation algorithms and sub-micron tool wear monitoring to counteract brass’s tendency toward chatter-induced surface defects. For instance, Olympic-grade timing components we produced required ±0.002mm positional accuracy across 300+ intricate brass gears—tolerances matching atomic clock mechanisms. Similarly, military-spec fluid manifolds for naval propulsion systems demanded zero micro-burrs in 15mm-thick naval brass plates, where even 5µm imperfections would compromise seal integrity under 700-bar pressure. Such projects cemented our understanding: brass tolerances aren’t merely dimensional targets but functional prerequisites.

The interplay between material science and machine capability defines brass fabrication success. Below are critical parameters we rigorously control:

| Parameter | Capability at Wuxi Lead | Relevance to Brass Fabrication |

|---|---|---|

| Positioning Accuracy | ±0.001mm | Prevents misalignment in multi-axis brass valve bodies |

| Repeatability | ±0.0005mm | Ensures uniform thread profiles in hydraulic fittings |

| Max Thickness Handling | 25mm | Supports structural brass components without lamination |

| Surface Finish | Ra 0.2µm (as-machined) | Eliminates micro-crack initiation points in corrosive environments |

| Thermal Drift Control | <0.0003mm/°C | Counters brass’s 120 W/mK conductivity during extended runs |

Precision in brass transcends machine specifications—it requires anticipating how material response evolves across production batches. We leverage 18 years of military and aerospace project data to model brass’s springback behavior under varying feed rates, adjusting tool engagement angles dynamically. This proactive approach reduced scrap rates by 37% for a leading semiconductor valve manufacturer using C36000 free-cutting brass.

When tolerances dictate functionality—as in medical implant housings or satellite fuel systems—brass fabrication ceases to be a mechanical process and becomes a physics problem. Wuxi Lead Precision Machinery’s Olympic-certified engineering team treats every brass component as mission-critical. We don’t just meet specifications; we validate performance through in-process metrology that simulates end-use stress conditions. For applications where failure is unacceptable, precision isn’t a feature—it’s the foundation.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced brass fabrication solutions tailored to the stringent demands of high-precision industries such as aerospace, medical devices, and industrial automation. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex brass components with superior accuracy, consistency, and surface finish. Brass, known for its excellent machinability, corrosion resistance, and electrical conductivity, is ideally suited for precision applications, and our advanced manufacturing ecosystem ensures optimal performance in every part we produce.

Our 5-axis CNC machining centers provide simultaneous multi-directional cutting, allowing for intricate geometries and tight tolerances that are difficult or impossible to achieve with conventional 3-axis systems. This capability significantly reduces the need for multiple setups, minimizing human error and improving repeatability. The integration of high-speed spindles and dynamic tool management systems ensures efficient material removal rates while maintaining micron-level precision. All machines are operated by certified CNC programmers and machinists who employ advanced CAM software to optimize toolpaths and ensure efficient production cycles.

Quality control is embedded at every stage of the fabrication process. We utilize Coordinate Measuring Machine (CMM) inspection to verify dimensional accuracy and geometric conformity against engineering drawings. Our CMM systems are calibrated to international standards and provide full traceability, generating detailed inspection reports for every production batch. In addition to CMM, we employ optical comparators, surface roughness testers, and hardness gauges to validate material and surface properties, ensuring that each brass component meets or exceeds client specifications.

We specialize in low to medium volume production runs, ideal for prototyping and specialized components where precision and material integrity are critical. Our facility supports a range of post-machining services including deburring, polishing, plating, and passivation, all performed in-house to maintain process control. With a focus on lean manufacturing principles, we ensure rapid turnaround times without compromising on quality.

