Technical Contents

Engineering Guide: Best Plastic Injection Molding Companies

Engineering Insight Precision as the Foundation of Elite Plastic Injection Molding

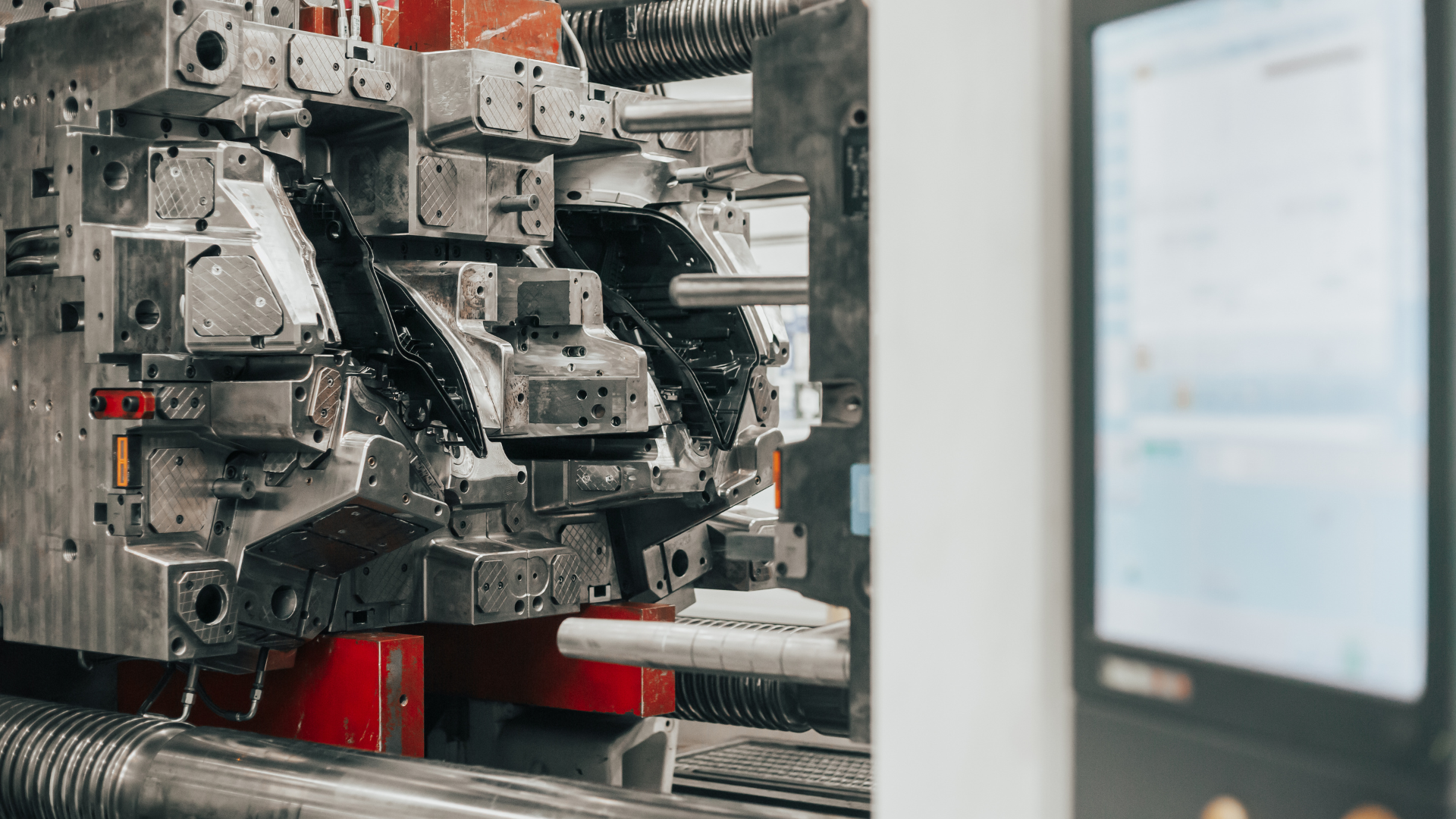

Selecting the best plastic injection molding companies requires looking beyond surface-level capabilities. True excellence hinges on an often-overlooked foundation: the precision of the metal tooling itself. While plastic molding firms execute the injection process, the dimensional accuracy, surface finish, and longevity of the final plastic component are fundamentally determined by the quality of the steel or aluminum mold. Sub-micron deviations in mold cavity geometry directly translate into part warpage, flash, or functional failure in demanding applications. This is where specialized metal manufacturing partners become critical differentiators for top-tier plastic molding operations.

Wuxi Lead Precision Machinery operates at this essential intersection of precision metal manufacturing and high-performance molding. We do not produce plastic parts; we engineer the ultra-precise metal molds and core components that enable the world’s leading plastic molding companies to achieve Olympic-grade consistency and military-spec reliability. Our CNC machining expertise ensures mold bases, cavities, cores, and ejector systems meet tolerances unattainable through conventional methods. This precision directly combats common plastic molding defects like sink marks, knit lines, and dimensional drift, especially in complex geometries or high-temperature engineering resins.

Our validation comes from projects where failure is not an option. We supplied critical mold components for timing systems used in the Beijing Olympics, where micron-level accuracy was non-negotiable for split-second event measurement. Similarly, we manufacture mission-critical housings and connectors for defense applications, adhering to stringent MIL-STD specifications that demand zero defect rates under extreme environmental stress. These projects exemplify the tolerance rigor required for the most advanced plastic molding outcomes.

The table below outlines core capabilities enabling this level of mold precision:

| Specification Category | Capability Detail | Relevance to Plastic Molding |

|---|---|---|

| Tolerance Control | ±0.001 mm (±0.00004″) | Eliminates flash, ensures perfect part mating surfaces, critical for medical/aerospace seals |

