Technical Contents

Engineering Guide: Best Injection Molding Companies

Engineering Insight: Precision as the Non-Negotiable Foundation in Injection Molding Excellence

In high-stakes injection molding, particularly for mission-critical metal components, precision transcends mere specification—it becomes the absolute determinant of functional integrity, assembly success, and long-term reliability. Tolerances measured in microns directly impact part performance under extreme conditions, where even microscopic deviations can trigger catastrophic failure in aerospace systems, medical devices, or defense hardware. The best injection molding companies understand that achieving this level of accuracy demands more than advanced machinery; it requires an integrated engineering philosophy spanning material science, thermal dynamics, tooling design, and rigorous process validation. Compromising on precision inevitably leads to increased scrap rates, costly assembly rework, field failures, and reputational damage—risks no leading manufacturer can afford when producing components for regulated or safety-critical industries.

Wuxi Lead Precision Machinery operates at this pinnacle of precision engineering, leveraging over 15 years of specialized expertise in custom metal manufacturing for the most demanding global sectors. Our approach begins with proprietary tooling design, utilizing multi-physics simulation to predict and counteract warpage, sink marks, and residual stress during the metal injection molding (MIM) and precision casting processes. This is executed on a foundation of state-of-the-art infrastructure, including climate-controlled production cells and in-house metrology labs certified to ISO 17025 standards. Every stage—from raw material verification through sintering and final finishing—is governed by real-time SPC data, ensuring dimensional stability and material properties meet exacting aerospace (AS9100) and medical (ISO 13485) requirements. Our commitment is proven through sustained partnerships delivering components for Olympic-grade athletic equipment requiring flawless balance and durability, alongside certified critical subsystems for military applications where failure is not an option.

The technical capability underpinning this precision is quantifiable through our core manufacturing parameters. The following table details our standard production envelope for high-integrity metal injection molding projects:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.001 mm to ±0.005 mm | CMM (Zeiss CONTURA) |

| Surface Roughness (Ra) | 0.05 µm to 0.8 µm | Profilometer (Mitutoyo SJ-410) |

| Material Compatibility | 17-4PH, 316L, 420SS, Ti-6Al-4V, Inconel 718 | ASTM/AMS Certified |

| Max Part Weight | 250 grams | Per MIM Industry Standard |

| Production Capacity | 50,000 – 500,000 pcs/month | Traceable Batch Control |

This level of controlled output is why global leaders in defense and elite sports engineering consistently select Lead Precision. When your application demands components that perform flawlessly under gravitational stress, corrosive environments, or life-support scenarios, partnering with a manufacturer whose precision is validated by Olympic podiums and military certifications is not an advantage—it is an operational necessity. We engineer certainty into every cavity, ensuring your most critical metal components meet the uncompromising standards your end-users depend on. Contact our engineering team to discuss validation protocols for your next high-integrity project.

Precision Specs & Tolerances

Technical Capabilities

Wuxi Lead Precision Machinery stands at the forefront of custom metal manufacturing, delivering precision-engineered components for demanding industries such as aerospace, medical, automotive, and industrial automation. Central to our technical excellence is our advanced 5-axis CNC machining capability, which enables the production of highly complex geometries with superior accuracy and surface finish. Unlike conventional 3-axis systems, our 5-axis CNC machines allow simultaneous movement across five planes, minimizing setup changes and reducing cumulative error. This results in tighter tolerances, improved part consistency, and faster turnaround times—critical advantages for high-performance applications where precision is non-negotiable.

Our machining centers are equipped with state-of-the-art controls and high-speed spindles, capable of maintaining micron-level accuracy across a wide range of materials, including stainless steel, aluminum alloys, titanium, and exotic superalloys. The integration of adaptive machining strategies and real-time tool monitoring ensures optimal cutting conditions, extended tool life, and consistent part quality throughout production runs. Whether producing low-volume prototypes or high-volume production batches, our 5-axis technology supports efficient, scalable manufacturing with minimal human intervention.

Quality control is embedded into every stage of the manufacturing process. We employ a comprehensive inspection protocol anchored by a Zeiss coordinate measuring machine (CMM), which provides full 3D metrology for dimensional verification. The CMM system enables non-contact and tactile probing, allowing for precise measurement of internal features, contours, and critical datums in compliance with ISO 10360 standards. All inspection data is documented and traceable, supporting full quality reporting for audit and certification purposes. In addition to CMM, our quality assurance process includes in-process checks, first-article inspection reports (FAIR), and final visual and dimensional verification.

