Technical Contents

Engineering Guide: Asa Electronics Sheet Metal Fabrication Capabilities

Engineering Insight: Precision as the Foundation of asa Electronics Sheet Metal Fabrication Capabilities

In the field of advanced electronics manufacturing, particularly for applications in aerospace, defense, and high-reliability industrial systems, the integrity of sheet metal components is not merely a matter of form—it is a determinant of function, safety, and long-term performance. The term asa electronics sheet metal fabrication capabilities refers to the specialized engineering and production processes required to meet the exacting standards of airborne, spaceborne, and avionics systems. At Wuxi Lead Precision Machinery, we recognize that precision in sheet metal fabrication is not an incremental benefit—it is the cornerstone of mission-critical reliability.

Precision in this context extends beyond tight tolerances. It encompasses material consistency, geometric accuracy, repeatable weld integrity, and surface finish control—all of which directly influence electromagnetic shielding, thermal management, structural durability, and compatibility with sensitive electronic assemblies. In asa-grade applications, even deviations measured in microns can compromise system performance or lead to catastrophic failure in extreme operational environments.

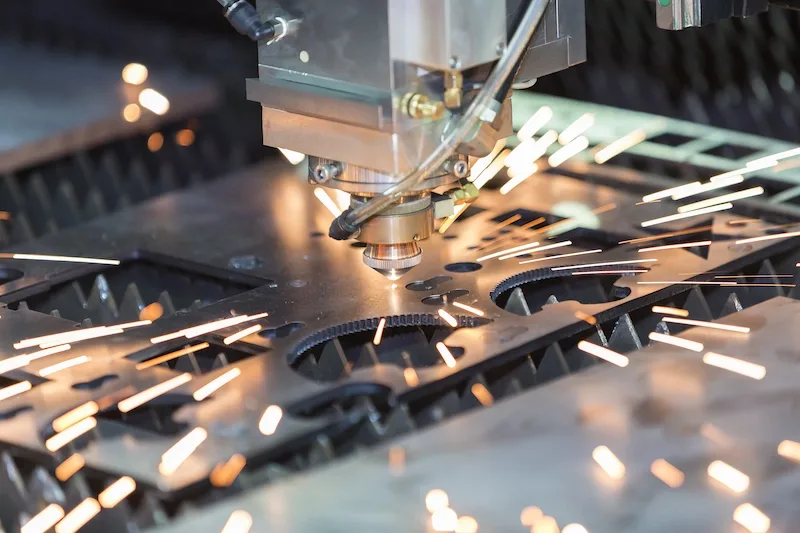

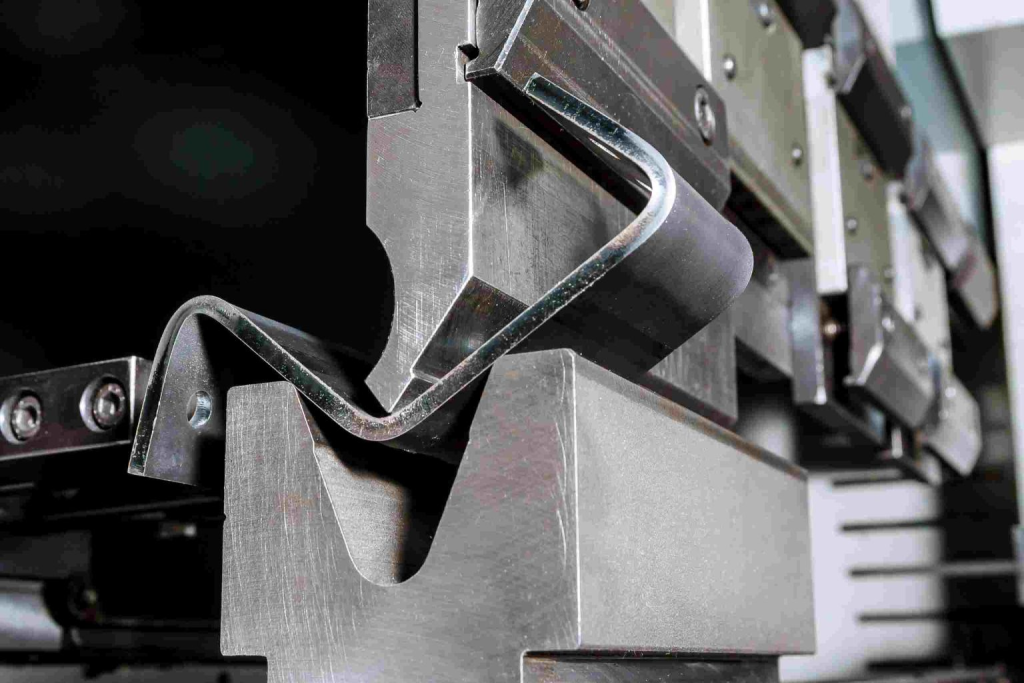

Our engineering approach integrates advanced CNC forming, laser cutting, and automated bending technologies with rigorous in-process inspection protocols. Every component is manufactured under ISO 13485 and AS9100-compliant quality systems, ensuring traceability from raw material to final assembly. With over 15 years of specialized experience serving Tier-1 defense contractors and aerospace OEMs, Wuxi Lead has contributed to projects ranging from satellite payload enclosures to onboard flight control housings—applications where failure is not an option.

Notably, our fabrication expertise has been validated through participation in high-profile national projects, including structural components for Olympic broadcast transmission systems and ruggedized enclosures for military-grade communication arrays. These engagements demanded not only micron-level dimensional control but also superior resistance to vibration, thermal cycling, and electromagnetic interference—conditions mirroring those found in aerospace environments.

Our facility supports a full spectrum of materials, including aluminum alloys (6061, 5052, 7075), stainless steels (304, 316L), and specialty conductive composites, all processed with optimized tooling strategies to minimize stress deformation and maintain signal integrity. With multi-axis fiber laser cutting and automated panel bending cells, we achieve repeatability within ±0.05 mm, ensuring seamless integration with PCBs and modular electronic subsystems.

