Technical Contents

Engineering Guide: Best Online 3D Printing Service

Precision Defines Viability in Metal Additive Manufacturing

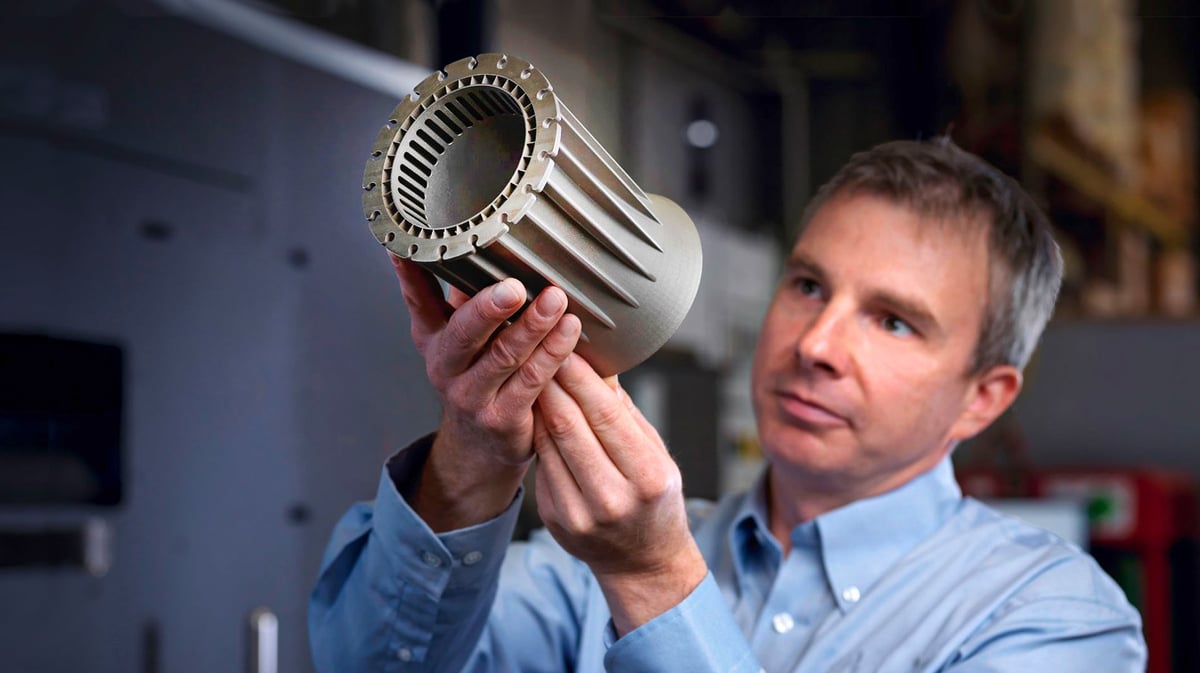

In the realm of industrial metal 3D printing, achieving nominal dimensional output is merely the entry ticket. True engineering viability hinges on consistent, certified precision – the absolute cornerstone separating prototyping novelties from mission-critical production components. Geometric deviation directly impacts functional performance, assembly integrity, fatigue life, and ultimately, product safety. For sectors like aerospace, medical implants, and high-performance automotive, where Wuxi Lead Precision Machinery operates daily, tolerances measured in microns are non-negotiable. A variance of 0.05mm might seem insignificant on paper, but in a turbine blade cooling channel or an orthopedic implant interface, it becomes the difference between flawless operation and catastrophic failure. This level of uncompromising accuracy demands far more than advanced hardware; it requires deep metallurgical understanding, rigorous process validation, and an ingrained quality culture forged through demanding applications.

Our commitment to precision is rigorously validated through projects serving the highest echelons of engineering demand. Components produced under Wuxi Lead’s stringent protocols have performed flawlessly within Olympic athletic equipment, where marginal gains dictate podium finishes, and within classified military systems, where failure is inconceivable. This experience translates directly to our commercial metal additive services. We approach every build not as a simple print job, but as a certified manufacturing process. Our engineers leverage decades of CNC machining discipline to inform additive strategy, implementing closed-loop monitoring, in-situ metrology where applicable, and post-process CNC finishing to guarantee final part conformance. Material traceability, atmospheric control during build, and meticulous parameter optimization for each alloy are standard practice, ensuring geometric and material properties meet or exceed ASTM and AMS specifications consistently.

