Technical Contents

Engineering Guide: Battlebot Parts

Engineering Insight: Precision as the Foundation of Battlebot Dominance

Battlebot combat exposes manufacturing flaws with brutal honesty. Components subjected to multi-ton impact forces and rotational stresses exceeding 3000G demand tolerances far beyond standard industrial applications. A weapon shaft deviating by 0.05mm induces catastrophic vibration at 10000 RPM, transforming kinetic energy into self-destruction. Armor plates with inconsistent hardness ratings fracture unpredictably under hammer strikes, while drivetrain misalignment guarantees immediate gear failure. This extreme environment necessitates precision manufacturing not as an option, but as the fundamental requirement for survival and victory. Standard machining practices simply cannot deliver the geometric accuracy, material integrity, and fatigue resistance demanded when robots collide at full speed.

Wuxi Lead Precision Machinery applies aerospace-grade discipline to battlebot component fabrication. Our CNC machining centers operate under stringent environmental controls, maintaining thermal stability critical for micron-level repeatability. This capability is forged through direct experience supplying mission-critical components where failure is unacceptable. We manufacture timing system elements for Olympic sports infrastructure requiring microsecond synchronization across global venues. More significantly, our facility produces classified structural components for military unmanned systems operating in contested environments – components where a single micron deviation compromises system integrity under explosive ordnance testing. This heritage translates directly to battlebots: our processes ensure weapon spindles achieve true runout below 0.003mm, armor interfaces maintain perfect flatness across complex geometries, and drivetrain assemblies eliminate parasitic losses through exacting concentricity control. The physics of high-impact robotics mirrors defense and elite sports engineering – only certified precision guarantees performance under duress.

The table below details critical battlebot components where our precision engineering delivers decisive competitive advantage:

| Component | Critical Specification | Standard Tolerance | Lead Precision Tolerance | Verification Method |

|---|---|---|---|---|

| Rotating Weapon Shaft | Runout at 10000 RPM | ±0.05mm | ±0.003mm | Laser Doppler Vibrometry |

| Impact Armor Plate | Surface Hardness Uniformity | ±15 HV | ±3 HV | Micro-Vickers Mapping |

| Drivetrain Hub | Bore-to-OD Concentricity | ±0.025mm | ±0.005mm | CMM with 3D Deviation Analysis |

Achieving these specifications requires more than advanced machinery; it demands material science expertise and process validation honed through defense sector audits. We implement real-time in-process gaging during machining of battlebot weapon components, capturing thermal drift data to dynamically compensate tool paths – a technique directly adapted from our military subcontracting work. Surface integrity is equally critical; our isotropic superfinishing processes eliminate micro-crack initiation points on armor edges, verified through SEM analysis matching Olympic bobsled runner protocols. When your robot faces the kill saw, the difference between victory and scrap metal lies in the unyielding consistency of every micron. Partner with engineering rigor proven where consequences matter most.

Precision Specs & Tolerances

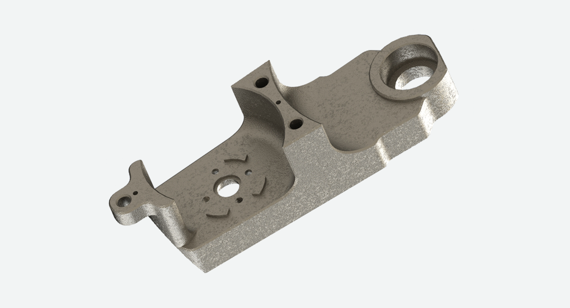

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the demanding requirements of high-performance applications, including battlebot components where precision, durability, and repeatability are non-negotiable. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, which enable us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis systems allow simultaneous movement across five planes, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is essential for fabricating intricate drivetrains, weapon systems, and structural chassis components common in competitive robotics.

Our machining fleet consists of high-rigidity, thermally stable CNC platforms equipped with automatic tool changers and high-resolution feedback systems. These machines support a wide range of engineering metals, including aerospace-grade aluminum alloys, hardened steels, titanium, and specialty composites. With rapid material removal rates and micron-level positioning accuracy, we ensure efficient production without compromising on dimensional fidelity. All operations are programmed using industry-leading CAM software, enabling optimized toolpaths, collision avoidance, and consistent part-to-part uniformity across both prototyping and volume production runs.

Quality assurance is integrated at every stage of manufacturing. Each component undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), which provides three-dimensional verification of critical features against CAD models. Our CMM system is calibrated to international standards and operated by certified metrology technicians, ensuring traceable, repeatable results. In addition to first-article inspection, we perform in-process and final inspections on all high-tolerance components, with full inspection reports available upon request.

