Technical Contents

Engineering Guide: As9100 Machine Shop

Engineering Insight: AS9100 Certified Machine Shop – The Benchmark of Precision in Aerospace Manufacturing

In the realm of high-performance industries such as aerospace, defense, and advanced transportation, precision is not merely a target—it is a non-negotiable standard. At Wuxi Lead Precision Machinery, we operate at the forefront of custom metal manufacturing, where adherence to the AS9100 quality management standard defines our engineering philosophy. AS9100 is more than a certification; it is a comprehensive framework that ensures every component we produce meets the rigorous demands of safety, reliability, and repeatability required by global aerospace authorities.

Precision in an AS9100-certified machine shop transcends tight tolerances. It encompasses a culture of continuous improvement, full traceability, and disciplined process control. From material sourcing to final inspection, every stage of production is documented, audited, and optimized. At Lead Precision, our AS9100 compliance enables us to deliver mission-critical components with tolerances as tight as ±0.001 mm, surface finishes down to Ra 0.4 μm, and full conformance to NADCAP and ITAR requirements. This level of control is essential when parts are destined for flight-critical systems where failure is not an option.

Our engineering team brings decades of experience in high-integrity manufacturing, having supported projects ranging from Chinese military aerospace platforms to precision components used in Olympic-grade athletic equipment. These applications, though distinct in end use, share a common demand: absolute reliability under extreme conditions. Whether machining titanium alloys for a jet engine housing or crafting high-strength aluminum assemblies for dynamic load environments, our processes are validated through rigorous first-article inspections and statistical process control (SPC).

