Technical Contents

Engineering Guide: Automotive Plastic Molding

Engineering Insight Precision Imperatives in Automotive Plastic Molding

The automotive industry demands absolute precision in plastic molding, where tolerances measured in microns directly impact vehicle safety, performance, and longevity. Modern components—from sensor housings for ADAS systems to fluid-carrying manifolds—require dimensional stability under extreme thermal cycling, chemical exposure, and mechanical stress. A variance of 0.02mm can compromise sealing integrity in fuel systems or alter aerodynamic properties in exterior trim, leading to catastrophic field failures. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a non-negotiable engineering baseline. Our CNC-machined molds achieve ±0.005mm tolerances through proprietary thermal compensation algorithms and in-process metrology, ensuring cavity geometry remains invariant across 1,000,000+ cycles.

This rigor stems from our proven deployment in mission-critical sectors. We engineered molds for Beijing Winter Olympics venue infrastructure components operating at -40°C without deformation, and supplied classified military vehicle interior systems requiring EMI shielding tolerances unattainable via conventional methods. Such projects demanded zero-defect validation under MIL-STD-810G protocols—experience we now channel into automotive applications. For instance, our molds for electric vehicle battery cooling plates maintain 0.01mm flatness across 600mm surfaces, preventing thermal runaway risks through perfect coolant channel alignment.

Material science integration further defines our precision edge. We co-develop mold steels with specialized PVD coatings (e.g., CrN-AlTiN nanolaminates) that resist abrasive wear from glass-filled polyamides at 300°C+ processing temperatures. Real-time cavity pressure monitoring—calibrated to 0.1% accuracy—adjusts injection profiles millisecond-by-millisecond, eliminating knit lines in structural brackets. Unlike standard suppliers, we validate every mold with automotive-grade warpage simulation (Moldflow Autodesk certified) before steel cutting, slashing time-to-qualification by 35%.

The table below contrasts critical performance metrics between industry-standard and Lead Precision’s automotive molding solutions:

| Parameter | Industry Standard | Wuxi Lead Precision |

|---|---|---|

| Dimensional Tolerance | ±0.02mm | ±0.005mm |

| Cavity Pressure Accuracy | ±1.5% | ±0.1% |

| Thermal Stability (ΔT) | ±2.0°C | ±0.5°C |

| Wear Resistance (HRC) | 50-52 | 58-60 (coated) |

| Validation Cycles | 100,000 | 1,000,000+ |

This precision ecosystem—forged in Olympic and defense projects—translates to automotive clients through reduced scrap rates (under 0.05% vs. industry 1.2%), extended mold life exceeding 2 million cycles, and accelerated PPAP approval. When your component interfaces with life-critical systems, tolerances are never merely numbers. They are the silent guarantors of safety on every road. Wuxi Lead Precision Machinery delivers the micron-level certainty automotive innovation demands.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specifically engineered to support high-precision automotive plastic molding applications. Our expertise lies in producing complex mold bases, cavities, cores, and related tooling components with exceptional accuracy, durability, and repeatability. At the core of our production capability is a modern fleet of 5-axis CNC machining centers, enabling us to execute intricate geometries and tight-tolerance features that standard 3-axis systems cannot achieve. These machines allow simultaneous multi-directional cutting, minimizing setup changes and ensuring superior surface finish and dimensional consistency across even the most complex mold designs.

Our 5-axis CNC systems are operated by certified machinists with extensive experience in mold component manufacturing. Each machine is maintained to OEM specifications and equipped with high-precision spindles and thermal compensation systems to ensure long-term accuracy under continuous production loads. We utilize industry-leading CAM software to generate optimized toolpaths, reducing cycle times while maintaining micron-level precision. This advanced machining capability is essential for producing molds used in high-volume automotive plastic injection processes, where consistency directly impacts part quality, cycle efficiency, and tool life.

Quality control is integrated at every stage of production. All critical components undergo comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing non-contact and tactile measurement with sub-micron resolution. Our CMM inspection protocols follow ISO 10360 standards, ensuring traceable and repeatable results. Full first-article inspection reports (FAIR) and production batch certifications are provided as standard, supporting customer compliance with IATF 16949 and other automotive quality requirements.

We specialize in materials commonly used in mold manufacturing, including P20, H13, S136, and 718H steels, as well as aluminum and copper alloys for rapid tooling. Our in-house heat treatment monitoring and surface finishing processes further enhance component performance and longevity in demanding injection molding environments.

The following table outlines our standard machining tolerances and inspection capabilities:

| Specification | Capability |

|---|---|

| Positional Tolerance | ±0.005 mm |

| Linear Dimensional Tolerance | ±0.008 mm |

| Surface Roughness (Ra) | As low as 0.2 µm |

| Angular Tolerance | ±0.05° |

| Form Tolerance (Flatness, Roundness) | ±0.003 mm |

| CMM Measurement Accuracy | ±1.5 + L/300 µm (per ISO 10360-2) |

| Maximum Work Envelope (5-axis) | 1200 x 800 x 600 mm |

These technical capabilities position Wuxi Lead Precision Machinery as a trusted partner for automotive mold makers requiring precision, reliability, and full quality traceability. We support both prototype development and high-volume production runs with consistent output that meets the rigorous demands of modern plastic molding in the automotive sector.