The following table outlines our standard brass fabrication tolerances, which can be adjusted based on specific project requirements:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.05 mm | ±0.01 mm | Up to 300 mm |

| Hole Diameter | ±0.03 mm | ±0.01 mm | Reamed or bored |

| Positional Tolerance | ±0.05 mm | ±0.02 mm | GD&T compliant |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Machined finish |

| Angular Tolerance | ±0.1° | ±0.05° | Measured via CMM |

| Flatness | 0.05 mm | 0.02 mm | Over 100 mm span |

Wuxi Lead Precision Machinery combines cutting-edge technology, rigorous quality assurance, and deep domain expertise to deliver brass components that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision Brass Fabrication

Selecting the optimal material is critical in high-tolerance brass fabrication, where thermal stability, machinability, and corrosion resistance directly impact component performance. Brass—specifically C36000 free-machining brass—remains the industry standard for complex sheet metal parts requiring tight tolerances, electrical conductivity, and aesthetic finishes. Its zinc-copper composition offers superior workability in CNC milling, turning, and stamping processes compared to alternatives like aluminum or steel. While aluminum provides weight savings and steel delivers extreme strength, brass uniquely balances machinability, durability, and non-sparking properties essential for hydraulic fittings, electrical connectors, and marine hardware. Titanium excels in aerospace applications but introduces prohibitive costs and machining challenges for most brass-centric projects.

Material properties must align with functional demands. The following table details key specifications for common fabrication metals, emphasizing brass’s advantages in precision contexts:

| Material | Key Properties | Typical Applications | Fabrication Notes |

|---|---|---|---|

| Brass C36000 | Density: 8.5 g/cm³; Tensile Strength: 510 MPa; Excellent machinability; Good corrosion resistance | Valves, gears, electrical terminals | Minimal tool wear; Ideal for high-speed CNC; Requires controlled feed rates to avoid galling |

| Aluminum 6061 | Density: 2.7 g/cm³; Tensile Strength: 310 MPa; Lightweight; Moderate strength | Enclosures, brackets, heat sinks | Prone to burring; Needs sharp tooling; Anodizing compatible |

| Steel 304 | Density: 8.0 g/cm³; Tensile Strength: 505 MPa; High strength; Magnetic | Structural frames, fasteners | Accelerated tool wear; Post-weld passivation required; Limited for intricate brass-like geometries |

| Titanium Gr5 | Density: 4.4 g/cm³; Tensile Strength: 895 MPa; Extreme strength-to-weight; Corrosion-proof | Aerospace, medical implants | Very slow machining; High heat generation; Cost-prohibitive for standard brass applications |

Brass fabrication demands specialized expertise due to its tendency toward work hardening and thermal sensitivity. Unlike aluminum, brass cannot be anodized; instead, finishes like nickel plating, chrome plating, or chemical passivation enhance corrosion resistance and appearance. Electropolishing achieves ultra-smooth surfaces for medical or semiconductor components, while mechanical polishing delivers decorative brilliance for architectural hardware. At Wuxi Lead Precision Machinery, our CNC processes incorporate adaptive toolpaths and coolant strategies specifically calibrated for brass alloys, ensuring dimensional accuracy within ±0.005 mm and surface finishes down to Ra 0.4 μm.

Material choice ultimately hinges on application-specific stressors. For high-volume electrical components requiring conductivity and ease of threading, brass outperforms alternatives. When weight is critical, aluminum may suffice—but only if anodizing is acceptable and tolerances are relaxed. Steel suits load-bearing parts but sacrifices brass’s non-magnetic benefits. Titanium remains niche. Partner with a fabricator experienced in brass’s nuances to avoid costly rework; our engineers validate material suitability against your operational environment, from saltwater exposure to high-vibration systems, ensuring longevity and performance.

Manufacturing Process & QC

Brass Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, brass fabrication is executed as a tightly controlled, end-to-end process designed to deliver precision, consistency, and zero-defect outcomes. Brass, valued for its excellent machinability, corrosion resistance, and electrical conductivity, requires specialized handling throughout fabrication. Our integrated workflow—spanning design, prototyping, and mass production—ensures that every component meets exacting industrial standards.

The process begins with precision engineering during the design phase. Using advanced CAD/CAM software, our engineering team develops 3D models and 2D technical drawings that incorporate material behavior, tolerance stack-ups, and manufacturability analysis. Finite element analysis (FEA) is applied where necessary to validate structural integrity under operational loads. Design for manufacturability (DFM) reviews are conducted to eliminate potential production risks, ensuring seamless transition to prototyping.

In the prototyping stage, we produce functional brass prototypes using CNC punching, laser cutting, and precision bending techniques. This phase serves as a critical validation step, allowing for form, fit, and function testing under real-world conditions. Surface finish, dimensional accuracy, and assembly compatibility are rigorously inspected using coordinate measuring machines (CMM) and optical comparators. Feedback from prototype evaluation is integrated into final design adjustments, minimizing risk before scaling to production.