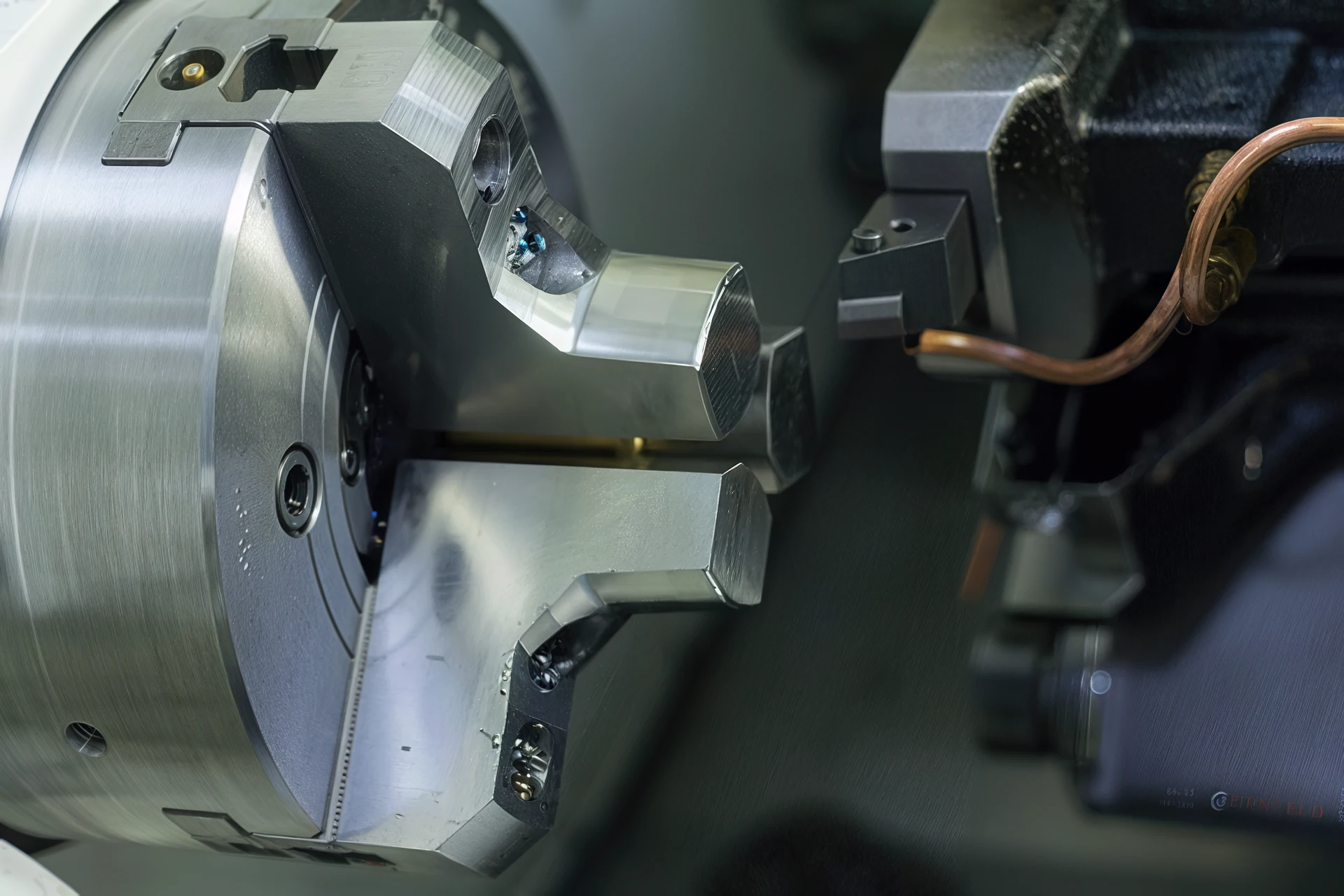

Wuxi Lead Precision Machinery leverages state-of-the-art CNC machining centers, 5-axis milling, Swiss-type turning, and advanced CMM inspection systems—all operating within an ISO 9001 and AS9100-certified environment. Our facility is equipped to handle low-volume, high-mix production runs with rapid prototyping capabilities, ensuring agility without compromising quality.

The following table outlines key technical capabilities that define our precision manufacturing standard:

| Specification | Capability |

|---|---|

| Maximum Work Envelope | 1200 x 800 x 650 mm |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Standard Tolerances | ±0.005 mm (machining), ±0.001 mm (critical features) |

| Surface Finish | As low as Ra 0.4 μm (polished), Ra 1.6 μm (standard) |

| Materials Processed | Aluminum 7075-T6, Ti-6Al-4V, Inconel 718, Stainless Steel 17-4PH, Magnesium Alloys |

| Quality Standards | AS9100D, ISO 9001:2015, NADCAP, ITAR Registered |

Our commitment to precision is reinforced by a zero-defect mindset and full digital traceability from raw material to final shipment. For OEMs and Tier-1 suppliers in aerospace and defense, partnering with an AS9100-certified machine shop like Wuxi Lead Precision Machinery ensures not only technical excellence but also regulatory compliance and supply chain integrity. In an industry where performance is measured in microns, we engineer confidence—part by part, process by process.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Aerospace Excellence

Precision is non-negotiable in aerospace manufacturing. At Wuxi Lead Precision Machinery, our AS9100 certified facility leverages advanced 5-axis CNC machining technology to deliver complex, high-integrity components meeting the most stringent aerospace and defense requirements. Our core competency lies in transforming challenging engineering designs into reality, consistently achieving geometries and surface finishes unattainable with conventional 3-axis systems. The integration of simultaneous 5-axis movement allows for single-setup machining of intricate contours, deep cavities, and undercuts, significantly reducing part handling errors, improving positional accuracy, and accelerating lead times for critical flight-critical hardware. We specialize in machining demanding aerospace alloys including titanium grades (Ti-6Al-4V), nickel-based superalloys (Inconel 718, 625), aluminum alloys (7075-T7351, 2024), and high-strength steels (17-4 PH, 4340), utilizing optimized toolpaths and high-pressure coolant strategies to ensure component integrity and extended tool life.

Rigorous quality control is embedded within our AS9100D quality management system. Every critical dimension and geometric feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon GLOBAL S series CMMs, operating within a certified Class 100,000 (ISO Class 8) cleanroom environment, provide micron-level measurement accuracy traceable to NIST standards. Full first-article inspection reports (FAIRs) per AS9102 are standard, detailing all critical-to-quality (CTQ) characteristics with comprehensive GD&T analysis. Real-time in-process inspection at strategic stages further ensures dimensional stability throughout production, preventing deviations before they occur and guaranteeing final part conformance. This systematic approach to metrology provides complete traceability and audit readiness for every component we produce.

