Technical Contents

Engineering Guide: Best Way To Cut Molding

Engineering Insight: The Best Way to Cut Molding in Precision Metal Manufacturing

In high-performance metal manufacturing, the method used to cut molding directly influences the integrity, fit, and long-term reliability of the final component. At Wuxi Lead Precision Machinery, we define the best way to cut molding not by speed or cost alone, but by the consistency of precision, dimensional stability, and surface finish achieved. This standard is especially critical in sectors such as aerospace, defense, and high-end industrial equipment, where failure is not an option.

Precision cutting of molding begins with material analysis and toolpath optimization. Whether working with aluminum alloys, titanium, or hardened steels, our engineering team applies finite element analysis (FEA) and advanced simulation software to predict material behavior during the cutting process. This predictive capability allows us to minimize residual stress, prevent warping, and maintain tight tolerances—often within ±0.005 mm. Such accuracy is not incidental; it is the result of over 15 years of refining processes in mission-critical applications.

Our expertise has been validated through participation in projects of national importance, including components for military-grade communications systems and structural elements used in Olympic-standard sporting installations. These applications demand more than just compliance with specifications—they require assurance of performance under extreme conditions. In each case, the success of the final assembly relied on the exactness of the cut molding, where even microscopic deviations could compromise structural integrity or functional alignment.

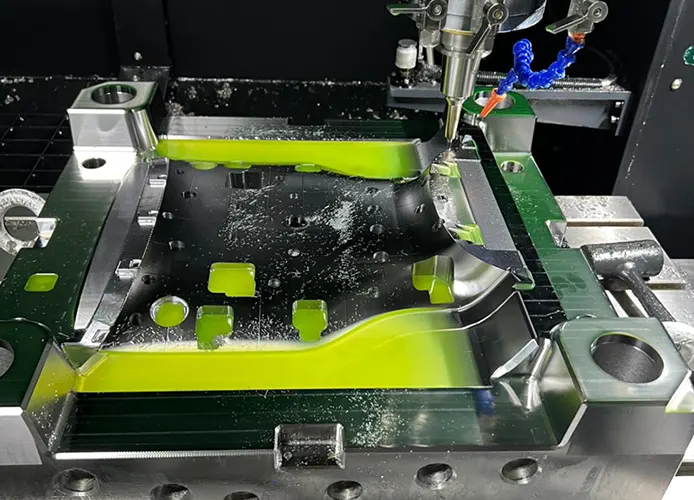

At the core of our cutting methodology is a hybrid approach combining multi-axis CNC milling with wire EDM (Electrical Discharge Machining) for ultra-fine features. This ensures clean, burr-free edges and preserves the metallurgical properties of the base material. We also employ in-process metrology using coordinate measuring machines (CMM) to verify dimensions in real time, enabling immediate correction and ensuring batch uniformity.

The table below outlines the key specifications achievable through our precision molding cutting processes:

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Minimum Feature Size | 0.1 mm internal radii | ±0.005 mm |

| Maximum Work Envelope | 2,000 mm × 1,500 mm × 800 mm | – |

| Surface Finish (Ra) | As low as 0.2 µm | ±10% of target value |

| Material Compatibility | Aluminum, Steel, Titanium, Inconel, Brass | – |

| Process Types | CNC Milling, Wire EDM, High-Speed Cutting | – |

| Repeatability (CpK ≥ 1.67) | Full batch consistency | Verified per ISO 9001 |

This level of control is only possible through integrated engineering oversight and investment in next-generation tooling systems. At Wuxi Lead Precision Machinery, we treat every molding cut as a precision event—not merely a manufacturing step. It is this philosophy, backed by proven performance in elite engineering environments, that defines our leadership in custom metal manufacturing.

