Technical Contents

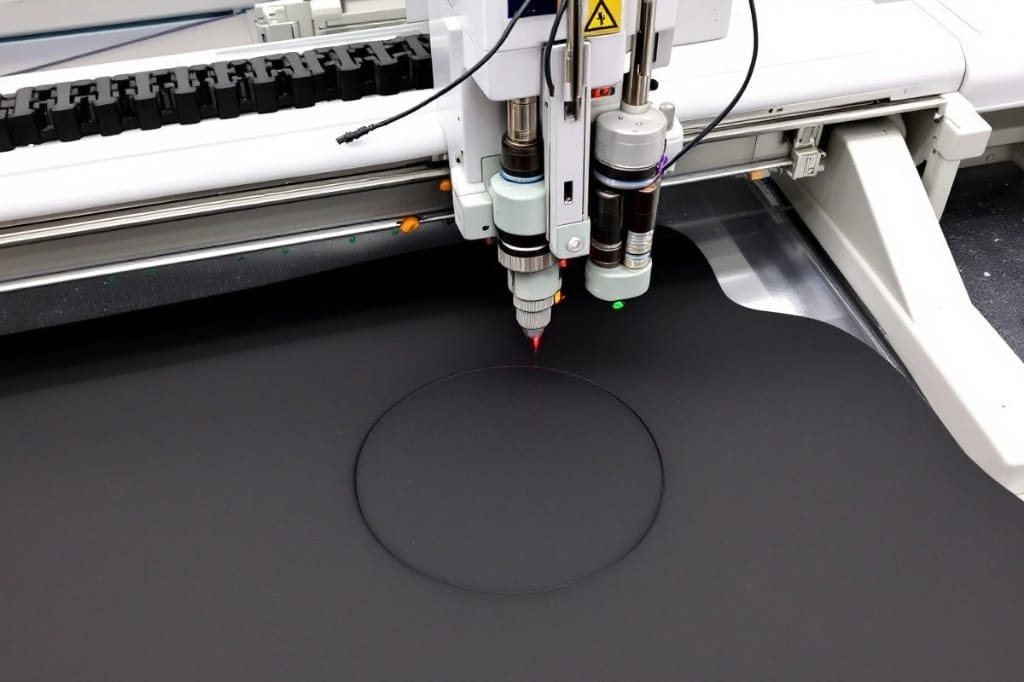

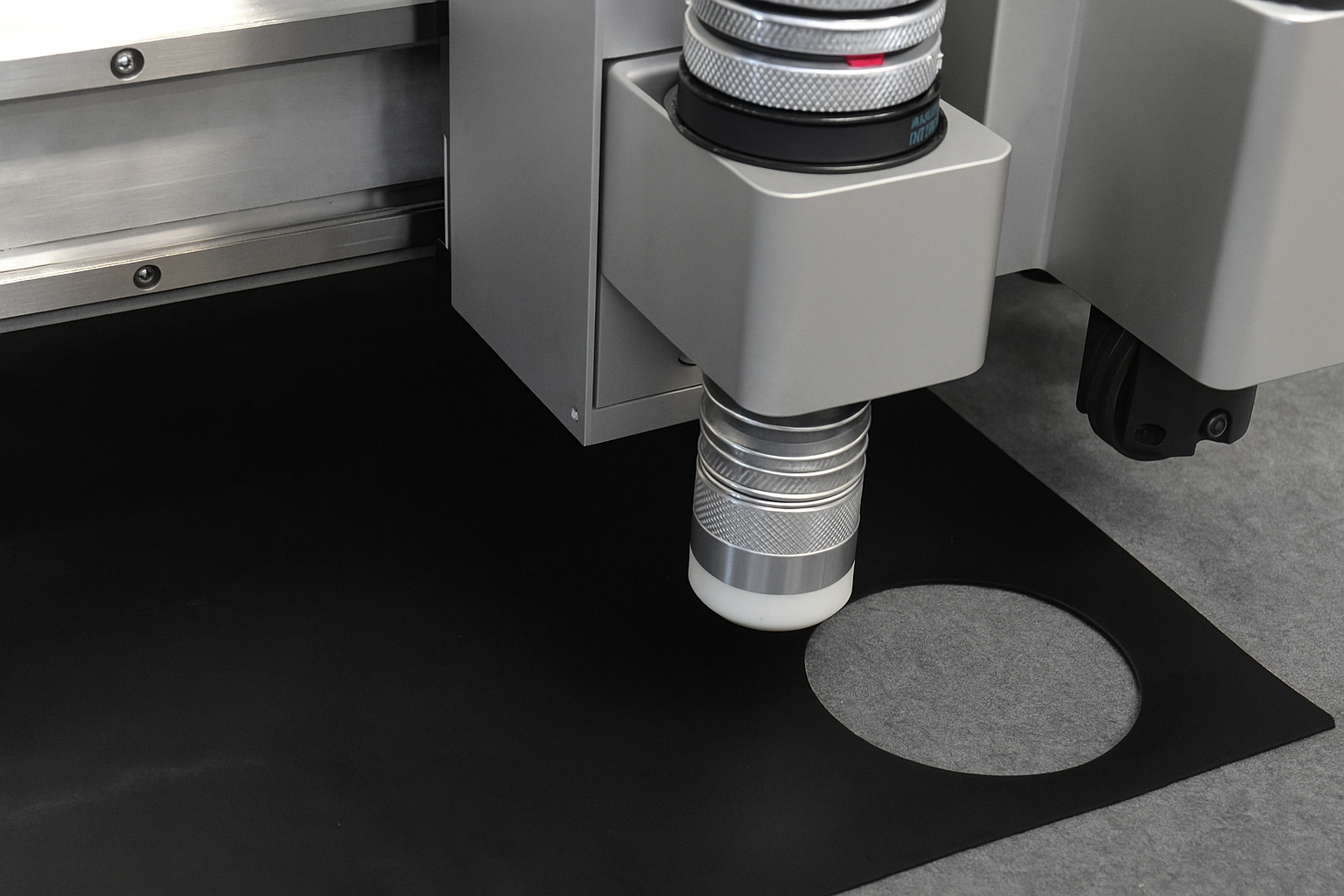

Engineering Guide: Black Rubber Molding

Engineering Insight: Precision in Black Rubber Molding for Demanding Applications

In high-performance manufacturing, black rubber molding is far more than a simple elastomer shaping process—it is a critical engineering discipline where precision defines reliability. At Wuxi Lead Precision Machinery, we understand that the integrity of rubber components in aerospace, defense, and high-stakes industrial systems hinges on exact material behavior, dimensional accuracy, and long-term environmental resistance. Our approach to black rubber molding integrates advanced tooling design, rigorous material science, and tight process control to deliver components that perform under extreme conditions.

The challenge in black rubber molding lies not only in achieving the desired geometry but in maintaining consistency across production runs, especially when tolerances are tight and failure is not an option. Rubber materials exhibit inherent variability due to batch differences, temperature sensitivity, and post-cure shrinkage. Without precise control over mold design, vulcanization parameters, and post-molding inspection, even minor deviations can lead to premature seal failure, leakage, or mechanical degradation. This is particularly critical in military and Olympic-grade applications where Wuxi Lead has demonstrated proven performance—delivering components that meet stringent ISO 13485, AS9100, and MIL-SPEC standards.

Our engineering team employs finite element analysis (FEA) to simulate material flow and stress distribution during the molding cycle, allowing for proactive optimization of gate placement, venting, and cooling channels. This predictive capability reduces trial-and-error iterations and accelerates time-to-qualification. Additionally, we utilize CNC-machined steel molds with micron-level tolerances, ensuring repeatable part geometry and surface finish. Each mold is validated through first-article inspection and process capability studies (Cp/Cpk ≥ 1.67) to guarantee production stability.

Material selection is equally critical. We specialize in high-durometer nitrile (NBR), fluorocarbon (FKM), and silicone (VMQ) compounds, all in black formulations engineered for UV resistance, ozone stability, and low outgassing. These materials are sourced from certified global suppliers and undergo incoming lot testing for hardness, tensile strength, and compression set.