Our commitment to precision is quantifiable through consistently achievable tolerance ranges, demonstrated below. These capabilities represent standard production performance; tighter tolerances are attainable for specific features and geometries through dedicated process optimization and engineering collaboration. Material selection, part geometry complexity, and feature size inherently influence the practical tolerance limits.

| Material Category | Standard Tolerance Range (mm) | Tight Tolerance Capability (mm) | Key Applications |

|---|---|---|---|

| Titanium Alloys (e.g., Ti-6Al-4V) | ±0.025 | ±0.005 – ±0.010 | Structural airframe, engine mounts |

| Nickel Superalloys (e.g., Inconel 718) | ±0.025 | ±0.008 – ±0.015 | Turbine blades, combustion chambers |

| High-Strength Aluminum (e.g., 7075) | ±0.020 | ±0.005 – ±0.010 | Actuators, landing gear components |

| Stainless & Tool Steels (e.g., 17-4 PH) | ±0.020 | ±0.005 – ±0.010 | Hydraulic manifolds, fasteners |

| General Engineering Alloys | ±0.015 | ±0.003 – ±0.008 | Prototypes, non-flight hardware |

These tolerances are achievable across complex 3D surfaces and internal features inherent to 5-axis machining. Surface finishes down to Ra 0.4 µm (16 µin) are routinely produced. Wuxi Lead Precision Machinery’s integrated technical capabilities—combining cutting-edge 5-axis CNC machining, AS9100D compliant processes, and rigorous CMM-based validation—provide aerospace manufacturers with a reliable, high-precision manufacturing partner capable of meeting the evolving demands of next-generation aircraft and defense systems. Contact our engineering team to discuss your specific component requirements and tolerance challenges.

Material & Finish Options

Material selection is a critical step in precision manufacturing, particularly for AS9100-certified machine shops serving aerospace, defense, and high-performance industrial sectors. At Wuxi Lead Precision Machinery, we ensure every material choice aligns with the functional, environmental, and regulatory demands of the final application. Among the most widely used metals in our custom manufacturing processes are aluminum, steel, and titanium—each offering distinct mechanical properties, weight characteristics, and corrosion resistance.