We maintain strict environmental controls within our metrology lab to ensure measurement stability, with temperature held at 20°C ±0.5°C and humidity regulated to minimize thermal expansion effects. This level of control is essential for achieving the tight tolerances required in mission-critical components. Our engineering team works closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance specifications, ensuring manufacturability without compromising performance.

The following table outlines the standard and achievable tolerances across key manufacturing parameters:

| Feature Type | Standard Tolerance | Achievable Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.02 mm | ±0.008 mm | Pin Gauges, CMM |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.01° | CMM, Precision Protractors |

These capabilities, combined with rigorous process controls and engineering expertise, position Wuxi Lead Precision Machinery as a trusted partner for high-precision metal components in technically advanced industries.

Material & Finish Options

Strategic Material Selection for High-Performance Injection Molds

Material selection fundamentally dictates mold longevity, thermal management, and final part quality in precision injection molding. At Wuxi Lead Precision Machinery, we prioritize engineered solutions where Aluminum, Steel, and Titanium each serve distinct high-value applications. Aluminum excels in rapid prototyping and low-to-medium volume production due to its exceptional thermal conductivity, enabling faster cycle times. Its machinability reduces lead times significantly, though it requires protective finishes like anodizing for extended use in abrasive polymer environments. Tool-grade Aluminum alloys (e.g., 7075-T6) balance strength and thermal response, ideal for consumer electronics and packaging molds demanding tight tolerances.

Hardened tool steels (P20, H13, S136) remain the industry standard for high-volume production. Their superior hardness (typically 28–54 HRC) and wear resistance withstand millions of cycles, especially with glass-filled or mineral-reinforced polymers. Steel’s lower thermal conductivity versus Aluminum necessitates precise cooling channel design—a specialty where our CNC expertise ensures uniform heat extraction, minimizing warpage in automotive or medical components. For extreme wear scenarios, pre-hardened steels offer optimal machinability before final heat treatment, streamlining complex cavity fabrication.

Titanium alloys (Grade 5 Ti-6Al-4V) address niche high-stress applications where corrosion resistance and strength-to-weight ratio are critical. Though cost-intensive, titanium molds excel in processing highly corrosive engineering plastics (e.g., PPS, PPA) or in aerospace components requiring absolute dimensional stability. Its biocompatibility also supports medical molding where steel contamination risks exist. Titanium’s lower thermal conductivity demands advanced cooling strategies, leveraging our proprietary simulation-driven design process.

Anodizing is non-negotiable for aluminum molds operating beyond prototype stages. This electrochemical process creates a dense, non-conductive oxide layer that dramatically enhances surface hardness (up to 60 Rockwell C equivalent), corrosion resistance, and release properties. Wuxi Lead applies Type II (sulfuric acid) and hardcoat Type III anodizing with micron-level thickness control (15–50 μm), tailored to polymer abrasiveness. Unlike paint or plating, anodizing integrates with the substrate, eliminating delamination risks during thermal cycling. Note that anodizing applies solely to aluminum; steel requires nitriding or PVD coatings, while titanium benefits from specialized passivation.

Material performance metrics guide optimal selection. The comparative specifications below reflect industry-standard tooling grades:

| Material | Thermal Conductivity (W/m·K) | Hardness Range (HRC) | Primary Applications |

|---|---|---|---|

| Aluminum 7075 | 130–150 | 45–50 (T6) | Prototypes, packaging, low-volume consumer |

| Steel H13 | 25–30 | 48–52 | High-volume automotive, medical, engineering |

| Titanium Ti-6Al-4V | 7–8 | 32–36 (as-machined) | Corrosive polymers, aerospace, medical implants |

