Technical Contents

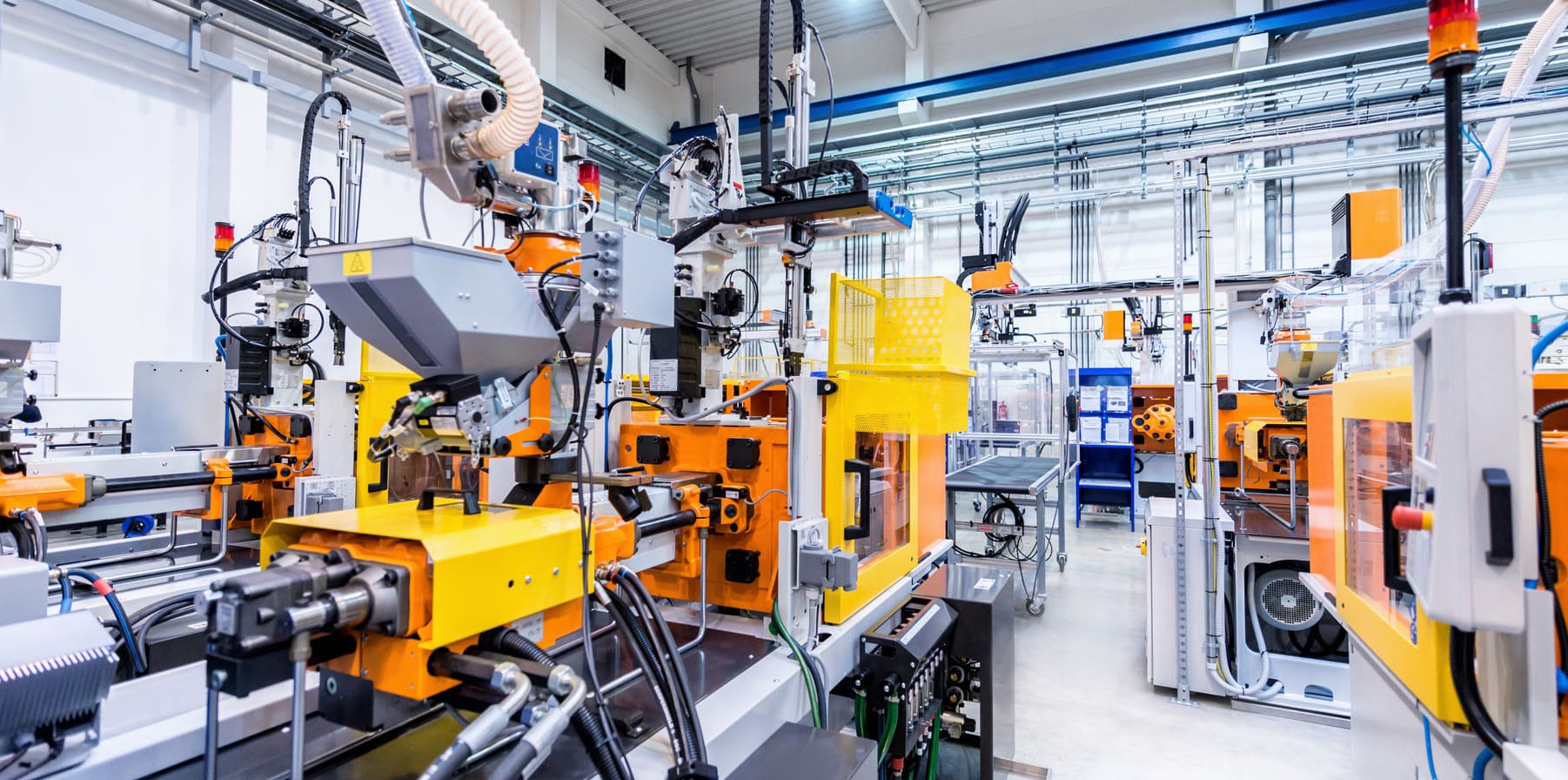

Engineering Guide: Automotive Injection Molding Companies

Engineering Insight: Precision in Automotive Injection Molding Tooling

In the highly competitive landscape of automotive manufacturing, injection molding companies face relentless demands for speed, consistency, and above all, precision. As vehicle systems grow more complex and lightweighting becomes a strategic imperative, the tolerances required in molded components have tightened to micrometer-level accuracy. This shift places extraordinary pressure on the tooling used in injection molding processes—tools that must maintain dimensional stability across thousands, if not millions, of cycles. At Wuxi Lead Precision Machinery, we understand that precision is not an outcome—it is engineered into every component from the earliest design phase.

