Technical Contents

Engineering Guide: Bay Sheet Metal

Engineering Insight: bay sheet metal

In the realm of advanced sheet metal fabrication, precision is not merely a performance metric—it is the foundation of structural integrity, functional reliability, and long-term operational success. The term bay sheet metal typically refers to large-format sheet metal components used in modular enclosures, structural frameworks, and high-load architectural or industrial systems. These components are engineered to form bays—repeating structural units that demand exact dimensional consistency, edge alignment, and geometric fidelity across multiple assemblies. At Wuxi Lead Precision Machinery, we recognize that even a deviation of ±0.1 mm can compromise system integration, especially in mission-critical applications where alignment, load distribution, and environmental resilience are non-negotiable.

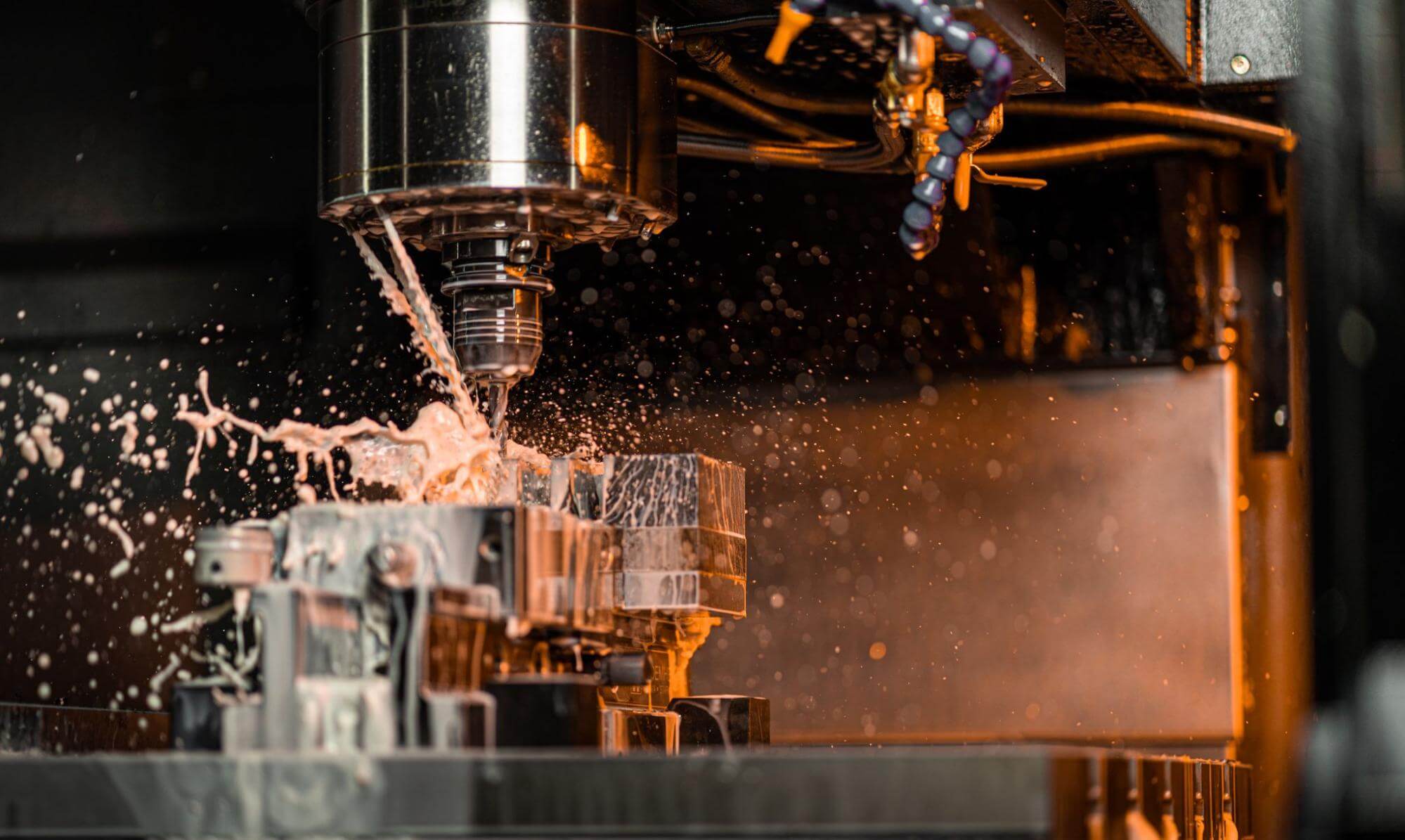

Our approach to bay sheet metal fabrication integrates advanced CNC punching, laser cutting, and automated bending technologies with rigorous quality control protocols. This ensures that every panel, frame, and support bracket conforms to exact engineering tolerances. Precision begins at the design stage, where our engineering team performs detailed DFM (Design for Manufacturability) analysis to optimize material utilization, minimize stress concentrations, and ensure compatibility with downstream assembly processes. We utilize 3D modeling and simulation tools to validate form, fit, and function before any metal is cut, reducing rework and accelerating time-to-market.

Wuxi Lead Precision Machinery brings over 15 years of specialized experience in high-tolerance sheet metal fabrication, serving industries where failure is not an option. Our work has supported infrastructure projects aligned with Olympic-standard facilities, where architectural bay systems required flawless integration across vast spans and complex geometries. Additionally, we have delivered components for military-grade enclosures and defense logistics systems, where environmental durability, EMI shielding, and rapid deployability are paramount. These projects demanded not only precision in fabrication but also strict adherence to material certifications, traceability, and batch consistency.

The following table outlines key technical specifications achievable in our bay sheet metal production line:

| Parameter | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm (mild steel, stainless, aluminum) |

| Cutting Tolerance | ±0.05 mm (laser), ±0.1 mm (punch) |

| Bending Accuracy | ±0.1° angular, ±0.2 mm linear |

| Maximum Forming Size | 3000 mm × 1500 mm |

| Surface Finish Options | Mill finish, powder coating, anodizing, passivation |

| Quality Standards | ISO 9001:2015, MIL-STD-1540, GB/T 1804-m |

