Dive into the world of metal bending with our comprehensive guide, exploring various methods like CNC pipe bending, custom metal and sheet metal bending, and their diverse applications across industries. Discover the art and science behind transforming metal sheets into functional and aesthetic components, and learn about the considerations and buyer intentions in this multifaceted field. Whether you’re an industry professional or a DIY enthusiast, explore the endless possibilities and innovations in metal bending.

The Art and Science of Bending Metal Sheets: A Comprehensive Guide

Bending metal sheets is a fascinating process that combines both art and science. It is a fundamental technique used in various industries such as manufacturing, construction, and automotive. This blog post delves into the intricacies of bending metal sheets, exploring the methods, applications, and considerations to keep in mind for achieving optimal results.

Understanding Metal Bending

Metal bending is the process of deforming metal sheets by applying force, which alters the shape without changing the volume. The primary goal is to create bends at specific angles and locations on the sheet, which can be achieved through various bending methods, each with its unique advantages and applications.

Methods of Bending Metal Sheets

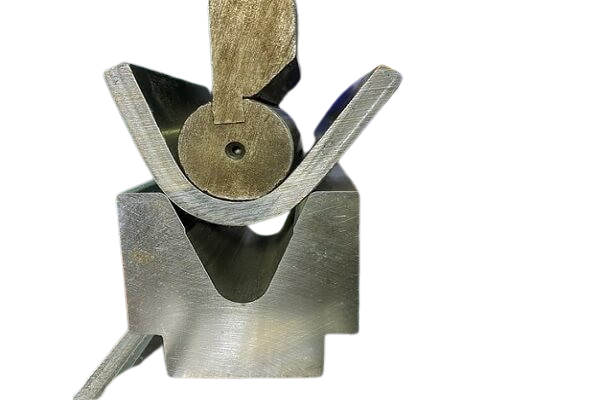

- V-Die Bending: This is the most common method, where the metal sheet is placed over a die and pressed into a V shape. It is versatile and suitable for different metals and thicknesses.

- U-Bend or Edge Bending: In this method, the sheet metal is bent over a straight edge, creating a U shape. It is ideal for making channels and pans.

- Rotary Bending: This technique uses a rotating die to bend the metal, minimizing scratching and providing high precision.

- Air Bending: Air bending involves positioning the sheet metal on top of a die and pressing it with a punch, allowing for a range of bend angles.

- Wipe Bending: Wipe bending is used to create closed shapes by wiping the metal sheet around a die.

Applications of Bended Metal Sheets

Bended metal sheets are integral to various industries, serving diverse purposes:

- Construction: In construction, bent metal sheets are used for roofing, cladding, and structural components, providing strength and stability to buildings.

- Automotive: The automotive industry utilizes bent metal sheets to form body panels, frames, and other parts of vehicles.

- Aerospace: In aerospace, precision-bent metal components are essential for aircraft structures, ensuring aerodynamic efficiency and safety.

- Manufacturing: Manufacturing industries employ metal bending for creating machinery parts, enclosures, and equipment housings.

- Art and Sculpture: Artists and sculptors use bent metal sheets to craft intricate designs and contemporary art pieces.

Considerations for Bending Metal Sheets

- Material Selection: The type of metal, its thickness, and properties influence the bending process. Commonly used metals include steel, aluminum, copper, and brass.

- Bend Radius: The bend radius is the curvature of the bend, which should be carefully calculated to avoid cracks and deformities.

- Bend Angle: The angle of the bend determines the final shape of the component. Accurate angle measurements are crucial for achieving the desired result.

- Springback: Metal sheets tend to spring back to their original shape after bending. Accounting for springback is essential for accurate bending.

- Tooling: Choosing the right tools and dies is vital for achieving precise bends and preventing damage to the metal sheet.

Understanding Buyer Intentions

When buyers search for “bend metal sheet”, their intentions can be diverse. Here are some possible intentions and questions they might have:

- Learning about Methods and Techniques:

- Buyers might be looking to understand how to bend metal sheets, the different methods available, and which method is best suited for their needs.

- Questions might include: “How do you bend metal sheets?”, “Which bending method is best for thin metal sheets?”, etc.

- Seeking Metal Bending Services:

- Buyers might be looking for companies or individuals that offer metal sheet bending services to complete specific projects or tasks.

- Questions might include: “Where can I find metal sheet bending services?”, “How much do metal sheet bending services cost?”, etc.