The following table outlines key technical capabilities that define our asa electronics sheet metal fabrication performance:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Tolerance (Bending) | ±0.1° angular, ±0.1 mm linear |

| Minimum Feature Size | 1.0 mm (laser cutting) |

| Max Work Envelope | 1500 mm × 3000 mm |

| Surface Roughness (Ra) | ≤1.6 µm (after finishing) |

| Supported Standards | AS9100, ISO 13485, MIL-STD-461 (EMI shielding) |

At Wuxi Lead Precision Machinery, we treat every enclosure, bracket, and chassis as a functional component of a larger, high-stakes system. Our engineering team collaborates directly with client design groups to optimize manufacturability, thermal pathways, and EMI shielding—ensuring that asa electronics sheet metal fabrication capabilities meet not just specifications, but operational reality.

Precision Specs & Tolerances

Advanced Sheet Metal Fabrication Capabilities for Precision Electronics

Wuxi Lead Precision Machinery delivers mission-critical sheet metal solutions engineered specifically for high-complexity electronics applications. Our integrated manufacturing ecosystem combines cutting-edge 5-axis CNC technology with rigorous metrology protocols to ensure dimensional integrity across every component. This capability is essential for ASA Electronics’ demanding requirements in signal integrity, thermal management, and miniaturized assembly where micron-level deviations directly impact product performance and yield.

Our 5-axis CNC machining centers form the core of this precision workflow. These systems execute complex geometries—including multi-plane contours, deep cavities, and asymmetric features—in a single setup. This eliminates cumulative errors from secondary operations while maintaining ±0.02 mm positional accuracy across work envelopes up to 1,200 x 800 x 600 mm. For electronics enclosures and chassis, this translates to perfect mating surfaces, consistent EMI shielding effectiveness, and zero-fit assembly without rework. Material versatility spans aluminum alloys (6061-T6, 7075), stainless steels (304, 316L), and copper alloys, all processed under controlled cleanroom protocols to prevent surface contamination.

Quality assurance is anchored by Zeiss CMM systems with 0.0005 mm volumetric accuracy and automated optical comparators. Every production run undergoes full first-article inspection against 3D CAD models, with real-time SPC data tracking critical dimensions. We implement AQL 1.0 sampling for high-volume batches and 100% feature verification for safety-critical components. This closed-loop process guarantees compliance with IPC-A-620 and MIL-STD-202 standards, providing ASA Electronics with full traceability from raw material to final shipment.

