Technical Contents

Engineering Guide: Black Anodized Aluminum Sheet Metal

Engineering Insight: Precision Imperatives in Black Anodized Aluminum Sheet Metal Fabrication

Achieving flawless black anodized aluminum sheet metal components demands uncompromising precision from initial blanking through final surface treatment. The anodizing process itself is highly sensitive to substrate geometry and surface condition. Microscopic dimensional deviations or inconsistent edge preparation directly translate into visible defects such as uneven coloration, streaking, or reduced corrosion resistance in the finished part. Tolerances that might be acceptable for raw sheet metal become critical failure points post-anodization. Dimensional deviations exceeding ±0.05mm can initiate micro-cracking in the anodic layer during bending or assembly, while inconsistent surface finishes prior to anodizing create unacceptable visual mottle under the black dye. This necessitates rigorous control over every fabrication step – laser cutting kerf width, CNC bending radii, deburring consistency, and chemical pretreatment – long before the part enters the anodizing bath. Precision isn’t merely desirable; it is the foundational requirement for functional reliability and aesthetic integrity in demanding applications.

At Wuxi Lead Precision Machinery, we engineer this precision into every black anodized component. Our CNC fabrication cells operate under ISO 2768-mK standards, with critical features routinely held to ±0.02mm. This capability stems from direct experience delivering mission-critical parts where failure is not an option. We supplied precision-formed and anodized structural components for the Beijing Winter Olympics venue systems, where thermal cycling and structural loads demanded absolute dimensional stability. Similarly, our processes meet stringent MIL-A-8625 Type II anodizing specifications for aerospace and defense clients, where coating adhesion and corrosion resistance under extreme environmental stress are non-negotiable. Our integrated workflow – from digital prototyping through in-house anodizing line oversight – ensures dimensional continuity. We control variables like material grain direction during forming and maintain exact bath chemistry parameters, preventing the warpage or color shifts common when fabrication and finishing are siloed. This holistic precision engineering guarantees the black anodic layer performs as a durable, functional surface, not just a cosmetic finish.

The table below outlines critical precision parameters we enforce for black anodized aluminum sheet metal, reflecting standards applied across aerospace, defense, and high-end industrial projects:

| Parameter | Standard Tolerance | Critical Application Tolerance | Material Specification |

|---|---|---|---|

| Sheet Thickness Range | 0.5mm – 6.0mm | 0.8mm – 3.0mm (optimal) | ASTM B209 6061-T6 |

| Fabrication Tolerance | ±0.10mm | ±0.02mm (critical features) | ISO 2768-mK |

| Anodizing Thickness | 15 – 25µm | 18 ± 2µm (military grade) | MIL-A-8625 Type II |

| Color Consistency (ΔE*) | < 1.5 | < 0.8 (visual critical apps) | ASTM D2244 |

| Flatness Post-Processing | < 0.5mm/m² | < 0.2mm/m² | Per customer drawing |

This disciplined approach to dimensional control and process integration ensures black anodized components meet the exacting performance and longevity requirements of advanced engineering applications. Precision fabrication is the non-negotiable prerequisite for a truly functional anodized finish.