Wuxi Lead Precision Machinery combines metallurgical expertise with advanced CNC capabilities to match material properties to your production volume, polymer chemistry, and part complexity. Our engineers collaborate from design through finishing to ensure mold materials maximize ROI—reducing downtime, scrap rates, and total cost of ownership. Consult our technical team for material validation specific to your application.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the manufacturing journey begins with an intensive design phase that integrates engineering excellence with client-specific requirements. Our team of senior CNC engineers and mechanical designers collaborates closely with clients to translate conceptual ideas into technically feasible, manufacturable designs. Utilizing advanced CAD/CAM software such as SolidWorks, AutoCAD, and Siemens NX, we conduct comprehensive design analysis, including tolerance stack-up evaluation, material selection, and mold flow simulation for injection molding compatibility. This ensures that every design is optimized for structural integrity, performance, and manufacturability. Finite element analysis (FEA) is applied to predict stress points and thermal behavior, minimizing risks before physical production begins. The result is a robust, precision-engineered blueprint that serves as the foundation for zero-defect manufacturing.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we move into the prototyping phase—a critical step in our zero-defect strategy. At Wuxi Lead, we employ high-precision CNC machining, 3D metal printing, and soft-tooling injection molding to produce functional prototypes that mirror final production parts. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and mechanical performance validation. Clients receive detailed test reports and physical samples for real-world evaluation. Any necessary design refinements are implemented digitally and re-validated before approval for mass production. This iterative process ensures that all potential flaws are identified and corrected early, significantly reducing the risk of defects during full-scale manufacturing.