Precision Tolerance Specifications

| Process | Standard Tolerance | Tight Tolerance Capability | Material Thickness Range |

|---|---|---|---|

| Laser Cutting | ±0.10 mm | ±0.05 mm | 0.5 – 6.0 mm |

| CNC Bending | ±0.15° / ±0.10 mm | ±0.05° / ±0.05 mm | 0.8 – 4.0 mm |

| 5-Axis Milling | ±0.02 mm | ±0.005 mm | All integrated features |

| Welding (TIG/Laser) | ±0.20 mm | ±0.10 mm | 0.5 – 3.0 mm |

| Surface Finish | Ra 0.8 μm | Ra 0.4 μm | Anodize, Passivation |

Our technical infrastructure extends beyond machinery to include GD&T-certified engineering support. We collaborate with ASA Electronics’ design teams during DFM stages to optimize manufacturability—reducing lead times by 30% while enhancing yield through feature consolidation and bend sequence refinement. All components undergo in-process verification at each stage, with final certification including CMM reports, material certs, and RoHS compliance documentation. This end-to-end precision control ensures your sheet metal assemblies meet the exacting demands of next-generation electronics, from 5G infrastructure to medical diagnostic systems. Wuxi Lead’s commitment to zero-defect delivery makes us the strategic partner for electronics manufacturers where precision is non-negotiable.

Material & Finish Options

Material Selection for High-Precision Sheet Metal Fabrication in Electronics Applications

Selecting the appropriate material for sheet metal fabrication is critical in the electronics industry, where performance, durability, and precision are non-negotiable. At Wuxi Lead Precision Machinery, we specialize in producing high-integrity components tailored to the stringent demands of electronic enclosures, chassis, heat sinks, and structural subassemblies. Our expertise spans three principal materials: aluminum, steel, and titanium—each offering distinct mechanical, thermal, and environmental characteristics.

Aluminum is the most widely used material in electronic sheet metal applications due to its excellent strength-to-weight ratio, high thermal and electrical conductivity, and natural corrosion resistance. Grades such as 5052, 6061, and 7075 are commonly selected based on formability, weldability, and strength requirements. Aluminum’s lightweight nature makes it ideal for portable devices and heat-sensitive environments. When enhanced with anodizing, aluminum demonstrates superior surface hardness and dielectric properties, essential for EMI shielding and insulation.

Steel, particularly cold-rolled steel (CRS) and stainless steel (304, 316), provides unmatched strength and structural rigidity. While heavier than aluminum, steel is preferred in applications requiring high mechanical durability, electromagnetic interference (EMI) containment, or operation in harsh environments. Stainless steel variants offer excellent resistance to oxidation and chemical exposure, making them suitable for industrial and outdoor electronic housings. However, steel’s lower thermal conductivity compared to aluminum must be considered in thermal management designs.

Titanium is reserved for mission-critical electronic systems in aerospace, defense, and high-performance computing. With an exceptional strength-to-density ratio and resistance to extreme temperatures and corrosion, titanium ensures long-term reliability under stress. Though more challenging to fabricate and cost-intensive, its use is justified in environments where failure is not an option.

Surface finishing is equally critical. Anodizing, particularly Type II (sulfuric acid) and Type III (hard coat), is a key post-processing technique for aluminum components. It enhances wear resistance, provides electrical insulation, and allows for color coding for identification. Anodized layers are integral to the base metal, ensuring they do not chip or peel under thermal cycling.

Below is a comparative overview of key material properties relevant to electronics fabrication:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | 167 | High | Enclosures, heat sinks, brackets |

| Stainless Steel 304 | 8.0 | 505–700 | 16.2 | Very High | Industrial control panels, EMI shields |

| Cold-Rolled Steel | 7.85 | 340–420 | 50.2 | Low (requires coating) | Server chassis, power supplies |

| Titanium Grade 5 | 4.43 | 860–895 | 7.2 | Exceptional | Aerospace avionics, military electronics |

At Wuxi Lead, we support material selection with in-house prototyping, DFMA analysis, and full traceability. Our anodizing partnerships ensure consistent, mil-spec compliant finishes. By aligning material properties with application requirements, we deliver sheet metal solutions that meet the highest standards of performance and reliability in the electronics sector.

Manufacturing Process & QC

Precision Sheet Metal Fabrication Process: From Concept to Zero-Defect Production

At Wuxi Lead Precision Machinery, our sheet metal fabrication process for demanding sectors like ASA electronics is engineered for uncompromising quality and repeatability. We integrate advanced technology with rigorous process control across three critical phases, ensuring zero defects are not an aspiration but the operational standard.

The foundation is collaborative design for manufacturability. Our engineering team works directly with client CAD data, conducting thorough DFM analysis using Siemens NX software. We identify potential fabrication challenges early—material grain direction, bend allowances, weld accessibility—and propose optimized solutions before tooling begins. This proactive engagement prevents costly revisions, reduces lead times, and ensures the design aligns precisely with the capabilities of our Amada CNC punch presses, laser cutters, and press brakes. Material certification and traceability are mandated from this initial stage, meeting stringent ASA electronics requirements for component integrity.