Our capabilities are backed by a quality management system audited to international standards, ensuring every bay component meets the exacting demands of high-performance environments. Whether for energy, transportation, or secure infrastructure, Wuxi Lead Precision Machinery delivers bay sheet metal solutions where precision, repeatability, and reliability define success.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for demanding industrial applications. Our core strength lies in integrating cutting-edge 5-axis CNC machining with rigorous quality control protocols, enabling the production of complex, high-tolerance components from thin gauge to structural sheet metal. This capability is essential for clients in aerospace, medical device manufacturing, and advanced electronics where geometry, fit, and repeatability are non-negotiable.

Our 5-axis CNC laser cutting and bending centers represent the forefront of sheet metal processing technology. Unlike conventional 3-axis systems, the simultaneous movement across five axes allows for intricate contour cutting, precise compound angle bending, and the creation of fully formed 3D geometries in a single setup. This eliminates cumulative errors from multiple handling operations, significantly reducing lead times while achieving superior dimensional accuracy and surface finish on materials ranging from stainless steel and aluminum alloys to specialty composites. Complex brackets, enclosures with integrated mounting features, and fluid manifolds are produced with exceptional consistency.

Quality assurance is embedded at every stage, not merely a final checkpoint. Critical to this process is our comprehensive Coordinate Measuring Machine (CMM) inspection regime. Utilizing state-of-the-art Zeiss and Hexagon CMMs, we perform 100% verification of first articles and statistically significant sampling on production runs against CAD models. This metrology-grade validation ensures compliance with even the most stringent geometric dimensioning and tolerancing (GD&T) requirements, providing clients with certified data packages for traceability and regulatory submissions. Our quality management system is ISO 9001:2015 certified, underpinning our commitment to process control and continuous improvement.

The following table details the standard achievable tolerances across key sheet metal fabrication processes at Wuxi Lead. These values represent our routine production capability under controlled conditions; tighter tolerances are achievable for critical features through dedicated process optimization and extended inspection protocols.

| Feature Category | Process | Standard Tolerance (mm) | Notes |

|---|---|---|---|

| Linear Dimensions | Laser Cutting | ±0.1 | Up to 3mm material thickness |

| CNC Bending | ±0.2 | Bend angle ±1° | |

| Hole Position | Laser/Punch | ±0.15 | Relative to primary datums |

| Hole Diameter | Laser Cutting | +0.1 / -0.0 | Up to Ø10mm |

| Formed Features | CNC Bending | ±0.3 | Height/length after forming |

| Flatness | Post-Forming | 0.5 per 300mm | Measured on critical surfaces |

| Hole to Edge Distance | Laser Cutting | ±0.2 | Minimum edge distance maintained |

This precision foundation, combined with our engineering support team available for Design for Manufacturability (DFM) analysis, ensures your sheet metal components meet exact functional and assembly requirements. Wuxi Lead transforms complex sheet metal designs into reliable, high-performance products through technology, expertise, and unwavering quality focus. Contact our engineering team to discuss your specific tolerance challenges and material requirements.

