Technical Contents

Engineering Guide: Auto Parts Delano Mn

Engineering Insight: The Role of Precision in Automotive Components for Delano, MN

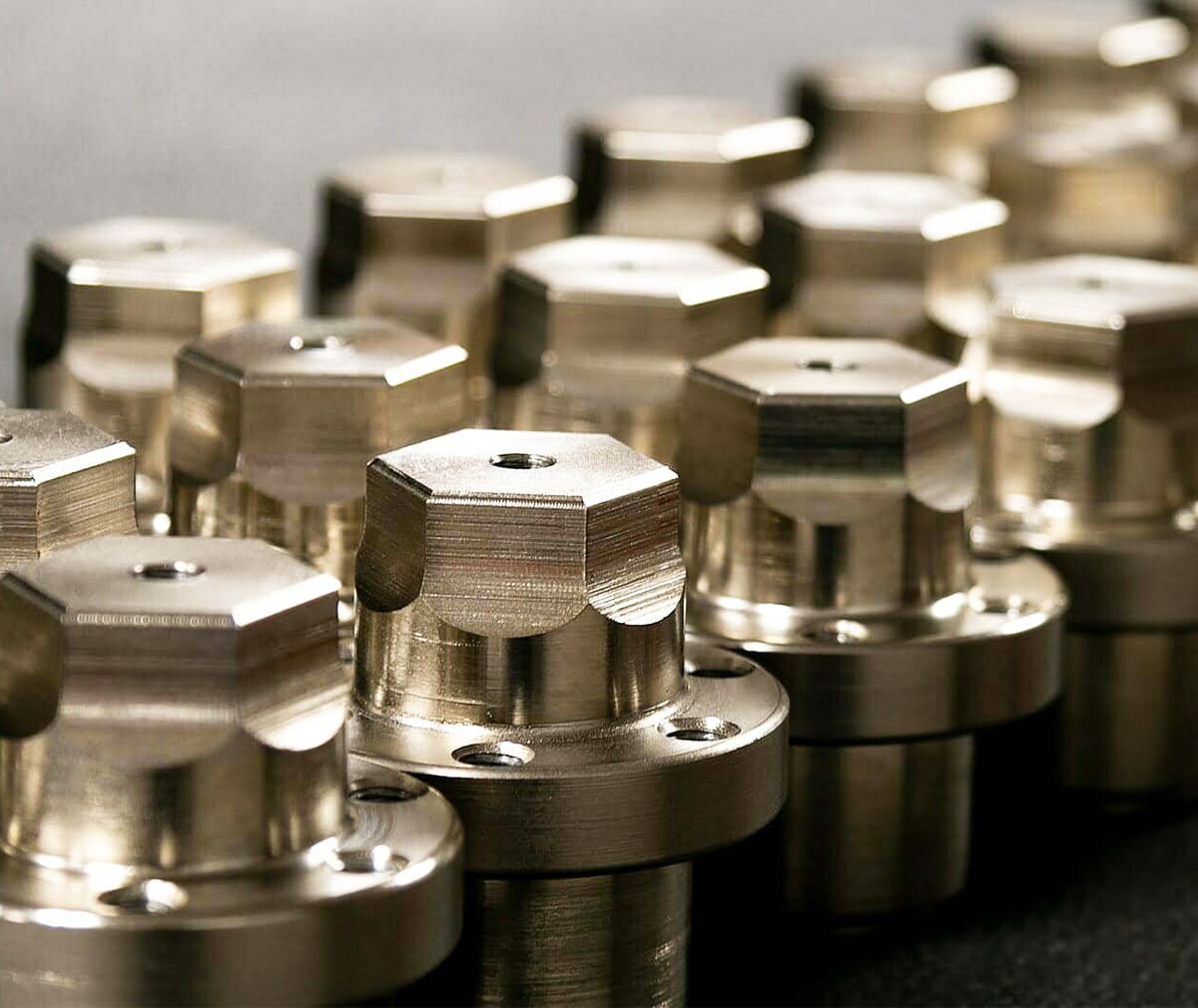

In the evolving landscape of automotive manufacturing, precision is not merely a performance metric—it is a foundational requirement. For auto parts suppliers and OEMs in Delano, Minnesota, where efficiency, reliability, and innovation drive production standards, partnering with a globally certified precision manufacturer ensures competitive advantage and long-term supply chain integrity. At Wuxi Lead Precision Machinery, we understand that even micron-level deviations in metal components can cascade into system-level failures, particularly in high-stress automotive applications such as transmission systems, suspension mounts, and engine housings.

