Technical Contents

Engineering Guide: Black Molding

Engineering Insight Precision Imperatives in Black Molding for Mission-Critical Components

Black molding, specifically referring to precision-engineered black oxide coating processes for metal components, transcends mere aesthetic finish in high-stakes industrial applications. It represents a critical functional surface treatment where dimensional integrity, material consistency, and process control directly dictate component performance, longevity, and reliability. At Wuxi Lead Precision Machinery, we understand that superficial application fails under demanding conditions; true black molding excellence is born from uncompromising precision engineering at every stage, from substrate preparation to final inspection. Deviations in base material flatness, surface roughness, or geometric tolerances propagate through the coating process, leading to inconsistent thickness, compromised corrosion resistance, adhesion failure, or interference in precision assemblies. This is unacceptable for sectors where failure is not an option.

The core challenge lies in maintaining micron-level dimensional stability while achieving the required chemical conversion coating. Variations in part geometry or surface topography cause uneven chemical reaction rates, resulting in non-uniform black oxide layers. This inconsistency directly impacts critical performance metrics like corrosion resistance and electrical conductivity. Furthermore, inadequate control over pre-treatment cleaning and activation steps leaves microscopic contaminants, creating weak points for coating delamination under thermal cycling or mechanical stress. Precision machining must therefore deliver not only the nominal part geometry but also the exact surface condition required for optimal coating adhesion and uniformity. Tolerances specified on the print are merely the starting point; the true engineering rigor involves ensuring the substrate surface is perfectly conditioned to accept and retain the coating within the tightest possible process windows.

Our commitment to this precision is validated through stringent internal protocols exceeding standard industry benchmarks. The table below outlines key parameters where our process control delivers measurable superiority for demanding black molding applications.

| Parameter | Industry Standard Range | Wuxi Lead Precision Specification | Verification Method |

|---|---|---|---|

| Surface Roughness (Ra) | 0.8 – 1.6 µm | ≤ 0.4 µm (Post-Machining) | profilometer (ISO 4287) |

| Coating Thickness | 0.5 – 2.5 µm | 1.0 ± 0.2 µm | Cross-section SEM/EDS |

| Dimensional Shift | ±0.01 mm | ≤ ±0.003 mm | CMM (ISO 10360-2) |

| Salt Spray Resistance | 96 – 120 hours | ≥ 240 hours (ASTM B117) | ASTM B117 |

| Adhesion | Pass Tape Test | Zero Flaking (Cross-hatch) | ASTM D3359 |

This level of control is non-negotiable for the aerospace, defense, and high-performance sporting goods sectors we serve. Our proven capability is demonstrated through components manufactured for Olympic-caliber equipment demanding absolute reliability under extreme conditions and critical subsystems meeting stringent military specifications where environmental resilience is paramount. Wuxi Lead Precision Machinery integrates advanced CNC machining, real-time process monitoring, and rigorous metrology specifically calibrated for coated component validation. We don’t just apply black molding; we engineer the substrate and control the entire process chain to ensure the final coated part meets the exacting functional requirements of your most demanding applications. Precision isn’t a step in our process—it is the foundation.