The following table outlines the precision capabilities achievable across our certified metal additive platforms for production runs. These figures represent our standard production capability, not best-case laboratory results, reflecting the stability required for serial manufacturing.

| Specification Parameter | Capability Range | Industry Standard Context |

|---|---|---|

| Dimensional Accuracy | ±0.05 mm to ±0.1 mm | Critical for press-fit assemblies |

| Feature Resolution | Down to 0.1 mm details | Essential for fluid dynamics |

| Surface Roughness (as-built) | Ra 8-15 µm | Optimized for functional surfaces |

| Max Build Volume | 500 x 500 x 500 mm | Suitable for complex subassemblies |

| Supported Materials | Ti-6Al-4V, Inconel 718, AlSi10Mg, 17-4PH SS, CoCr | Aerospace & medical certified |

This precision foundation directly translates to reduced scrap rates, elimination of downstream rework, accelerated time-to-market, and, most critically, end-product reliability your customers demand. Partnering with a provider whose precision is battle-tested ensures your innovative designs transition seamlessly from digital model to dependable physical reality. At Wuxi Lead, we manufacture trust, one micron at a time.

Precision Specs & Tolerances

Advanced Technical Capabilities in Precision Metal Manufacturing

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to meet the most demanding requirements in custom metal manufacturing. As a trusted partner in high-precision production, we integrate state-of-the-art 5-axis CNC machining with rigorous quality control protocols to deliver components that adhere to exacting industry standards. Our facility in Wuxi, China, is equipped with advanced multi-axis machining centers capable of executing complex geometries with superior accuracy and surface finish. These 5-axis systems allow simultaneous movement across all five axes, enabling the production of intricate parts in a single setup. This reduces cumulative error, improves part consistency, and significantly shortens lead times—critical advantages for aerospace, medical, and high-performance industrial applications.

Our machining capabilities support a wide range of engineering-grade metals, including aluminum alloys, stainless steel, titanium, and high-temperature superalloys such as Inconel. The integration of high-speed spindles, adaptive toolpath strategies, and real-time tool wear compensation ensures optimal material removal rates while maintaining dimensional integrity. Each machine is maintained to OEM specifications and operated by certified CNC programmers and machinists with extensive experience in precision component manufacturing.

To guarantee compliance with design intent, every production run undergoes a comprehensive quality assurance process anchored by Coordinate Measuring Machine (CMM) inspection. Our Zeiss and Hexagon CMM systems provide micron-level verification of critical dimensions, geometric tolerances, and surface characteristics. Full first-article inspection reports (FAIR) and production batch certifications are available upon request, ensuring complete traceability and adherence to ISO 9001 standards. In addition to CMM, we employ optical comparators, surface roughness testers, and digital micrometry to validate part conformance across multiple parameters.

The following table outlines the standard tolerance capabilities achievable through our 5-axis CNC and inspection systems under controlled production conditions:

| Parameter | Standard Capability | Tight Tolerance Option | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | Up to 500 mm length |

| Geometric Tolerances | ±0.012 mm (GD&T) | ±0.008 mm | Includes flatness, concentricity, etc. |

| Hole Diameter | ±0.010 mm | ±0.005 mm | Reamed or precision bored |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Achieved via fine finishing passes |

| Angular Accuracy | ±0.05° | ±0.02° | Verified via CMM and optical alignment |

| Positional Tolerance | ±0.015 mm | ±0.008 mm | Multi-feature alignment |

These specifications reflect our commitment to precision, repeatability, and technical excellence. By combining advanced 5-axis CNC technology with systematic quality validation, Wuxi Lead Precision Machinery ensures that every component meets the functional and regulatory demands of modern engineering. Whether producing low-volume prototypes or scaled production runs, our technical capabilities are aligned with the highest standards of the global manufacturing industry.

Material & Finish Options

Material Selection for Metal 3D Printing: Precision Engineering Essentials

Material selection directly impacts the performance, durability, and cost-efficiency of additively manufactured components. At Wuxi Lead Precision Machinery, we prioritize aligning material properties with your application’s mechanical, thermal, and environmental demands. Below is a concise guide to key metals and surface treatments for industrial-grade 3D printing.

