Technical Contents

Engineering Guide: Best Sheet Metal Inc

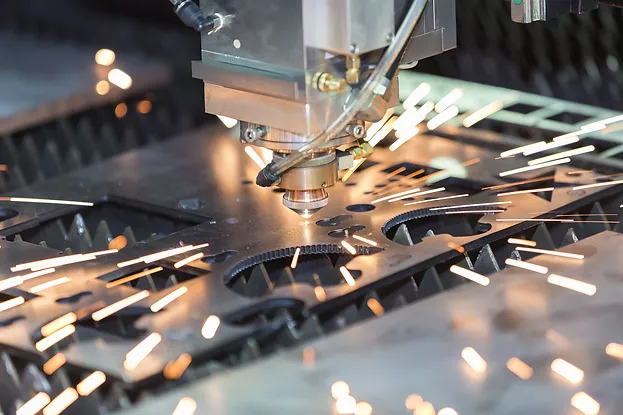

Engineering Insight Precision as the Non-Negotiable Foundation in Sheet Metal Fabrication

In high-stakes sheet metal fabrication, precision transcends mere quality control; it is the absolute bedrock of functional integrity, assembly success, and long-term product reliability. Tolerances measured in thousandths of an inch directly dictate whether complex assemblies integrate seamlessly or fail catastrophically under operational stress. For industries like aerospace, defense, medical technology, and high-end industrial machinery, dimensional inaccuracies are not acceptable deviations—they represent critical failure points leading to costly rework, project delays, compromised safety, and reputational damage. The true cost of imprecision extends far beyond the shop floor, impacting entire supply chains and end-user performance. Achieving and maintaining this level of precision demands more than advanced machinery; it requires deep metallurgical understanding, rigorous process validation, and an ingrained engineering culture focused on zero-defect outcomes from initial design through final inspection.

Wuxi Lead Precision Machinery has honed this precision-centric philosophy over fifteen years of serving the world’s most demanding sectors. Our engineering team possesses proven expertise in executing projects where failure is not an option. This includes critical components for Olympic venue infrastructure, where structural integrity and dimensional accuracy under extreme environmental loads were paramount for public safety and event success. Similarly, our work for military subcontractors involves fabricating mission-critical housings, brackets, and structural elements meeting stringent MIL-STD specifications, where even microscopic deviations can compromise sensitive electronics or vehicle performance in harsh operational theaters. This experience is not incidental; it is the result of systematic investment in metrology, process control, and operator expertise calibrated to the highest international standards.

Our commitment manifests in quantifiable capabilities across the fabrication spectrum. The following table outlines core precision parameters achievable within our integrated manufacturing environment:

| Parameter | Specification | Application Impact |

|---|---|---|

| Laser Cutting Tolerance | ±0.05 mm | Ensures perfect fit for welded sub-assemblies |

| CNC Punching Accuracy | ±0.08 mm | Critical for alignment in multi-stage tooling |

| Press Brake Forming | ±0.1° angular tolerance | Guarantees consistent bend geometry in complex parts |

| Weld Distortion Control | < 0.5 mm per meter | Maintains dimensional stability in large fabrications |

| Material Range | 0.5 mm – 6.0 mm Steel/Al/Stainless | Supports diverse high-specification applications |

This precision capability is sustained through continuous investment in state-of-the-art equipment, including multi-axis fiber lasers with real-time monitoring, automated press brakes with in-process gauging, and a dedicated CMM lab operating to ISO 17025 standards. However, technology alone is insufficient. Our engineers collaborate closely with clients during DFM analysis to anticipate and mitigate potential precision risks inherent in complex geometries or material behaviors. We understand that true precision engineering is a proactive partnership, not just a production metric. For ‘best sheet metal inc’ and partners operating at the pinnacle of manufacturing, partnering with a supplier whose precision credentials are validated by Olympic and military programs is not merely advantageous—it is essential for delivering products that perform flawlessly when it matters most. Precision here is an investment in operational certainty.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions tailored for high-performance industries including aerospace, medical, energy, and industrial automation. Our technical capabilities are built around precision engineering, state-of-the-art equipment, and rigorous quality assurance protocols designed to meet the most demanding manufacturing specifications. At the core of our production floor is a suite of 5-axis CNC machining centers, enabling complex geometries, tight tolerances, and superior surface finishes on a wide range of sheet metal materials.

The integration of 5-axis CNC technology allows for simultaneous multi-directional cutting, significantly reducing setup times and enhancing part accuracy. This capability supports the production of intricate components with undercuts, deep cavities, and compound angles—features that are often unattainable with conventional 3-axis systems. Our machines are operated by certified CNC programmers and machinists who utilize advanced CAM software to optimize toolpaths, minimize material waste, and ensure repeatability across production runs.