Precision Specs & Tolerances

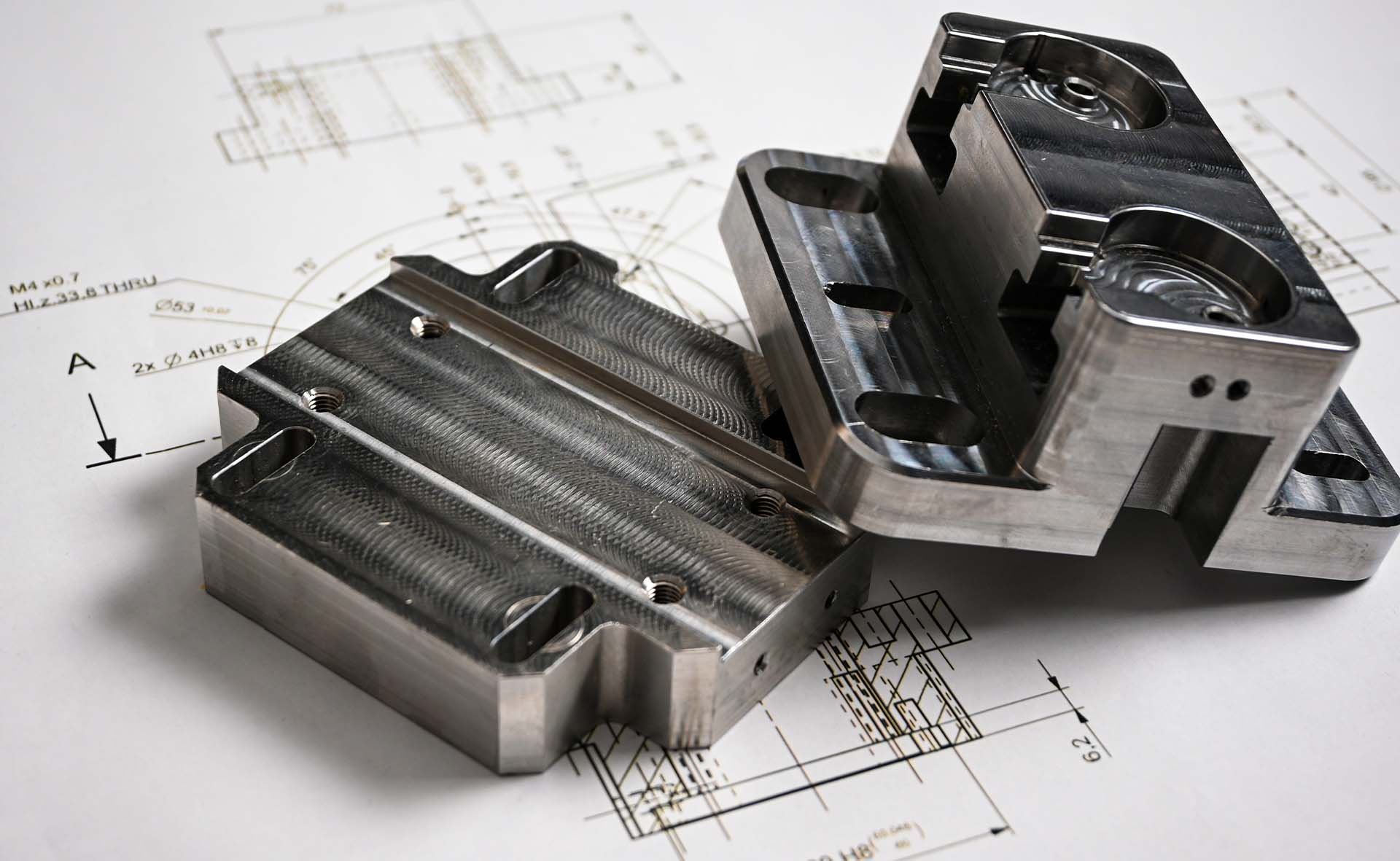

Precision Mold Manufacturing Capabilities at Wuxi Lead Precision Machinery

Achieving exceptional precision in mold manufacturing demands advanced technical execution, particularly for complex geometries and stringent surface requirements. At Wuxi Lead Precision Machinery, our integrated 5-axis CNC machining platform forms the cornerstone of our high-accuracy mold production. Utilizing HAAS and DMG MORI dual-spindle systems with simultaneous 5-axis interpolation, we eliminate multi-setup errors and maintain micron-level consistency across contoured surfaces, undercuts, and deep cavities. This capability is critical for injection molds, die-casting tools, and composite forming dies where part integrity hinges on exact dimensional replication. Our machining centers operate within a climate-controlled facility (20°C ±0.5°C), ensuring thermal stability during extended production runs for molds up to 1,200 x 800 x 600 mm.

Material versatility defines our process adaptability. We routinely machine P20, H13, S7 tool steels, aluminum 7075-T6, and high-hardness alloys (up to 60 HRC post-heat treat) using optimized toolpath strategies that minimize deflection and maximize surface finish. Advanced high-speed machining protocols reduce cycle times by 30% while preserving edge definition in fine details like texture patterns or micro-features below 0.1 mm radius. All programs undergo rigorous virtual simulation via Mastercam and NCSIMUL to prevent collisions and verify tool engagement before metal cutting begins.

Quality assurance is non-negotiable in mold production. Every component undergoes 100% dimensional verification using Zeiss CONTURA G3 Coordinate Measuring Machines (CMM) with 2.2 + L/300 μm accuracy. Our AS9100-certified inspection process includes pre-machining material certification, in-process checks at critical stages, and final full-spectrum GD&T validation against CAD models. Surface roughness is quantified via Mitutoyo SJ-410 profilometers, with reports traceable to NIST standards. This closed-loop metrology ensures molds meet the most demanding automotive, aerospace, and medical specifications on first article submission.