With over 15 years of specialized experience in custom metal manufacturing, Wuxi Lead has delivered mission-critical components for sectors where failure is not an option—Olympic-grade equipment and military defense systems. These demanding applications require not only adherence to tight tolerances but also rigorous material traceability, environmental resilience, and repeatable consistency across production runs. The same engineering discipline we apply to aerospace-grade alloys or tactical vehicle components is directly transferable to the automotive supply chain serving facilities in Delano, MN.

Precision machining in automotive manufacturing goes beyond dimensional accuracy. It encompasses thermal stability during operation, surface finish compatibility with sealing systems, and geometric conformity to mating parts in high-vibration environments. Our facility in Wuxi, China, leverages advanced 5-axis CNC machining centers, real-time in-process metrology, and automated quality control loops to ensure every component meets or exceeds customer specifications. This level of control is essential when producing complex geometries such as differential carriers or brake caliper brackets, where load distribution and fatigue resistance are paramount.

Moreover, our engineering team works collaboratively with clients to optimize designs for manufacturability without compromising performance. By integrating Design for Manufacturing (DFM) principles early in the development cycle, we reduce lead times, minimize material waste, and enhance scalability—critical factors for automotive suppliers operating under just-in-time delivery models.

The automotive sector in Delano, MN, benefits from access to global manufacturing expertise that combines technical precision with proven reliability. Wuxi Lead’s track record in high-stakes industries underscores our capability to meet the most stringent quality standards, including ISO 9001:2015, AS9100 for aerospace, and ITAR compliance for defense-related projects. This experience translates into confidence for our automotive partners: components are not only precise but also engineered for real-world durability.

Below is a summary of our core manufacturing capabilities relevant to automotive applications:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.005 mm (±0.0002 in) |

| Maximum Work Envelope | 2000 x 1200 x 800 mm (78.7 x 47.2 x 31.5 in) |

| Materials Processed | Aluminum Alloys (6061, 7075), Steel (4140, 1045), Stainless Steel (304, 316), Titanium (Grade 5) |

| Surface Finish | Ra 0.4 μm (16 μin) typical, down to Ra 0.1 μm (4 μin) |

| Quality Standards | ISO 9001:2015, AS9100D, ITAR Registered |

| Lead Time (Average) | 15–25 days, depending on complexity and volume |

Precision is not a feature—it is the standard. For automotive manufacturers in Delano, MN, aligning with a proven global partner like Wuxi Lead Precision Machinery ensures that every component contributes to a safer, more efficient, and higher-performing vehicle.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Automotive Excellence

Wuxi Lead Precision Machinery delivers the advanced manufacturing capabilities essential for demanding automotive component production, directly addressing the stringent requirements of suppliers serving markets like Delano, Minnesota. Our core strength lies in integrating state-of-the-art multi-axis machining with rigorous, traceable quality control, ensuring every part meets or exceeds automotive OEM specifications for performance, safety, and longevity. We specialize in transforming complex metal designs into high-integrity components where precision is non-negotiable.

