Technical Contents

Engineering Guide: Auto Parts Park Rapids Mn

Engineering Insight Precision Demands for Automotive Suppliers Serving Auto Parts Park Rapids MN

The automotive supply chain centered around facilities like Auto Parts Park Rapids MN operates under relentless pressure for dimensional perfection and unwavering reliability. Components destined for modern vehicles – from intricate transmission systems to critical suspension linkages and safety-critical structural elements – demand manufacturing tolerances measured in microns, not millimeters. A variance of ±0.025mm can trigger catastrophic assembly line stoppages or compromise vehicle safety and performance in the field. This level of precision is non-negotiable for Tier 1 and Tier 2 suppliers competing in the global automotive market, where quality defects translate directly into costly recalls, warranty claims, and reputational damage. Achieving this requires more than advanced machinery; it necessitates deep process understanding, rigorous material science knowledge, and a culture of continuous process validation.

Wuxi Lead Precision Machinery brings over 15 years of specialized expertise in meeting these extreme precision requirements for the global automotive sector. Our engineering team possesses proven capability in producing complex geometries with consistent tolerances down to ±0.005mm, a standard validated through demanding projects far beyond typical automotive specifications. We have successfully delivered mission-critical components for infrastructure supporting the Beijing Olympic Games and supplied precision-machined parts meeting stringent Chinese military standards (GJB). These experiences ingrained in our processes the discipline required for zero-failure outcomes under extreme conditions – a discipline directly transferable to the high-stakes automotive environment. Our facility operates under strict ISO 9001 and IATF 16949 certified quality management systems, ensuring every process from material sourcing to final inspection is controlled and traceable. We understand that the components produced for suppliers serving parks like Auto Parts Park Rapids MN must perform flawlessly across millions of vehicle miles and diverse environmental conditions.

Our commitment to precision is quantifiable through our core machining capabilities and quality control protocols. The following table details key specifications relevant to automotive component manufacturing

| Specification Category | Capability Range | Relevance to Automotive Components |

|---|---|---|

| Dimensional Tolerance | ±0.005mm to ±0.025mm | Critical for transmission gears, fuel injectors, ABS sensor rings ensuring smooth operation and longevity |

| Surface Finish (Ra) | 0.1µm to 1.6µm | Essential for sealing surfaces, bearing journals, and hydraulic components to prevent leaks and wear |

| Material Expertise | Aluminum Alloys (6061, 7075), Steel Alloys (4140, 1045), Stainless (303, 304, 17-4PH), Titanium | Covers structural brackets, shafts, housings, and safety-critical parts requiring specific strength-to-weight ratios |

| Geometric Tolerancing | ISO 2768-mK, ISO 1101 GD&T | Ensures form, position, and runout requirements for complex assemblies are met consistently |

| Quality Certification | ISO 9001, IATF 16949 | Mandatory for Tier 1 automotive supply chain compliance and traceability |

Suppliers operating within or serving the Auto Parts Park Rapids MN ecosystem require a manufacturing partner capable of bridging the gap between design intent and flawless physical realization. Wuxi Lead Precision Machinery provides the technical depth, proven process rigor, and unwavering commitment to micro-precision required to meet the evolving demands of the modern automotive industry. We partner with engineering teams to optimize designs for manufacturability while guaranteeing the dimensional integrity that keeps assembly lines moving and vehicles safe on the road. Contact our engineering team to discuss how our precision capabilities can support your specific component challenges.