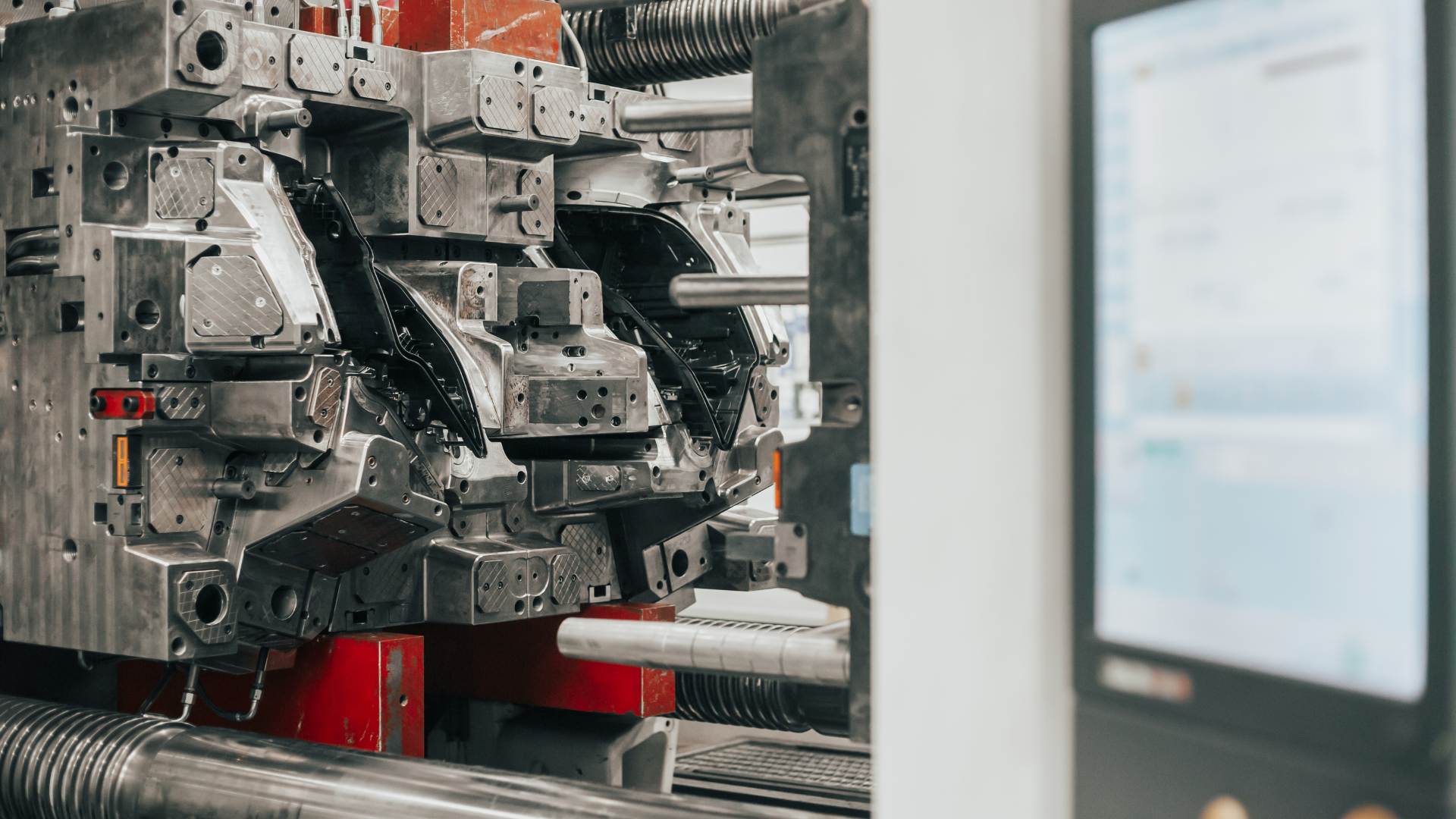

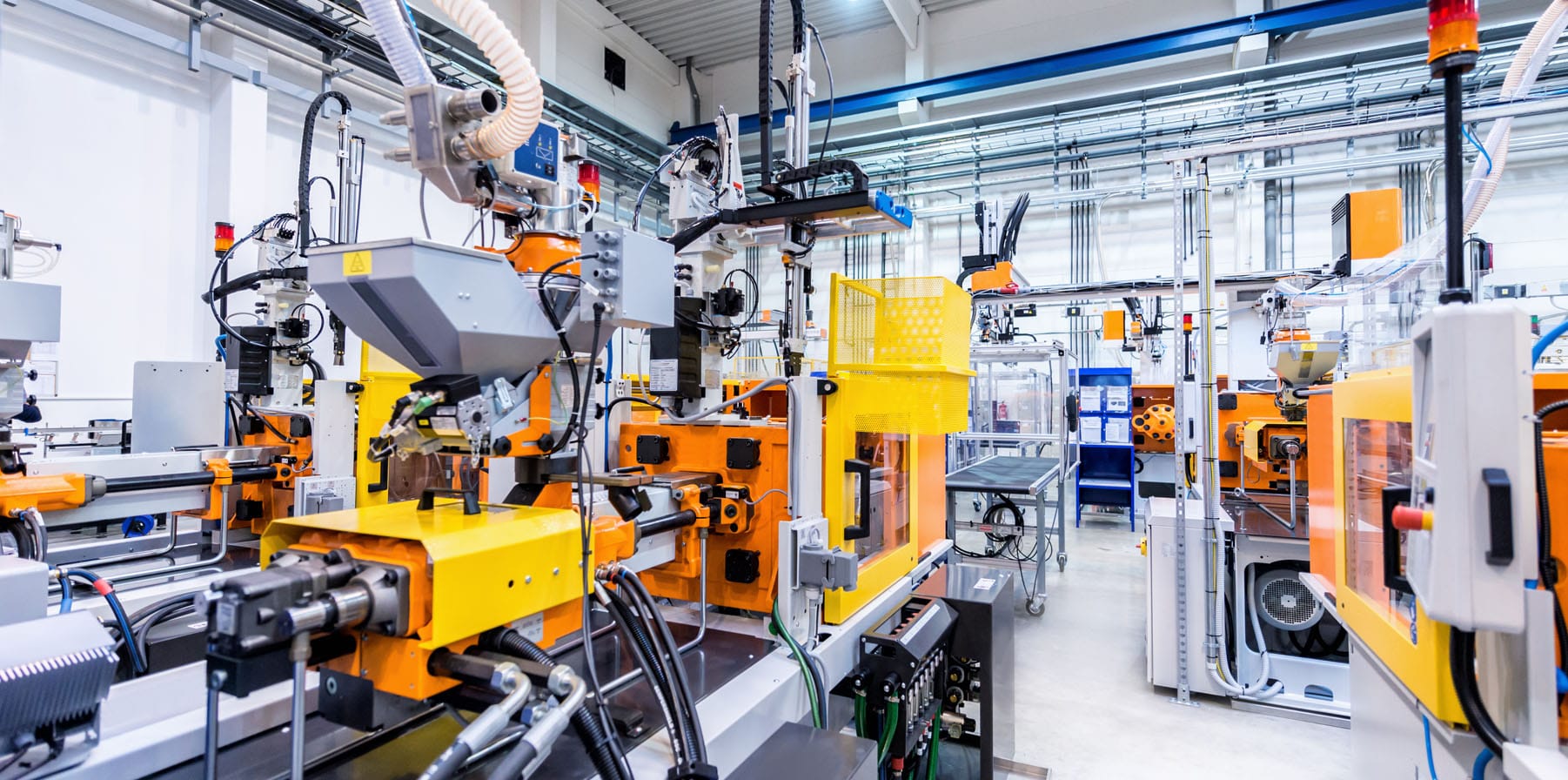

Mass Production: Scalable Precision with Zero-Defect Assurance

With design and prototype approval secured, Wuxi Lead initiates mass production using state-of-the-art automated injection molding and CNC-integrated metal forming systems. Our facility in Wuxi operates under ISO 9001 and IATF 16949-certified quality management systems, ensuring consistency and traceability across every production batch. Real-time monitoring via IoT-enabled machinery allows for immediate detection of process deviations, while statistical process control (SPC) ensures tight adherence to dimensional tolerances. Each component is inspected using automated optical inspection (AOI) and CMM verification at critical control points. Our closed-loop feedback system enables instant adjustments, maintaining a defect rate below 10 PPM (parts per million).

The following table outlines key production specifications and capabilities at Wuxi Lead Precision Machinery:

| Parameter | Specification |

|---|---|

| Material Compatibility | Aluminum Alloys, Stainless Steel, Tool Steels, Brass |

| Tolerance Range | ±0.005 mm |

| Surface Finish | Ra 0.2 – 1.6 µm |

| Production Capacity | Up to 500,000 units/month |

| Injection Molding Machines | 50–1,500 Ton Clamping Force |

| Quality Standard | ISO 9001, IATF 16949, RoHS Compliant |

| Lead Time (Mass Production) | 15–30 days (after prototype approval) |

Through seamless integration of design intelligence, prototyping validation, and precision-controlled mass production, Wuxi Lead Precision Machinery delivers custom metal components with uncompromising quality—ensuring zero defects and maximum reliability for high-performance applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Metal Components in Injection Molding

Precision metal components are the silent foundation of high-performance injection molds. When tolerances slip or material integrity falters, entire production lines face costly downtime and scrap. At Wuxi Lead Precision Machinery, we engineer custom metal parts to the exacting standards demanded by the world’s most advanced injection molding operations. Our focus isn’t merely on meeting specifications—it’s on eliminating the hidden variables that undermine mold longevity, part consistency, and your bottom line.

