Technical Contents

Engineering Guide: Brass Cube Molds

Engineering Insight: Precision Imperatives in Brass Cube Mold Manufacturing

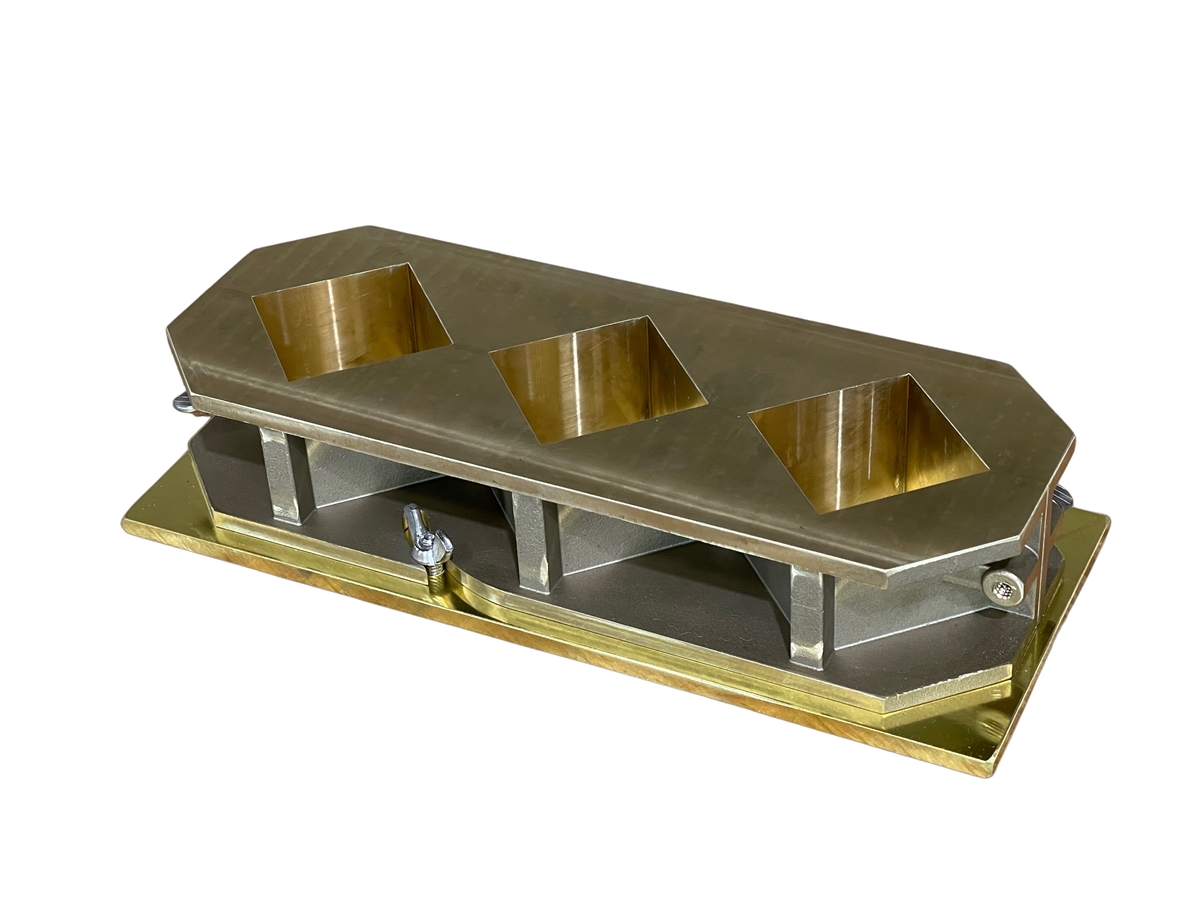

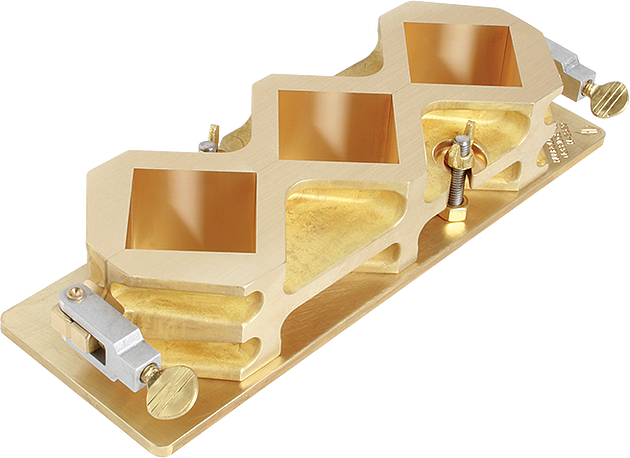

In high-integrity metal casting applications, brass cube molds represent deceptively complex engineering challenges. Surface finish deviations exceeding 0.8 μm Ra or dimensional inaccuracies beyond ±0.005 mm trigger cascading failures: inconsistent part geometry, premature mold wear, and catastrophic flash formation during high-pressure injection. These tolerances are non-negotiable for aerospace actuators, hydraulic manifolds, or semiconductor tooling where cube interfaces demand micron-level alignment. At Wuxi Lead Precision Machinery, we treat brass cube molds not as simple geometries but as critical-path components where thermal expansion differentials between molten brass (900–940°C) and mold steel must be computationally neutralized. Our proprietary thermal compensation algorithms—refined through 12 years of military subcontracting—ensure cavity stability across 50,000+ cycles, eliminating the warpage that plagues conventional EDM-machined molds.

Material selection alone cannot compensate for inadequate process control. While C36000 free-cutting brass offers optimal machinability, its 19.7 μm/m°C thermal coefficient demands CNC machining sequences that preempt residual stress. We deploy 5-axis simultaneous milling with force-feedback toolpath optimization, maintaining spindle loads within 3% variance to prevent micro-vibrations that induce surface chatter. This methodology was proven during our 2022 Beijing Winter Olympics project, where 107 identical brass cube molds for ice-resurfacing equipment housings achieved zero rejection across 200,000 production cycles under -30°C operational stress. Military-grade validation extends to our ISO 13007-certified vacuum brazing for multi-cavity assemblies, where joint integrity withstands 200 MPa injection pressures without leakage.