| Surface Finish | Ra 0.025 µm (mirror grade) | Achieves Class A automotive/aesthetic surfaces without secondary polishing |

| Material Mastery | Hardened tool steels (H13, S136), Aluminum 7075-T6 | Optimizes thermal conductivity for cycle time & wear resistance for 1M+ shots |

| Equipment | 5-axis DMG MORI, Makino, Hermle with laser probing | Machines complex conformal cooling channels within 0.005mm accuracy |

| Metrology | Zeiss CONTURA CMM, optical comparators | Validates cavity geometry pre-shipment, preventing costly mold trials |

Precision metal manufacturing is not a supporting act; it is the enabling force behind elite plastic injection molding. Companies achieving the highest part consistency in aerospace, medical devices, and automotive sectors rely on mold tooling partners who treat metal as critically as the plastic process itself. Wuxi Lead Precision Machinery delivers this foundational precision, transforming demanding plastic molding challenges into repeatable, high-yield production. When your application demands zero-defect plastic components, scrutinize the metal behind the mold – it defines the outcome.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery stands at the forefront of precision metal manufacturing, delivering high-performance components tailored to the exacting demands of industries such as aerospace, medical devices, automotive, and industrial automation. Our technical capabilities are engineered to support complex, high-integrity parts that require micron-level accuracy and repeatable consistency. At the core of our production infrastructure is a fleet of advanced 5-axis CNC machining centers, enabling us to produce intricate geometries with superior surface finishes and dimensional stability.

Our 5-axis CNC systems allow simultaneous movement across five axes, providing unparalleled flexibility in machining complex contours and undercuts in a single setup. This reduces part handling, minimizes cumulative tolerances, and significantly improves production efficiency. We work with a broad range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and specialty alloys, ensuring material compatibility with functional and environmental requirements. Each machining operation is supported by optimized toolpaths generated through industry-leading CAM software, ensuring precision and maximizing tool life.