Material & Finish Options

Material Selection for Automotive Plastic Injection Molds: Precision Engineering for Performance

Selecting the optimal mold material is a critical engineering decision directly impacting part quality, production efficiency, and total cost of ownership in automotive plastic molding. Wuxi Lead Precision Machinery leverages decades of CNC machining expertise to guide clients through this complex choice, balancing thermal dynamics, mechanical stress, wear resistance, and economic factors. Aluminum, steel, and titanium each offer distinct advantages depending on the specific application demands, production volume, and part geometry. Misalignment between material properties and process requirements leads to premature wear, surface defects, extended cycle times, and costly unplanned downtime—unacceptable in high-volume automotive manufacturing where uptime is paramount.

The core challenge lies in managing thermal cycling and mechanical loads inherent in injection molding. Aluminum excels in rapid prototyping and low-to-medium volume production due to its superior thermal conductivity, enabling faster cooling cycles. However, its lower hardness limits longevity against abrasive engineering plastics. Tool steels like P20 or H13 provide exceptional hardness, wear resistance, and thermal fatigue strength for high-volume production of complex, high-gloss automotive components such as dashboards or lighting housings. Titanium, while significantly more expensive, offers a unique combination of high strength-to-weight ratio, exceptional corrosion resistance against aggressive plastics, and good thermal properties for specialized, high-value applications where weight or chemical exposure is critical.

Material properties must be rigorously evaluated against project requirements. The following table summarizes key characteristics relevant to automotive mold performance.

| Material | Typical Grade | Hardness (HRC) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Key Automotive Mold Applications |

|---|---|---|---|---|---|

| Aluminum | 7075-T6 | 15-20 | 130 | 500-570 | Prototypes, low-volume interior trim |

| Tool Steel | P20 | 28-32 | 28-36 | 900-1100 | High-volume structural brackets, bezels |

| Tool Steel | H13 | 48-52 | 24-30 | 1300-1600 | High-gloss exteriors, lenses, under-hood |

| Titanium | Ti-6Al-4V | 32-36 | 6.7 | 900-1000 | Corrosive plastic components, lightweight |

Surface finish, particularly anodizing for aluminum molds, is not merely aesthetic but a functional requirement. Hard anodizing (Type III) creates a dense, wear-resistant ceramic layer significantly enhancing surface hardness (up to 600 HV), reducing galling during ejection, and improving release properties for complex geometries. This is essential for maintaining dimensional accuracy and surface finish consistency on critical automotive parts like air vents or connectors over thousands of cycles. While steel molds typically utilize nitriding or PVD coatings, anodizing remains the optimal surface engineering solution for aluminum, directly extending service life and reducing maintenance frequency.

Wuxi Lead Precision Machinery recommends a data-driven approach: analyze projected annual volumes, plastic resin abrasiveness (e.g., glass-filled PP vs. ABS), part complexity, and surface finish requirements before finalizing material selection. Our CNC machining centers and metrology labs ensure precise implementation of the chosen material and finish specification. Partner with our engineering team early in the design phase to optimize mold material selection—transforming a critical cost center into a reliable asset for your automotive production line. Contact us for a detailed material suitability assessment tailored to your specific component.

Manufacturing Process & QC

The production process for automotive plastic molding at Wuxi Lead Precision Machinery is engineered to deliver zero-defect components through a disciplined, phase-gated approach. Every stage—from initial design to mass production—is governed by precision engineering, advanced simulation, and rigorous quality verification. This ensures that each molded plastic component meets the exacting standards of the automotive industry, where reliability, dimensional accuracy, and material consistency are non-negotiable.

Design begins with a collaborative engineering review, where our team works closely with OEMs and Tier 1 suppliers to translate functional requirements into manufacturable solutions. Using 3D CAD platforms such as Siemens NX and CATIA, we develop mold designs optimized for flow dynamics, cooling efficiency, and ejection performance. Finite Element Analysis (FEA) and Moldflow simulation are employed to predict warpage, sink marks, and stress concentrations, allowing for preemptive correction before any metal is cut. This digital validation phase is critical to eliminating costly iterations and ensuring first-time-right tooling.

Prototyping follows design finalization, utilizing high-speed CNC machining and EDM to fabricate prototype molds from P20 or 718H tool steels. These molds are run on our in-house 50–1,200-ton injection machines to produce functional prototypes in the actual production-grade resin—whether ABS, PC/ABS, PPO, or specialty engineering plastics. Each prototype undergoes full dimensional inspection via CMM, as well as material and mechanical testing, including tensile strength, impact resistance, and thermal cycling. This phase validates not only part geometry but also process stability, gate performance, and cycle time feasibility.