Precision Specs & Tolerances

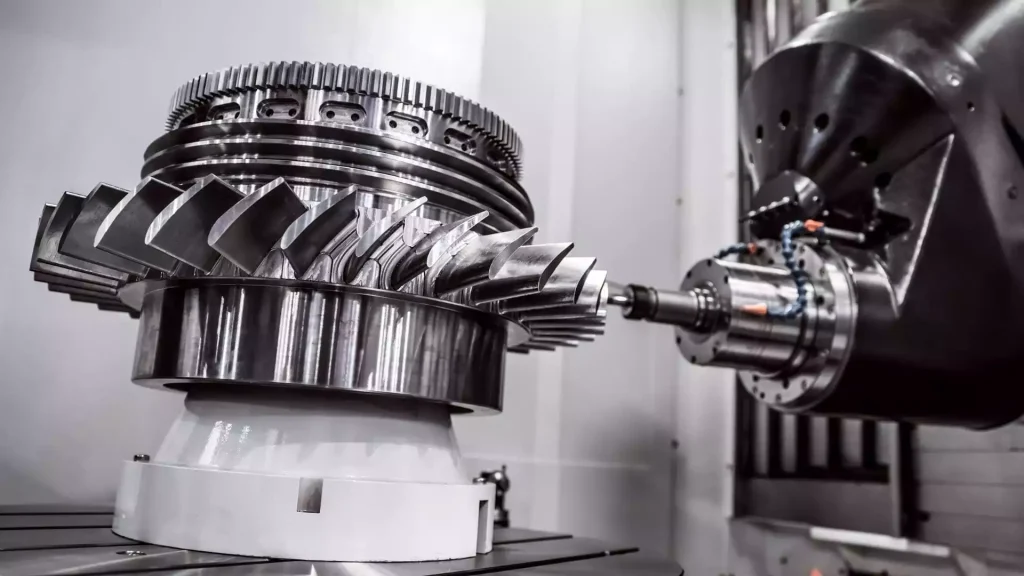

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to meet the demanding requirements of high-precision industries such as aerospace, medical, automotive, and industrial automation. At the core of our production system is our 5-axis CNC machining technology, which enables us to produce complex geometries with exceptional accuracy and surface consistency. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five axes, minimizing setup cycles and enabling single-operation completion of intricate components. This capability significantly enhances part integrity, reduces lead times, and ensures repeatability across production batches.

Our machining centers are equipped with high-speed spindles, automatic tool changers, and real-time tool wear compensation systems, ensuring consistent performance during extended production runs. We work with a broad range of engineering metals, including aluminum alloys, stainless steel, titanium, and high-temperature superalloys, tailored to the functional and environmental demands of the end application. Each machining process is supported by advanced CAM programming and simulation software, ensuring optimal toolpaths, material removal rates, and collision avoidance.

Quality assurance is integrated at every stage of production. All critical components undergo comprehensive inspection using our Coordinate Measuring Machine (CMM) system, which provides micron-level verification of dimensional accuracy and geometric conformity. The CMM inspection process is fully programmable and repeatable, allowing us to validate first articles, conduct in-process checks, and perform final batch certification. Data from each inspection is documented and archived, providing full traceability and compliance with ISO 9001 and customer-specific quality standards.

Our technical team combines deep manufacturing expertise with engineering insight, enabling us to support clients from design for manufacturability (DFM) through to full-scale production. We specialize in low-to-medium volume runs where precision, reliability, and material performance are paramount. Our facility in Wuxi is equipped with climate-controlled environments for both machining and inspection, minimizing thermal drift and ensuring measurement stability.

The following table outlines the standard technical specifications and tolerances achievable through our 5-axis CNC and quality inspection processes:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Positional Tolerance | ±0.025 mm | ±0.010 mm |

| Linear Dimensional Tolerance | ±0.03 mm | ±0.012 mm |

| Geometric Tolerance (GD&T) | ±0.02 mm (Profile, Position) | ±0.008 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm (polished finishes) |

| Feature Size Resolution | 0.1 mm (internal features) | 0.05 mm (micro-machining) |

| Maximum Work Envelope | 1200 x 800 x 600 mm | Custom fixturing available |

| Inspection Accuracy (CMM) | ±(2.5 + L/300) µm | Calibrated to ISO 10360 |

These capabilities reflect our commitment to precision, consistency, and technical excellence in every component we manufacture.

Material & Finish Options

Material Selection for Precision Black Molding Applications

Selecting the optimal material for black molding components is critical to achieving both functional performance and aesthetic integrity in high-end manufacturing. At Wuxi Lead Precision Machinery, our CNC processes demand materials that balance machinability, durability, and compatibility with black finishes like anodizing. Aluminum, steel, and titanium each offer distinct advantages but require careful evaluation against application-specific loads, environmental exposure, and finish requirements. Misalignment here risks premature wear, finish adhesion failure, or dimensional instability under operational stress.