Our experience in delivering custom metal manufacturing solutions for mission-critical sectors—including aerospace, defense, and Olympic-grade equipment—has honed our ability to meet the most stringent precision requirements. Components we have produced for military applications, where failure is not an option, demand repeatability within ±0.002 mm. Similarly, parts developed for high-performance systems used in Olympic training facilities required flawless surface finishes and exact geometric conformity. These experiences directly inform our approach to serving automotive injection molding companies: we treat every mold insert, cavity, and ejector component as a high-integrity system.

Precision in mold tooling translates directly into part quality, cycle time efficiency, and production yield. A core challenge in automotive molding lies in managing thermal expansion across mold sections. Even minor deviations in cooling channel placement or surface flatness can lead to warpage, sink marks, or inconsistent wall thickness in final parts. Our engineering team leverages advanced CNC milling, wire EDM, and coordinate measuring machine (CMM) verification to ensure every tool meets tight geometric dimensioning and tolerancing (GD&T) specifications.

We specialize in hardened steel molds, pre-hardened tool steels, and aluminum rapid tooling solutions—each selected and processed to match the production volume, material type, and functional requirements of the molded part. Our in-house heat treatment and surface coating capabilities further enhance wear resistance and extend tool life, even under aggressive polycarbonate or glass-filled nylon processing conditions.

The table below outlines typical precision specifications achievable through our manufacturing processes:

| Parameter | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm to ±0.01 mm | ISO 2768-m, ISO 1101 |

| Surface Roughness (Ra) | 0.05 µm to 0.4 µm | ISO 4287 |

| Flatness | ≤ 0.003 mm over 100 mm | ASME Y14.5 |

| Hole Positional Accuracy | ±0.005 mm | ISO 10135 |

| Tool Life (Cycle Endurance) | 500,000 to 1,000,000+ cycles | Based on P20/H13 steel, 30% GF PA6 |

| Material Options | P20, H13, S136, 718H, Aluminum 7075 | ASTM Standards |

At Wuxi Lead Precision Machinery, we align our engineering rigor with the operational realities of automotive injection molding. Our goal is not only to deliver precision tooling but to become a long-term engineering partner capable of supporting innovation, reducing time-to-market, and ensuring consistent part quality across global production lines.

Precision Specs & Tolerances

Technical Capabilities for Precision Automotive Mold Manufacturing

Wuxi Lead Precision Machinery delivers the dimensional accuracy and surface integrity essential for high-performance automotive injection molds. In an industry where mold precision directly dictates part quality, cycle time, and production yield, our integrated manufacturing and quality control systems ensure components meet the most stringent automotive Tier 1 and OEM specifications. We specialize in transforming complex mold designs into reality through advanced metal fabrication processes, minimizing assembly errors and maximizing mold longevity.