We understand that injection molders require partners who speak the language of micron-level accuracy and industrial durability. Our ISO 9001-certified facility in Wuxi integrates German-engineered CNC milling, turning, and grinding systems with rigorous in-process metrology. Every component undergoes full dimensional validation against your CAD data, ensuring seamless integration into complex mold assemblies. This precision directly translates to reduced cycle times, minimized flash, and extended mold life for your clients.

Our technical team collaborates closely with your engineers from concept to validation. Whether you require hardened tool steels for core/cavity inserts, corrosion-resistant alloys for corrosive resins, or ultra-smooth polished surfaces for optical applications, we deliver solutions grounded in deep materials science expertise. We prioritize your intellectual property security through NDAs and controlled data protocols, treating your designs with the confidentiality they deserve.

Below are key capabilities critical to injection mold performance:

| Specification | Capability | Relevance to Injection Molding |

|---|---|---|

| Tolerance Control | ±0.002 mm | Ensures precise cavity/core alignment, eliminating part flash |

| Surface Finish | Ra 0.05 µm (mirror polish) | Critical for optical/electronic components; reduces ejection force |

| Materials Expertise | H13, S136, 420SS, Titanium, Inconel | Optimized for wear resistance, thermal stability, and resin compatibility |

| Max. Part Size | 1,200 x 800 x 600 mm | Supports large mold bases and multi-cavity systems |

| Lead Time (Standard) | 15-25 working days | Accelerates mold commissioning and time-to-market |

Choosing a metal manufacturing partner is a strategic decision that impacts your reputation for quality and reliability. Wuxi Lead Precision Machinery operates as an extension of your engineering team, combining Chinese manufacturing efficiency with European-grade precision standards. We invest in your success through proactive communication, rigorous first-article inspection reports, and rapid iteration for design refinements.

The next high-stakes mold project demands a partner who treats precision as non-negotiable. Contact our technical sales team to discuss how our custom metal solutions can elevate your injection molding outcomes. Share your design challenges, material requirements, and timeline—we’ll respond within 24 hours with a detailed capability assessment.

Initiate your precision partnership today. Email [email protected] for a confidential consultation and engineering support tailored to your injection molding objectives.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.