Aluminum alloys, particularly 6061-T6 and 7075-T6, dominate black molding applications due to their exceptional machinability, lightweight nature, and perfect synergy with anodizing. Hard anodizing creates a dense, wear-resistant black oxide layer integral to the substrate, providing superior corrosion resistance without dimensional shift. This makes aluminum ideal for aerospace brackets, consumer electronics housings, and medical device components where weight savings and consistent matte-black aesthetics are non-negotiable.

Carbon and stainless steels (e.g., 304, 316, 4140) deliver unmatched strength and thermal stability for high-load black molding scenarios. However, steel cannot undergo true anodizing. Achieving a black finish requires alternatives like black oxide coating, PVD, or powder coating, which sit on the surface rather than integrating with it. This introduces potential adhesion risks under extreme vibration or temperature cycling. Steel remains the prudent choice for hydraulic manifolds, automotive drivetrain parts, or tooling fixtures where mechanical robustness outweighs finish integration concerns.

Titanium Grade 5 (Ti-6Al-4V) excels in corrosive or high-temperature environments like marine or aerospace systems. While titanium can be anodized for color, achieving a true black finish is impractical; PVD coatings are typically specified. Its high cost and challenging machinability necessitate justification through extreme operational demands where aluminum or steel would fail.

Material Comparison for Black Molding

| Material | Key Properties | Anodizing Suitability | Best Applications |

|---|---|---|---|

| Aluminum 6061-T6 | Lightweight, excellent machinability, good corrosion resistance | Ideal for hard black anodizing | Consumer electronics, drone components, medical enclosures |

| Stainless Steel 316 | High strength, superior corrosion resistance, heat tolerant | Not applicable; requires black oxide/PVD | Marine hardware, chemical processing parts, surgical instruments |

| Titanium Ti-6Al-4V | Extreme strength-to-weight, biocompatible, exceptional corrosion resistance | Limited to colored anodizing; black requires PVD | Aerospace actuators, implantable medical devices, deep-sea components |

The finish method directly impacts material selection. Hard anodizing for black finishes is exclusively viable for aluminum, creating a monolithic, abrasion-resistant surface. Steel and titanium demand supplementary coatings, adding process complexity and potential failure points. Always prioritize the operational environment: if salt spray resistance is critical, anodized aluminum outperforms coated steel. For parts enduring >300°C, titanium or specialized steel coatings may be mandatory. Consult our engineering team early to align material properties, CNC tolerances, and finish specifications—ensuring your black molding components perform flawlessly from prototype to volume production.

Manufacturing Process & QC

The production process for black molding at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to deliver zero-defect components for high-end industrial applications. Rooted in precision engineering and advanced quality control, our methodology spans three core phases: Design, Prototyping, and Mass Production. Each stage is governed by stringent standards to ensure dimensional accuracy, material integrity, and long-term performance under demanding operational conditions.

Design begins with a comprehensive analysis of the client’s technical specifications, environmental requirements, and functional objectives. Our engineering team utilizes advanced CAD/CAM software to model the black molding components, integrating thermal, stress, and flow simulations to optimize geometry and material behavior. Special attention is given to surface finish, tolerance bands, and corrosion resistance—critical parameters for black oxide or black-coated metal parts used in automotive, aerospace, and medical systems. Design for manufacturability (DFM) reviews are conducted in-house to preempt production challenges and ensure seamless transition to prototyping.

Prototyping serves as the validation phase, where initial components are produced using the same tooling and materials intended for mass production. At Wuxi Lead, we employ CNC machining, precision stamping, or die casting—depending on the part complexity and volume requirements—to fabricate functional prototypes. These are subjected to rigorous metrology testing, including CMM (Coordinate Measuring Machine) inspection, salt spray testing for coating durability, and micro-hardness evaluation. Any deviations are traced back to the design or process parameters and corrected before approval. Client feedback is integrated at this stage to ensure full alignment with performance expectations.