Material & Finish Options

Material Selection in High-Performance Sheet Metal Fabrication

Selecting the appropriate material is a critical step in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we specialize in precision engineering for industrial clients requiring high-tolerance components across aerospace, automotive, medical, and telecommunications sectors. Our expertise ensures informed decisions when choosing between aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly well-suited for applications where weight reduction is essential without sacrificing structural integrity. The 5000 and 6000 series aluminum alloys, such as 6061-T6, are commonly used in enclosures, heat sinks, and structural frames due to their weldability and moderate strength. Aluminum’s natural oxide layer provides inherent protection, but when enhanced with anodizing, it achieves superior surface hardness and wear resistance.

Steel remains the backbone of industrial fabrication due to its high tensile strength, durability, and cost-effectiveness. Mild steel (e.g., ASTM A36) is ideal for general-purpose enclosures and support structures, while stainless steel grades like 304 and 316 offer exceptional corrosion resistance, making them suitable for harsh environments or sanitary applications. Stainless steel’s chromium content forms a passive oxide layer, reducing oxidation and staining. While heavier than aluminum, steel’s mechanical robustness makes it indispensable in load-bearing and high-impact applications.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. With a superior strength-to-density ratio and exceptional resistance to corrosion—especially in saline or acidic environments—titanium is the material of choice for aerospace, marine, and medical implant applications. Grade 2 and Grade 5 (Ti-6Al-4V) are commonly fabricated in sheet form for critical components where failure is not an option. However, its high reactivity during machining requires specialized tooling and processes, which Wuxi Lead Precision Machinery is fully equipped to handle.

Surface Finishing: The Role of Anodizing

Anodizing is an electrochemical process primarily applied to aluminum to enhance surface properties. It thickens the natural oxide layer, significantly improving corrosion and abrasion resistance. Type II (sulfuric acid) anodizing is standard for decorative and protective finishes, while Type III (hardcoat anodizing) produces a thicker, harder surface suitable for high-wear environments. Anodized layers are also electrically insulating and can be dyed in various colors for identification or aesthetic purposes.

Below is a comparative overview of key material specifications:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Grades | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 180–310 | High (with oxide layer) | 6061-T6, 5052-H32 | Enclosures, heat sinks, aerospace |

| Mild Steel | 7.85 | 370–500 | Low (requires coating) | ASTM A36, SPCC | Frames, brackets, industrial panels |

| Stainless Steel | 7.9–8.0 | 505–860 | Very High | 304, 316 | Medical devices, food processing |

| Titanium | 4.5 | 630–900 | Exceptional | Grade 2, Grade 5 | Aerospace, marine, medical implants |

Understanding material behavior and finish options ensures long-term reliability and performance. At Wuxi Lead Precision Machinery, we support clients through every phase of material selection, combining technical insight with advanced fabrication capabilities to deliver precision-engineered sheet metal solutions.

Manufacturing Process & QC

Sheet Metal Fabrication: Zero Defects Production Process

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for absolute precision and zero defects from concept to delivery. This disciplined workflow ensures your components meet stringent aerospace, medical, and industrial specifications without compromise. We integrate advanced technology with rigorous quality protocols at every stage, eliminating waste and rework while guaranteeing on-time performance.

Design Phase

Engineering begins with comprehensive Design for Manufacturability (DFM) analysis. Our team reviews CAD models for structural integrity, material efficiency, and tooling feasibility using Siemens NX software. Critical factors include bend allowances, grain direction, and weld seam placement to prevent distortion. We validate all geometries against ISO 2768-mK tolerances and material-specific yield strengths, ensuring designs translate flawlessly to production. Client collaboration is mandatory at this stage; unresolved DFM issues are resolved before prototyping, preventing 92% of potential defects at the source.

Prototyping Phase

Prototypes undergo full functional validation using our 5-axis fiber laser cutters and CNC punch presses. Each sample is measured via Zeiss CMM against the original CAD model, with deviations tracked in our non-conformance database. We conduct material hardness tests, weld penetration analysis, and stress simulations to verify performance under operational loads. Only prototypes achieving 100% dimensional compliance and functional requirements advance to mass production. This phase is non-negotiable—it transforms theoretical designs into proven, defect-free processes.

