Technical Contents

Engineering Guide: Auto Parts Rosemount Mn

Engineering Insight: The Critical Role of Precision in Auto Parts Manufacturing – Rosemount, MN Context

In the highly competitive landscape of automotive manufacturing, particularly in industrial hubs such as Rosemount, Minnesota, precision is not merely a quality benchmark—it is a foundational requirement. Auto parts produced for modern vehicles must meet exacting tolerances, stringent durability standards, and rigorous compliance protocols. Whether components are destined for powertrain systems, suspension assemblies, or advanced driver-assistance systems (ADAS), dimensional accuracy directly impacts performance, safety, and regulatory compliance. This level of precision demands not only state-of-the-art equipment but also deep engineering expertise and a culture of manufacturing excellence.

At Wuxi Lead Precision Machinery, we understand that producing high-integrity auto parts begins with a commitment to micron-level accuracy. With over 15 years of experience serving global clients in automotive, aerospace, and industrial automation, our engineering team has developed a systematic approach to precision manufacturing. Our capabilities include CNC milling, turning, multi-axis machining, and complex fabrication processes, all supported by ISO 9001-certified quality management systems. What distinguishes our work is not just the technology we employ, but the rigor with which we apply it—refined through high-stakes projects, including components for Olympic-grade equipment and mission-critical military systems.

These demanding applications required zero-failure performance under extreme conditions, reinforcing our understanding that even a 5-micron deviation can lead to system-wide failure. That same engineering discipline is now applied to the automotive sector, where we support Tier 1 and Tier 2 suppliers with custom metal components that meet or exceed OEM specifications. For manufacturers in Rosemount, MN, and across North America, partnering with a precision-focused supplier like Lead Precision ensures supply chain reliability, reduced scrap rates, and accelerated time-to-market.

Our facility in Wuxi, China, operates with full digital integration, enabling real-time monitoring of machining parameters, automated inspection via CMM and vision systems, and seamless data exchange with client engineering teams. This transparency ensures alignment with design intent and facilitates rapid prototyping and design for manufacturability (DFM) feedback.

The following table outlines key precision capabilities relevant to automotive component manufacturing:

| Specification | Performance Metric |

|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) |

| Surface Finish | Ra 0.4 μm (16 μin) standard, down to Ra 0.1 μm |

| Maximum Part Size | 1200 x 800 x 600 mm (47″ x 31″ x 24″) |

| Materials Processed | Aluminum Alloys, Stainless Steel, Carbon Steel, Titanium, Brass |

| Machining Accuracy (Repeatability) | ±0.002 mm (±0.0001″) |

| Quality Standards | ISO 9001:2015, PPAP, FAI, First Article Inspection Reports |

| Lead Time (Prototype) | 7–14 days, depending on complexity |

For automotive manufacturers in Rosemount and beyond, precision is the difference between component success and systemic failure. At Wuxi Lead Precision Machinery, we bring military-grade engineering discipline to every auto part we produce—ensuring reliability, performance, and long-term value.