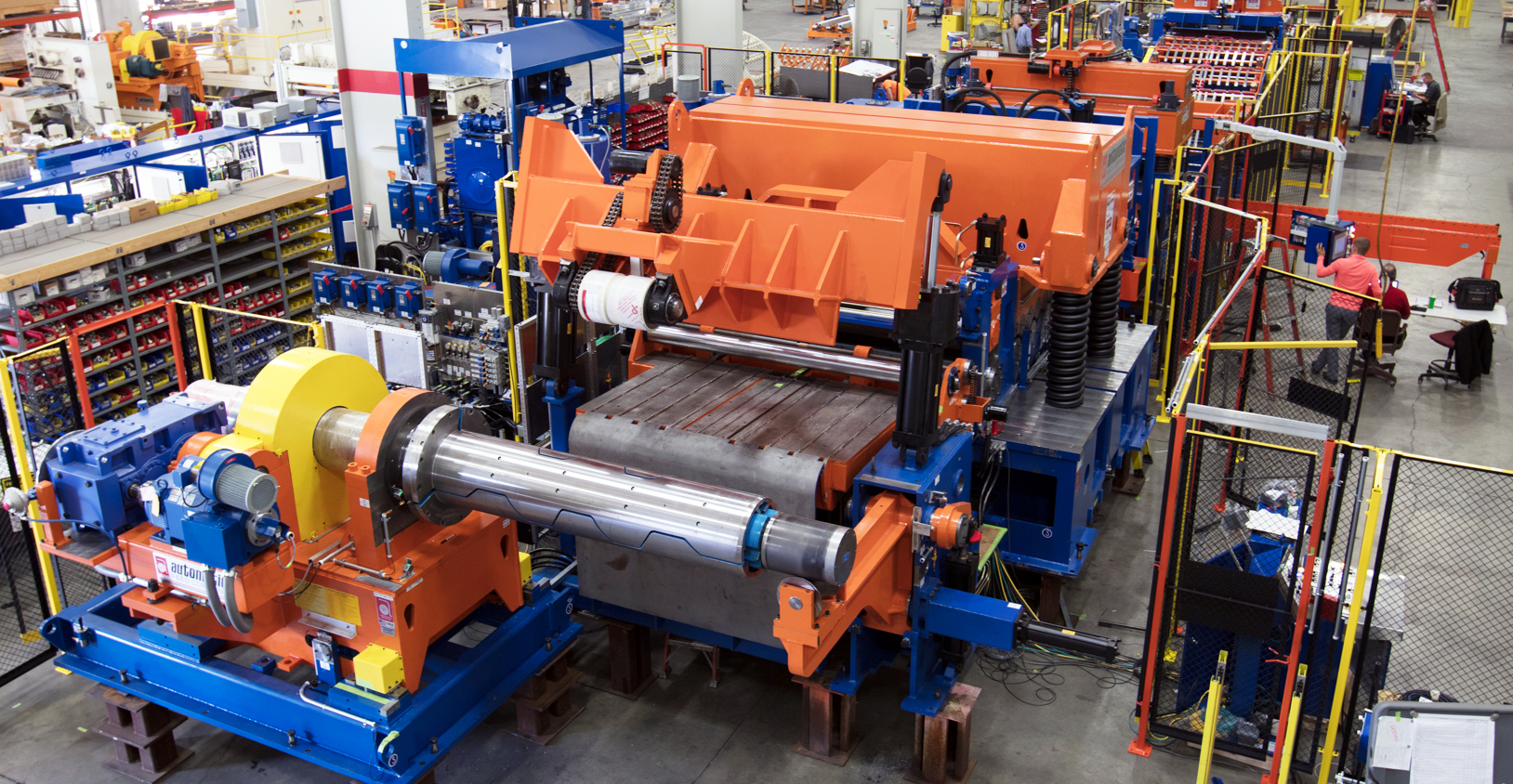

Our foundation is built upon a modern fleet of 5-axis CNC machining centers from industry leaders like DMG MORI and Makino. These systems provide the simultaneous multi-directional movement necessary to machine intricate geometries—such as transmission housings with internal spline features, complex suspension knuckles, or cylinder heads with intersecting coolant passages—in a single setup. This eliminates cumulative errors from multiple fixturing operations, significantly enhancing dimensional accuracy and surface integrity while reducing lead times. Our machines maintain exceptional thermal stability and positional repeatability down to 0.001 mm, critical for components operating under high stress and thermal cycling in automotive applications. Material expertise spans aerospace-grade aluminum alloys, high-strength steel, cast iron, and specialized composites commonly used in modern vehicle systems.

Quality assurance is not a final step but an integrated process at Wuxi Lead. Every critical dimension undergoes meticulous verification using calibrated Coordinate Measuring Machines (CMM), primarily Zeiss CONTURA and GLOBAL series systems. Our CMM inspection protocol provides full first-article inspection reports (FAIR) and production part approval process (PPAP) Level 3 documentation as standard, ensuring complete traceability from raw material to finished component. This systematic approach guarantees conformance to geometric dimensioning and tolerancing (GD&T) requirements specified in blueprints, mitigating risks of assembly line disruptions for our automotive partners. Real-time SPC data monitoring during production allows for immediate process adjustments, maintaining consistent output quality batch after batch.