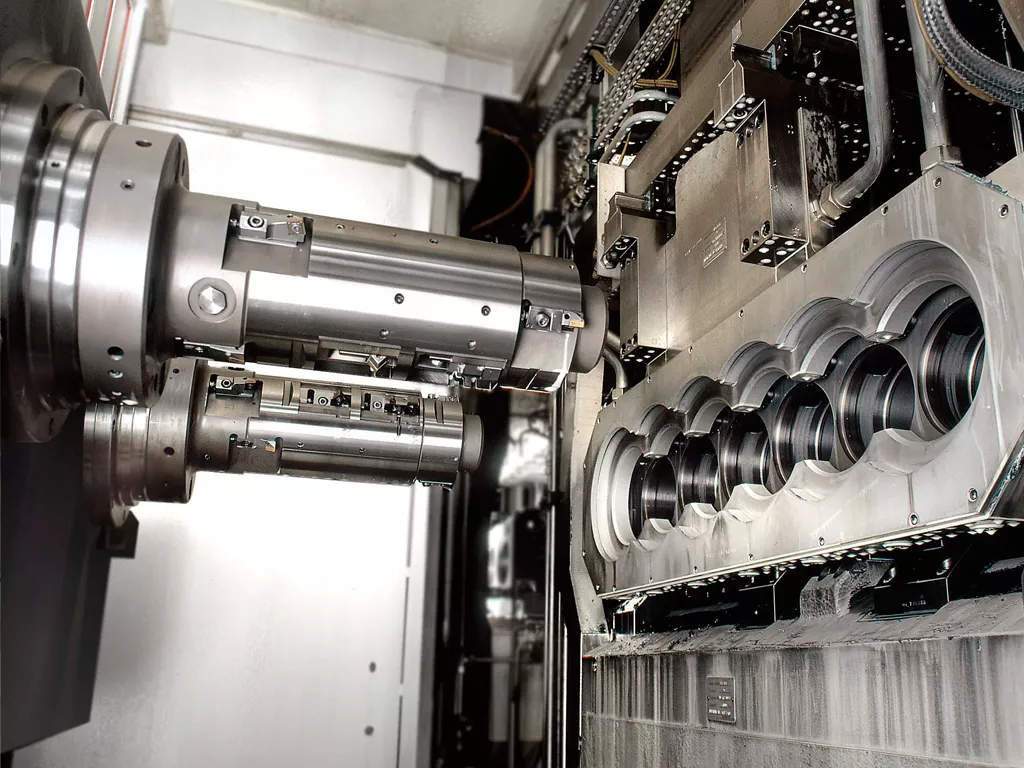

Precision Machining Capabilities

Our core manufacturing strength lies in a modern fleet of multi-tasking 5-axis CNC machining centers. These systems enable the complete machining of intricate mold bases, cavities, cores, and lifters in a single setup, eliminating cumulative errors inherent in multi-operation workflows. This capability is critical for producing the complex undercuts, conformal cooling channels, and freeform surfaces demanded by next-generation automotive components. Utilizing high-rigidity machines with sub-5μm positional repeatability, we achieve superior surface finishes directly off the machine, reducing hand polishing requirements and ensuring optimal part release and surface aesthetics. Advanced CAM programming optimizes toolpaths for material removal rates while maintaining thermal stability, crucial for large mold plates and hardened tool steels common in high-volume automotive applications.

Rigorous Quality Assurance Protocol

Precision machining is validated through our comprehensive, multi-stage quality control system. Every critical feature undergoes meticulous inspection using state-of-the-art Coordinate Measuring Machines (CMM) within our ISO 17025-accredited metrology laboratory. Our CMM fleet, featuring high-accuracy scanning probes and temperature-controlled environments, provides full 3D geometric dimensioning and tolerancing (GD&T) verification against original CAD models. This data-driven approach ensures absolute conformance to design intent, identifying potential fit or function issues before mold assembly. All inspection reports are fully traceable to international standards (NIST, PTB) and provided digitally, offering complete transparency and enabling proactive collaboration during engineering reviews. This rigorous validation is non-negotiable for automotive applications where mold failure causes significant production line downtime.

The following table details our standard and achievable tolerance capabilities for critical mold features, reflecting our commitment to automotive-grade precision:

| Feature Type | Standard Capability (μm) | Tight Capability (μm) | Notes |

|---|---|---|---|

| Bore Diameter | ±8 | ±4 | Up to Ø50mm, hardened steel |

| Flatness | 8 | 4 | Over 100x100mm surface |

| Parallelism | 10 | 5 | Between opposing faces |

| Perpendicularity | 10 | 5 | Relative to primary datum |

| Position (Holes) | ±10 | ±5 | Relative to datums, critical locations |

| Surface Roughness (Ra) | 0.8 | 0.4 | Machined finish, no polishing |

Achievable tolerances are dependent on part geometry, material, and size. Our engineering team collaborates closely with clients during the design phase to optimize features for manufacturability while meeting the exacting demands of automotive injection molding production. Contact our technical sales team to discuss your specific mold precision requirements.

Material & Finish Options

Material selection is a critical factor in the success of custom metal components used in automotive injection molding applications. The performance, durability, and cost-efficiency of tooling and structural parts depend heavily on choosing the right base material and surface treatment. At Wuxi Lead Precision Machinery, we specialize in precision-engineered solutions tailored to the demanding requirements of automotive manufacturing. Our expertise in aluminum, steel, and titanium allows us to support clients in optimizing material choices based on strength, weight, thermal conductivity, and lifecycle cost.

