Technical Contents

Engineering Guide: Automotive Plastic Mould

Engineering Insight: The Critical Role of Precision in Automotive Plastic Mould Manufacturing

In the high-stakes arena of automotive manufacturing, the integrity and performance of every component are non-negotiable. Among the most vital stages in producing interior and exterior plastic components—from dashboards to bumpers—is the development of precision-engineered plastic moulds. At Wuxi Lead Precision Machinery, we understand that precision is not a feature—it is the foundation. Our decades of experience in custom metal manufacturing have been forged in environments where failure is not an option, including projects supporting Olympic infrastructure and military-grade equipment. This pedigree directly informs our approach to automotive plastic mould production, where micron-level accuracy determines functionality, safety, and cost-efficiency at scale.

Automotive plastic moulds must endure thousands, often millions, of injection cycles while maintaining dimensional stability, surface finish, and part consistency. Even deviations as slight as ±0.01 mm can result in part warpage, flash, or assembly misalignment—defects that cascade into costly recalls, production delays, and reputational damage. The complexity is amplified by the integration of multi-cavity designs, hot runner systems, and advanced cooling channels, all of which demand rigorous thermal and structural simulation during the design phase.

At Lead Precision, we deploy a closed-loop engineering process that begins with 3D CAD/CAM modeling and extends through finite element analysis (FEA), prototype validation, and real-time in-process metrology. Our CNC machining centers, operating with sub-micron repeatability, are staffed by engineers trained in both traditional toolmaking and digital manufacturing protocols. This hybrid expertise enables us to produce moulds that not only meet but exceed OEM specifications, particularly for high-performance polymers such as PPS, PEEK, and long-fiber reinforced thermoplastics used in modern lightweight vehicle platforms.

Our track record in mission-critical sectors has instilled a culture of zero-defect manufacturing. For instance, components produced for Olympic transportation systems required uninterrupted reliability under extreme environmental loads—conditions mirrored in automotive applications. Similarly, our military projects demanded resistance to vibration, thermal cycling, and corrosive exposure, all of which are directly transferable to under-hood and structural automotive components.

The table below outlines key technical specifications that define our automotive plastic mould capabilities:

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.01 mm |

| Mould Life Expectancy | 500,000 to 1,000,000 cycles |

| Surface Finish (Cavity/Core) | Ra ≤ 0.05 µm (Polished), MT-11 (Textured) |

| Materials Used | P20, 718H, S136, H13, Stainless Tool Steels |

| Machining Accuracy | 0.002 mm positional accuracy (5-axis CNC) |

| Lead Time (Average) | 45–60 days (complex multi-cavity moulds) |

| Quality Standards | ISO 9001, IATF 16949, Full First Article Inspection (FAI) |

Precision in automotive plastic moulds is not merely about dimensional correctness—it is about predictability, longevity, and system-wide reliability. At Wuxi Lead Precision Machinery, we engineer every mould as if it will support a critical national infrastructure project—because in the automotive world, it often does.

Precision Specs & Tolerances

Technical Capabilities for Automotive Plastic Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision and reliability in custom metal manufacturing for the demanding automotive plastic mold sector. Our integrated technical capabilities are engineered specifically to meet the stringent geometric complexity, surface finish requirements, and longevity expectations inherent in high-volume automotive component production. We combine advanced machinery with rigorous process control to ensure molds perform consistently across millions of cycles, directly impacting our clients’ production efficiency and part quality.

Advanced 5-Axis CNC Machining forms the cornerstone of our precision manufacturing. Utilizing state-of-the-art DMG MORI and Makino 5-axis vertical machining centers, we achieve exceptional accuracy on complex mold cores, cavities, slides, and intricate cooling circuits in a single setup. This eliminates cumulative errors from multiple fixtures, critical for maintaining tight positional tolerances between features like core pins and ejector sleeves. Our programming expertise leverages Siemens NX CAM to optimize toolpaths for hardened tool steels (P20, H13, S136, NAK80) and pre-hardened blocks, ensuring optimal surface integrity and minimizing post-machining handwork. The result is superior mold geometry fidelity, reduced cycle times during mold tryout, and extended mold service life under high-pressure injection conditions.

Rigorous Quality Control is non-negotiable in automotive applications. Every critical mold component undergoes comprehensive dimensional verification using calibrated Zeiss CONTURA and GLOBAL S coordinate measuring machines (CMM). Our inspection protocols, aligned with IATF 16949 standards, go beyond simple dimensional checks. We perform full 3D surface deviation analysis against the master CAD model, meticulously verifying complex contours, draft angles, radii, and critical clearance zones. This granular data ensures the physical mold geometry perfectly replicates the digital design intent, preventing costly part defects like flash, warpage, or dimensional non-conformance downstream. Real-time measurement feedback also drives continuous process improvement within our machining cells.