Precision Specs & Tolerances

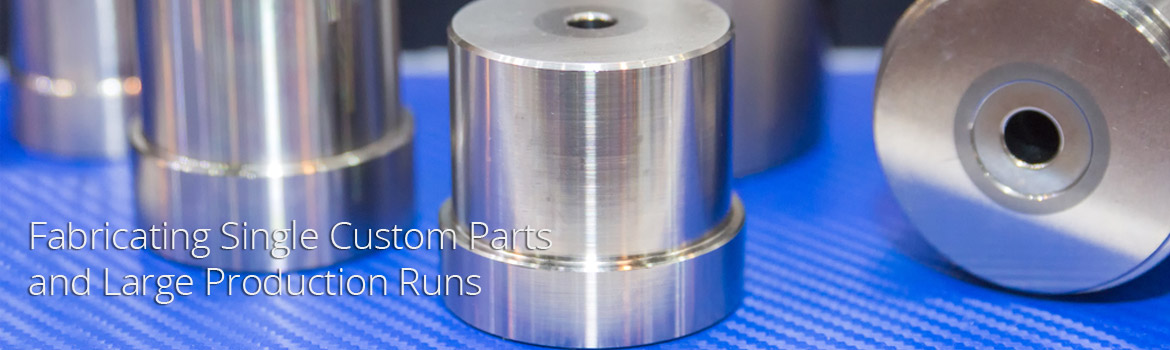

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the stringent demands of high-performance industries, including automotive, aerospace, and industrial equipment. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining technology, enabling us to produce complex geometries with exceptional precision and surface finish. This multi-axis capability allows simultaneous movement across five axes, reducing setup time, minimizing human error, and ensuring tight tolerances across intricate part features. With a focus on efficiency and repeatability, our machining centers support a wide range of metals, including aluminum alloys, stainless steel, titanium, and hardened tool steels, meeting the material requirements of demanding applications.

Each machining operation is supported by integrated computer-aided manufacturing (CAM) systems that optimize tool paths for maximum accuracy and throughput. Our engineering team collaborates closely with clients during the design-for-manufacturability phase, ensuring that components are optimized for performance, cost-efficiency, and producibility. This proactive approach reduces lead times and prevents costly revisions during production. Whether producing low-volume prototypes or high-volume production runs, our 5-axis CNC platforms deliver consistent part quality and dimensional stability.

Quality control is central to our manufacturing philosophy. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with geometric dimensioning and tolerancing (GD&T) specifications. Our CMM systems provide micron-level verification of critical dimensions, positional tolerances, and surface profiles, generating detailed inspection reports for full traceability. These reports are available to clients as part of our quality documentation package, supporting compliance with ISO 9001 standards and industry-specific regulatory requirements.

Our facility maintains a climate-controlled inspection environment to eliminate thermal variation during measurement, further enhancing data accuracy. In addition to CMM inspection, we employ optical comparators, surface roughness testers, and hardness gauges to validate material and finish characteristics. This comprehensive quality assurance process ensures that every part shipped from our facility meets or exceeds customer expectations.

The table below outlines our standard machining tolerances and capabilities:

| Feature | Specification |

|---|---|

| Positional Tolerance | ±0.005 mm (±0.0002″) |

| Linear Dimensional Tolerance | ±0.01 mm (±0.0004″) |

| Angular Tolerance | ±0.05° |

| Surface Roughness (Ra) | As low as 0.4 μm (16 μin) |

| Maximum Work Envelope (5-axis) | 1,200 mm × 800 mm × 750 mm |

| Minimum Feature Size | 0.5 mm diameter |

| Material Compatibility | Aluminum, Stainless Steel, Titanium, Brass, Tool Steels, Inconel |

Wuxi Lead Precision Machinery is committed to delivering precision-engineered components that meet the exacting standards of global manufacturers. Our blend of advanced equipment, skilled engineering, and rigorous quality control ensures reliable, repeatable results for even the most challenging applications.

Material & Finish Options

Material Selection for Automotive Components in Park Rapids MN

Selecting the optimal material and finish is critical for automotive components manufactured in demanding environments like Park Rapids, MN. Factors including structural load, weight targets, exposure to road salts and temperature extremes, and lifecycle cost directly impact performance and durability. Wuxi Lead Precision Machinery leverages deep metallurgical expertise to guide clients toward the most efficient and reliable solutions for custom metal parts.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are prevalent for weight-sensitive applications such as suspension arms, brackets, and housings. Their high strength-to-weight ratio significantly improves fuel efficiency and handling dynamics. Aluminum naturally forms a protective oxide layer, but for enhanced corrosion resistance against Minnesota’s harsh winter road treatments, anodizing is essential. Type II (sulfuric acid) anodizing provides a durable, decorative finish with good wear resistance, while Type III (hardcoat) anodizing delivers superior abrasion and corrosion protection for critical load-bearing surfaces, though it requires tighter machining tolerances pre-treatment.