Aluminum is widely used in automotive injection molding systems due to its excellent thermal conductivity and lightweight properties. It enables faster cooling cycles, improving production efficiency. Aluminum alloys such as 6061 and 7075 offer good machinability and moderate strength, making them ideal for prototype molds and low-to-medium volume production. However, aluminum’s lower hardness compared to steel limits its use in high-wear applications.

Steel, particularly tool steels like P20, H13, and S136, remains the standard for high-volume injection molding tools. These alloys provide superior hardness, wear resistance, and dimensional stability under repeated thermal cycling. Hardened steels can withstand aggressive molding materials and extended production runs, reducing maintenance downtime. For applications requiring corrosion resistance, stainless tool steels offer enhanced performance without sacrificing toughness.

Titanium is selected for specialized components where extreme strength-to-density ratio and corrosion resistance are paramount. While not commonly used for full mold bases due to cost and machinability challenges, titanium finds application in inserts, ejector pins, and other high-stress, wear-prone areas. Its biocompatibility and resistance to oxidation also make it suitable for medical-grade automotive components.

Surface finishing plays a pivotal role in mold performance and part quality. Anodizing is a key finishing process for aluminum components, significantly enhancing surface hardness, wear resistance, and corrosion protection. Type II (sulfuric acid) anodizing provides a decorative and protective layer, while Type III (hardcoat) anodizing delivers a dense, abrasion-resistant surface capable of withstanding industrial molding environments. Anodized layers are electrically insulating and chemically stable, supporting consistent release properties and reduced maintenance.

For steel components, alternative surface treatments such as nitriding, chrome plating, or PVD coatings are typically recommended, as anodizing is not applicable. Titanium can also be treated with anodizing, though for aesthetic and minor corrosion enhancement rather than structural improvement.

Below is a comparative overview of key material properties relevant to automotive injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Common Applications | Suitable for Anodizing |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 15–20 HB | 167 | Prototype molds, jigs, fixtures | Yes (Type II/III) |

| Steel P20 | 950–1100 | 28–32 | 28–31 | Mold bases, cores, cavities | No |

| Steel H13 | 1200–1400 | 45–52 | 30–34 | High-temperature molds | No |

| Titanium Grade 5 | 900–1000 | 36–41 | 7.2 | Inserts, pins, high-stress components | Yes (decorative) |

Selecting the optimal material and finish requires a comprehensive understanding of production volume, part geometry, resin type, and environmental conditions. Wuxi Lead Precision Machinery provides engineering consultation to ensure each component is manufactured to exact performance criteria, maximizing tool life and process efficiency.

Manufacturing Process & QC

Precision Manufacturing Process for Automotive Injection Molding Tooling

At Wuxi Lead Precision Machinery, we execute a rigorously controlled production process specifically engineered for the demanding requirements of automotive injection molding companies. Our methodology eliminates defects at source, ensuring tooling delivers exceptional part consistency, longevity, and compliance from Day One. The journey begins with Engineering Design, where our deep automotive expertise converges with advanced simulation. Utilizing 3D CAD/CAM (Siemens NX, SolidWorks) and Moldflow analysis, we optimize mold geometry, cooling circuits, and gating for minimal warpage, sink marks, and cycle time. Critical to Zero Defects, our Design for Manufacturing (DFM) review, conducted jointly with the client, validates manufacturability against IATF 16949 standards, material specifications, and tight GD&T tolerances before any metal is cut. This phase prevents costly downstream errors by addressing potential flow imbalances, venting issues, and ejection challenges virtually.

Prototyping transforms validated designs into physical reality for exhaustive validation. We employ high-speed CNC machining (5-axis DMG MORI, Makino) and precision EDM to fabricate prototype molds using the exact production-grade tool steels (e.g., H13, S136). These prototypes undergo rigorous testing on our dedicated molding presses, replicating client production parameters. Comprehensive First Article Inspection Reports (FAIR), including CMM validation against 3D models and critical feature checks, confirm dimensional accuracy and surface finish. Mold flow analysis data is cross-verified against actual part performance. This stage is non-negotiable for Zero Defects; it proves the mold design, refines process parameters, and secures client approval before committing to full-scale production, eliminating assumptions.

