Technical Contents

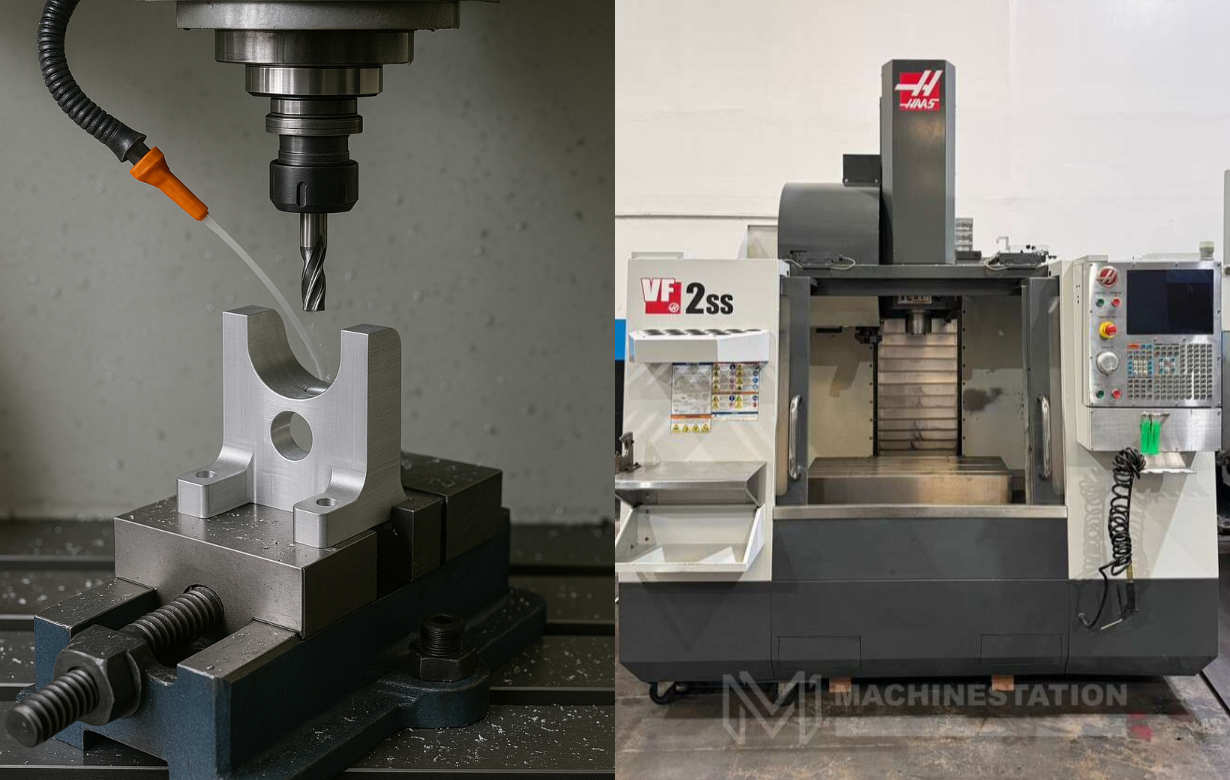

Engineering Guide: Best Cnc Machines For Beginners

Engineering Insight: Precision as the Non-Negotiable Foundation for Beginner CNC Success

Selecting the first CNC machine for a manufacturing operation is a critical strategic decision, far beyond mere cost or basic functionality. For beginners entering precision CNC machining, the paramount consideration must be inherent machine precision. This is not merely about achieving tight tolerances on a single part; it is the foundational element ensuring consistent, repeatable results batch after batch, directly impacting scrap rates, throughput, and ultimately, profitability. Substandard precision leads to costly rework, extended setup times, and an inability to confidently bid on higher-value contracts. True precision encompasses thermal stability, structural rigidity, servo responsiveness, and advanced control algorithms working in unison. It is the bedrock upon which dimensional integrity, surface finish quality, and process reliability are built. Beginners often underestimate how machine limitations can constrain future growth; investing in genuine precision from day one avoids the expensive and disruptive need for machine replacement as capabilities and customer demands evolve.