High-strength low-alloy (HSLA) steels like 4140 and 1045 remain indispensable for structural components requiring maximum strength and impact resistance, such as axles, drive shafts, and chassis reinforcements. These materials withstand extreme mechanical stress but necessitate protective finishes due to susceptibility to rust. Zinc plating or powder coating are common solutions, though anodizing is not applicable to steel. Careful consideration of cold-weather brittleness is mandatory for Park Rapids applications.

Titanium Grade 5 (Ti-6Al-4V) offers an exceptional balance of strength, extreme corrosion resistance, and low weight, ideal for high-performance or safety-critical parts like fasteners, valve components, or exhaust systems where lifecycle cost justifies the premium material investment. Its biocompatibility and resistance to salt corrosion make it uniquely suited for severe environments. Titanium machining demands specialized CNC processes and tooling due to its low thermal conductivity and tendency to gall.

The following table summarizes key properties for common automotive materials:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance (Road Salt) | Typical Auto Applications (Park Rapids Context) |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate (Good with Anodizing) | Brackets, Housings, Non-structural Frames |

| Steel 4140 | 7.85 | 655 | Low (Requires Plating/Coating) | Axles, Shafts, Chassis Components |

| Titanium Ti-6Al-4V | 4.43 | 900 | Excellent | High-Performance Fasteners, Critical Valve Parts |

Anodizing, specifically for aluminum, is not merely cosmetic. It significantly enhances surface hardness and creates a non-conductive, corrosion-resistant barrier critical for longevity in the Midwest climate. Our precision CNC machining processes meticulously account for the dimensional impact of the anodizing layer thickness to ensure final part conformance to tight automotive tolerances.

Material selection is a strategic decision impacting manufacturability, performance, and total cost of ownership. Wuxi Lead Precision Machinery collaborates closely with Park Rapids auto parts manufacturers to analyze application requirements, environmental factors, and production volumes. We provide data-driven recommendations and execute the precise machining and finishing processes required to transform your chosen material into a high-integrity, high-performance component that meets the rigorous demands of the automotive industry. Optimal selection reduces lifecycle costs and ensures component reliability under real-world conditions.