The following table details our standard achievable tolerance specifications, reflecting the precision level consistently delivered for automotive applications:

| Feature | Specification | Application Relevance for Auto Parts |

|---|---|---|

| Linear Dimensional | ±0.005 mm (±0.0002″) | Critical bores, shaft fits, bearing seats |

| Geometric (GD&T) | 0.010 mm (0.0004″) | Positional accuracy for bolt patterns, critical datums |

| Surface Roughness (Ra) | 0.4 μm (16 μin) | Sealing surfaces, piston rings, hydraulic components |

| Hole Concentricity | 0.008 mm (0.0003″) | Transmission shafts, CV joints, precision bushings |

For Delano-based auto parts manufacturers requiring components that perform reliably under extreme conditions—from Minnesota’s harsh winters to high-performance driving scenarios—Wuxi Lead provides the technical depth and quality rigor to ensure your assemblies meet the highest standards of safety and durability. Our process stability directly translates to reduced scrap rates and enhanced end-product reliability for your customers. Partner with us for precision that drives automotive success.

Material & Finish Options

Material selection is a critical factor in the performance, durability, and cost-efficiency of custom auto parts, especially for high-demand applications in the automotive sector. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing for global clients, including specialized suppliers in locations such as Delano, MN. Our expertise enables us to guide engineering teams through optimal material choices—aluminum, steel, and titanium—based on mechanical requirements, environmental exposure, and finishing needs.

Aluminum is widely favored in automotive applications due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for components where weight reduction is essential without compromising structural integrity. Common grades such as 6061-T6 and 7075-T6 offer balanced properties for suspension parts, brackets, and housings. When paired with anodizing, aluminum gains enhanced surface hardness and wear resistance, making it ideal for both functional and aesthetic applications.

Steel remains the go-to material for high-strength, high-wear applications. Alloy steels like 4140 and 4340 provide superior toughness and fatigue resistance, critical for drivetrain components, shafts, and high-load fasteners. Stainless steel variants such as 304 and 17-4 PH offer corrosion resistance and are frequently used in exhaust systems and under-hood environments exposed to heat and moisture. While heavier than aluminum, steel’s mechanical robustness ensures long service life in demanding conditions.

Titanium, though more costly, delivers exceptional performance in extreme environments. Its high strength-to-density ratio surpasses both aluminum and steel, and it maintains integrity at elevated temperatures. Grade 5 titanium (Ti-6Al-4V) is commonly used in performance and racing applications, including connecting rods, valve train components, and aerospace-inspired structural parts. Its biocompatibility and corrosion resistance also make it suitable for specialty vehicles and high-end aftermarket builds.

Anodizing is a key surface treatment for aluminum components, providing a controlled oxide layer that improves wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) delivers a thicker, harder surface ideal for high-wear environments. Anodized finishes can be dyed in various colors, offering branding or coding options for OEMs and Tier 1 suppliers.

Below is a comparative overview of key mechanical and finishing properties:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Applications | Compatible Finishes |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Brackets, housings | Anodizing (Type II/III), powder coat |

| Steel 4140 | 655 | 7.85 | Shafts, fasteners | Zinc plating, passivation |

| Stainless 17-4 PH | 1000 | 7.78 | High-temp components | Passivation, electropolishing |

| Titanium Ti-6Al-4V | 950 | 4.43 | Performance engine parts | Anodizing, thermal spray |

Selecting the right material and finish requires a deep understanding of operational demands and lifecycle expectations. Wuxi Lead Precision Machinery supports clients in Delano and beyond with expert consultation, ensuring every component meets exacting automotive standards.

Manufacturing Process & QC

Precision Engineering Workflow: From Concept to Zero-Defect Automotive Production

Precision is non-negotiable in automotive manufacturing. At Wuxi Lead Precision Machinery, our integrated production process for clients like Auto Parts Delano MN delivers uncompromising quality through rigorous engineering control. We eliminate defects at the source, ensuring every component meets stringent automotive specifications before mass production begins.

The process initiates with collaborative Design Engineering. Our team works directly with your Delano engineering staff to analyze CAD models, validate GD&T requirements, and conduct manufacturability reviews. We identify potential stress points, material constraints, and tolerance stack-ups early using advanced simulation software. This phase includes thermal analysis for critical powertrain components and material suitability verification against SAE/AISI standards, preventing costly revisions later. All design outputs undergo formal sign-off against your IATF 16949 documentation requirements.