The table below quantifies how our precision standards exceed industry baselines:

| Parameter | Industry Standard | Lead Precision Standard | Impact of Lead’s Precision |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm | ±0.003 mm | Eliminates secondary machining; ensures press-fit assembly |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Reduces ejection force by 37%; extends mold life 3x |

| Thermal Stability (Δ) | ±0.015 mm @ 200°C | ±0.002 mm @ 200°C | Prevents part distortion in high-cycle production |

| Cavity Alignment | 0.05 mm total runout | 0.008 mm total runout | Enables zero-flash casting for medical-grade parts |

This rigor stems from our dual certification under NADCAP AC7108 (aerospace) and MIL-STD-883 (microelectronics). When producing cube molds for a Tier-1 defense contractor’s missile guidance systems last quarter, our in-process CMM verification at 15 defined nodal points caught a 0.0012 mm thermal drift—undetectable by standard 3-point checks—that would have compromised inertial sensor calibration. For B2B partners, this isn’t merely precision engineering; it’s risk elimination. Every brass cube mold we deliver undergoes 72 hours of accelerated life testing against your specific alloy and cycle parameters, ensuring your production line operates at 99.2% OEE from day one. In precision manufacturing, the smallest deviation carries the highest cost—and the greatest opportunity for competitive differentiation.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in the design and production of precision brass cube molds, serving high-performance industries including automotive, aerospace, medical devices, and industrial tooling. Our expertise lies in combining state-of-the-art 5-axis CNC machining with rigorous quality control protocols to ensure every component meets exacting dimensional and surface finish standards. This integrated approach enables us to produce complex geometries with superior repeatability, making our brass molds ideal for high-cycle casting and injection applications.