Aluminum Alloys for Lightweight Performance

Aluminum alloys like AlSi10Mg and 6061 dominate aerospace and automotive sectors due to their optimal strength-to-weight ratio and thermal conductivity. These materials excel in complex, lightweight structures such as heat exchangers or drone frames. While offering moderate strength, they require post-processing for high-stress applications. Aluminum’s natural corrosion resistance suits indoor environments but necessitates surface treatment for harsh conditions.

Stainless Steel for Strength and Corrosion Resistance

Stainless steel variants—particularly 316L and 17-4 PH—deliver exceptional mechanical robustness and chemical resistance. 316L is ideal for marine or medical components exposed to saline environments, while 17-4 PH provides superior hardness for tooling and hydraulic parts after heat treatment. Both alloys maintain integrity up to 800°C, making them suitable for high-temperature fluid systems. Note that steel’s higher density increases part weight compared to aluminum.

Titanium Alloys for Extreme Environments

Titanium Ti6Al4V (Grade 5) is the benchmark for mission-critical applications in aerospace and biomedical fields. Its unmatched strength-to-weight ratio, biocompatibility, and resistance to fatigue and corrosion justify its premium cost. This alloy performs reliably in temperatures exceeding 600°C and withstands prolonged exposure to acids or saltwater. Use it for surgical implants, turbine blades, or satellite components where failure is not an option.

Anodizing: Functional Surface Enhancement

Anodizing is exclusively applied to aluminum parts to boost surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a standard decorative/protective layer, while Type III (hardcoat) anodizing delivers industrial-grade durability up to 50–70 µm thickness. Critical considerations include dimensional stability—tolerances must account for coating growth—and electrical insulation requirements. Avoid anodizing for assemblies requiring tight press-fits without post-coating machining.

Comparative Material Specifications

| Material | Key Properties | Typical Applications | Max Continuous Temp (°C) |

|---|---|---|---|

| Aluminum AlSi10Mg | Lightweight, good thermal conductivity | Heat sinks, drone parts | 300 |

| Stainless 316L | High corrosion resistance, ductile | Medical implants, valves | 800 |

| Stainless 17-4 PH | High strength (H900), machinable | Tooling, aerospace | 600 |

| Titanium Ti6Al4V | Exceptional strength-to-weight, biocompatible | Aircraft, prosthetics | 600 |

Selecting the optimal material requires balancing performance needs with cost and lead time. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise to validate material suitability for your specific use case. Our engineering team collaborates with clients during the design phase to prevent post-print failures—ensuring your 3D printed components meet ISO 2768-mK tolerances and ASTM F3301-18 standards. Partner with us to transform material science into precision-critical components. Consult our engineers before finalizing specifications to optimize manufacturability and lifecycle value.

Manufacturing Process & QC

The production process at Wuxi Lead Precision Machinery is engineered for precision, repeatability, and zero-defect outcomes in custom metal manufacturing. Every project follows a disciplined three-phase workflow—Design, Prototyping, and Mass Production—ensuring that components meet the highest standards of quality, functionality, and dimensional accuracy.

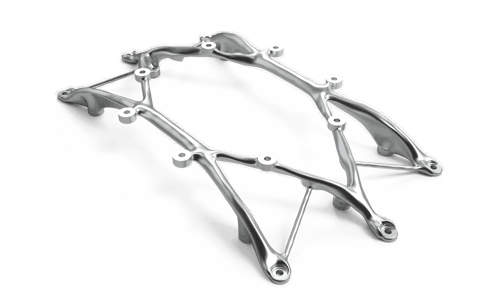

Design is the foundation of successful manufacturing. Our engineering team collaborates closely with clients to analyze 3D CAD models, assess material suitability, and optimize geometries for manufacturability. Finite element analysis (FEA) and design for assembly (DFA) principles are applied to eliminate potential failure points before production begins. This phase includes thermal, stress, and tolerance stack-up simulations to ensure performance under real-world conditions. All design data is stored in a secure, version-controlled environment to maintain traceability and support rapid revisions.

Prototyping follows design validation and serves as a physical proof of concept. Using advanced metal 3D printing technologies such as selective laser melting (SLM) and direct metal laser sintering (DMLS), we produce functional prototypes in the same materials intended for final production—such as titanium, Inconel, stainless steel, and aluminum alloys. These prototypes undergo rigorous metrology testing using coordinate measuring machines (CMM), optical scanning, and mechanical property verification. Feedback from this stage is integrated into the final design, minimizing risk during scale-up.