The following table details our standard and enhanced tolerance capabilities for key automotive mold features, achievable through our integrated 5-axis machining and CMM validation processes:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Cavity/Core Dimensions | ±0.010 mm | ±0.005 mm |

| Slide/Core Pin Bore Diam. | H7 (+0.015/0) | H6 (+0.009/0) |

| Parting Line Flatness | 0.02 mm | 0.01 mm |

| Ejector Pin Clearance | +0.025/-0.000 mm | +0.015/-0.000 mm |

| Cooling Channel Alignment | ±0.05 mm | ±0.02 mm |

| Surface Finish (Cavity) | Ra 0.4 µm | Ra 0.1 µm (Mirror Polish) |

This commitment to measurable precision, from initial machining through final validation, ensures Wuxi Lead molds deliver consistent part quality, minimize production downtime, and maximize return on investment for automotive tier suppliers and OEMs. We translate complex engineering requirements into robust, high-performance tooling solutions.

Material & Finish Options

Material selection is a critical phase in the development of high-performance automotive plastic moulds, directly influencing tool life, production efficiency, and part quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of the automotive industry. Our expertise enables clients to make informed decisions when selecting between aluminum, steel, and titanium for mould construction, as well as choosing appropriate surface treatments such as anodizing.

Aluminum is often selected for low- to medium-volume production due to its excellent machinability and thermal conductivity. It allows for faster cooling cycles, reducing overall cycle times during injection moulding. While not as durable as steel, modern high-strength aluminum alloys offer sufficient wear resistance for prototyping and short-run manufacturing. It is particularly advantageous when rapid iteration or time-to-market is a priority.

Steel remains the dominant material for high-volume automotive moulding applications. Tool steels such as P20, H13, and S136 offer exceptional hardness, wear resistance, and thermal stability. These properties ensure long service life under continuous operation and resistance to deformation under high pressure and temperature. For aggressive polymer formulations or abrasive fillers, hardened steel is indispensable. Its durability justifies the higher initial machining cost over extended production runs.

Titanium, while less common, presents unique benefits in specialized applications. Its high strength-to-density ratio and corrosion resistance make it suitable for lightweight, high-stress mould components. However, due to its cost and challenging machinability, titanium is typically reserved for niche uses where weight reduction and extreme environmental resistance are paramount.

Surface finishing plays a complementary role in enhancing mould performance. Anodizing, particularly for aluminum moulds, significantly improves surface hardness and corrosion resistance. The process creates a controlled oxide layer that can be tailored for specific wear conditions. Type II (sulfuric acid) anodizing is commonly used for general protection, while Type III (hard anodizing) delivers a thicker, more durable coating suitable for high-wear zones. Anodized surfaces also provide excellent adhesion for coatings and can be dyed for identification purposes.

The following table summarizes key mechanical and thermal properties of the three materials:

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case |

|---|---|---|---|---|

| Aluminum | 300–500 | 40–50 | 120–180 | Prototyping, low-volume production |

| Steel | 900–2000 | 28–52 | 25–40 | High-volume, long-life moulds |

| Titanium | 900–1200 | 35–45 | 7–10 | Specialized, corrosion-prone environments |

At Wuxi Lead Precision Machinery, we guide clients through these material and finish decisions based on production volume, part complexity, polymer type, and lifecycle requirements. Our engineering team ensures optimal material pairing with precision manufacturing to deliver moulds that meet the highest standards of performance and reliability in automotive applications.

Manufacturing Process & QC

Automotive Plastic Mold Production: Precision Engineering from Concept to Zero-Defect Delivery

At Wuxi Lead Precision Machinery, we execute automotive plastic mold production through a rigorously controlled sequence: Design, Prototyping, and Mass Production. This integrated workflow ensures every component meets the uncompromising safety and performance standards demanded by the automotive sector. Zero defects are non-negotiable; they are engineered into every phase through advanced methodology and relentless validation.

The Design phase begins with deep collaboration between our engineering team and the client. We translate functional requirements into precision 3D models using Siemens NX, incorporating critical factors like material behavior under thermal cycling, structural load paths, and gate location optimization for weld line elimination. Mold flow analysis simulates filling, packing, and cooling to preempt sink marks or warpage. Geometric Dimensioning and Tolerancing (GD&T) is applied per ISO 1101 standards, ensuring dimensional stability across 100,000+ cycles. This phase concludes with a Design Failure Mode and Effects Analysis (DFMEA) sign-off, locking in a defect-proof blueprint.