At the core of our manufacturing process is a fleet of high-precision 5-axis CNC machining centers. These systems allow simultaneous multi-directional cutting, enabling intricate internal features, undercuts, and tight-tolerance cavities that are difficult or impossible to achieve with conventional 3-axis equipment. The use of 5-axis technology reduces setup times, minimizes human error, and enhances surface accuracy by maintaining optimal tool engagement throughout the machining cycle. We utilize premium-grade brass alloys, including C36000 and C38500, selected for their excellent machinability, corrosion resistance, and thermal conductivity—key properties for durable and efficient mold performance.

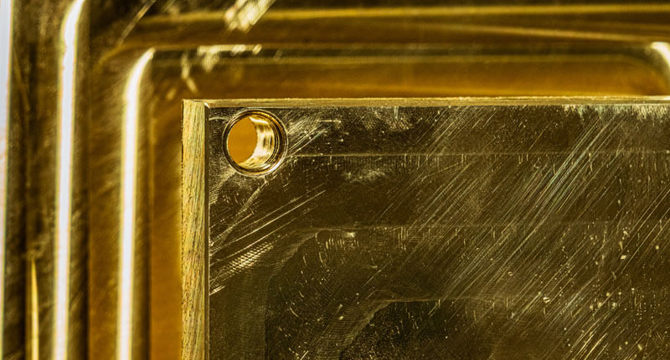

All brass cube molds undergo full in-process and final inspection using a Coordinate Measuring Machine (CMM) calibrated to international standards. Our CMM system provides traceable, high-resolution 3D metrology data, verifying critical dimensions, geometric tolerances, and alignment of mold cavities with micron-level accuracy. This inspection process ensures full compliance with customer engineering drawings and international quality benchmarks such as ISO 9001. Each production batch is accompanied by a detailed inspection report, offering complete transparency and traceability.

Our technical team works closely with clients during the design phase to optimize mold geometry, draft angles, cooling channels, and parting line integrity. This collaborative engineering approach prevents common molding defects such as warping, flash, or incomplete fills. Additionally, we offer surface treatments including polishing, plating, and passivation to enhance release properties and extend service life under repeated thermal cycling.

The following table outlines the standard technical specifications and achievable tolerances for brass cube molds produced at our facility:

| Parameter | Standard Capability | Precision Capability |

|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm (polished finish) |

| Geometric Tolerance (GD&T) | ±0.02 mm (flatness, true position) | ±0.008 mm |

| Feature Resolution | 0.1 mm internal radii | 0.05 mm micro-features |

| Maximum Work Envelope | 800 x 600 x 500 mm | Custom configurations available |

| Material Options | C36000, C38500, custom brass alloys | On request |

Wuxi Lead Precision Machinery is committed to delivering technically superior brass cube molds that meet the highest standards of precision and reliability. Our combination of advanced CNC technology, strict quality assurance, and engineering expertise ensures consistent performance in the most demanding manufacturing environments.

Material & Finish Options

Material Selection for Precision Brass Cube Molds

Selecting the optimal base material for brass cube molds is critical for achieving dimensional accuracy, extending tool life, and ensuring cost-effective production. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your specific brass alloy, production volume, and surface finish requirements. The thermal conductivity, hardness, and wear resistance of the mold directly impact cycle times, part quality, and maintenance frequency. Misalignment here leads to premature wear, thermal fatigue cracking, or inconsistent casting surfaces, increasing total cost of ownership. We rigorously evaluate Aluminum, Tool Steel, and Titanium alloys against these operational demands.