The following table details our standard achievable tolerances for mold components under controlled production conditions:

| Specification Category | Standard Tolerance | Extended Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | CMM / Air Gaging |

| Angular Features | ±0.005° | ±0.001° | CMM / Optical Comparator |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm | Profilometer |

| Positional Accuracy | ±0.01 mm | ±0.005 mm | CMM (Full 3D) |

| Flatness | 0.008 mm/m² | 0.003 mm/m² | CMM / Granite Table |

These tolerances are consistently maintained through proactive tool wear compensation, real-time spindle load monitoring, and our proprietary thermal drift compensation algorithm. We recognize that mold performance directly impacts your production yield and part quality. Partner with Wuxi Lead to transform complex mold designs into dimensionally perfect, production-ready tools where every micron contributes to your operational success. Our engineering team collaborates from DFM through final validation to ensure your mold meets functional requirements on schedule.

Material & Finish Options

Material Selection for Precision Molding in High-Performance Applications

Selecting the right material for molding components is critical in high-end manufacturing, where performance, durability, and precision converge. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions tailored to the exacting demands of aerospace, automotive, and industrial equipment sectors. The choice between aluminum, steel, and titanium depends on mechanical requirements, environmental exposure, and cost-efficiency targets. Each material offers distinct advantages in strength, weight, and machinability—factors that directly influence the final product’s functionality and lifespan.

Aluminum is widely favored for molding applications requiring lightweight construction and excellent thermal conductivity. Its low density reduces overall component weight, making it ideal for dynamic systems where inertia and energy consumption are concerns. Aluminum also machines efficiently, allowing for tight tolerances and complex geometries. When paired with anodizing, aluminum gains enhanced surface hardness and corrosion resistance. Anodizing creates a durable oxide layer that can be dyed for aesthetic or identification purposes, making it a preferred finish for both functional and visible components.

Steel, particularly tool steel and stainless variants, delivers superior strength and wear resistance. It is the material of choice for high-pressure molding tools, dies, and fixtures subjected to repetitive stress. While heavier than aluminum, steel’s longevity under abrasive or high-temperature conditions justifies its use in high-volume production environments. Proper heat treatment further enhances its hardness and dimensional stability. For corrosive environments, stainless steel grades such as 304 or 17-4 PH offer a balanced combination of mechanical performance and oxidation resistance.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, even in extreme environments such as marine or high-temperature aerospace applications. Though more challenging to machine and significantly more costly, titanium is indispensable where weight savings and structural integrity are non-negotiable. Its biocompatibility also makes it suitable for medical molding tools. Due to its reactivity at high temperatures, titanium requires specialized cutting tools and controlled machining parameters to prevent galling and tool wear.

The following table summarizes key physical and mechanical properties of these materials relevant to molding applications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Hardness (HB) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 95 | Moderate (improved with anodizing) | Lightweight molds, enclosures |

| Steel (4140) | 7.85 | 655 | 200 | Low (requires coating) | High-wear tooling, structural dies |

| Stainless 304 | 8.0 | 505 | 185 | High | Food-grade, chemical molds |

| Titanium Gr5 | 4.4 | 900 | 330 | Excellent | Aerospace, medical, marine dies |

Material selection must be integrated with finishing strategies. Anodizing, for example, is not applicable to steel or titanium in the same way as aluminum, but alternative surface treatments such as nitriding or PVD coatings can enhance performance. At Wuxi Lead Precision Machinery, we support clients in matching material and finish to application demands, ensuring optimal performance and cost-effectiveness in every custom molding solution.

Manufacturing Process & QC

Precision Metal Molding Cutting: The Zero-Defect Production Framework

Achieving flawless metal molding components demands a rigorously controlled production sequence, not merely sequential steps. At Wuxi Lead Precision Machinery, our Zero-Defect methodology integrates advanced engineering with real-time process validation from initial concept through high-volume output. This ensures every machined molding insert or cavity meets exacting aerospace, medical, and automotive specifications without compromise.

The process begins with Integrated Design & Simulation. Our engineering team collaborates closely with client CAD data, performing comprehensive Design for Manufacturability (DFM) analysis specific to molding applications. Critical factors like gate location stress points, cooling channel interference, and ejector pin alignment are modeled using finite element analysis (FEA) software. We validate toolpaths virtually, simulating material behavior under high-speed 5-axis machining loads to preempt deflection or thermal distortion. This phase establishes the geometric and material blueprint where tolerances are defined, not negotiated later. Strict adherence to GD&T standards is non-negotiable.