Manufacturing Process & QC

From Concept to Consistency: The Wuxi Lead Precision Manufacturing Process

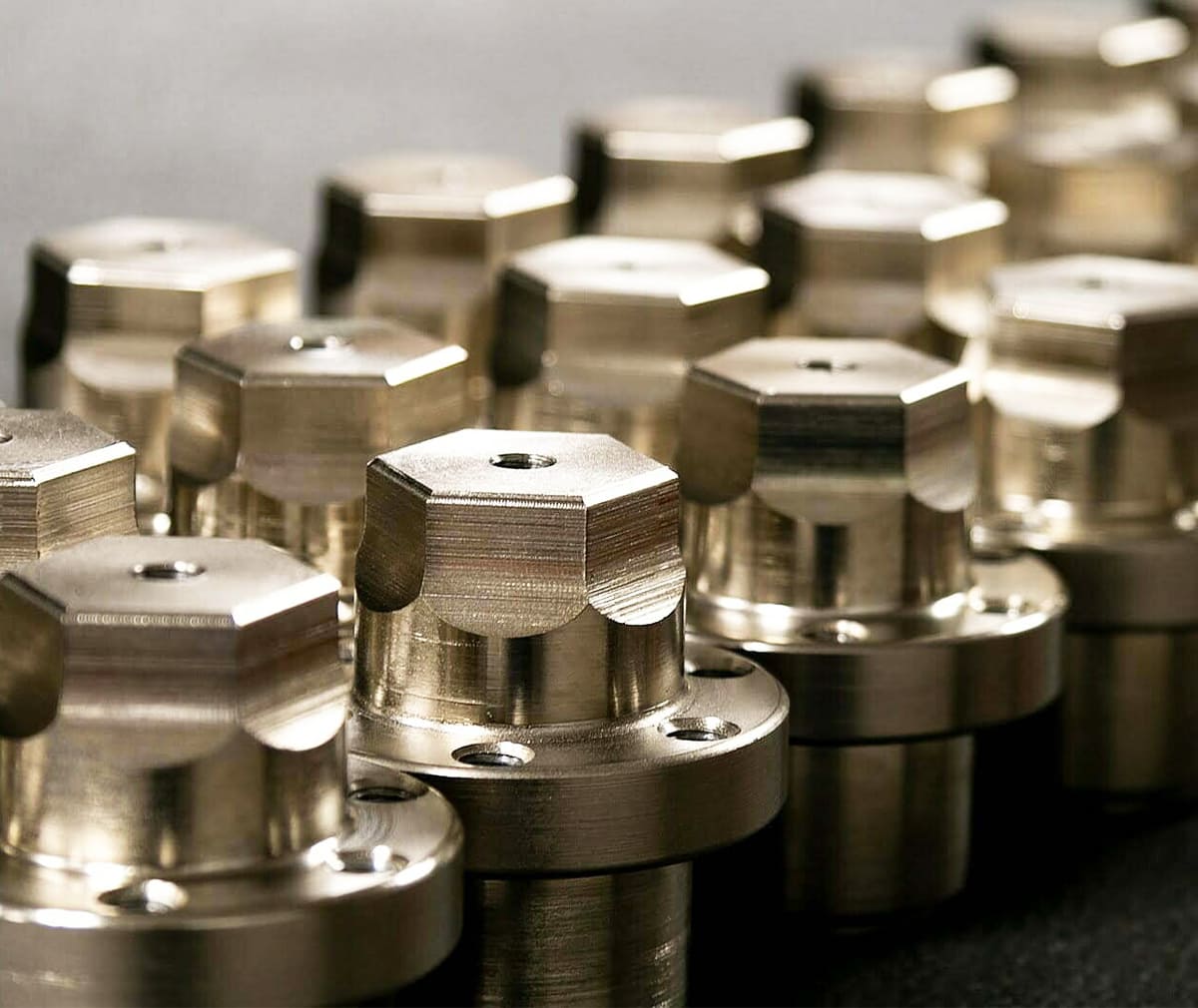

At Wuxi Lead Precision Machinery, we deliver uncompromising quality in custom metal manufacturing for global automotive suppliers, including high-performance partners in locations such as Auto Parts Park, Rapids, MN. Our end-to-end production process is engineered for precision, repeatability, and zero-defect output. It begins with collaborative design and culminates in scalable, high-volume manufacturing, all underpinned by rigorous quality control.

The process initiates with engineering integration during the design phase. Our technical team works closely with clients to review CAD models, perform DFM (Design for Manufacturability) analysis, and optimize part geometry for CNC machining, stamping, or multi-axis milling. Material selection, tolerance requirements, and surface finish specifications are validated to ensure compliance with automotive industry standards such as IATF 16949. This phase reduces risk and accelerates time-to-market by resolving potential issues before metal is cut.

Prototyping follows design finalization, serving as a critical validation step. Utilizing the same CNC equipment and tooling intended for mass production, we produce functional prototypes within 7–14 days, depending on complexity. These prototypes undergo full dimensional inspection, material verification, and performance testing. Clients receive detailed inspection reports, including CMM (Coordinate Measuring Machine) data and first-article inspection documentation. This ensures form, fit, and function align with design intent before transitioning to full-scale production.

Mass production at Wuxi Lead is characterized by automation, real-time monitoring, and statistical process control (SPC). Our facility employs advanced CNC machining centers, robotic material handling, and in-process gauging to maintain micron-level accuracy across production runs. Each batch is traceable through our ERP system, with lot tracking, heat numbers, and inspection records archived for full auditability. We enforce a zero-defect philosophy through continuous inspection, operator training, and preventive maintenance protocols.