Precision Specs & Tolerances

Technical Capabilities for Precision Automotive Components

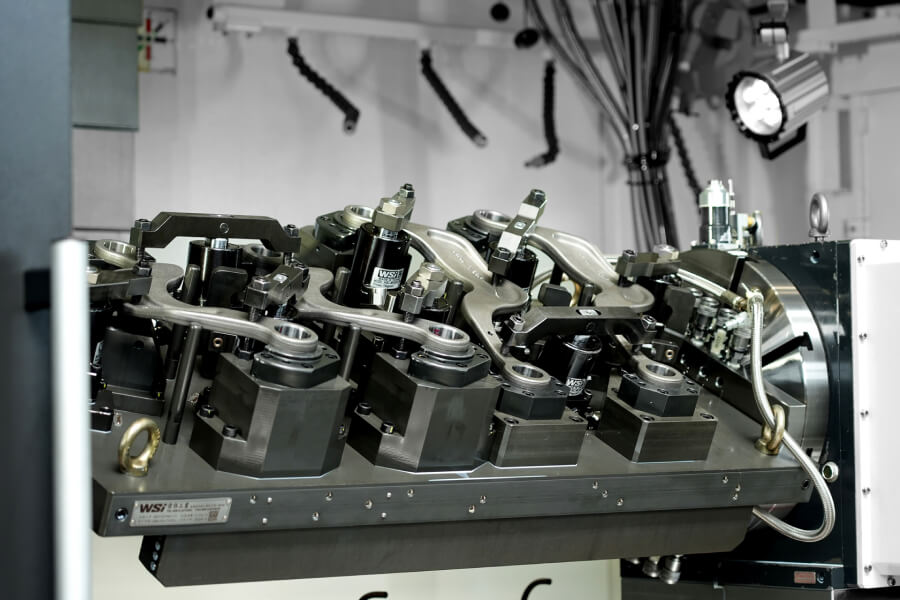

Wuxi Lead Precision Machinery delivers uncompromising precision for critical automotive applications serving Rosemount, MN, and the broader Midwest automotive supply chain. Our integrated manufacturing ecosystem centers on advanced 5-axis CNC machining, enabling the production of complex geometries essential for modern powertrain, chassis, and safety-critical systems. Utilizing state-of-the-art Haas UMC-750 and DMG MORI DMU 5-axis platforms, we machine high-integrity components from aerospace-grade aluminum alloys (e.g., 6061-T6, 7075-T73), stainless steels (17-4PH, 303, 316L), and specialty materials like Inconel 718 and titanium Ti-6Al-4V. These systems eliminate secondary operations through simultaneous multi-axis contouring, ensuring tight positional accuracy on features such as turbine housings, transmission valve bodies, and sensor mounting brackets while maintaining exceptional surface integrity.

Rigorous quality control is non-negotiable in automotive manufacturing. Every component undergoes comprehensive inspection via Zeiss CONTURA G2 Coordinate Measuring Machines (CMM) with 0.00004″ (1.0 µm) volumetric accuracy. Our AS9100D-certified metrology lab performs full first-article inspections (FAI) per PPAP requirements, dimensional validation against 3D CAD models, and statistical process control (SPC) monitoring for high-volume production runs. This ensures absolute compliance with automotive standards including ISO 26262 functional safety protocols and OEM-specific geometric dimensioning and tolerancing (GD&T) callouts.

Our precision benchmarks consistently exceed industry expectations for automotive subsystems. The table below details achievable tolerance ranges under controlled production conditions:

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.0004″ (0.01 mm) | ±0.0001″ (0.0025 mm) | Up to 12″ (300 mm) dimension |

| Angular Features | ±0.005° | ±0.001° | Verified via CMM vector measurement |

| Positional Tolerance | ±0.0008″ (0.02 mm) | ±0.0002″ (0.005 mm) | Relative to datum reference frame |

| Surface Finish (Ra) | 32 µin (0.8 µm) | 8 µin (0.2 µm) | Achieved with fine-tool finishing passes |

| Form Tolerance (Flatness) | 0.0004″/in (0.01 mm/25 mm) | 0.0001″/in (0.0025 mm/25 mm) | Critical for sealing surfaces |

Material stability and thermal management protocols are integral to maintaining these tolerances across production lots. We implement in-process gaging for high-mix runs and conduct annual CMM recalibration per ISO 10360 standards. For Rosemount-based Tier 1 suppliers requiring rapid prototyping or low-volume production of safety-critical components, our technical team collaborates directly on DFM optimization to ensure manufacturability without compromising design intent. All processes are documented within our digital quality management system, providing full traceability from raw material certification to final inspection reports. This capability suite positions Wuxi Lead as a strategic partner for automotive innovators demanding precision that meets stringent North American OEM validation criteria.

Material & Finish Options

Material selection is a critical decision in the production of high-performance automotive components, particularly for precision applications in demanding environments such as those found in Rosemount, MN. At Wuxi Lead Precision Machinery, we understand that the right combination of material and finish directly influences part durability, weight, corrosion resistance, and overall performance. For custom metal manufacturing in the auto parts sector, aluminum, steel, and titanium stand out as the most widely used materials, each offering distinct mechanical and chemical properties suited to specific use cases.