- Purchasing Bended Metal Sheet Products:

- Buyers might be interested in purchasing pre-bended metal sheet products for construction, decoration, or other purposes.

- Questions might include: “Where can I buy bended metal sheets?”, “What is the price of bended metal sheets?”, etc.

- Looking for Metal Bending Machinery and Tools:

- Buyers might be in search of machinery and tools used for bending metal sheets.

- Questions might include: “Which metal sheet bending machine is the best?”, “How to choose metal sheet bending tools?”, etc.

- Searching for Metal Sheet Bending Suppliers or Manufacturers:

- Buyers might be looking for suppliers or manufacturers who can provide custom bended metal sheets, including those in China.

- Questions might include: “Which manufacturers in China provide metal sheet bending?”, “How to contact metal sheet bending suppliers?”, etc.

- Exploring Applications and Industry Standards:

- Buyers might want to know about the applications of bended metal sheets in different industries and the relevant industry standards and specifications.

- Questions might include: “What are the applications of bended metal sheets?”, “What are the industry standards for bended metal sheets?”, etc.

Bending metal sheets is a versatile and invaluable technique with widespread applications across various industries. By understanding the different methods, applications, considerations, and buyer intentions involved, one can master the art and science of bending metal sheets to create high-quality, functional, and aesthetically pleasing products. Whether you are a professional in the field or a DIY enthusiast, the world of metal bending offers endless possibilities and opportunities for innovation.

Bending Metal Sheets: Frequently Asked Questions (FAQs)

Bending metal sheets is a process integral to numerous industries, and for those delving into this field, several questions often arise. This article aims to address some of the most frequently asked questions about bending metal sheets, providing insights into methods, services, purchasing, machinery, suppliers, and applications.

- How do you bend metal sheets?

Bending metal sheets involves applying force to deform the sheet, altering its shape without changing the volume. Various methods such as V-Die Bending, U-Bend or Edge Bending, Rotary Bending, Air Bending, and Wipe Bending are used, each suitable for different types of metals and thicknesses.

- Which bending method is best for thin metal sheets?

V-Die Bending and Air Bending are often considered suitable for thin metal sheets due to their versatility and the ability to create precise bends with minimal material damage.

- Where can I find metal sheet bending services?

Metal sheet bending services can be found through online directories, local classifieds, or industry-specific forums. Reputable companies often have websites showcasing their services, portfolio, and contact information.

- How much do metal sheet bending services cost?

The cost of metal sheet bending services varies depending on factors such as the complexity of the project, the type of metal used, the bending method employed, and the service provider’s pricing structure. It is advisable to obtain quotes from multiple service providers for a comprehensive cost assessment.

- Where can I buy bended metal sheets?

Bended metal sheets can be purchased from manufacturers, suppliers, and retailers specializing in metal products. Online platforms such as Alibaba, Amazon, and eBay also offer a variety of bended metal sheets for different applications.

- What is the price of bended metal sheets?

The price of bended metal sheets depends on factors such as the type of metal, thickness, size, and the seller’s pricing strategy. Comparing prices from different sellers and considering bulk purchase discounts can help in finding competitive pricing.

- Which metal sheet bending machine is the best?

The choice of a metal sheet bending machine depends on specific project requirements, including the type of metal, thickness, and desired bend angles. Researching and comparing different machine models, reading user reviews, and consulting industry experts can aid in making an informed decision.

- How to choose metal sheet bending tools?

Choosing metal sheet bending tools involves considering the type of metal, the bending method, tool durability, and user compatibility. It is essential to select tools that are suitable for the specific metal and bending technique being used.

- Which manufacturers in China provide metal sheet bending?

Several manufacturers in China specialize in metal sheet bending, including Jiangsu Hoston Machine Tools Co., Ltd., Anhui Runbang Heavy Industry Machinery Co., Ltd., and Maanshan Durmapress Machinery Technology Co., Ltd. Conducting thorough research and contacting manufacturers directly can help in finding the right partner.

- How to contact metal sheet bending suppliers?

Metal sheet bending suppliers can be contacted through their official websites, email addresses, phone numbers, or social media platforms. Trade shows and industry events also provide opportunities to meet suppliers and discuss potential collaborations.

- What are the applications of bended metal sheets?

Bended metal sheets are widely used in construction, automotive, aerospace, manufacturing, art, and sculpture. They serve various purposes, including forming structural components, vehicle body panels, machinery parts, equipment housings, and artistic creations.

- What are the industry standards for bended metal sheets?