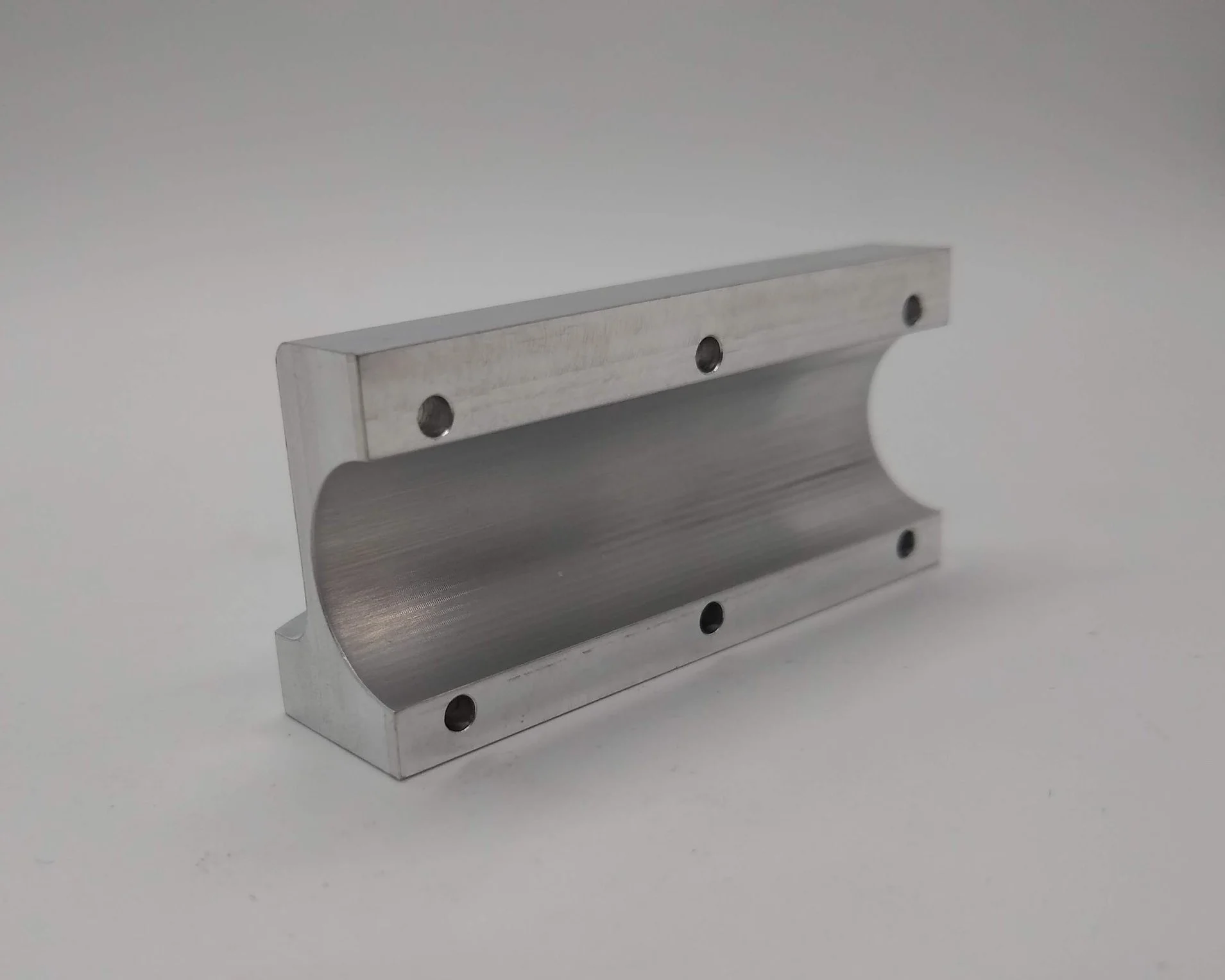

Aluminum is favored for its excellent strength-to-weight ratio, machinability, and thermal conductivity. It is ideal for aerospace components, enclosures, and heat sinks where weight reduction is paramount. The most common grades we utilize include 6061-T6 and 7075-T6, with the latter offering higher strength for structural applications. While aluminum is naturally corrosion-resistant, it benefits significantly from surface treatments such as anodizing to enhance durability and wear resistance.

Steel, particularly alloy and stainless variants, delivers superior strength, hardness, and temperature resistance. We frequently machine 4140, 4340, and 17-4 PH stainless steel for landing gear components, actuators, and high-stress fittings. These materials maintain integrity under extreme loads and elevated temperatures, making them suitable for mission-critical systems. Stainless steels also provide inherent corrosion resistance, essential for parts exposed to harsh environments.

Titanium, specifically Grade 5 (Ti-6Al-4V), is the material of choice when extreme strength, low density, and outstanding corrosion resistance are required. Its performance in high-temperature and saline environments makes it indispensable in jet engines, airframes, and marine applications. While more challenging to machine due to its low thermal conductivity and tendency to gall, our AS9100-compliant processes ensure tight tolerances and optimal surface finish.

Surface finishing plays a vital role in component longevity and performance. Anodizing, particularly Type II (sulfuric acid) and Type III (hardcoat), is the preferred finish for aluminum parts. It creates a durable, non-conductive oxide layer that improves wear resistance and allows for color coding. Our in-house anodizing capabilities ensure batch consistency and full traceability, meeting AMS 2469 and MIL-A-8625 standards.

Below is a comparative overview of key material properties we consider during selection:

| Material | Typical Grade | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 7075-T6 | 570 | 2.81 | Moderate (improved with anodizing) | Aerospace structures, housings |

| Stainless Steel | 17-4 PH | 1310 | 7.75 | High | Actuators, fasteners, valves |

| Alloy Steel | 4340 | 1250 | 7.85 | Moderate | Landing gear, shafts |

| Titanium | Ti-6Al-4V (Gr 5) | 950 | 4.43 | Excellent | Jet engines, airframes |

At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to select the optimal material and finish based on operational conditions, lifecycle requirements, and certification standards. This disciplined approach ensures every component we produce meets the highest benchmarks in reliability and performance.

Manufacturing Process & QC

Precision Execution: The AS9100 Production Framework at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, our AS9100-certified production process is engineered for absolute reliability in custom metal manufacturing. This rigorous framework transforms client specifications into flawless aerospace and defense components through three integrated phases, ensuring zero defects are not an aspiration but a guaranteed outcome. Every step adheres strictly to AS9100 Rev D requirements, embedding quality into the product lifecycle rather than inspecting it in post-production.

The Design phase begins with deep collaboration between our engineering team and the client. We conduct mandatory Design for Manufacturability (DFM) reviews, leveraging advanced CAD/CAM simulation to identify potential geometric conflicts, material stress points, or tooling limitations before metal touches machine. This digital validation ensures the design is not only feasible but optimized for our high-precision CNC equipment, eliminating theoretical errors early. Comprehensive documentation, including 3D models with explicit GD&T callouts and material traceability matrices, is generated and formally approved, forming the immutable baseline for all subsequent stages.