Prototyping transitions design into physical validation under production-intent conditions. Utilizing our 5-axis Amada LC 3015 AJ fiber laser (cutting up to 25mm stainless steel) and precision press brakes with automatic angle correction, we produce functional prototypes mirroring final production quality. Each prototype undergoes comprehensive first-article inspection per AS9102 standards, including CMM verification of critical dimensions, surface finish assessment, and fit-check validation within sub-assemblies. Client feedback is incorporated rapidly, with iterative adjustments made within 72 hours, ensuring the process is perfected before scaling.

Mass production executes the validated process with embedded quality control. Our automated production cells operate under real-time SPC monitoring. Every component passes through defined inspection checkpoints: in-process checks for bend angles and hole positions using optical comparators, 100% visual inspection for surface defects, and periodic CMM re-validation of critical features. Statistical process control charts track key parameters like laser cut kerf width and press brake tonnage, triggering immediate process correction if trends approach specification limits. Material handling utilizes anti-static protocols and dedicated clean zones for ASA electronics assemblies, preventing contamination. Final shipment includes full traceability documentation, first-article reports, and SPC data packages.

This closed-loop methodology, combining advanced machinery with disciplined quality gates, guarantees consistent output meeting the exacting demands of high-reliability electronics manufacturing. Zero defects is achieved through prevention, not detection.

Key Production Capabilities for ASA Electronics Fabrication

| Parameter | Capability | Control Method |

|---|---|---|

| Material Thickness | 0.5mm – 25.4mm (Stainless, Al, Cu) | Laser power calibration, feed rate |

| Tolerance (Laser) | ±0.05mm (up to 10mm thickness) | Real-time SPC, daily calibration |

| Bend Accuracy | ±0.2° (Repeatability ±0.1°) | Automatic angle measurement system |

| Surface Finish | Ra ≤ 0.8µm (Deburred, Clean) | Automated deburring, ISO Class 8 |

| Production Volume | 1 pc – 100,000+ units | Flexible cell configuration |

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery to unlock next-generation sheet metal fabrication capabilities tailored for advanced electronics applications. As a trusted manufacturing partner in China, we specialize in delivering precision-engineered sheet metal solutions for the demanding requirements of the electronics industry. From complex enclosures to high-tolerance chassis components, our expertise ensures your designs are transformed into high-performance, production-ready parts with unmatched consistency and quality.

At Lead Precision, we understand that electronics manufacturers require more than just fabrication—they demand engineering collaboration, rapid prototyping, and scalable production that aligns with global quality standards. Our facility is equipped with state-of-the-art CNC punching, laser cutting, bending, and welding systems, enabling tight tolerances down to ±0.05 mm and repeatability essential for sensitive electronic housings and thermal management structures. Whether you’re developing medical electronics, industrial control systems, or high-speed communication hardware, our team works closely with your engineers to optimize designs for manufacturability, cost-efficiency, and long-term reliability.

Our ISO 9001-certified processes, combined with rigorous in-process inspections and final QA protocols, ensure every component meets the highest benchmarks for dimensional accuracy, surface finish, and structural integrity. We support materials ranging from cold-rolled steel and stainless steel to aluminum alloys and specialty conductive or EMI-shielding substrates, with surface treatments including powder coating, anodizing, plating, and passivation to meet environmental and functional requirements.

Below are key capabilities that define our sheet metal fabrication services for electronics applications:

| Specification | Capability |

|---|---|

| Material Thickness | 0.5 mm – 6.0 mm |

| Tolerance | ±0.05 mm (standard), tighter upon request |

| Max Part Size | 1500 mm × 3000 mm |

| Laser Cutting Accuracy | ±0.1 mm |

| CNC Punching | Up to 30 tons, micro-hole capability |

| Bending Accuracy | ±0.2° angular, ±0.1 mm linear |

| Welding Processes | TIG, MIG, Spot, Laser Welding |

| Finishing Options | Powder coating, anodizing, zinc plating, passivation |

| Production Volume | Prototypes to high-volume series (100,000+ units/year) |

| Quality Standards | ISO 9001, RoHS compliant, First Article Inspection (FAI) available |

We pride ourselves on being more than a supplier—we are a strategic partner committed to your product’s success. Our responsive engineering support, transparent communication, and on-time delivery performance make us the preferred choice for international electronics OEMs seeking reliable, high-precision manufacturing in China.

Take the next step toward seamless, high-quality production. Contact us today at [email protected] to discuss your sheet metal fabrication needs and discover how Wuxi Lead Precision Machinery can become an extension of your engineering team.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.