Precision Specs & Tolerances

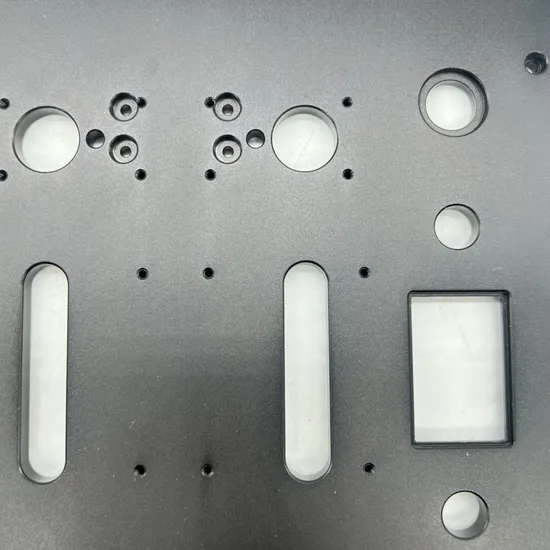

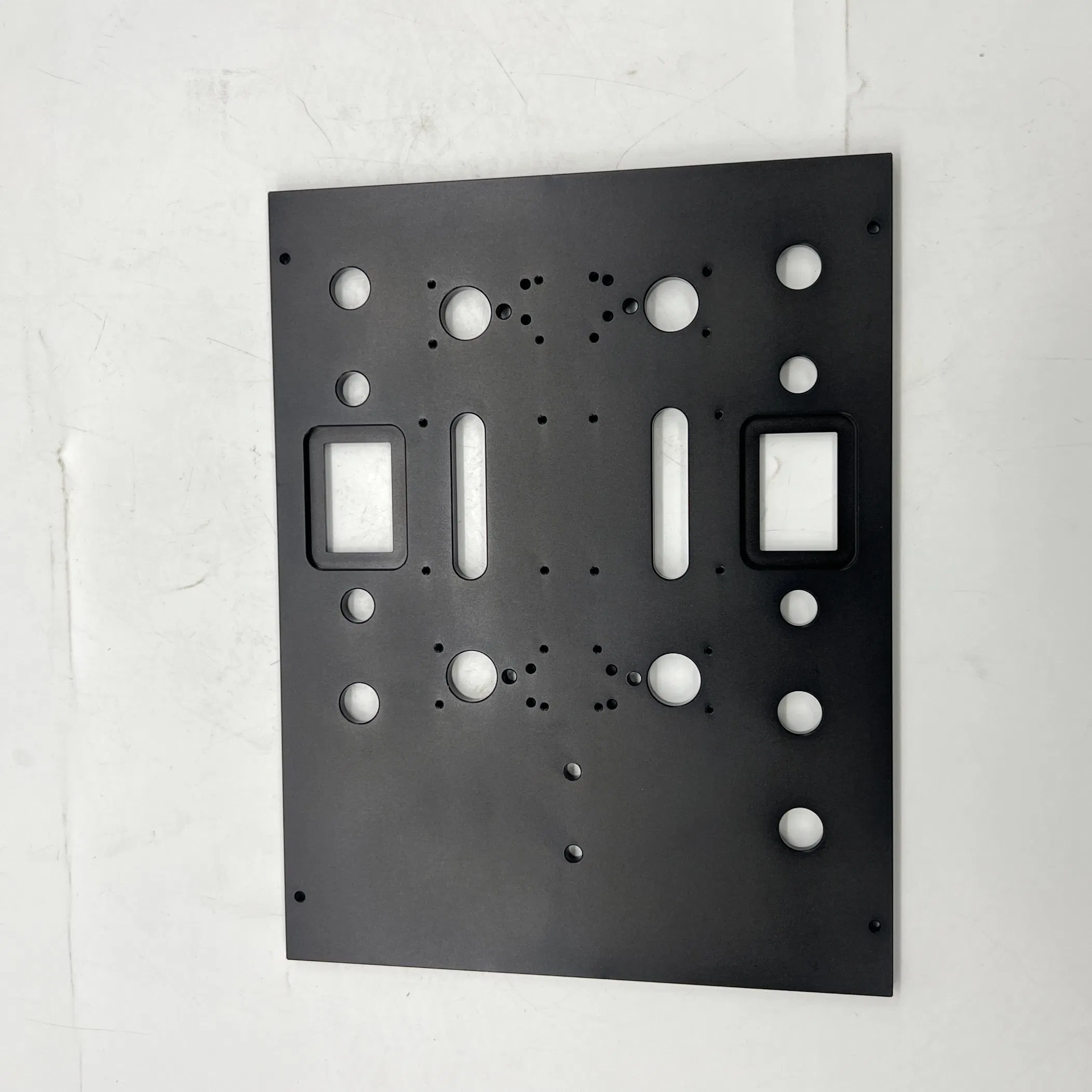

Wuxi Lead Precision Machinery specializes in high-precision sheet metal fabrication, delivering advanced manufacturing solutions for demanding industrial applications. Our expertise in processing black anodized aluminum sheet metal combines state-of-the-art technology with rigorous quality assurance to meet the exacting standards of aerospace, medical, electronics, and automation industries. Black anodized aluminum presents unique challenges due to its surface finish and dimensional stability requirements, which we address through tightly controlled machining and post-processing protocols.

Our technical foundation is built around 5-axis CNC machining centers, which enable complex geometries and tight tolerances on aluminum components. These multi-axis systems allow simultaneous movement across five planes, ensuring superior accuracy and surface integrity—especially critical when working with pre-anodized or post-anodized aluminum sheets. The 5-axis capability reduces the need for multiple setups, minimizing cumulative error and preserving the integrity of the black anodized layer during precision cutting, drilling, and contouring operations.

All black anodized aluminum parts undergo comprehensive dimensional validation using Coordinate Measuring Machine (CMM) inspection. Our CMM systems are calibrated to international standards and operated by certified metrology technicians. This ensures full traceability and compliance with ISO 17025 requirements. Inspection reports are provided with each production batch, documenting critical dimensions, geometric tolerances, and surface finish parameters. We also perform non-destructive testing when required, ensuring that the anodized layer remains intact and free from micro-cracking or edge chipping after machining.

Material handling is optimized to prevent surface marring. We utilize cleanroom-compatible tooling and non-abrasive fixturing to maintain the aesthetic and functional quality of the black anodized finish. Our operators are trained in low-contact techniques to avoid scratching or discoloration during loading, machining, and post-processing stages.