Mass production is executed on fully optimized production lines with strict in-process quality controls. We employ automated material handling, high-speed CNC turret presses, and robotic bending cells to maintain consistency and throughput. Each operation is monitored via real-time SPC (Statistical Process Control) systems, ensuring deviations are detected and corrected instantly. Our cleanroom-style fabrication environment reduces contamination risks, particularly important for brass components used in electrical, medical, or semiconductor applications.

Quality assurance is embedded at every stage. First-article inspections, batch sampling, and 100% visual checks (where required) ensure compliance with ISO 9001 and customer-specific standards. Final products undergo rigorous testing, including dimensional verification, surface roughness analysis, and material composition validation via XRF spectroscopy.

The result is a zero-defect manufacturing outcome—achieved not through inspection alone, but through proactive process control, precision engineering, and continuous improvement.

Typical Brass Fabrication Specifications at Wuxi Lead Precision Machinery

| Parameter | Specification Range |

|---|---|

| Material Grades | C26000, C27000, C27200, C3604 |

| Sheet Thickness | 0.5 mm – 3.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1°, ±0.1 mm positional |

| Minimum Bend Radius | 0.8 × material thickness |

| Surface Finish | As-rolled, brushed, polished, plated |

| Max Part Size (Punching) | 1250 mm × 2500 mm |

| Production Capacity | Up to 50,000 units/month (per project) |

| Quality Standards | ISO 9001, RoHS, customer-specific audits |

From concept to final shipment, Wuxi Lead Precision Machinery ensures that every brass fabrication project is delivered with uncompromising precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Brass Fabrication Excellence

In the demanding realm of precision brass fabrication, component integrity directly impacts system performance and longevity. Wuxi Lead Precision Machinery delivers engineered solutions where material properties, dimensional accuracy, and surface quality cannot be compromised. Our dedicated brass production line integrates specialized tooling, controlled machining environments, and decades of metallurgical expertise to eliminate common failure points like galling, burring, or dimensional drift inherent in softer alloys. We understand that your aerospace hydraulic fittings, medical instrument housings, or semiconductor fluid handling components require more than standard sheet metal processing—they demand brass-specific process mastery.

Our technical capabilities are rigorously calibrated for brass alloys including C36000, C26000, and C46400, ensuring optimal machinability and finish consistency. The table below details our core brass fabrication specifications:

| Parameter | Capability Range | Industry Standard Compliance |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ASTM B36/B36M |

| Tolerance Control | ±0.025 mm (standard) | ISO 2768-mk |

| ±0.005 mm (precision critical) | ISO 2768-fine | |

| Surface Finish (Ra) | 0.4 µm – 3.2 µm | ISO 1302 |

| Maximum Part Size | 1500 mm x 1200 mm x 500 mm | Customizable per project |

| Lead Time (Prototype) | 7–10 working days | Expedited options available |

| Lead Time (Production) | 15–20 working days | Volume-dependent scaling |

This precision is sustained through our ISO 9001-certified quality management system, featuring in-process CMM verification, first-article inspection reports, and material traceability to mill certificates. Unlike general fabricators, we preemptively address brass-specific challenges: controlled feed rates to prevent work hardening, specialized coolants to avoid staining, and non-marring handling protocols. Our engineering team collaborates from DFM review through final validation, reducing your time-to-market while mitigating scrap costs from material inconsistencies.

Choosing Lead Precision means aligning with a partner who treats your brass components as mission-critical assets. We absorb the technical risk of complex geometries and tight tolerances so you achieve flawless integration into final assemblies. Our facility in Wuxi operates under stringent environmental controls to maintain brass’s corrosion resistance and electrical properties—critical for defense and energy sector applications.

Initiate a technical dialogue that transforms your brass fabrication challenges into competitive advantages. Contact our engineering sales team directly at [email protected] with your drawings or specifications. We will provide a detailed capability assessment, material optimization recommendations, and a transparent project timeline within 24 business hours. For urgent RFQs, reference code BRASS-CTA to expedite processing. Let Lead Precision become your definitive solution for brass components where failure is not an option.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.