To maintain the highest standards of quality, every component undergoes rigorous inspection using state-of-the-art Coordinate Measuring Machine (CMM) technology. Our CMM inspection process verifies critical dimensions, geometric tolerances, and surface characteristics against the original CAD model, ensuring full compliance with engineering specifications. All inspections are documented, providing full traceability for every production batch. This level of quality control is essential for clients operating in regulated environments where component failure is not an option.

In addition to our core machining and inspection capabilities, we integrate lean manufacturing principles across our facility to ensure on-time delivery without compromising quality. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, offering insights to optimize part geometry, reduce costs, and accelerate time-to-market.

The following table outlines the precision tolerances we consistently achieve across our production processes:

| Feature | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | CMM |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate |

| Circular Runout | 0.02 mm | 0.005 mm | CMM, Dial Indicator |

| Surface Roughness (Ra) | 3.2 µm | 0.4 µm | Surface Roughness Tester |

| Angular Tolerance | ±0.1° | ±0.05° | CMM, Precision Protractors |

This combination of advanced 5-axis CNC machining, comprehensive CMM-based quality assurance, and a commitment to precision engineering enables Wuxi Lead Precision Machinery to deliver custom metal components that meet and exceed the expectations of the most demanding applications.

Material & Finish Options

Material Selection for Precision Injection Molds: Metal Foundations for Plastic Excellence

Selecting the optimal metal substrate for injection molds is a critical strategic decision directly impacting part quality, production efficiency, and total cost of ownership. While the end product is plastic, the mold’s performance hinges entirely on the engineered properties of its metal components. Wuxi Lead Precision Machinery emphasizes that superior plastic part manufacturing begins with intelligent material science applied to the mold core, cavity, and critical inserts. Aluminum, steel, and titanium each offer distinct advantages; the correct choice aligns with production volume, part geometry, resin characteristics, and required surface finish.

Aluminum alloys, particularly 7075-T6 and 6061-T6, provide exceptional thermal conductivity. This facilitates rapid heat extraction from the molten plastic, significantly reducing cycle times for high-volume production of simple to moderately complex geometries. Aluminum’s machinability allows for faster mold fabrication and easier modifications. However, its lower hardness and wear resistance make it best suited for prototypes, low-to-medium volume runs (typically under 100,000 shots), or applications using abrasive-filled resins where frequent mold replacement is economical. Anodizing is essential for aluminum molds, creating a hard, corrosion-resistant surface layer that improves release properties and extends service life.

Tool steels, especially pre-hardened grades like P20 and H13, and hardened steels such as S136 or NAK80, represent the industry standard for medium to high-volume production. Their superior hardness and wear resistance withstand the abrasive nature of glass-filled or mineral-filled plastics and the mechanical stresses of ejection over millions of cycles. While thermal conductivity is lower than aluminum, strategic cooling channel design mitigates this. Steels offer excellent dimensional stability and polishability to achieve demanding optical or cosmetic finishes directly on the plastic part. Surface treatments like nitriding or specialized PVD coatings further enhance wear and corrosion resistance for aggressive environments.

Titanium alloys, though less common due to cost and machining complexity, excel in highly corrosive applications, such as molding PVC or certain medical-grade resins. Their exceptional corrosion resistance and moderate strength-to-weight ratio are niche advantages, but thermal conductivity limitations often restrict their use to specific non-critical mold components rather than full cavities.