The following table outlines the standard technical specifications and achievable tolerances for black anodized aluminum sheet metal fabrication at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Type | 5052, 6061, 7075 Aluminum (black anodized) |

| Sheet Thickness Range | 0.5 mm – 6.0 mm |

| Minimum Feature Size | 0.8 mm (slots, holes) |

| Machining Tolerance (standard) | ±0.025 mm |

| Positional Tolerance | ±0.02 mm |

| Flatness Tolerance | 0.1 mm per 100 mm |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (as machined) |

| Edge Quality | Deburred, no chipping on anodized layer |

| Inspection Method | CMM, optical comparator, surface profilometer |

| Lead Time (prototype) | 7–10 working days |

| Lead Time (production) | 15–20 working days |

We support both prototype and high-volume production runs, with scalable workflows that maintain consistency across batches. Our engineering team collaborates directly with clients to review DFM (Design for Manufacturing) feedback, ensuring optimal manufacturability without compromising design intent. Wuxi Lead Precision Machinery is committed to delivering precision, reliability, and repeatable quality in every black anodized aluminum component.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication: Aluminum, Steel, Titanium & Black Anodizing

Selecting the optimal base material and finish is foundational to achieving performance, longevity, and cost-efficiency in precision sheet metal components. At Wuxi Lead Precision Machinery, we guide clients through this critical decision, balancing technical requirements with manufacturing realities. Aluminum, steel, and titanium each offer distinct advantages, while finishes like black anodizing significantly enhance functionality and aesthetics, particularly for aluminum.

Aluminum alloys dominate aerospace, electronics, and architectural applications due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and excellent machinability. Steel, especially stainless grades, provides superior strength and wear resistance for structural or high-load applications but carries greater weight. Titanium excels in extreme environments like aerospace and medical implants, offering unmatched corrosion resistance and strength at high temperatures, though at a significantly higher material and processing cost. For electrical enclosures, heat sinks, and consumer-facing components, aluminum often presents the optimal balance.