The following table outlines our standard machining tolerances, which are routinely achieved and verified under controlled environmental conditions:

| Feature Type | Standard Tolerance | Tight Tolerance (Available) | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.01 mm | ±0.003 mm | Air Gauges, CMM |

| Positional Accuracy | ±0.02 mm | ±0.008 mm | CMM |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm | Surface Roughness Tester |

| Flatness | 0.02 mm | 0.005 mm | CMM, Optical Flat |

| Angular Features | ±0.05° | ±0.01° | CMM, Precision Protractor |

All tolerances are achievable in materials up to 600 mm in length, with scalable processes for larger assemblies. Our facility maintains strict environmental controls to minimize thermal drift during both machining and inspection. By combining advanced 5-axis CNC technology with comprehensive quality validation, Wuxi Lead Precision Machinery ensures that every battlebot component meets the highest standards of performance and reliability.

Material & Finish Options

Material Selection for BattleBot Competition Components

Selecting optimal materials is critical for BattleBot success where components face extreme impact, torsional stress, and weight constraints. At Wuxi Lead Precision Machinery we understand the unique demands of competitive robotics. Material choice directly influences weapon lethality structural integrity and overall robot survivability. This guide outlines key considerations for aluminum steel and titanium alloys alongside essential surface finishing requirements.

Aluminum alloys particularly 7075-T6 dominate chassis and structural frames due to their exceptional strength-to-weight ratio. This aerospace-grade alloy provides high yield strength while minimizing mass crucial for mobility and weapon spin-up. Steel alloys like 4140 and 4340 are indispensable for high-impact weapon systems such as vertical spinners and hammers where ultimate tensile strength and fracture resistance are paramount. Titanium Grade 5 (6Al-4V) offers the ultimate solution for critical load-bearing joints or weapon mounts where its superior fatigue strength and corrosion resistance justify the higher cost and machining complexity. Each material requires precise CNC processing to achieve the necessary geometries and tolerances under dynamic combat loads.

The following table details essential mechanical properties for common BattleBot materials:

| Material | Yield Strength (MPa) | Hardness (HB) | Density (g/cm³) | Machinability Rating |

|---|---|---|---|---|

| Aluminum 7075-T6 | 503 | 150 | 2.81 | Good |

| Steel 4140 | 655 | 200 | 7.85 | Moderate |

| Steel 4340 | 860 | 240 | 7.85 | Moderate-Poor |

| Titanium 6Al-4V | 880 | 360 | 4.43 | Poor |

Surface finishing is non-negotiable for BattleBot components. Standard decorative anodizing lacks the necessary durability. Hard anodizing (Type III) is mandatory providing a significantly thicker ceramic oxide layer. This process enhances surface hardness to 500-900 HV drastically improving wear resistance against impacts and abrasion from arena hazards. Critical specifications include a minimum coating thickness of 50-75μm and proper sealing to prevent moisture ingress which can lead to corrosion or coating spallation under stress. Unsealed or thin coatings will fail catastrophically during combat. Our precision anodizing processes strictly adhere to MIL-A-8625 standards ensuring consistent performance across all critical surfaces.

Wuxi Lead Precision Machinery combines deep material science expertise with advanced 5-axis CNC milling and turning capabilities. We specialize in machining these demanding alloys to tight tolerances ±0.005mm while maintaining structural integrity. Our integrated hard anodizing services guarantee coatings meet the rigorous demands of BattleBot competition. Selecting the right material-finish combination processed to exacting standards is not merely an option—it is the foundation of a competitive and resilient machine. Partner with us to transform your design into a battle-ready component.

Manufacturing Process & QC

At Wuxi Lead Precision Machinery, we specialize in delivering precision-engineered metal components tailored for high-performance applications such as battlebots, where reliability, strength, and exacting tolerances are non-negotiable. Our end-to-end manufacturing process is engineered for zero defects, ensuring every part meets the most rigorous operational demands. The journey from concept to final production is structured in three distinct phases: Design, Prototyping, and Mass Production.

The process begins with Design, where our engineering team collaborates closely with clients to translate functional requirements into manufacturable designs. Utilizing advanced CAD/CAM software and finite element analysis (FEA), we optimize geometry, material selection, and load-bearing characteristics. This phase includes comprehensive design for manufacturability (DFM) reviews to preempt potential production issues, reduce cycle times, and enhance part performance under dynamic stress conditions typical in combat robotics.