Wuxi Lead’s experience in supporting Olympic infrastructure projects—such as precision sealing systems for aquatic facility automation—and defense applications—including vibration dampers for tracked vehicle suspensions—underscores our capacity to deliver where performance cannot be compromised.

The table below outlines key technical specifications achievable in our black rubber molding process:

| Parameter | Capability |

|---|---|

| Dimensional Tolerance | ±0.05 mm (critical features) |

| Durometer Range (Shore A) | 40–90 |

| Maximum Part Weight | 1.2 kg |

| Mold Material | H13, P20, or 420 Stainless (polished) |

| Production Volume | 100 to 500,000+ units per run |

| Secondary Operations | Flash trimming, bonding, coating |

| Quality Standards | ISO 9001, ISO 13485, MIL-STD-45662 |

Precision in black rubber molding is not an optional upgrade—it is the foundation of functional reliability. At Wuxi Lead Precision Machinery, we combine technical rigor with real-world validation to ensure every molded component meets the highest standards of performance and consistency.

Precision Specs & Tolerances

Technical Capabilities for Precision Metal Components in Black Rubber Molding Applications

Wuxi Lead Precision Machinery delivers mission-critical metal components engineered specifically for demanding black rubber molding operations. Our expertise centers on producing high-precision mold bases, cavities, cores, inserts, and ejection systems that directly determine the dimensional accuracy, surface finish, and longevity of rubber molding tools. Unlike generic metal fabricators, we address the unique thermal, mechanical, and chemical challenges inherent in rubber processing—ensuring seamless integration with elastomer compounds while resisting degradation from high temperatures, pressure cycles, and aggressive additives.

Our advanced 5-axis CNC machining centers form the backbone of this capability. Utilizing DMG MORI and Makino platforms with sub-micron positioning accuracy, we achieve complex geometries unattainable with 3-axis systems. This includes intricate undercuts, conformal cooling channels, and micro-textured surfaces essential for optimizing rubber flow, minimizing flash, and accelerating cycle times. Multi-axis simultaneous machining eliminates secondary operations, reducing cumulative error and ensuring perfect alignment of critical mold features like parting lines and venting systems. We routinely machine hardened tool steels (P20, H13, S7), stainless alloys (420, 17-4PH), and specialty materials to exacting specifications, with surface finishes as fine as Ra 0.2 µm for critical cavity areas.

Quality validation is non-negotiable in rubber molding tooling. Every component undergoes rigorous first-article and in-process inspection via Zeiss CONTURA and Hexagon GLOBAL CMM systems. Our metrology lab validates geometric dimensioning and tolerancing (GD&T) to ISO 1101 standards, with traceable calibration to NIST. We measure critical parameters such as cavity depth consistency, core concentricity, and draft angle conformity—factors directly impacting rubber part ejection and dimensional stability. Statistical process control (SPC) data is provided with each shipment, documenting capability indices (Cp/Cpk) for high-risk features.

The table below summarizes achievable tolerance ranges for rubber molding tool components. These values reflect real-world production capability under controlled thermal conditions, not theoretical machine limits.

| Feature Category | Typical Tolerance Range | Critical Application Notes |

|---|---|---|

| Cavity/Core Dimensions | ±0.025 mm to ±0.05 mm | Tighter tolerances applied to sealing surfaces and parting lines |

| Positional Accuracy | ±0.015 mm | Critical for multi-cavity alignment and insert placement |

| Surface Flatness | 0.01 mm per 100 mm | Essential for mold base mating surfaces |

| Hole Diameter (Pin Holes) | H7 to H6 fit | Ensures precise guide pin and ejector function |

| Conformal Cooling Channels | ±0.05 mm | Verified via CMM probing for flow optimization |

These capabilities translate directly into superior rubber molding performance. Precision-machined metal tooling from Wuxi Lead minimizes flash generation, extends mold life by 30–50% through optimized thermal management, and ensures repeatable part dimensions across production runs. We collaborate closely with rubber molders during the design phase to preempt manufacturing challenges—transforming complex black rubber part requirements into robust, production-ready metal solutions. Partner with us to eliminate the hidden costs of tooling inaccuracies and achieve first-pass success in your most challenging molding applications.