Industry standards for bended metal sheets vary depending on the application and region. Common standards include ISO 9001 for quality management, ASTM A36 for structural steel, and ANSI B16.5 for flanges and flanged fittings. Adherence to relevant standards ensures product quality, safety, and compatibility.

Understanding the intricacies of bending metal sheets is essential for both industry professionals and enthusiasts. This FAQ article sheds light on common queries, aiding in enhancing knowledge and making informed decisions in the realm of metal bending. Whether you are seeking services, purchasing products, or exploring applications, the world of metal bending is vast and full of opportunities.

Exploring the World of Custom Metal Bending: A Diverse Landscape

In the realm of metal fabrication, various techniques and services have emerged to meet the diverse needs of industries and individual projects. Among these, CNC pipe bending, custom metal bending, and sheet metal bending services stand out, offering precision, versatility, and customization. This article delves into these distinct yet interconnected topics, exploring the nuances and applications of each.

- CNC Pipe Bending

CNC pipe bending is a sophisticated technique that utilizes computer numerical control (CNC) technology to achieve precise bends on pipes and tubes. This method is renowned for its accuracy, repeatability, and efficiency, making it a preferred choice for industries such as automotive, aerospace, and construction, where precision is paramount.

- Custom Metal Bending

Custom metal bending encompasses a range of techniques and services tailored to create unique and specific metal components. This customization allows for the creation of parts that meet exact specifications and requirements, catering to various industries, including machinery, architecture, and art. Whether it’s steel, aluminum, or copper, custom metal bending provides solutions for diverse materials and applications.

- Custom Sheet Metal Bending

A subset of custom metal bending, custom sheet metal bending focuses on the deformation of sheet metal to form desired shapes and angles. This service is essential for manufacturing enclosures, brackets, and panels, offering versatility and adaptability to meet the intricate needs of different projects.

- Sheet Metal Bending Services

Sheet metal bending services are widely sought after for their ability to transform flat sheets of metal into three-dimensional objects. These services are integral to industries such as electronics, HVAC, and furniture, providing the foundation for the fabrication of a myriad of products and components.

- CNC Sheet Metal Bending

Merging technology with versatility, CNC sheet metal bending employs computer-controlled machinery to achieve precise and consistent bends on sheet metal. This method is especially valuable for high-volume production runs, where uniformity and accuracy are crucial.

- Custom Steel Bending

Delving into material-specific bending, custom steel bending is a service that specializes in manipulating steel to form desired shapes and structures. This technique is widely used in construction and automotive industries, where the strength and durability of steel are essential.

- Custom Metal Tube Bending

Custom metal tube bending is a versatile service that caters to the bending of various metal tubes, including steel, aluminum, and stainless steel. This service finds applications in sectors such as healthcare, automotive, and industrial equipment manufacturing.

- Custom Stainless Steel Bending

Focusing on a specific material, custom stainless steel bending is a technique used to deform stainless steel, known for its corrosion resistance and strength. This service is vital in industries such as food processing, medical, and marine, where the properties of stainless steel are highly valued.

- Custom Stainless Steel Tube Bending

Custom stainless steel tube bending takes the bending of stainless steel to a more specialized level, focusing on tubes used in applications like exhaust systems, handrails, and medical devices. The corrosion resistance and aesthetic appeal of stainless steel make it a popular choice for such applications.

The world of metal bending is diverse and multifaceted, offering a plethora of services and techniques to meet the varying needs of industries and projects. From CNC pipe bending to custom stainless steel tube bending, each service brings unique advantages and applications, contributing to the advancement of fabrication and manufacturing. Whether you are exploring options for a specific project or seeking to understand the landscape of metal bending, the possibilities are vast and ever-evolving.

The exploration of bending metal sheets and custom metal bending reveals a world rich with possibilities and innovations. These techniques, combining both art and science, play a pivotal role in various industries, shaping the structures and components that are integral to our daily lives. From the precision of CNC pipe bending to the versatility of custom sheet metal bending, each method offers unique advantages and applications. Understanding the intricacies of these processes, the considerations involved, and the diverse intentions of buyers opens up a realm of opportunities for both professionals and enthusiasts. Whether you are delving into the practical applications in construction and manufacturing or appreciating the artistic creations sculpted from metal, the knowledge and insights gained from this comprehensive guide serve as a foundation for mastering the art and science of metal bending. Here’s to exploring further, innovating more, and bending the boundaries of what metal can achieve!