Following design finalization, we proceed to Prototyping. This stage is critical for validating form, fit, and function. Using CNC milling, turning, and precision grinding, we produce a limited batch of prototype parts in the intended production material—typically aerospace-grade aluminum, titanium, or hardened steel. These prototypes undergo rigorous in-house testing, including dimensional inspection via coordinate measuring machines (CMM), hardness testing, and stress simulation. Any deviations are addressed through iterative refinement, ensuring the design is fully optimized before scaling to mass production.

Once the prototype is approved, we transition to Mass Production using fully automated CNC machining cells equipped with real-time monitoring systems. Our facility operates under ISO 9001-certified quality management protocols, with statistical process control (SPC) implemented at every stage. Each component is traceable, with material certifications, inspection reports, and process logs maintained for full transparency. In-process inspections occur at defined intervals, while final inspection includes 100% critical dimension checks and random sampling for non-critical features.

Our commitment to zero defects is reinforced by redundant quality checkpoints, operator training, and preventive maintenance schedules. We utilize high-precision tooling with wear compensation algorithms to maintain consistency across production runs, whether manufacturing 50 or 5,000 units.

Below are key specifications supported in our production workflow:

| Parameter | Capability |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Materials | Aluminum 6061, 7075; Titanium Grade 5; Stainless Steel 304, 316; Tool Steel |

| Max Workpiece Size | 800 mm × 500 mm × 400 mm |

| Surface Finish | Ra 0.8 µm to Ra 3.2 µm (custom finishes available) |

| Production Capacity | Up to 10,000 units/month (per part type) |

| Lead Time (Prototype) | 7–10 business days |

| Lead Time (Mass Production) | 15–25 business days (depending on volume) |

Every battlebot component we manufacture is built to withstand extreme impact, friction, and fatigue. By integrating precision engineering with disciplined process control, Wuxi Lead ensures consistent, defect-free output—delivering performance-ready parts on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Battlebot Dominance

When your battlebot weapon shatters on impact or your chassis fails under stress, milliseconds decide victory. Generic manufacturers cannot replicate the precision-engineered resilience demanded by competitive robotics. At Wuxi Lead Precision Machinery, we engineer battlebot components to survive catastrophic forces—not just meet specifications. Our CNC expertise merges aerospace-grade material science with rapid iteration cycles, ensuring your design translates into arena-ready performance. We understand that a ±0.05mm tolerance error in a spinner hub accelerates bearing failure, or that improper heat treatment in titanium armor invites fracture under hammer strikes. This is why we deploy certified metallurgists alongside CNC programmers to optimize every cut, anneal, and surface finish for combat dynamics.

Our facility operates exclusively for mission-critical metal fabrication, featuring 5-axis milling centers with sub-micron repeatability and in-process probing for real-time geometric validation. Unlike standard job shops, we simulate battlebot-specific loads during production—validating rotational stability at 15,000 RPM for weapon shafts or impact resistance in wedge geometries. This eliminates the guesswork that plagues competitors relying on generic QA protocols. Below outlines our battlebot-optimized manufacturing capabilities:

| Specification Category | Performance Standard | Battlebot Relevance |

|---|---|---|

| Material Options | 4140 Chromoly, 7075-T6 Aluminum, 6AL-4V Titanium, Maraging Steel 300 | Weight-to-strength optimization for weapon inertia and chassis survival |

| Dimensional Tolerance | ±0.005mm (critical interfaces), ±0.025mm (non-critical) | Prevents binding in high-RPM weapon assemblies and drivetrain alignment |

| Surface Finish | Ra 0.8µm (bearing seats), Ra 3.2µm (structural) | Reduces friction in spinning mechanisms and minimizes stress risers |

| Impact Validation | 100+ drop tests per design iteration (up to 50J) | Simulates hammer strikes and arena barrier collisions |

| Lead Time | 72-hour rapid prototyping for validated designs | Accelerates tournament preparation cycles |

Speed without compromise defines our partnership model. Submit CAD files, and our engineering team delivers a failure-mode analysis within 4 business hours—highlighting stress concentrations, material suitability, and manufacturability risks before machining begins. We’ve reduced weapon system iteration time by 60% for top-tier BattleBots competitors through this proactive collaboration. When deadlines loom before events like RoboGames or BattleBots World Championship, our dedicated production cells bypass standard queuing to prioritize your build sequence.

Do not risk your tournament run on manufacturers who treat battlebots as generic machining jobs. Contact our engineering sales team directly at [email protected] with your component specifications or CAD files. Include “BattleBot Precision Request” in the subject line for immediate technical review. We will provide a detailed manufacturability report, material certification options, and a timeline synchronized to your competition schedule—all within one business day. Your robot’s durability starts with the precision of its foundation. Partner with the only CNC facility engineered for combat.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.