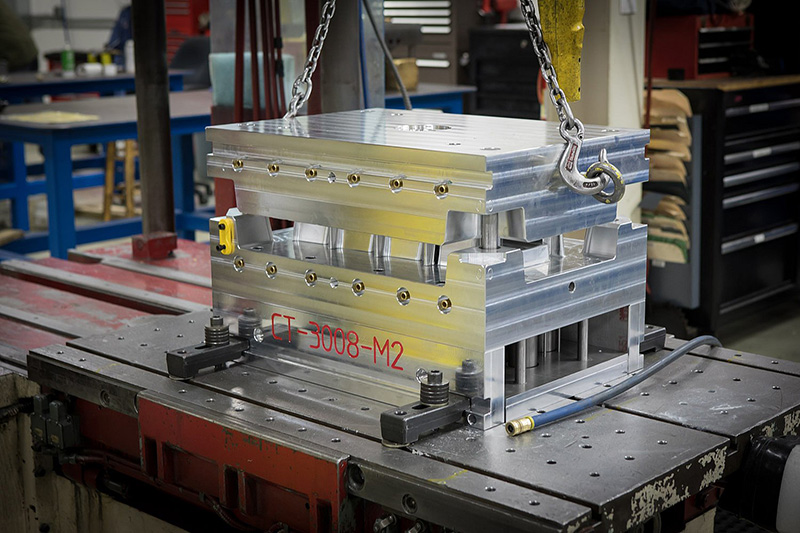

Prototyping transitions the validated design into physical reality. We deploy high-speed CNC machining (±0.002 mm accuracy) and wire EDM for critical cavities, using pre-hardened P20 or H13 tool steels. The first article mold undergoes rigorous trial runs on our in-house 500-ton injection press. Parts are subjected to comprehensive metrology: CMM scans verify all critical dimensions against CAD, while material labs test tensile strength and thermal resistance per ASTM D638/D696. Any deviation triggers immediate mold correction—never part rework. This stage typically requires 2-3 iterations, compressing validation time by 30% versus industry averages through our rapid iteration protocol.

Mass Production activates our zero-defect ecosystem. Molds run in climate-controlled cells with real-time pressure sensors and cavity pressure monitoring. Every cycle is logged via MES integration, tracking parameters like melt temperature (±1°C) and clamp force. Automated optical inspection (AOI) systems scan 100% of parts for micro-burrs or surface defects at line speed, rejecting outliers before secondary operations. Statistical Process Control (SPC) charts monitor CpK >1.67 for critical features, with corrective actions auto-triggered at 1.33. Final shipment includes full traceability: material lot numbers, process logs, and first-article reports compliant with IATF 16949.

Key Production Specifications

| Parameter | Standard Specification | Zero Defects Protocol |

|---|---|---|

| Tolerance | ±0.025 mm | Real-time SPC with AI-driven anomaly detection |

| Surface Finish (Ra) | 0.4 µm (SPI-A1) | In-line laser roughness verification |

| Cavity Count | 1-16 cavities | Individual cavity balancing via pressure mapping |

| Cycle Time Stability | ±0.5 sec | Closed-loop hydraulic adjustment |

| Thermal Stability | ΔT ≤ 2°C across mold | Dual-zone cooling with IR monitoring |

This closed-loop process—where design intelligence informs production execution and real-world data refines future molds—delivers automotive molds that consistently achieve <50 PPM defect rates. Wuxi Lead transforms material science and metrology into your competitive advantage, one zero-defect component at a time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Engineered Automotive Plastic Moulds

In the demanding world of automotive manufacturing, the quality of plastic components directly impacts performance, safety, and consumer satisfaction. At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal solutions tailored specifically for automotive plastic mould applications. As a trusted partner in advanced manufacturing, we combine engineering excellence with state-of-the-art CNC technology to produce moulds that meet the exacting standards of global automotive OEMs and Tier 1 suppliers.

Our expertise lies in the complete development cycle of plastic injection moulds—from initial design and material selection to precision machining, heat treatment, and final assembly. Every component we manufacture is built to withstand high-cycle production environments while maintaining dimensional accuracy and surface integrity. We utilize premium-grade tool steels and advanced surface treatments such as nitriding and PVD coating to extend mould life and reduce maintenance downtime.

What sets Wuxi Lead Precision Machinery apart is our commitment to collaboration and technical transparency. We work closely with engineering teams to optimize mould design for manufacturability, ensuring faster cycle times, reduced part warpage, and improved ejection performance. Our in-house metrology lab, equipped with CMMs and 3D scanning systems, guarantees that every mould meets tight tolerances—down to ±0.002 mm.

We understand that automotive projects demand more than just precision—they require reliability, scalability, and responsive support. That’s why we offer full project management from prototype to mass production, with real-time updates and rigorous quality documentation including First Article Inspection (FAI) and Process Failure Mode Analysis (PFMEA) reports.

For partners seeking a long-term manufacturing ally, Wuxi Lead Precision Machinery delivers consistent quality, competitive lead times, and scalable production capacity across our 15,000 sqm facility in Wuxi, China. Our ISO 9001-certified processes and adherence to IATF 16949 standards ensure compliance with the highest automotive quality requirements.

Below are key technical specifications we support for automotive plastic mould manufacturing:

| Specification | Capability |

|---|---|

| Mould Weight Range | Up to 15,000 kg |

| Maximum Mould Size | 2,500 x 2,000 x 1,800 mm |

| Tolerance | ±0.002 mm |

| Surface Roughness | Ra 0.05 µm (polished) |

| Materials | P20, 718H, H13, S136, NAK80, and custom alloys |

| Machining Equipment | 5-axis CNC, EDM, High-Speed Milling, Wire Cut |

| Quality Standards | ISO 9001, IATF 16949, FAI, PPAP Level 3 |

Partner with Wuxi Lead Precision Machinery to elevate your automotive plastic mould performance. Contact us today at [email protected] to discuss your next project with our engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.