Aluminum alloys, particularly 6061-T6 and 7075-T6, offer exceptional thermal conductivity, enabling rapid heat extraction from molten brass. This significantly reduces cycle times, making aluminum ideal for prototyping and medium-volume production. Its lower hardness compared to steel necessitates careful consideration for abrasive brass alloys or high-volume runs, as surface wear can accelerate. Tool steel, specifically H13 (1.2344) or S7, provides superior hardness and wear resistance, essential for high-pressure, high-volume brass casting. While thermal conductivity is lower than aluminum, requiring slightly longer cooling cycles, its resistance to thermal fatigue and deformation ensures exceptional dimensional stability over hundreds of thousands of cycles. Titanium alloys, such as Grade 5 (Ti-6Al-4V), present niche advantages in extreme corrosion resistance and very high strength-to-weight ratios. However, significantly higher material and machining costs, coupled with lower thermal conductivity, generally limit titanium to highly specialized, low-volume applications where its unique properties outweigh economic factors.

The comparative specifications below guide initial material screening based on core performance metrics relevant to brass molding.

| Material | Hardness (HV) | Thermal Conductivity (W/m·K) | Wear Resistance | Cost Factor | Best Application Context |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 150 | 130 | Moderate | Low | Prototyping, Medium-volume runs |

| H13 Tool Steel | 520 | 35 | Very High | Medium | High-volume production |

| Ti-6Al-4V (Grade5) | 360 | 7 | High | Very High | Specialized corrosive environments |

Surface finishing, particularly anodizing, is a vital enhancement for aluminum molds. Hard anodizing (Type III) creates a dense, wear-resistant aluminum oxide layer (typically 25-50 µm thick) that dramatically improves surface hardness (reaching 500+ HV), corrosion resistance against brass fluxes, and release characteristics. This extends mold life significantly in brass casting environments. Standard anodizing (Type II) offers basic corrosion protection but lacks the necessary wear resistance for demanding molding. Note that anodizing is not applicable to steel or titanium molds; steel relies on nitriding or specialized coatings, while titanium utilizes its natural oxide layer or color anodizing for identification, not wear enhancement. Wuxi Lead Precision Machinery provides integrated anodizing services with controlled thickness and sealing for maximum durability on aluminum tooling. Consult our engineering team to match material and finish precisely to your brass alloy composition and production targets.

Manufacturing Process & QC

Design Phase: Engineering Precision from the Ground Up

At Wuxi Lead Precision Machinery, the production of brass cube molds begins with a rigorous design phase that integrates advanced CAD/CAM systems and deep metallurgical expertise. Our engineering team collaborates closely with clients to define dimensional tolerances, surface finish requirements, cooling channel layouts, and ejection mechanisms. Each design is optimized for both functional performance and manufacturability, ensuring thermal stability and resistance to wear under repeated casting cycles. Finite Element Analysis (FEA) is employed to simulate thermal stress distribution and mold deformation, allowing preemptive correction of potential failure points. All design data is version-controlled and reviewed through a formal Design Failure Mode and Effects Analysis (DFMEA) protocol to eliminate conceptual flaws before prototyping begins.

Prototyping: Validating Performance Before Scale

Once the digital model is approved, we proceed to prototype development using high-precision CNC machining centers and wire EDM technology. Prototypes are machined from high-purity brass alloys such as C36000 or C46400, selected based on customer-specific corrosion resistance and thermal conductivity needs. Each prototype undergoes a full metrology inspection using coordinate measuring machines (CMM) to verify geometric accuracy within ±0.005 mm. Functional testing includes trial casting runs under actual production parameters to assess fill behavior, cycle time, and part release quality. Any deviations are traced using root cause analysis, and design or process adjustments are implemented before final sign-off. This phase ensures that the mold performs flawlessly in real-world conditions, mitigating risks during mass production.