Mass production is executed on automated, high-repeatability lines with real-time SPC (Statistical Process Control) monitoring. Each batch undergoes 100% visual inspection and automated defect detection using optical scanning systems. Our zero-defect philosophy is enforced through ISO 9001-certified quality management protocols, with traceability maintained at the serial level. In-process audits and final QA checks ensure conformity to the highest standards before shipment.

The following table outlines key specifications and capabilities for black molding production at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel, Aluminum, Carbon Steel, Alloy Steel |

| Surface Finish | Black Oxide, Electrophoretic Coating, Powder Coat |

| Tolerance Range | ±0.005 mm to ±0.05 mm (depending on process) |

| Production Processes | CNC Machining, Stamping, Die Casting, Molding |

| Coating Thickness | 5–25 µm (adjustable per requirement) |

| Quality Standards | ISO 9001, IATF 16949, RoHS Compliant |

| Lead Time (Prototype) | 7–15 days |

| Lead Time (Mass Production) | 20–45 days (based on order volume) |

| Inspection Equipment | CMM, Optical Comparator, Salt Spray Tester, Hardness Tester |

Through tightly integrated design, validation, and production systems, Wuxi Lead Precision Machinery ensures that every black molding component meets the uncompromising demands of modern industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Definitive Black Molding Solutions

In high-performance industries like aerospace, medical device manufacturing, and precision instrumentation, the integrity of surface treatments is non-negotiable. Standard black oxide processes often fail to deliver consistent corrosion resistance, dimensional stability, or aesthetic uniformity—resulting in field failures, rework costs, and compromised brand reputation. At Wuxi Lead Precision Machinery, we engineer black molding not as a commodity finish, but as a mission-critical component of your product lifecycle. Our integrated approach combines military-grade process control with ISO 9001-certified CNC manufacturing, ensuring every part meets exacting functional and cosmetic specifications.

Our black molding process transcends conventional methods through proprietary chemical formulations and real-time environmental monitoring. We eliminate batch variations by controlling bath chemistry within ±0.5% tolerance and maintaining temperature stability at ±1°C. This precision guarantees repeatable matte-black finishes with zero dimensional drift on features as tight as ±0.005mm. Unlike competitors who outsource surface treatment, we manage the entire workflow in-house—from CNC machining to final inspection—preventing supply chain vulnerabilities and ensuring seamless traceability from raw material to finished component.

The technical superiority of our black molding is validated through rigorous industry-standard testing. Below are key performance metrics consistently achieved across client projects:

| Parameter | Specification | Industry Standard | Relevance |

|---|---|---|---|

| Coating Thickness | 0.7–1.0 μm | MIL-DTL-13924 | Prevents peeling on micro-features |

| Salt Spray Resistance | 96+ hours | ASTM B117 | Validates corrosion protection |

| Dimensional Shift | ≤ ±0.002 mm | ISO 2768-mK | Critical for press-fit assemblies |

| Surface Roughness | Ra 0.4–0.8 μm | ISO 1302 | Ensures uniform light absorption |

| RoHS Compliance | Fully compliant | Directive 2011/65/EU | Mandatory for global markets |

This level of control is why leading medical OEMs specify Lead Precision for surgical instrument blackening and defense contractors trust us for radar-absorbing components. We do not merely apply coatings; we solve root-cause challenges like hydrogen embrittlement in high-strength steels or thermal stability in titanium alloys through material-science-driven process design.

Your next project demands more than a vendor—it requires a precision engineering partner who treats your specifications as inviolable. Submit your technical requirements to [email protected] with the subject line Black Molding Validation Request. Our applications engineering team will respond within 4 business hours with a process capability analysis tailored to your component geometry, material grade, and performance criteria. Include dimensional drawings and environmental exposure requirements to receive a guaranteed conformance assessment—no generic quotes, only engineered solutions. When failure is not an option, partner with the standard-setter in mission-critical black molding. Precision begins at the molecular level.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.