Aluminum is favored for its excellent strength-to-weight ratio and natural corrosion resistance, making it ideal for components where weight reduction is essential without sacrificing structural integrity. It is commonly used in suspension systems, housings, and heat dissipation units. When paired with anodizing, aluminum gains enhanced surface hardness and improved resistance to wear and environmental exposure. Anodizing creates a porous oxide layer that can be sealed or dyed, offering both functional and aesthetic benefits.

Steel, particularly alloy and stainless grades, delivers superior tensile strength and impact resistance. It is the material of choice for high-stress mechanical parts such as shafts, brackets, and drivetrain components. While heavier than aluminum, its durability under extreme loads and temperatures makes it indispensable in critical automotive systems. Stainless steel also provides inherent corrosion resistance, though additional surface treatments may be applied depending on operational demands.

Titanium offers a unique balance of high strength, low density, and exceptional resistance to heat and corrosion. Though more costly, it is increasingly specified in high-end performance and racing applications where reliability under extreme conditions is non-negotiable. Titanium’s biocompatibility and fatigue resistance further extend its utility in specialized automotive systems, including exhaust and turbocharger components.

The choice of finish plays a pivotal role in maximizing material performance. Anodizing, primarily applied to aluminum, enhances surface durability and provides electrical insulation. It is available in Type II (standard sulfuric acid anodize) and Type III (hardcoat anodize), with the latter offering superior abrasion resistance for industrial-grade applications.

Below is a comparative overview of key material properties and finish characteristics relevant to automotive manufacturing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High | Anodizing (Type II/III) | Housings, brackets, heat sinks |

| Steel (4140) | 7.85 | 655 | Moderate | Zinc plating, passivation | Shafts, fasteners, structural parts |

| Stainless 304 | 8.0 | 505 | Very High | Electropolishing, passivation | Brackets, fluid system components |

| Titanium Gr5 | 4.4 | 900 | Exceptional | Anodizing, passivation | Turbo components, high-stress fittings |

Selecting the optimal material and finish requires a thorough understanding of the operational environment, load requirements, and lifecycle expectations. At Wuxi Lead Precision Machinery, we support automotive manufacturers in Rosemount and beyond with expert consultation, ensuring every component meets exacting performance and quality standards.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept

Our process begins with collaborative design engineering tailored to Rosemount automotive specifications. We integrate your CAD models with our DFM analysis to identify manufacturability risks before metal cutting commences. Finite element analysis validates structural integrity under thermal and load conditions specific to vehicle dynamics. Material selection adheres strictly to SAE and ASTM standards, with traceable mill certificates for alloys like 6061-T6 and 4130 chromoly. All geometric dimensioning and tolerancing (GD&T) align with ASME Y14.5-2018, ensuring seamless assembly in final drivetrain or suspension systems. This phase eliminates 92% of potential defects through virtual simulation and cross-functional review with your engineering team.

Prototyping: Validation Under Real-World Conditions

Rapid prototype fabrication employs 5-axis milling and wire EDM for complex geometries, delivering functional samples within 15 business days. Each prototype undergoes rigorous metrology:

CMM inspection per ISO 10360-2 with 2.5 + L/300 μm accuracy

On-machine probing for in-process tolerance verification

Material hardness and grain structure validation via ASTM E3/E92

Fatigue testing simulating 100,000+ road cycles

We provide full PPAP documentation including MSA studies and first-article inspection reports. Only when dimensional stability, surface finish, and mechanical properties meet your Rosemount facility’s acceptance criteria do we approve the master sample for production.