At Wuxi Lead Precision Machinery, we understand that beginners require machines engineered for real-world industrial demands, not just simplified operation. Our design philosophy, forged through decades of delivering mission-critical components for Olympic sporting equipment and stringent military applications, prioritizes uncompromising accuracy and robustness. These high-stakes projects demand sub-micron tolerances and absolute reliability under continuous operation – standards we embed into every machine, including our entry-tier models. This heritage means our beginner-focused CNCs are not stripped-down compromises but rigorously tested platforms built with the same core principles as our high-end systems. We provide the stability and accuracy necessary for newcomers to learn best practices on a machine that won’t hinder their development or disappoint demanding customers. The confidence gained from predictable, high-precision machining is invaluable for establishing a competitive foothold.

The following specifications highlight the precision capabilities inherent in our VMC-500 model, specifically designed as an accessible entry point without sacrificing core performance:

| Specification | Value | Industry Relevance for Beginners |

|---|---|---|

| Positioning Accuracy | ±0.003 mm (X, Y, Z) | Ensures first-part correctness, minimizes scrap |

| Repeatability | ±0.002 mm (X, Y, Z) | Guarantees consistent batch quality, reduces inspection burden |

| Thermal Compensation | Full 3-Axis Active | Maintains accuracy during extended runs, critical for unattended operation |

| Spindle Runout (TIR) | ≤ 0.001 mm | Directly impacts surface finish and tool life |

| Bed Material | Meehanite FC35 Cast Iron | Provides long-term stability and vibration damping |

This level of specification is non-negotiable for sustainable growth. Beginners partnering with Wuxi Lead gain immediate access to precision engineering proven in the most demanding environments. Our support extends beyond the machine; we provide comprehensive training focused on leveraging this precision effectively, ensuring new operators maximize their investment from the first machining cycle. Choosing a machine built to military and Olympic standards provides beginners not just with equipment, but with a strategic advantage in quality and reliability that accelerates their path to becoming a trusted precision supplier. Precision is the starting line, not the finish line.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities through state-of-the-art 5-axis CNC machining systems, engineered for precision, efficiency, and repeatability in complex part production. Our integrated manufacturing platform supports clients across aerospace, medical, automotive, and industrial equipment sectors, where tight tolerances and high consistency are mission-critical. The foundation of our technical excellence lies in multi-axis simultaneous machining, which enables the creation of intricate geometries in a single setup, reducing cycle times and minimizing cumulative error from repositioning.

Our 5-axis CNC centers are equipped with high-speed spindles, dynamic tool compensation, and real-time monitoring systems that ensure optimal cutting conditions across a wide range of materials, including aluminum alloys, titanium, stainless steel, and engineering plastics. This flexibility allows us to maintain dimensional stability and surface integrity even in the most demanding applications. Advanced CAM software drives toolpath optimization, ensuring smooth transitions and minimal tool wear, which translates into consistent part quality and extended tool life.

To uphold the integrity of every machined component, Wuxi Lead implements a rigorous quality control protocol centered on Coordinate Measuring Machine (CMM) inspection. Each part undergoes comprehensive metrological verification, with data collected across critical dimensions, geometric tolerances, and surface profiles. Our CMM systems are calibrated to international standards and operated by certified metrology technicians, ensuring traceability and compliance with ISO 9001 and IATF 16949 requirements. This closed-loop inspection process enables immediate feedback for process adjustments, minimizing deviation and ensuring first-time-right outcomes.

The precision achievable at Wuxi Lead is defined by our commitment to maintaining tight tolerances across all production runs. Below is a summary of our standard and high-precision tolerance capabilities, reflecting both general machining performance and the enhanced control achieved through optimized fixturing, environmental stability, and advanced inspection.

| Feature | Standard Tolerance | High-Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions (up to 500 mm) | ±0.01 mm | ±0.005 mm | CMM, Micrometers |

| Angular Tolerance | ±0.05° | ±0.02° | CMM, Precision Probes |

| Positional Tolerance | ±0.012 mm | ±0.008 mm | CMM |

| Flatness | 0.01 mm per 100 mm | 0.005 mm per 100 mm | CMM, Surface Plate |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Surface Roughness Tester |

| Circular Runout | 0.015 mm | 0.005 mm | CMM, Dial Indicator |

These technical capabilities are reinforced by continuous investment in workforce training, machine calibration, and process validation. At Wuxi Lead Precision Machinery, we do not simply manufacture parts—we engineer reliability into every component, ensuring our clients receive products that meet the highest standards of precision and quality.