Prototyping transitions the validated design into physical reality under full AS9100 process control. A single prototype undergoes exhaustive first-article inspection (FAI) per AS9100 Section 8.1.1. Critical dimensions, material properties, and surface finishes are measured against the approved baseline using calibrated CMMs, optical comparators, and metallurgical testing. This phase is not merely a sample build; it is a full process validation where fixture setups, cutting parameters, and inspection protocols are proven. Any deviation triggers an immediate corrective action loop, documented within our non-conformance system, ensuring the production process is perfected before scale-up. The table below details key AS9100-controlled parameters verified during prototyping and production.

| Parameter | AS9100 Control Requirement | Verification Method |

|---|---|---|

| Material Traceability | Full lot/batch certification with MTRs | Cross-referenced against purchase order and heat treat records |

| Dimensional Accuracy | Conformance to specified GD&T tolerances | CMM inspection with 100% feature reporting |

| Surface Finish | Ra ≤ 0.8μm (aerospace standard) | Profilometer measurement at 5+ locations |

| Process Documentation | Real-time digital work instructions | Operator sign-off with timestamped system logs |

Mass Production executes the perfected process with relentless vigilance. Statistical Process Control (SPC) monitors critical dimensions in real-time via in-machine probes and automated data collection. Our integrated MES system tracks every component’s journey—from raw material bin location to final inspection—ensuring full traceability. Automated tool-wear compensation and in-process gaging prevent drift, while layered process audits by QA engineers verify adherence to work instructions. Crucially, the zero-defect mandate is sustained through closed-loop corrective actions; any anomaly detected at any stage triggers immediate line stoppage, root cause analysis, and systemic correction before production resumes. Final inspection includes 100% critical feature checks and batch-level material revalidation.

This seamless Design-Prototyping-Production continuum, governed by AS9100 discipline, transforms complexity into certainty. At Wuxi Lead, zero defects is achieved through proactive engineering rigor, not reactive sorting—delivering mission-critical components where failure is never an option.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision Engineering Excellence in AS9100-Certified Manufacturing

When your aerospace, defense, or high-integrity industrial project demands uncompromising quality, partnering with a trusted AS9100-certified machine shop is not just an advantage—it’s a necessity. At Wuxi Lead Precision Machinery, we specialize in delivering mission-critical metal components that meet the rigorous standards of global aerospace supply chains. Our certification to AS9100D ensures that every process—from design review to final inspection—is governed by a disciplined quality management system focused on defect prevention, continuous improvement, and total customer satisfaction.

Located in Wuxi, China, our facility combines advanced CNC machining capabilities with deep engineering expertise to serve OEMs and Tier-1 suppliers worldwide. We understand that precision is not measured in tolerances alone but in reliability, repeatability, and responsiveness. That’s why our team of senior CNC engineers and manufacturing specialists work closely with clients to optimize part designs, select appropriate materials, and streamline production cycles—ensuring on-time delivery without sacrificing quality.

Our commitment to excellence is reflected in our state-of-the-art equipment and inspection protocols. With multi-axis machining centers, automated tool management systems, and coordinate measuring machines (CMM) integrated into our workflow, we maintain tight control over dimensional accuracy down to ±0.002 mm. Whether you require complex 5-axis milled components, high-precision turned parts, or fully assembled subsystems, our processes are designed to meet the exacting demands of aerospace-grade specifications.

Below are key technical and operational capabilities that define our service offering:

| Specification | Detail |

|---|---|

| AS9100 Certification | AS9100D Compliant (with full documentation traceability) |

| Machining Capabilities | 3-axis to 5-axis CNC milling, CNC turning, multi-tasking machines |

| Materials Processed | Aluminum alloys (2024, 6061, 7075), titanium (Grade 2, 5), stainless steel (17-4 PH, 316L), Inconel 718, tool steels |

| Tolerance Control | ±0.002 mm (standard), tighter upon request |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), Ø400 x 1000 mm (turning) |

| Inspection Equipment | Zeiss CMM, optical comparators, surface roughness testers, hardness testers |

| Lead Times | Prototype: 7–14 days; Production: 15–25 days (varies by complexity) |

| Secondary Services | Heat treatment coordination, surface finishing (anodizing, passivation), custom packaging, first article inspection (FAI) reporting |

We serve clients across North America, Europe, and Asia, providing end-to-end manufacturing support with full documentation in English, including PPAP, FAI, and material certifications. Our export experience ensures seamless customs clearance and logistics coordination.

Your next high-precision project deserves a partner who understands the stakes. Contact us today at [email protected] to discuss your requirements with our engineering team. Let Wuxi Lead Precision Machinery become your trusted extension in delivering AS9100-compliant components with precision, consistency, and confidence.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.