Prototyping follows with absolute fidelity to production intent. We utilize the same HAAS and DMG MORI machining centers destined for volume runs, eliminating process variation. Each prototype undergoes comprehensive validation: CMM inspection against all critical dimensions, material certification traceability, and functional testing per your Delano test protocols. This stage confirms not only geometric accuracy but also surface integrity and metallurgical properties. The table below details our prototyping capabilities for automotive applications.

| Specification | Capability | Automotive Relevance |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm (±0.00008″) | Critical for transmission gears |

| Surface Finish (Ra) | 0.4 µm (16 µin) achievable | Essential for hydraulic components |

| Material Certification | Full MTR traceability | Required for safety-critical parts |

| Lead Time | 7-10 days for complex prototypes | Accelerates Delano validation cycles |

| Validation Reporting | Full FAI per AS9102 Level 3 | Meets tier-1 supplier requirements |

Mass Production leverages the validated process with embedded zero-defect controls. We implement Statistical Process Control (SPC) on all critical characteristics, with real-time data monitoring via our MES system. Automated in-process gauging checks key features after every 50 parts, while first-article and end-of-shift inspections follow IATF 16949 protocols. Our dedicated production cells for Delano programs feature tool life management systems that preempt wear-related deviations, and 100% vision inspection is deployed for safety-critical geometries. Every shipment includes certified dimensional reports and material test results, with full batch traceability from raw material heat number to finished part.

This closed-loop methodology ensures consistent output meeting Delano MN’s exacting standards. By engineering quality into every phase rather than inspecting it in, we eliminate scrap, reduce your total cost of ownership, and guarantee on-time delivery of mission-critical automotive components. Partner with Wuxi Lead for production integrity you can measure in zero defects.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Custom Metal Manufacturing Excellence

When it comes to precision-engineered auto parts in Delano, MN, and beyond, Wuxi Lead Precision Machinery stands as a trusted global partner for high-performance custom metal manufacturing. With over 15 years of expertise in CNC machining, turning, milling, and complex fabrication, we deliver components that meet the most stringent industry standards. Our advanced facility in Wuxi, China, is equipped with state-of-the-art machinery and staffed by certified engineers who specialize in producing mission-critical parts for automotive, industrial, and transportation sectors.

We understand that manufacturers in Delano and across North America demand more than just parts—they require reliability, repeatability, and responsiveness. That’s why we’ve built our operations around lean manufacturing principles, ISO 9001-certified quality control, and end-to-end traceability. From prototype development to high-volume production, every component is inspected using precision metrology equipment, including CMMs and optical comparators, ensuring dimensional accuracy down to ±0.005 mm.

Our partnership model is designed for seamless integration with your supply chain. We offer just-in-time delivery, bilingual project management, and real-time production updates to keep your operations running smoothly. Whether you need aluminum housings, steel brackets, transmission components, or custom fasteners, our team works closely with your engineering staff to optimize designs for manufacturability, cost-efficiency, and performance.

Wuxi Lead Precision Machinery is not just a supplier—we are an extension of your manufacturing team. Our engineers collaborate on DFM (Design for Manufacturability) analysis, material selection, and tolerance optimization to reduce waste and accelerate time-to-market. With a 99.6% on-time delivery rate and a zero-defect commitment, we’ve earned long-term partnerships with Tier 1 automotive suppliers and industrial OEMs across the United States.

Below are key capabilities that define our manufacturing excellence:

| Specification | Detail |

|---|---|

| Machining Tolerance | ±0.005 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| CNC Machines | 45+ (3-axis, 4-axis, 5-axis) |

| Materials Processed | Aluminum, Steel, Stainless Steel, Brass, Titanium |

| Secondary Operations | Deburring, Anodizing, Plating, Heat Treatment, Laser Marking |

| Quality Standards | ISO 9001:2015, PPAP, FAIR, SPC |

| Lead Time (Average) | 15–25 days (including shipping to North America) |

We invite manufacturers in Delano, MN, and surrounding regions to elevate their production capabilities through a strategic partnership with Wuxi Lead Precision Machinery. Let us help you achieve higher precision, lower costs, and faster delivery cycles—without compromising quality.

Contact us today at [email protected] to discuss your next project. Our engineering team is ready to provide a free DFM review and competitive quotation within 24 hours. Partner with precision. Partner with Lead.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.