Mass Production leverages the insights gained to achieve sustained Zero Defects output. Our ISO 9001 and IATF 16949 certified facility employs Statistical Process Control (SPC) with real-time monitoring of critical parameters like cavity pressure, temperature, and clamp force. Every component undergoes 100% dimensional verification using calibrated CMMs and optical comparators against approved samples. Full material traceability, from certified steel mill certs through every machining and assembly step, is maintained via our digital MES system. Automated in-process gauging and final inspection against PPAP Level 3 requirements ensure absolute conformance. Continuous improvement is embedded; any deviation triggers immediate root cause analysis and corrective action, preventing recurrence. This closed-loop system guarantees the tooling consistently produces automotive parts meeting stringent OEM specifications, minimizing scrap and maximizing uptime for our clients.

Critical Process Specifications for Automotive Tooling

| Parameter | Specification | Automotive Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (critical features) | Ensures precise fit, function, and assembly of safety-critical components |

| Surface Finish (Cavity) | Ra 0.05 µm (mirror) to Ra 0.8 µm (VDI) | Meets strict aesthetic and functional requirements for interior/exterior parts |

| Material Certification | Full traceable certs (H13, S136, etc.) | Compliance with OEM material specifications and IMDS reporting |

| Lead Time (Prototype) | 4-6 weeks (design validated) | Accelerates client validation and time-to-market for new vehicle programs |

| Process Capability (Cpk) | ≥1.67 (sustained) | Demonstrates statistical confidence in Zero Defects production capability |

| Documentation | Complete PPAP Level 3 package | Mandatory for Tier 1/Tier 2 supplier qualification and audits |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing for Automotive Injection Molding

In the high-stakes world of automotive injection molding, precision, durability, and consistency are non-negotiable. Every component—from mold bases to ejector systems and core pins—must meet exacting standards to ensure seamless production, minimal downtime, and long-term reliability. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing engineered specifically for the demands of modern automotive molding applications. Our advanced CNC machining capabilities, combined with decades of industry experience, position us as the strategic partner of choice for forward-thinking injection molding companies worldwide.

We understand that your success hinges on components that perform under pressure—literally and operationally. That’s why every part we produce is crafted with micron-level accuracy, using premium-grade tool steels, stainless alloys, and specialty materials tailored to your application. From prototype development to full-scale production runs, our integrated manufacturing ecosystem ensures rapid turnaround without compromising quality. Our ISO-certified facility in Wuxi, China, leverages state-of-the-art 5-axis CNC machines, wire EDM, surface grinding, and CMM inspection systems to deliver components that meet or exceed international standards.

Our engineering team works collaboratively with your designers and toolmakers to optimize part geometry, improve cooling efficiency, enhance wear resistance, and extend mold life. Whether you require complex cavity inserts, hardened guide pillars, or custom manifold systems, we bring your vision to life with precision and repeatability. We support global logistics with reliable delivery timelines, making us a trusted extension of your supply chain.

Below are the key technical capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis, 4-axis, 5-axis simultaneous milling |

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Tolerance Capability | ±0.002 mm |

| Surface Finish | Ra ≤ 0.2 µm (polished), Ra ≤ 1.6 µm (machined) |

| Materials Processed | P20, H13, S136, 420SS, 17-4PH, Aluminum 7075, Brass |

| Heat Treatment | Vacuum hardening up to 58 HRC, stress relieving, cryogenic treatment |

| Secondary Operations | Wire EDM, grinding, tapping, texturing, coating (TiN, CrN) |

| Quality Assurance | Full CMM reporting, first-article inspection, PPAP support |

| Industry Standards | ISO 9001:2015, IATF 16949 compliant processes |

Partnering with Wuxi Lead Precision Machinery means gaining more than a supplier—you gain a technical ally committed to your operational success. We are equipped to handle low-volume, high-mix orders as well as high-volume production with equal rigor, ensuring consistency across batches and years of service.

For automotive injection molding companies seeking precision, reliability, and responsive collaboration, the next step is clear. Contact us today at [email protected] to discuss your project requirements, request a quote, or schedule a technical consultation. Let Lead Precision be the foundation of your next generation of mold performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.