Validated Prototyping transforms the digital model into physical proof. We machine initial prototypes using the exact production-grade alloys and hardened tool steels specified for final parts. Each prototype undergoes full metrology: Coordinate Measuring Machine (CMM) scans verify dimensional accuracy against the master CAD model at critical molding interfaces, while surface profilometry confirms micro-finish requirements essential for part release and longevity. Any deviation triggers immediate root-cause analysis and process refinement before committing to mass production tooling. This iterative validation loop eliminates assumptions.

Zero-Defect Mass Production leverages the insights gained, deploying fully automated, monitored workflows. Our CNC cells utilize in-process probing for real-time feature verification, automatically compensating for tool wear or thermal drift. Statistical Process Control (SPC) charts track critical dimensions continuously, with automatic machine hold if trends approach specification limits. Every component undergoes 100% automated optical inspection against the golden prototype dataset, ensuring surface integrity and absence of micro-burrs that could damage molding surfaces. Closed-loop feedback between inspection systems and machine controllers guarantees sustained sub-micron repeatability across batches of 10,000+ parts.

This seamless transition from validated design through proven prototyping to monitored mass production is the cornerstone of our Zero-Defect commitment. We engineer out failure points at the source, ensuring your molding tools perform with absolute reliability from first shot to end-of-life.

| Critical Specification | Wuxi Lead Precision Standard | Measurement Method |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm | CMM (Calibrated to ISO 17025) |

| Surface Roughness (Ra) | 0.05 – 0.4 µm | Surface Profilometer |

| Geometric Accuracy (GD&T) | ISO 2768-mK / Custom per GD&T | CMM & Optical Comparator |

| Material Hardness Verification | As Specified (e.g., HRC 52-54) | Rockwell Hardness Tester |

| Burr-Free Critical Edges | 100% Automated Optical Check | Vision Inspection System |

| In-Process Dimensional Control | Real-Time SPC Monitoring | Machine-Integrated Probes |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Precision Metal Cutting for Molds

At Wuxi Lead Precision Machinery, we understand that the success of your high-performance molding operations hinges on precision, consistency, and material integrity. As a leading provider in custom metal manufacturing, we specialize in advanced cutting solutions tailored specifically for mold fabrication. Our engineering team combines decades of industrial experience with state-of-the-art CNC technology to deliver cutting processes that meet the most stringent tolerances and surface quality standards required in aerospace, automotive, medical, and electronics industries.

When you partner with Lead Precision, you’re not just sourcing a machining service—you’re gaining a strategic manufacturing ally. From initial design consultation to final production, we work closely with your engineering teams to optimize material selection, cutting strategies, and workflow efficiency. Our facility in Wuxi, China, is equipped with multi-axis CNC machining centers, high-speed wire EDM systems, and laser cutting platforms, all calibrated to handle complex geometries and hardened tool steels with micron-level accuracy.

We recognize that every mold application presents unique challenges—whether it’s minimizing thermal distortion in intricate cavities, achieving mirror finishes on core surfaces, or ensuring long tool life under high-cycle production. Our process-driven approach includes comprehensive pre-machining simulation, real-time monitoring, and post-processing inspection using coordinate measuring machines (CMM) and 3D scanning. This ensures that every cut meets your exact specifications and performs reliably over thousands of cycles.

Our clients choose us not only for technological capability but for reliability, transparency, and responsiveness. We maintain strict quality control under ISO 9001 standards and provide full traceability for every component produced. With streamlined logistics and dedicated project management, we support both prototyping and high-volume production with consistent turnaround times.

Below are key technical specifications that define our cutting capabilities:

| Parameter | Capability |

|---|---|

| Maximum Workpiece Size | 2000 mm × 1200 mm × 800 mm |

| Minimum Tolerance | ±0.002 mm |

| Surface Finish (Ra) | As low as 0.1 µm |

| Materials Processed | P20, H13, S136, NAK80, Stainless Steel, Aluminum, Titanium |

| Cutting Methods | CNC Milling, Wire EDM, Laser Cutting, High-Speed Machining |

| Lead Time (Typical) | 7–15 days (depending on complexity) |

| Quality Standards | ISO 9001:2015, Full Inspection Reporting |

For mold manufacturers demanding the best in precision cutting, partnering with Wuxi Lead Precision Machinery means access to advanced technology, expert engineering support, and a commitment to excellence. Contact us today at [email protected] to discuss your next project. Let us help you achieve tighter tolerances, faster cycles, and superior mold performance—engineered to lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.