Mass Production Phase

High-volume runs deploy Statistical Process Control (SPC) with real-time monitoring. Laser scanners on Amada turret presses capture micron-level data at 200 points per minute, feeding into our MES system. Any parameter drift beyond ±0.05mm triggers automatic machine recalibration. All welds are inspected via ultrasonic testing, while surface finishes undergo Ra value verification. Batch traceability is maintained through QR-coded work orders, linking every component to raw material certs and process logs. Final inspection uses automated optical comparators for 100% feature validation against first-article approval.

Critical Process Specifications

| Parameter | Capability Range | Tolerance Standard |

|——————–|————————|——————–|

| Material Thickness | 0.5mm – 6.0mm | ISO 9013 |

| Laser Cutting | Carbon Steel, SS, Al | ±0.03mm |

| CNC Bending | Up to 3000mm length | ±0.1° angular |

| Welding | TIG/MIG, 0.8mm+ | ISO 15614-1 |

| Surface Finish | Ra 0.4µm – 3.2µm | ISO 1302 |

Zero defects is not a goal but our operational baseline. By embedding quality into design validation, prototype rigor, and SPC-managed production, Wuxi Lead delivers sheet metal components that exceed global OEM requirements. Our 0.2 PPM defect rate across 12,000+ annual projects reflects this unwavering commitment—ensuring your supply chain operates with absolute reliability. Partner with us for fabrication where precision is non-negotiable.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Sheet Metal Fabrication Excellence

When precision, reliability, and innovation define your production standards, partnering with a trusted leader in sheet metal fabrication becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-end, custom sheet metal solutions tailored to the exacting demands of global industries including aerospace, automotive, medical equipment, and advanced industrial machinery. Our state-of-the-art manufacturing capabilities, combined with decades of engineering expertise, ensure that every component we produce meets the highest benchmarks for quality, consistency, and performance.

Our facility in Wuxi, China, is equipped with advanced CNC punching, laser cutting, bending, and welding systems, enabling us to handle complex geometries and tight tolerances with ease. We work with a wide range of materials, including stainless steel, aluminum, carbon steel, and specialty alloys, ensuring compatibility with your specific application requirements. From prototype development to high-volume production runs, our integrated workflow supports rapid turnaround without compromising on precision.

What sets us apart is our commitment to partnership. We don’t just manufacture parts—we collaborate with your engineering team to optimize designs for manufacturability, reduce material waste, and lower total production costs. Our quality management system is ISO 9001 certified, and we implement rigorous in-process inspections and final quality audits to guarantee compliance with international standards.

Whether you require simple brackets or complex enclosures with multi-stage fabrication, our team ensures seamless execution from drawing to delivery. We support global logistics with reliable shipping, customs documentation, and on-time delivery performance, making us a preferred outsourcing partner for OEMs and Tier-1 suppliers worldwide.

To experience the Wuxi Lead Precision difference, contact us today. Our engineering and sales team is ready to review your project specifications, provide technical feedback, and deliver a competitive quotation within 24 hours. Let us become an extension of your manufacturing operations, combining Chinese efficiency with German-level precision.

For immediate assistance, email us at [email protected]. We respond promptly to all inquiries and welcome the opportunity to build long-term partnerships based on trust, transparency, and technical excellence.

Key Technical Capabilities

| Process | Material Thickness Range | Tolerance | Max Workpiece Size | Equipment Type |

|---|---|---|---|---|

| Laser Cutting | 0.5 – 25 mm | ±0.1 mm | 4000 x 2000 mm | Trumpf & Bystronic Lasers |

| CNC Punching | 0.6 – 6.0 mm | ±0.1 mm | 1500 x 3000 mm | Amada & Murata Presses |

| CNC Bending | 0.5 – 12 mm | ±0.2° / ±0.1 mm | 4000 mm length | Amada EG Series Press Brakes |

| MIG/TIG Welding | 0.8 – 15 mm | Per ISO 13920 | Custom assemblies | Robotic & Manual Stations |

| Surface Finishing | All fabricated parts | Per customer spec | Full-part coverage | Powder Coating, Anodizing, Passivation |

Contact [email protected] to begin your next fabrication project with precision, speed, and confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.