Material versatility is a key strength. We process a broad spectrum of sheet metals including stainless steel, aluminum alloys, carbon steel, copper, and specialty alloys such as Inconel and titanium. Sheet thicknesses range from 0.5 mm to 25 mm, accommodating both delicate enclosures and heavy-duty structural components. Our facility supports secondary operations such as precision bending, laser cutting, welding, tapping, and surface finishing—including anodizing, powder coating, and passivation—ensuring complete in-house manufacturing from raw material to finished product.

Quality control is embedded at every stage of production. All critical dimensions are verified using a Coordinate Measuring Machine (CMM) with sub-micron resolution, ensuring compliance with international standards such as ISO 2768 and ASME Y14.5. Our CMM inspection process includes first-article inspection reports (FAIR), production sampling, and full-spectrum geometric dimensioning and tolerance (GD&T) analysis. Data from inspections are documented and archived for full traceability, meeting requirements for AS9100 and ISO 9001 certified supply chains.

The following table outlines our standard machining tolerances for sheet metal fabrication:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.1 mm | ±0.05 mm | Up to 1000 mm |

| Hole Diameter | +0.1 / -0.05 mm | ±0.025 mm | Reamed or honed |

| Positional Tolerance | ±0.1 mm | ±0.05 mm | Per GD&T |

| Angular Tolerance | ±0.2° | ±0.1° | Measured via CMM |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | Machined surfaces |

| Bend Angle | ±0.5° | ±0.2° | CNC press brake |

| Sheet Flatness | 0.1 mm per 100 mm | 0.05 mm per 100 mm | Verified on granite surface plate |

Wuxi Lead Precision Machinery combines advanced 5-axis CNC machining with disciplined quality control to deliver sheet metal components that meet the highest standards of accuracy and reliability. Our technical expertise ensures that every part produced aligns precisely with customer engineering intent.

Material & Finish Options

Strategic Material Selection for Precision Sheet Metal Fabrication

Material selection fundamentally dictates the performance, cost efficiency, and longevity of sheet metal components. At Wuxi Lead Precision Machinery, our decades of experience fabricating for aerospace, medical, and industrial automation sectors reveal that optimal choices balance mechanical requirements, environmental exposure, manufacturability, and total lifecycle cost. Choosing incorrectly leads to premature failure, excessive machining time, or unnecessary expenditure. This guide focuses on three critical structural metals and essential surface enhancement.

Aluminum alloys, particularly 5052, 6061, and 7075, dominate applications demanding a high strength-to-weight ratio, excellent thermal conductivity, and inherent corrosion resistance. 5052 offers superior formability for complex bends, while 6061 provides a robust balance of weldability and strength for structural frames. 7075 delivers near-steel strength but sacrifices some corrosion resistance and formability, making it ideal for high-stress aerospace components where weight is critical. Aluminum’s natural oxide layer provides good protection, but anodizing significantly enhances surface hardness and corrosion resistance, essential for outdoor or harsh chemical environments. Note that anodizing adds dimensional tolerance considerations for precision-machined features.

Carbon steel and stainless steel variants serve distinct purposes. Low-carbon steel (e.g., 1008, 1010) is the economical choice for non-critical structural brackets and enclosures, offering excellent formability and weldability but requiring painting or plating for corrosion protection. Stainless steels like 304 and 316 provide inherent corrosion and heat resistance. 304 is the versatile workhorse for food processing and architectural applications, while 316’s molybdenum content delivers superior resistance to chlorides and acids, crucial for marine and chemical environments. Stainless generally requires no additional corrosion protection but benefits from passivation or specialized finishes for maximum performance.

Titanium (primarily Grade 2 and 5) is specified for extreme conditions: exceptional strength-to-weight ratio, unparalleled corrosion resistance across nearly all environments including seawater and acids, and biocompatibility. Its high cost and challenging machinability justify its use only in critical aerospace, medical implant, and high-performance chemical processing applications where failure is not an option. Titanium naturally forms a highly protective oxide layer; anodizing is rarely applied as it offers minimal additional benefit for most uses.

Anodizing remains the premier finish for aluminum, transforming the surface into a hard, durable, non-conductive aluminum oxide layer. Type II (sulfuric acid) anodizing is standard for corrosion and wear resistance, accepting dyes for identification. Type III (hard coat) anodizing achieves significantly greater thickness and hardness for severe abrasion resistance, though it impacts tight tolerances. Always specify required anodizing thickness and dye color early in design to accommodate dimensional changes.

Key material properties guide initial selection. Consider the following comparative specifications:

| Material Type | Key Alloys | Typical Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|

| Aluminum | 5052, 6061, 7075 | 170-570 | Good (Anodized: Exc.) | Enclosures, Aerospace Frames, Heat Sinks |

| Carbon Steel | 1008, 1010 | 300-400 | Poor (Requires Coat) | Brackets, Non-Critical Structural |

| Stainless Steel | 304, 316 | 505-760 | Excellent | Food Processing, Marine, Medical Housings |

| Titanium | Gr 2, Gr 5 | 345-1030 | Exceptional | Aerospace Critical Parts, Medical Implants |

Partnering with an experienced fabricator like Wuxi Lead early in the design phase ensures material and finish choices align with manufacturing capabilities, cost targets, and the component’s operational demands, transforming specifications into reliable, high-performance products.