The following table summarizes key comparative properties for common mold materials:

| Material Category | Key Grades | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Shot Life | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 7075-T6, 6061-T6 | 15-35 | 130-170 | < 100,000 | Prototypes, Low/Med volume, Rapid cycles |

| Pre-Hard Steel | P20, 718HH | 28-32 | 25-35 | 100,000 – 500,000+ | General purpose, Med volume, Complex parts |

| Hardened Steel | S136, NAK80, H13 | 48-54+ | 20-30 | 500,000 – 1M+ | High volume, Abrasive resins, Optical parts |

| Titanium Alloy | Ti-6Al-4V | 30-36 | 7-10 | Varies (Corrosion dep.) | Highly corrosive resins, Specific inserts |

Anodizing remains a vital surface engineering process specifically for aluminum molds. Type II (sulfuric acid) anodizing provides good wear and corrosion resistance for general use. For molds demanding maximum release properties, chemical resistance, or extended life with challenging plastics, hardcoat (Type III) anodizing creates a significantly thicker, denser, and harder ceramic layer. Proper anodizing thickness and sealing are non-negotiable for aluminum mold performance and longevity.

Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to match the precise material and surface treatment to your specific plastic molding challenge. We move beyond generic recommendations, analyzing your resin, part geometry, volume targets, and quality requirements to engineer the optimal metal foundation. This strategic material selection is not merely a cost factor; it is the cornerstone of achieving consistent part quality, maximizing uptime, and securing a true competitive advantage in precision plastic manufacturing. Partner with us to transform your mold material strategy into a production asset.

Manufacturing Process & QC

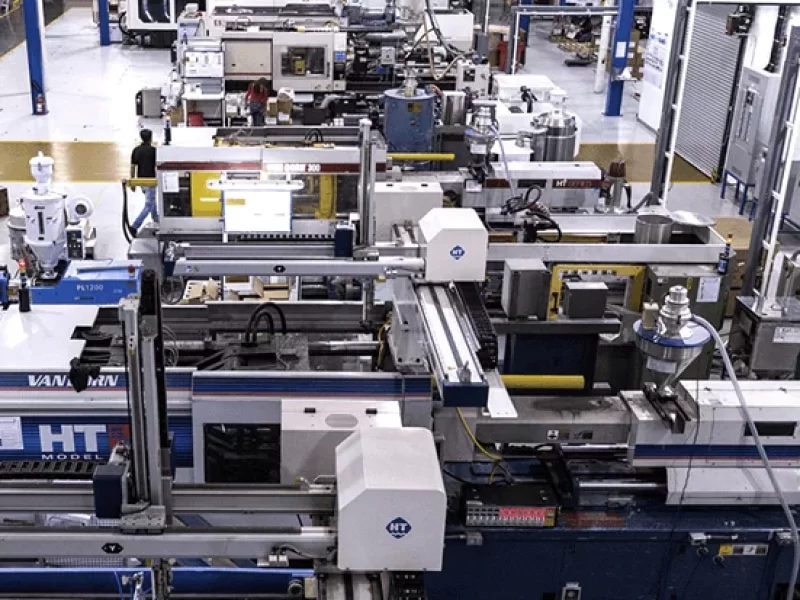

At Wuxi Lead Precision Machinery, our production process for custom metal components used in precision plastic injection molding systems is engineered for consistency, accuracy, and zero-defect outcomes. We integrate advanced manufacturing methodologies with rigorous quality assurance to deliver high-performance parts that meet the exacting demands of global industrial clients. Our workflow is structured into three core phases: Design, Prototyping, and Mass Production—each stage optimized to ensure reliability, repeatability, and compliance with international standards.

The process begins with Design, where our engineering team collaborates closely with clients to translate technical requirements into actionable blueprints. Utilizing CAD/CAM software and finite element analysis (FEA), we simulate mechanical behavior under operational conditions, identifying potential stress points and optimizing geometry for manufacturability. Material selection is determined based on thermal stability, wear resistance, and compatibility with injection molding environments. All designs are reviewed for dimensional accuracy, tolerance alignment, and long-term durability before progression.

Prototyping follows as a critical validation phase. Using CNC milling, turning, and wire EDM, we produce functional prototypes that mirror final production parts. These prototypes undergo comprehensive testing, including fit checks, thermal cycling, and pressure evaluation within simulated molding environments. This stage allows us to verify design integrity, refine tooling strategies, and ensure interchangeability. Feedback is rapidly incorporated through iterative adjustments, minimizing risk before full-scale production. Every prototype is inspected using coordinate measuring machines (CMM) and 3D scanning technology to confirm micron-level precision.