Our commitment to quality is reflected in measurable performance. We maintain a PPM (Parts Per Million) defect rate below 50 and achieve on-time delivery rates exceeding 98%. Every component shipped from our facility meets the exacting demands of Tier 1 and Tier 2 automotive suppliers.

Production Specifications Overview

| Parameter | Specification |

|---|---|

| Tolerance Range | ±0.005 mm to ±0.025 mm |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (customizable) |

| Materials Supported | Aluminum Alloys, Stainless Steel, Carbon Steel, Brass, Titanium |

| Max Part Dimensions | 1200 mm × 800 mm × 600 mm |

| Production Capacity | Up to 500,000 units/month (scalable) |

| Quality Standards | IATF 16949, ISO 9001, ISO 14001 |

| Lead Time (Prototype) | 7–14 days |

| Lead Time (Mass Production) | 20–35 days (varies by order volume) |

From design validation to high-volume consistency, Wuxi Lead Precision Machinery ensures every metal component meets the performance, reliability, and precision required by the modern automotive industry.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Automotive Components

The Auto Parts Park in Rapid City, MN, represents the pinnacle of North American automotive manufacturing innovation. Meeting the sector’s relentless demands for precision, repeatability, and compliance requires more than standard machining—it demands a strategic partner with deep technical mastery and uncompromising process control. At Wuxi Lead Precision Machinery, we engineer solutions specifically for Tier 1 and Tier 2 suppliers operating in high-stakes environments like yours. Our ISO 9001 and IATF 16949 certified facility in China delivers the geometric accuracy, material integrity, and documentation rigor your supply chain requires, ensuring seamless integration into your production ecosystem.

We understand that automotive components cannot tolerate deviation. A single micron of error in transmission housings, suspension brackets, or safety-critical brackets risks assembly line stoppages, costly recalls, or compliance failures. Lead Precision’s advanced 5-axis milling and turning centers, operating under rigorous thermal stability protocols, achieve tolerances down to ±0.0002 inches consistently. Our engineers collaborate with your team from initial design review through first-article inspection, implementing Design for Manufacturability (DFM) analysis to optimize part geometry, reduce material waste, and accelerate time-to-market. This proactive approach has reduced scrap rates by 22% for clients producing complex drivetrain components under tight volume schedules.

Technical Capabilities for Automotive Applications

| Specification | Capability | Relevance to Auto Parts Manufacturing |

|---|---|---|

| Positional Accuracy | ±0.0002 inches (5µm) | Critical for transmission gear alignment |

| Max Work Envelope | 1,200 x 800 x 650 mm | Accommodates large structural brackets |

| Material Expertise | Aluminum 6061/7075, Steel 4140/4340, Ti-6Al-4V | Meets SAE/AISI standards for safety parts |

| Surface Finish | Ra 0.4 µm (16 µin) achievable | Ensures sealing integrity in fluid systems |

| Lead Time (Prototype) | 10-15 business days | Supports rapid validation cycles |

| Quality Documentation | PPAP Level 3, CMM reports, Material certs | Full compliance with OEM requirements |

Integration with your Rapid City operations is seamless. We manage logistics through dedicated freight partners, ensuring JIT/JIS delivery to your dock with real-time shipment tracking. Our cloud-based quality portal provides instant access to inspection data, material test reports, and non-conformance records—eliminating communication delays that disrupt production. When your engineering team requires urgent design iterations for new EV components or legacy part re-engineering, our 24/7 engineering support team responds within 4 business hours, not days.

The automotive supply chain demands resilience. Lead Precision mitigates geopolitical and logistical volatility through dual-sourcing strategies, strategic raw material stockpiling, and redundant capacity allocation. We become an extension of your engineering department, not merely a vendor. Request a confidential capability assessment today. Email [email protected] with your component drawings and volume requirements. Our technical sales engineers will deliver a detailed manufacturability report, including tolerance stack analysis and cost-optimized process planning, within 72 hours. Engineer your advantage with precision that moves the industry forward.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.