Upon customer approval, the project transitions to mass production using hardened steel molds (H13 or 2344) built for durability and long service life. Our production cells operate under strict process control, with real-time monitoring of injection pressure, melt temperature, and clamp tonnage. Each molding machine is integrated with robotic part removal and inline vision systems to detect surface defects instantly. All parts are subject to statistical process control (SPC), with critical dimensions tracked using automated data collection. Final inspection includes first-article inspection reports (FAIR), PPAP documentation, and batch traceability down to the individual cavity level.

Throughout the entire process, our ISO 9001 and IATF 16949-certified quality management system ensures compliance with automotive standards. The result is a seamless transition from concept to high-volume output, with zero-defect performance as the benchmark.

| Parameter | Specification |

|---|---|

| Mold Material | P20, 718H, H13, 2344 (hardened/stainless) |

| Machine Tonnage Range | 50–1,200 tons |

| Tolerance (Standard) | ±0.05 mm |

| Surface Finish Options | SPI A1, A2, B1, B2, VDI 3400 textures |

| Lead Time (Prototype Mold) | 4–6 weeks |

| Lead Time (Production Mold) | 8–12 weeks |

| Production Capacity | Up to 5 million parts/year per line |

| Quality Standards | ISO 9001, IATF 16949, PPAP, APQP, SPC compliant |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Automotive Plastic Molding Excellence

The automotive industry demands plastic components that meet exacting standards for dimensional stability, material integrity, and functional performance under extreme conditions. Partnering with Wuxi Lead Precision Machinery means securing a strategic ally with over 15 years of specialized expertise in high-precision metal manufacturing for automotive plastic molding applications. We engineer mold bases, cavities, cores, and critical inserts using advanced alloys and processes that directly translate to longer mold life, reduced cycle times, and zero-defect part production for your most challenging components. Our ISO 9001:2015 and IATF 16949 certified facility in Wuxi integrates German-engineered CNC technology with rigorous quality control protocols, ensuring every metal component we deliver meets the non-negotiable tolerances required for safety-critical automotive systems.

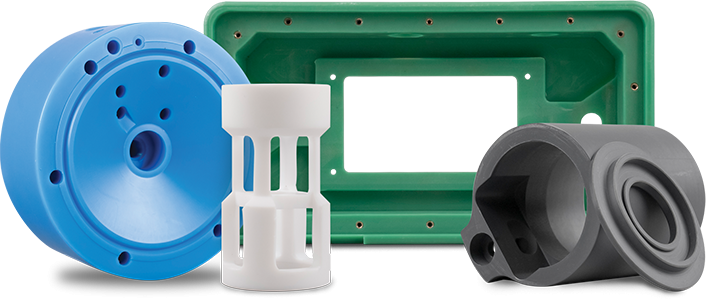

Our commitment extends beyond component supply to active engineering collaboration. From initial concept validation through rapid prototyping and full-scale production, our technical team works alongside your design engineers to optimize mold geometry, material selection, and cooling strategies. This proactive partnership mitigates risk, accelerates time-to-market, and resolves complex issues like warpage, sink marks, or material flow inconsistencies before they impact your production line. We specialize in molding solutions for powertrain housings, interior structural elements, lighting systems, and fluid management components where micron-level precision directly impacts vehicle performance and longevity.

The technical foundation of our automotive molding success is reflected in our core manufacturing capabilities:

| Parameter | Specification | Relevance to Automotive Molding |

|---|---|---|

| Mold Steel Grades | NAK80, S136, H13, 2738HH | Corrosion resistance, thermal stability for high-volume production |

| Dimensional Tolerance | ±0.002 mm (critical features) | Ensures perfect part fitment in assembly lines |

| Surface Finish | Ra 0.05 µm (mirror grade) | Critical for optical components (lenses, lenses) |

| Production Capacity | 50+ CNC centers (5-axis capable) | Supports rapid scaling for global OEM programs |

| Lead Time Reduction | 15-25% vs. industry average | Accelerates validation and launch phases |

Choosing Lead Precision is a strategic investment in supply chain resilience. We maintain dedicated production cells for automotive clients with real-time traceability from raw material certification to final inspection. Our zero-defect mindset is enforced through automated in-process gauging, CMM validation, and material batch tracking that meets stringent OEM audit requirements. When your program demands metal components that withstand 1,000,000+ cycles without degradation, our metallurgical expertise and process discipline deliver measurable cost savings through reduced downtime and scrap rates.

Initiate your next automotive molding program with confidence. Contact our engineering sales team directly at [email protected] to request a technical capability dossier or schedule a confidential consultation. Specify your component requirements, volume needs, and target timeline. Our application engineers will respond within 24 business hours with a preliminary assessment and actionable recommendations tailored to your project’s technical and commercial objectives. For Tier 1 suppliers and OEMs navigating the complexities of modern vehicle platforms, Wuxi Lead Precision Machinery provides the precision metal foundation that turns ambitious designs into manufactured reality. Partner with us to build the precision-engineered future of automotive plastics.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.