Black anodizing is a highly recommended electrochemical finish for aluminum sheet metal, transforming the surface into a durable, corrosion-resistant aluminum oxide layer. Unlike paint or powder coat, anodizing is integral to the metal substrate. Type II (sulfuric acid) anodizing offers good corrosion and wear resistance with a consistent black color, suitable for many industrial enclosures and fixtures. For demanding applications requiring maximum surface hardness, abrasion resistance, and superior corrosion protection – such as military hardware, high-wear fixtures, or marine components – Type III (hardcoat) anodizing is essential. Crucially, the anodized layer is non-conductive, making it ideal for electrical insulation needs, while maintaining aluminum’s thermal conductivity.

The following table summarizes key comparative specifications for common sheet metal fabrication materials:

| Material | Density (g/cm³) | Typical Tensile Strength (MPa) | Key Applications | Anodizing Compatibility |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Aerospace frames, marine hardware, optics | Excellent (Standard) |

| Stainless Steel 304 | 8.0 | 515 | Food processing, chemical tanks, architecture | Not Applicable |

| Titanium Grade 2 | 4.5 | 345 | Medical implants, aerospace fasteners, chemical | Limited (Specialized) |

Black anodized aluminum sheet, particularly 6061-T6, delivers a compelling solution where weight savings, corrosion resistance, electrical insulation, and a professional aesthetic are required. Its durability surpasses painted finishes, eliminating chipping risks. While steel offers raw strength and titanium handles extreme conditions, aluminum with black anodizing frequently provides the best overall value proposition for high-precision, high-reliability components across diverse industries. Consider the operational environment, mechanical loads, electrical requirements, and lifecycle costs when selecting.

Wuxi Lead Precision Machinery leverages ISO 9001-certified processes and deep material science expertise to execute precise fabrication and high-quality anodizing. We advise consulting our engineering team early in the design phase to optimize material and finish selection for your specific performance criteria and production volume, ensuring manufacturability and long-term component success. Contact us for material data sheets and process capability analysis.

Manufacturing Process & QC

The production process for black anodized aluminum sheet metal at Wuxi Lead Precision Machinery follows a disciplined, end-to-end workflow designed to ensure precision, consistency, and zero defects. Every stage—from initial design to mass production—is governed by strict quality control protocols and advanced manufacturing standards.

Design begins with a detailed engineering review, where our technical team evaluates customer specifications, functional requirements, and environmental conditions. Using industry-leading CAD/CAM software, we develop 3D models and flat patterns optimized for manufacturability. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to anticipate stress points, thermal expansion, and assembly compatibility. This proactive approach eliminates potential flaws before physical production begins, ensuring dimensional accuracy and long-term performance.

Prototyping follows design validation, where we produce a limited batch of components using the same equipment and materials intended for full-scale production. This ensures real-world performance testing under actual manufacturing conditions. Our prototyping phase includes laser cutting, precision bending, CNC punching, and automated welding, all performed on ISO-certified machinery. Each prototype undergoes rigorous inspection via coordinate measuring machines (CMM) and optical comparators to verify tolerances within ±0.05 mm. Surface finish, edge quality, and hole alignment are meticulously reviewed. Only after customer approval and internal QA sign-off does the project advance to mass production.

Mass production is executed on fully integrated, automated production lines monitored in real time. Our facility utilizes robotic material handling, in-process gauging, and statistical process control (SPC) systems to maintain consistency across thousands of parts. All black anodized aluminum components are processed through a multi-stage anodizing line, ensuring uniform coating thickness, superior corrosion resistance, and deep, consistent black coloration. The anodizing process is tightly controlled for voltage, temperature, and electrolyte concentration to meet MIL-A-8625 standards.

Throughout the production cycle, Wuxi Lead enforces a zero-defect philosophy. Each component is traceable via batch coding, and every process step includes built-in inspection checkpoints. Final quality assurance includes salt spray testing (per ASTM B117), adhesion testing, and visual inspection under standardized lighting. Non-conforming parts are immediately quarantined and analyzed through root cause corrective action (RCCA) procedures.