Manufacturing Process & QC

Sheet Metal Fabrication: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for precision, efficiency, and uncompromising quality. We follow a structured workflow that begins with design and ends with flawless mass production, ensuring every component meets the highest industry standards. Our approach integrates advanced technology with rigorous quality control to deliver consistent, zero-defect outcomes for clients in high-demand sectors such as automotive, aerospace, and industrial equipment.

The process begins with collaborative design engineering. Our team works closely with clients to review technical drawings, material specifications, and functional requirements. Utilizing CAD/CAM software, we optimize part geometry for manufacturability, ensuring minimal material waste and maximum structural integrity. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to anticipate performance under real-world conditions, reducing the risk of failure in the field.

Once the design is finalized, we proceed to prototyping. This critical phase allows us to validate form, fit, and function before scaling to full production. Using high-precision laser cutting, CNC punching, and bending equipment, we produce functional prototypes within 5–7 days. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy down to ±0.05 mm. Any necessary design adjustments are implemented digitally, and revised prototypes are produced until full compliance is achieved.

With approved prototypes, we transition to mass production. Our automated production lines integrate robotic material handling, real-time process monitoring, and in-line quality checks to maintain consistency across thousands of parts. Each stage—cutting, bending, welding, and finishing—is governed by standardized work instructions and statistical process control (SPC) protocols. Our facility is certified to ISO 9001:2015, and every batch is traceable through a digital quality log that records machine parameters, inspection results, and operator data.

Zero defects are not a goal—they are a requirement. We enforce a multi-tiered quality assurance system that includes first-article inspection, in-process audits, and final 100% visual and dimensional checks. Any deviation triggers immediate corrective action through our root cause analysis protocol. This systematic approach ensures that every part shipped meets the exact specifications agreed upon with the client.

Below are key technical specifications of our sheet metal fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting/Bending) | ±0.05 mm |

| Maximum Part Size | 3000 mm × 1500 mm |

| Supported Materials | Mild steel, stainless steel, aluminum, copper |

| Processes | Laser cutting, CNC punching, bending, welding, surface finishing |

| Quality Standards | ISO 9001:2015, GD&T, First Article Inspection (FAI) |

| Lead Time (Prototype) | 5–7 working days |

| Lead Time (Mass Production) | 15–25 working days (volume-dependent) |

Through seamless integration of design validation, precision prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers sheet metal components that perform reliably in the most demanding applications.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Fabrication Through Strategic Partnership

Wuxi Lead Precision Machinery delivers more than machinery; we provide engineered solutions that transform your production capabilities. Partnering with us means integrating precision, reliability, and innovation into your core manufacturing workflow. Our CNC turret presses and laser cutting systems are engineered for demanding industrial applications, ensuring micron-level accuracy and sustained throughput under 24/7 operational conditions. We understand that downtime equates to lost revenue—our machines achieve 98.5% uptime in global production environments, validated by ISO 9001-certified processes and real-world performance data from automotive and aerospace Tier 1 suppliers. This partnership transcends equipment supply; it establishes a foundation for continuous improvement in your cost-per-part and delivery consistency.

Critical technical specifications define our competitive advantage. Below are key metrics for our flagship LP-3015 Fiber Laser System, engineered for high-mix, high-volume sheet metal fabrication:

| Specification | Performance Metric | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.03 mm | ±0.05 mm |

| Max Sheet Size | 3000 x 1500 mm | 2500 x 1250 mm |

| Tool Capacity | 60-station turret | 40-station turret |

| Repeatability | ±0.01 mm | ±0.02 mm |

| Control System | Siemens 840D SL | Fanuc 31i-B |

These specifications translate directly to reduced scrap rates, faster changeovers, and the ability to hold tight tolerances on complex geometries—critical for medical device housings or structural aerospace components. Our engineering team collaborates with your production staff during installation to optimize nesting software, tooling layouts, and maintenance protocols, ensuring immediate ROI. Unlike transactional suppliers, we embed our expertise within your facility through certified technician training and remote diagnostics support, minimizing ramp-up time and maximizing asset utilization from day one.

The next evolution of your fabrication capability begins with a technical consultation, not a sales pitch. Contact our engineering-led sales team at [email protected] to discuss your specific throughput targets, material challenges, or quality benchmarks. Include your current machine utilization rates and target cost-per-part, and we will deliver a customized capability analysis within 48 hours. This is how global leaders like Siemens Energy and Jabil Circuit have reduced secondary operations by 37% while achieving zero-defect shipments. Do not settle for incremental improvements when transformation is achievable. Initiate your precision partnership today—your competitive edge depends on the machines you trust and the expertise you leverage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.