Material & Finish Options

Material Selection Fundamentals for Entry-Level CNC Machining

Selecting appropriate materials is critical for beginners implementing CNC machining. The wrong choice can lead to excessive tool wear, poor surface finishes, machine strain, and costly errors. Focus on materials balancing machinability, cost, and project requirements to ensure early success and process stability. Aluminum alloys represent the optimal starting point for most new CNC operators due to their favorable characteristics.

Aluminum Alloys

Aluminum, particularly grades 6061-T6 and 7075-T6, offers excellent machinability with high chip evacuation rates and low cutting forces. Its thermal conductivity minimizes heat buildup during milling or turning, reducing the risk of workpiece distortion. Beginners achieve consistent results with standard carbide tooling and moderate spindle speeds. Aluminum is lightweight, corrosion-resistant, and cost-effective, making it ideal for prototypes, enclosures, and non-structural components. Ensure coolant application is optimized to prevent built-up edge, a common novice issue.

Carbon and Alloy Steels

Steels like 1018, 1045, and 4140 provide greater strength and wear resistance than aluminum but demand more robust machine setups. Higher cutting forces require rigid CNC platforms with sufficient torque, especially for deeper cuts or interrupted machining. Tool wear accelerates significantly compared to aluminum; beginners must implement strict tool life monitoring and use appropriate coated carbide inserts. Pre-hardened steels (e.g., 4140) necessitate slower speeds and careful heat management. Steel machining is essential for structural parts, shafts, and tooling but requires disciplined parameter control.

Titanium Alloys

Titanium (primarily Grade 5, Ti-6Al-4V) presents substantial challenges unsuitable for initial CNC learning curves. Its low thermal conductivity causes intense localized heat, demanding high-pressure coolant systems and specialized tool geometries. Material removal rates are inherently slow, and the alloy work-hardens rapidly under improper feeds/speeds. Significant machine rigidity and vibration damping are non-negotiable to prevent chatter. Reserve titanium for critical applications where its strength-to-weight ratio justifies the complexity and cost premium. Beginners should gain extensive steel machining experience first.

Anodizing Considerations

Anodizing is a vital secondary process for aluminum parts, enhancing corrosion resistance and enabling color coding. Type II (sulfuric acid) anodizing is standard for general use, while Type III (hardcoat) offers superior wear resistance. Crucially, anodizing dimensional changes occur—typically 0.0002-0.001 inches per surface. Design parts with this growth in mind, especially for tight-tolerance features. Mask critical bearing surfaces or threads. Wuxi Lead provides precise pre-anodize machining allowances and collaborates with certified finishing partners to ensure seamless integration.

Material Property Comparison for CNC Beginners

| Material | Typical Grades | Machinability Rating | Critical Machine Requirements | Relative Cost |

|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | Excellent (90-100%) | Standard rigidity, moderate RPM | Low |

| Carbon Steel | 1018, 1045 | Good (55-65%) | High rigidity, high torque | Medium |

| Alloy Steel | 4140, 4340 | Moderate (40-50%) | Very high rigidity, HP coolant | Medium-High |

| Titanium | Ti-6Al-4V (Gr5) | Poor (20-30%) | Extreme rigidity, HP coolant | Very High |

Begin with aluminum to master toolpath strategies, workholding, and inspection protocols before progressing to steels. Understand that material choice directly impacts machine capability requirements, tooling costs, and cycle times. Wuxi Lead Precision Machinery provides dedicated support for material-specific parameter optimization and process validation, ensuring your entry-level CNC investment delivers immediate, reliable results. Partner with us to navigate these selections confidently.

Manufacturing Process & QC

The journey from concept to final product in precision CNC machining begins with a meticulously structured production process. At Wuxi Lead Precision Machinery, we adhere to a disciplined workflow—Design, Prototyping, and Mass Production—engineered to deliver zero-defect components for high-end industrial applications. Each phase integrates advanced technology, rigorous validation, and continuous feedback loops to ensure dimensional accuracy, material integrity, and long-term reliability.

Design is the foundation. Our engineering team collaborates closely with clients to translate initial concepts into detailed 3D CAD models. These models are optimized for manufacturability, considering material properties, tool access, thermal behavior, and geometric tolerances. Finite Element Analysis (FEA) and Design for Manufacturing (DFM) reviews are conducted to preempt potential issues. Once approved, the design is converted into CNC toolpaths using industry-leading CAM software, ensuring optimal cutting strategies, reduced cycle times, and minimal tool wear.