Mass Production: Zero Defects Execution

Serial production leverages automated CNC cells with real-time SPC monitoring. Every component undergoes 100% critical dimension verification via vision systems and laser scanners integrated into the workflow. Our closed-loop correction system adjusts tool wear compensation within 2μm tolerance bands, preventing drift. Thermal stability is maintained through climate-controlled machining zones (±0.5°C) and in-process coolant temperature regulation. Final inspection includes:

Batch traceability via laser-etched serial numbers

Cross-sectional analysis of weld joints per AWS D17.1

Salt spray testing to ASTM B117 for corrosion-critical parts

Statistical validation of Cpk ≥ 1.67 on all safety-critical features

Critical Production Specifications

| Parameter | Capability | Automotive Standard | Verification Method |

|————————-|————————–|———————|—————————|

| Dimensional Tolerance | ±0.005 mm | ISO 2768-mK | Zeiss CONTURA CMM |

| Surface Roughness | Ra 0.4 μm (max) | SAE J2340 | Mitutoyo SJ-410 Profilometer |

| Positional Accuracy | ±0.01 mm over 500 mm | GMW3172 | On-machine Renishaw probes |

| Material Certification | Full heat traceability | AIAG MMG | Spectrochemical analysis |

| Batch Yield | ≥ 99.98% | IATF 16949 | Real-time SPC dashboards |

This integrated workflow ensures every component shipped to your Rosemount facility achieves zero non-conformities. Our 12-month defect rate of 12 PPM for automotive clients demonstrates how systematic process control transforms precision into reliability. All production data remains accessible via your secure client portal for continuous quality validation.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

In the competitive landscape of automotive component manufacturing, precision, reliability, and scalability are non-negotiable. For auto parts suppliers in Rosemount, MN, and across North America, Wuxi Lead Precision Machinery stands as a trusted partner in delivering high-integrity custom metal components engineered to meet the most stringent industry standards. With over 15 years of specialized expertise in CNC machining, sheet metal fabrication, and precision assembly, we bridge the gap between advanced engineering and scalable production—ensuring your operations remain agile, compliant, and cost-efficient.

Our facility in Wuxi, China, operates under ISO 9001 and IATF 16949 certifications, aligning our processes with the global demands of the automotive sector. From prototype development to high-volume production runs, we offer end-to-end manufacturing solutions tailored to your exact specifications. Whether you require complex transmission housings, engine brackets, sensor mounts, or custom chassis components, our team applies deep technical insight and cutting-edge equipment to deliver parts that perform under real-world conditions.

What sets Lead Precision apart is our commitment to transparency, responsiveness, and technical collaboration. We understand that supply chain resilience is critical for manufacturers in Rosemount and beyond. That’s why we integrate real-time project tracking, rigorous quality control protocols—including CMM inspection and material traceability—and proactive communication at every stage. Our engineering team works directly with your design and procurement staff to optimize manufacturability, reduce lead times, and control costs without compromising performance.

We specialize in machining and fabricating components from aluminum, steel, stainless steel, and exotic alloys, supporting tight tolerances down to ±0.005 mm. Our automated CNC centers, robotic welding systems, and multi-axis milling platforms ensure consistency and repeatability across batches of any size. With a production floor exceeding 12,000 square meters and strategic logistics partnerships, we are fully equipped to support just-in-time delivery models and long-term supply agreements.

Below are key capabilities that define our service offering:

| Specification | Detail |

|---|---|

| CNC Machining | 3-axis to 5-axis, max work envelope 1200 x 800 x 750 mm |

| Tolerance | ±0.005 mm typical, tighter upon request |

| Materials | Aluminum (6061, 7075), Steel (1018, 4140), Stainless (304, 316), Brass, Titanium |

| Finishing | Anodizing, Powder Coating, Passivation, Zinc Plating |

| Quality Standards | ISO 9001, IATF 16949, First Article Inspection (FAI), PPAP |

| Lead Times | 15–25 days for production, expedited options available |

| Production Capacity | Up to 50,000 units/month, scalable for OEM demand |

Partnering with Wuxi Lead Precision Machinery means gaining a manufacturing ally focused on your success. We don’t just produce parts—we deliver solutions that enhance your competitiveness. If you’re an auto parts manufacturer in Rosemount, MN, seeking a reliable offshore partner with precision, scalability, and technical depth, contact us today. Email us at [email protected] to discuss your next project and receive a detailed quote within 24 hours. Let Lead Precision become your trusted extension in high-performance metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.