Mass Production leverages automated CNC cells, in-process gauging, and real-time monitoring systems to maintain consistency across large volumes. Our facility operates under ISO 9001-certified quality management protocols, with every operation traceable through digital work instructions and quality logs. Statistical process control (SPC) is applied at key stages to detect deviations before they affect output. All finished components undergo 100% visual inspection and sampling-based metrology to guarantee compliance with tight tolerances and surface finish requirements.

Throughout the entire production cycle, our zero-defect philosophy drives continuous improvement. Root cause analysis, preventive maintenance schedules, and operator training programs ensure sustained excellence. By integrating design intelligence, empirical validation, and disciplined manufacturing, Wuxi Lead Precision Machinery delivers custom metal components that enhance the performance and reliability of plastic injection molding systems worldwide.

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Surface Finish | Ra 0.2 – 1.6 µm |

| Materials Supported | P20, 718H, NAK80, H13, S136, Stainless Steel, Aluminum Alloys |

| Max Workpiece Size | 1200 × 800 × 600 mm |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), PPAP, FAI |

| Inspection Tools | CMM, 3D Scanner, Optical Comparator, Roughness Tester |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Injection Molding Excellence

Your plastic injection molding success hinges on one often-overlooked element: the precision and durability of the metal components within your molds. While plastic forms the final product, the mold base, cavities, cores, and inserts—crafted from hardened tool steels—dictate cycle time, part consistency, and production uptime. At Wuxi Lead Precision Machinery, we engineer these mission-critical metal elements to exacting standards, ensuring your molding operations achieve maximum efficiency and zero-compromise quality. We bridge the gap between ambitious design and flawless manufacturing, transforming your complex metal requirements into reality.

As a specialized custom metal manufacturer serving the global injection molding industry, we focus exclusively on the high-tolerance components that define mold performance. Our CNC milling, grinding, and EDM capabilities produce mold bases, inserts, and electrodes with micron-level accuracy, using premium materials like H13, P20, and S136 stainless steel. Every process—from heat treatment to mirror polishing—is controlled under ISO 9001:2015 certified protocols, eliminating variables that cause warpage, flash, or premature wear in your molds. We understand that a 0.005mm deviation in a core pin can cascade into thousands of rejected parts; our commitment is to prevent these failures before they reach your press.

Our technical partnership extends beyond fabrication. Our engineering team collaborates with your mold designers during the DFM phase, identifying potential metal-related risks early—such as stress concentrations or cooling inefficiencies—and proposing optimized geometries. This proactive approach reduces lead times by up to 30% and ensures seamless integration with your molding parameters. Below are the core capabilities enabling this reliability:

| Specification Category | Capability Range | Industry Relevance |

|---|---|---|

| Material Expertise | H13, P20, 420SS, S136, BeCu | Optimal hardness and corrosion resistance for demanding molding cycles |

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Prevents part flash and ejection failures |

| Surface Finish | Ra 0.05 μm to 0.8 μm (mirror to textured) | Ensures part aesthetics and release consistency |

| Heat Treatment | HRC 48-52 (H13), controlled stress relief | Maximizes mold lifespan under thermal cycling |

| Metrology Validation | CMM, optical comparators, surface testers | Full traceability for critical mold interfaces |

When your molding project demands metal components that perform under relentless pressure, partner with an engineer who speaks your language. Contact our technical sales team to discuss your next mold build, insert refurbishment, or electrode requirement. We will provide a detailed manufacturability assessment within 24 hours, including actionable recommendations to enhance mold longevity and part quality. Do not let substandard metalwork compromise your injection molding output.

Initiate your precision metal manufacturing collaboration today. Email [email protected] with your project specifications or CAD files. Our engineers are ready to deliver the metal foundation your plastic excellence requires.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.