Prototyping follows as a critical validation step. A small batch of parts is produced under production-intent conditions, using the same CNC machines, tooling, and quality inspection protocols. This phase allows us to verify form, fit, and function. Components undergo full metrological inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Any deviations are analyzed, and process adjustments are made before advancing to full-scale production. The prototype serves not only as a physical proof of concept but also as a benchmark for quality assurance.

Mass production is executed with the same precision and scrutiny as the prototype phase. Our facility employs high-performance CNC machines, including 5-axis milling centers and precision turning centers, all maintained under strict calibration schedules. Real-time monitoring systems track spindle load, tool wear, and environmental conditions to detect anomalies before they affect part quality. Every component is subject to in-process and final inspection, with traceability maintained through digital quality records. Our zero-defect philosophy is enforced through Statistical Process Control (SPC), root cause analysis, and continuous operator training.

This end-to-end process ensures that every part meets the highest standards of precision and reliability. By integrating design intelligence, empirical validation, and disciplined manufacturing, Wuxi Lead Precision Machinery delivers consistent, high-quality results—on time and to specification.

| Specification | Detail |

|---|---|

| Machine Types | 5-Axis CNC Milling, CNC Turning, Vertical Machining Centers |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Engineering Plastics |

| Maximum Work Envelope | 1200 x 800 x 600 mm (XYZ) |

| Surface Finish | Ra 0.4 µm (standard), down to Ra 0.1 µm (precision polish) |

| Quality Standards | ISO 9001:2015, Full First Article Inspection (FAI), SPC Reporting |

Why Choose Wuxi Lead Precision

Strategic Partnership for Your CNC Foundation

Selecting your first CNC machine requires more than evaluating technical specifications. It demands a partnership with a manufacturer who understands the unique challenges faced by new adopters in precision manufacturing. At Wuxi Lead Precision Machinery, we recognize that beginners prioritize reliability, intuitive operation, and responsive technical support above all else. Our mission is to eliminate the steep learning curve associated with CNC integration, transforming initial investment into immediate productivity. We provide not just machines, but a complete ecosystem designed for operational success from day one.

Wuxi Lead Precision Machinery specializes in entry-level CNC solutions engineered for real-world manufacturing environments. Our LEAD-200 Series milling centers embody this commitment, blending industrial-grade rigidity with user-centric design. Unlike generic entry models, these machines feature factory-calibrated linear guides, sealed spindle units for extended service life, and a simplified control interface compatible with common CAM software. This ensures rapid operator proficiency while maintaining the dimensional accuracy demanded by aerospace, medical, and automotive supply chains. Below are critical specifications demonstrating our beginner-optimized engineering:

| Feature | Specification | Beginner Benefit |

|---|---|---|

| Control System | Fanuc 0i-F Plus | Intuitive graphical interface; minimal retraining |

| Spindle Speed Range | 8,000 RPM (Constant Torque) | Reduced chatter on first attempts; safer operation |

| Work Envelope | 500 x 350 x 300 mm | Fits standard workshop layouts; low footprint |

| Tool Magazine | 24-Position ATC | Unattended operation capability from day one |

| Positioning Accuracy | ±0.005 mm (ISO 230-2) | Eliminates costly scrap during skill development |

Beyond hardware, our partnership model delivers tangible operational advantages. Every LEAD-200 installation includes on-site commissioning by certified engineers, ensuring perfect machine alignment and process validation. Our dedicated Beginner Support Portal provides 24/7 access to video tutorials, G-code troubleshooting libraries, and live chat with application specialists. Crucially, we implement a phased training program – starting with basic setup and progressing to advanced toolpath optimization – so your team builds confidence incrementally. This structured approach reduces downtime by up to 65% compared to industry averages during the critical first six months of operation.

The true cost of a CNC investment lies not in the purchase price, but in delayed production and unresolved technical hurdles. Wuxi Lead Precision Machinery mitigates these risks through proactive engineering and unwavering post-sale commitment. We measure our success by your machine uptime and part quality, not just the transaction.

Initiate your precision manufacturing journey with a partner who guarantees operational readiness. Contact our Engineering Solutions Team directly at [email protected] to schedule a personalized machine demonstration and receive a complimentary Beginner’s Process Integration Assessment. Specify reference code LP-B2B2024 in your correspondence to expedite technical consultation. Let us transform your CNC adoption from a challenge into your most strategic operational advantage.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.