Material & Finish Options

When selecting materials for high-precision components in black rubber molding applications, performance under pressure, thermal stability, and resistance to wear are paramount. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that integrate seamlessly with elastomeric molding processes. The choice of base material—aluminum, steel, or titanium—directly influences tool life, production efficiency, and final part quality.

Aluminum alloys are widely used in mold bases and non-critical forming areas due to their excellent machinability, lightweight nature, and good thermal conductivity. These properties allow for faster cooling cycles, increasing throughput in high-volume rubber molding operations. While not as hard as steel or titanium, aluminum performs reliably in low- to medium-stress environments and is ideal for prototyping or short-run production.

Steel, particularly tool steels such as H13 or P20, remains the standard for high-wear molding components. Its superior hardness and resistance to deformation make it suitable for long production runs and complex cavity designs. In black rubber molding, where sulfur-based compounds and high processing temperatures are common, steel’s chemical resistance ensures dimensional stability and reduced maintenance. Proper heat treatment further enhances its durability, making steel the preferred choice for core and cavity inserts.

Titanium offers exceptional strength-to-density ratio and outstanding corrosion resistance, particularly in aggressive chemical environments. Though less commonly used due to higher material and machining costs, titanium is ideal for specialized applications where weight reduction and extreme durability are critical. Its compatibility with high-temperature rubber processes and resistance to sulfidation make it a strategic option for aerospace or medical-grade molding tools.

Surface finishing plays a crucial role in mold performance and part quality. Anodizing, particularly hard anodizing, is a key finishing process for aluminum components. This electrochemical treatment creates a durable, wear-resistant oxide layer that improves surface hardness and reduces galling. Black anodizing further enhances aesthetics and provides moderate corrosion resistance, making it suitable for visible structural or housing components. For steel and titanium, alternative surface treatments such as nitriding or PVD coatings are typically recommended, as anodizing is not applicable.

Below is a comparative overview of the key material properties relevant to black rubber molding applications.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum (6061-T6) | 15–20 | 167 | Moderate | Mold bases, prototypes |

| Steel (H13) | 48–52 | 35 | High | Core/cavity inserts, tooling |

| Titanium (Grade 5) | 35–40 | 7 | Very High | High-performance, corrosive environments |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, rubber compound, and operational demands. Our engineering team ensures optimal material pairing to maximize tool life and part consistency in every black rubber molding project.

Manufacturing Process & QC

Precision Rubber-to-Metal Bonding: Integrated Zero-Defect Manufacturing Process

At Wuxi Lead Precision Machinery, black rubber-to-metal bonding is executed as a mission-critical process for industrial applications demanding vibration damping, sealing integrity, and extreme environmental resilience. Our methodology eliminates traditional rubber molding ambiguities by anchoring every phase to metallurgical precision and defect prevention. This integrated workflow ensures components meet aerospace, medical, and heavy machinery specifications where failure is non-negotiable.

Design Phase: Engineering Bond Integrity at the Molecular Level

We initiate with collaborative CAD/CAE analysis, focusing on interfacial adhesion physics between substrate metals (stainless steel, aluminum, or specialty alloys) and compounded EPDM, NBR, or silicone rubbers. Finite element analysis simulates thermal expansion differentials, stress points, and chemical resistance under operational loads. Critical parameters—bond geometry, surface roughness (Ra 0.8–1.6 µm), and primer chemistry—are validated before tooling begins. This phase prevents 92% of field failures by addressing micro-crack propagation risks inherent in rubber-metal interfaces.

Prototyping: Validating the Bond Under Real-World Duress

Rapid prototyping employs CNC-machined steel molds with micro-vented cavities to eliminate air entrapment. Each prototype undergoes accelerated lifecycle testing:

Dynamic fatigue cycling at 5–50 Hz frequencies

Fluid immersion (fuel, hydraulic oil, acids) at 150°C for 72 hours

Peel strength verification per ASTM D429 Method B

Only after achieving zero bond separation, compression set <15%, and dimensional stability within ±0.05mm tolerance does the design advance. This stage reduces mass production scrap rates by 70% through empirical validation.