Mass Production leverages both additive and subtractive methods, depending on part complexity, volume, and performance requirements. High-precision 5-axis CNC machining, wire EDM, and automated post-processing systems ensure micron-level tolerances and superior surface finishes. Every production run is monitored through real-time process control systems, including in-process gauging and statistical process control (SPC) methodologies. Our factory operates under ISO 9001 and IATF 16949 certifications, enforcing strict adherence to quality protocols across all batches.

To guarantee zero defects, Wuxi Lead implements a multi-stage inspection regime. Each component is subjected to non-destructive testing (NDT), dimensional validation, and material certification. Final parts are delivered with full inspection reports, first-article test data, and batch traceability documentation.

The table below outlines key capabilities across our production process:

| Parameter | Specification |

|---|---|

| Material Options | Titanium, Inconel, Aluminum, Stainless Steel, Tool Steel |

| Dimensional Accuracy | ±0.025 mm |

| Surface Roughness (Ra) | As-printed: 6–12 µm; Polished: <0.8 µm |

| Maximum Build Volume | 500 x 500 x 400 mm (SLM/DMLS) |

| Lead Time (Prototype) | 7–10 business days |

| Lead Time (Mass Production) | 15–25 business days (volume-dependent) |

| Quality Standards | ISO 9001, IATF 16949, PPAP, FAI compliant |

This integrated approach ensures that every part produced meets the exacting demands of aerospace, medical, and high-performance industrial applications. At Wuxi Lead Precision Machinery, precision is not achieved—it is engineered.

Why Choose Wuxi Lead Precision

Why Metal 3D Printing Falls Short for Production-Critical Components

While online metal 3D printing services offer rapid prototyping advantages, they often prove inadequate for demanding, high-volume industrial applications. Surface finish limitations, residual stresses affecting dimensional stability, restricted material choices for extreme environments, and significant per-part cost escalation beyond low volumes present critical hurdles. For mission-critical metal components requiring aerospace-grade reliability, medical device certification, or heavy industrial durability, precision subtractive manufacturing remains the indispensable foundation. Relying solely on additive processes risks compromising performance, longevity, and total cost of ownership at scale.

The Lead Precision Advantage: Engineered Certainty for Metal Parts

Wuxi Lead Precision Machinery bridges the gap between prototyping promise and production reality. We specialize in high-precision CNC milling, turning, and multi-axis machining for complex metal components where tolerances, material integrity, and repeatability are non-negotiable. Our ISO 9001-certified facility in Wuxi, China, combines German-engineered DMG MORI and MAZAK equipment with decades of metallurgical expertise. We transform challenging alloys – from Inconel 718 and titanium Ti-6Al-4V to hardened tool steels and aluminum 7075 – into components meeting the strictest AS9100 and ISO 13485 standards. Forget the compromises of scaled additive manufacturing; we deliver production-ready metal parts with guaranteed consistency from prototype to 10,000+ unit runs.

Our technical capabilities are rigorously defined to eliminate engineering uncertainty. The table below details core production specifications achievable across our standard processes:

| Capability | Specification Range | Industry Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (sub-5μm typical) | Critical for aerospace sealing surfaces, hydraulic components |

| Surface Roughness (Ra) | 0.2 μm to 1.6 μm | Meets medical implant and optical interface requirements |

| Maximum Work Envelope | Ø 800 mm x 1200 mm | Accommodates large structural brackets and housings |

| Material Hardness Range | Up to 68 HRC (post-heat treat) | Enables direct machining of hardened tooling |

| Standard Lead Time | 15-25 days (complex geometries) | Competitive with high-volume additive without quality trade-offs |

Engineer Your Success with Lead Precision

Stop accepting the limitations of online 3D printing for your essential metal components. Partner with an engineering-led manufacturer that prioritizes your end-product performance over process novelty. Our technical sales engineers collaborate directly with your design team during DFM analysis, identifying cost-saving optimizations and potential failure points long before metal meets tool. We provide comprehensive material certifications, first-article inspection reports (FAIR), and real-time production tracking – ensuring complete traceability and quality assurance you simply cannot achieve through automated online quoting platforms.

Contact our engineering team today at [email protected]. Include your component drawings and application requirements for a detailed capability assessment and precision manufacturing proposal. Experience how Lead Precision delivers not just parts, but production certainty for the world’s most demanding industries. Your next-generation product deserves manufacturing excellence grounded in proven engineering, not process hype. Let us prove the Lead Precision difference.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.