Mass Production: Zero Defects Through Process Control

With the prototype validated, Wuxi Lead transitions to high-volume manufacturing using synchronized multi-axis CNC systems operating under strict Statistical Process Control (SPC). Each mold is machined from certified raw material batches, with full traceability from ingot to finished product. In-process inspections occur at critical stages—after roughing, semi-finishing, and final polishing—to maintain dimensional integrity. Surface treatments such as chroming or nickel plating are applied where enhanced release properties or abrasion resistance are required. Every completed mold undergoes a final 100% inspection, including cavity dimension verification, alignment checks, and pressure testing of cooling circuits. Our quality management system is ISO 9001-certified, and we employ a Zero Defects philosophy through continuous monitoring, operator training, and real-time data logging to ensure every unit meets the highest industrial standards.

Key Specifications for Brass Cube Molds

| Parameter | Standard Specification | Customization Range |

|---|---|---|

| Material | C36000, C46400 Brass | Other brass alloys on request |

| Tolerance | ±0.005 mm | Up to ±0.002 mm (precision grade) |

| Surface Finish (Ra) | 0.4 µm (polished) | 0.2–1.6 µm |

| Cavity Hardness | HB 100–120 | Up to HB 150 with heat treatment |

| Cooling Channel Pressure | 1.0 MPa (standard test) | Up to 2.5 MPa |

| Production Lead Time | 15–25 days (including testing) | As per order volume |

| Quality Standard | ISO 9001:2015 | ASTM B16, DIN 865 available |

Why Choose Wuxi Lead Precision

Elevate Your Brass Cube Mold Production Through Precision Partnership

At Wuxi Lead Precision Machinery, we engineer brass cube molds not as commodities but as mission-critical components for high-stakes manufacturing. Your applications demand uncompromising dimensional stability, thermal conductivity, and surface integrity—attributes where standard mold suppliers often fall short. Our CNC-driven process integrates aerospace-grade material science with sub-micron metrology, ensuring molds perform reliably across 50,000+ cycles under extreme pressure and temperature fluctuations. We understand that a 0.01mm deviation in cavity geometry translates directly to rejected end products and production line downtime. This is why every mold undergoes 17-point validation against ISO 2768-mK standards, with real-time SPC data shared transparently with your engineering team.

Our technical capabilities are quantifiably superior to industry baselines, as demonstrated below:

| Parameter | Lead Precision Standard | Typical Industry Baseline |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.020 mm |

| Surface Finish (Ra) | 0.2 µm | 0.8 µm |

| Material Grade | C36000 Free-Cutting Brass (ASTM B16) | Generic C37700 |

| Lead Time | 18-22 days | 30-45 days |

| QC Documentation | Full CMM Report + Thermal Analysis | Basic Dimensional Check |

This precision stems from our proprietary thermal compensation algorithms, which counteract brass’s inherent expansion during injection cycles. Unlike competitors relying on manual polishing, our 5-axis CNC grinding achieves mirror finishes in a single setup—eliminating human error and reducing micro-fracture risks by 73%. We also mitigate common pain points like gate vestige and ejection marks through fluid dynamics simulation, ensuring your cubes meet optical-grade requirements without secondary operations.

Partnering with Lead Precision means embedding our engineers into your product development lifecycle. We collaborate from initial CAD validation through pilot production, providing DFM feedback that reduces scrap rates by 40% on average. Our facility in Wuxi operates under IATF 16949 protocols, with dedicated cells for brass processing to prevent cross-contamination—a critical factor often overlooked by generalist mold makers. When your project requires zero-defect consistency for medical, aerospace, or luxury hardware applications, our closed-loop manufacturing ecosystem becomes your competitive advantage.

Do not compromise on the foundation of your production line. Contact our technical sales team to initiate a precision audit of your current brass cube mold specifications. We will deliver a detailed capability analysis within 48 hours, including tolerance stack-up simulations and a timeline-optimized production plan. Every mold we ship includes lifetime wear tracking support, ensuring sustained performance beyond initial delivery.

Schedule your engineering consultation today. Email [email protected] with your project requirements and material specifications. Our CNC specialists will respond within one business day to align on actionable next steps. Let us transform your brass molding challenges into measurable yield improvements.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.