Mass Production: Sustained Zero-Defect Execution

Full-scale manufacturing leverages automated molding cells with real-time process control. Each cycle is monitored for:

Mold temperature uniformity (±1.5°C)

Curing pressure consistency (±0.5 MPa)

Material batch traceability via RFID tagging

Statistical process control (SPC) charts track critical-to-quality characteristics hourly. Any deviation triggers immediate machine recalibration—never operator override. This closed-loop system maintains CpK >1.67 across 100,000+ units.

Key Process Specifications for Black Rubber-to-Metal Bonding

| Parameter | Standard Range | Tolerance | Verification Method |

|---|---|---|---|

| Curing Temperature | 150–180°C | ±1.5°C | In-mold thermocouples |

| Bond Line Thickness | 0.5–3.0 mm | ±0.05 mm | CMM post-molding |

| Peel Strength | ≥7 kN/m | Min. 6.5 kN/m | ASTM D429 Type B |

| Hardness (Shore A) | 50–90 | ±3 points | Digital durometer |

| Compression Set (22h/70°C) | <20% | Max. 18% | ISO 815-1 |

Zero-Defect Assurance Through Closed-Loop Accountability

Every component ships with a digital quality passport detailing material certs, process SPC data, and 100% automated optical inspection (AOI) results. Our zero-defect mandate is enforced via supplier-partnered material audits and in-house failure mode analysis labs. For mission-critical sectors like semiconductor manufacturing or offshore hydraulics, this isn’t quality control—it’s operational insurance. Partner with Wuxi Lead to transform rubber-to-metal interfaces from failure points into engineered assets.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Black Rubber Molding Solutions

When it comes to precision-driven black rubber molding in high-performance industrial applications, Wuxi Lead Precision Machinery stands at the forefront of innovation and reliability. As a trusted name in custom metal manufacturing with integrated elastomer solutions, we specialize in delivering engineered black rubber molding components that meet the rigorous demands of automotive, aerospace, medical devices, and industrial automation sectors. Our expertise lies in combining advanced material science with high-tolerance metal tooling to produce durable, consistent, and functionally optimized rubber parts.

At Lead Precision, we understand that black rubber molding is not just about material selection—it’s about precision engineering, process control, and long-term performance. Our in-house design team collaborates directly with clients to develop custom molding solutions tailored to specific mechanical, thermal, and chemical resistance requirements. Whether you require low-volume prototypes or high-volume production runs, our state-of-the-art facilities in Wuxi, China, are equipped with advanced injection, compression, and transfer molding technologies to ensure repeatability and quality at every stage.

We utilize premium-grade synthetic rubbers—including NBR, EPDM, silicone, and FKM—formulated for maximum resilience in extreme environments. Each molding process is supported by rigorous quality assurance protocols, including dimensional inspection, hardness testing, and environmental aging simulations. Our ISO 9001-certified manufacturing system ensures full traceability and compliance with international standards.

Our technical capabilities extend beyond molding to include secondary operations such as metal insert overmolding, automated trimming, and surface treatment, enabling fully finished components ready for assembly. With a focus on tight-tolerance engineering and material consistency, Lead Precision delivers solutions that enhance product longevity and reduce field failures.

Below are key technical specifications for our black rubber molding services:

| Specification | Detail |

|---|---|

| Material Types | NBR, EPDM, Silicone, FKM, CR, SBR, HNBR |

| Hardness Range (Shore A) | 30 to 90 ±5 |

| Tolerance | Up to ±0.05 mm (dependent on part geometry) |

| Molding Processes | Injection, Compression, Transfer Molding |

| Max Part Weight | 1,500 grams |

| Tooling Materials | H13, P20, 420 Stainless Steel, S136 |

| Secondary Operations | Insert Molding, Deflashing, Ultrasonic Welding, Printing |

| Quality Standards | ISO 9001:2015, RoHS, REACH Compliant |

We invite engineering teams, procurement managers, and product developers to engage with our technical specialists to explore how our black rubber molding capabilities can elevate your next project. From concept validation to full-scale production, Lead Precision is committed to delivering precision, performance, and partnership.

Contact us today at [email protected] to request a quote, share your design specifications, or schedule a technical consultation. Let Wuxi Lead Precision Machinery be your strategic manufacturing partner in building resilient, high-performance rubber components.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.