The table below outlines key specifications for our black anodized aluminum sheet metal production:

| Parameter | Specification |

|---|---|

| Material Grades | 5052, 6061, 6063, 7075 |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Bending) | ±0.05 mm |

| Anodizing Standard | MIL-A-8625, Type II or III |

| Coating Thickness | 10–25 μm (standard), up to 50 μm (hard coat) |

| Color Consistency | ΔE ≤ 1.0 (measured by spectrophotometer) |

| Salt Spray Resistance | ≥ 500 hours (neutral salt spray) |

| Surface Roughness (Ra) | 0.4–1.6 μm (as machined), customizable |

This systematic approach—combining precision engineering, validated prototyping, and defect-free mass production—ensures that every black anodized aluminum component meets the highest standards of quality and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Black Anodized Aluminum Solutions

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical black anodized aluminum sheet metal fabrication. We transcend conventional manufacturing by integrating aerospace-grade process control with deep materials science expertise, specifically engineered for the stringent demands of black anodized components. Our vertically integrated facility in Wuxi, China, operates under ISO 9001:2015 and IATF 16949 certifications, ensuring every sheet meets exacting global standards for corrosion resistance, wear performance, and aesthetic consistency. Unlike standard suppliers, we deploy in-line spectrophotometric color monitoring and automated anodizing bath chemistry management, eliminating batch variations that compromise optical density and adhesion in black finishes. This precision is non-negotiable for applications in semiconductor equipment, medical devices, and high-end consumer electronics where surface integrity directly impacts product lifetime and brand perception.

Our technical capabilities are rigorously defined to match your engineering specifications. The following table details our core black anodized aluminum sheet metal production parameters:

| Specification Category | Standard Capability | Precision Option | Industry Standard Met |

|---|---|---|---|

| Material Grade | 6061-T6, 5052-H32 | 7075-T6, Custom Alloys | ASTM B209, AMS QQ-A-250 |

| Thickness Range | 0.5 mm – 6.0 mm | 0.3 mm – 10.0 mm | ASTM B209 |

| Anodizing Type | Type II (Sulfuric Acid) | Type III (Hardcoat) | ASTM B580, MIL-A-8625 |

| Coating Thickness | 15–25 μm | 25–50 μm | ASTM B137 |

| Color Consistency (ΔE*) | ≤ 0.8 | ≤ 0.5 | ISO 12647-2 |

| Surface Roughness (Ra) | ≤ 0.8 μm | ≤ 0.4 μm | ISO 4287 |

This level of control stems from our proprietary anodizing process, featuring real-time electrolyte temperature stabilization within ±0.5°C and digitally calibrated dye concentration systems. We mitigate common industry failures—such as color streaking, poor dye retention, or dimensional instability—through pre-treatment validation protocols and post-anodizing sealing in nickel acetate baths compliant with AMS 2471. Our engineering team collaborates from the design phase, providing DFM analysis to optimize part geometry for anodizing uniformity and minimize secondary handling costs.

Choosing Wuxi Lead Precision means securing a partner invested in your product’s success beyond transactional delivery. We offer full material traceability with mill test reports, first-article inspection packages per AS9102, and dedicated project management for complex builds. Our logistics network ensures on-time delivery to North America, Europe, and Asia through consolidated shipping with customs documentation expertise. For black anodized components where surface performance dictates market acceptance, our zero-defect manufacturing philosophy delivers measurable risk reduction and total cost savings.

Initiate your project with engineered confidence. Contact our technical sales engineering team directly at [email protected] to discuss material selection, process validation, or request a comparative sample kit. Specify your application requirements and target volume for a tailored capability assessment within 24 business hours. Partner with precision—where every micron and micron defines excellence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.