Technical Contents

Engineering Guide: Anodize Aluminum Kit

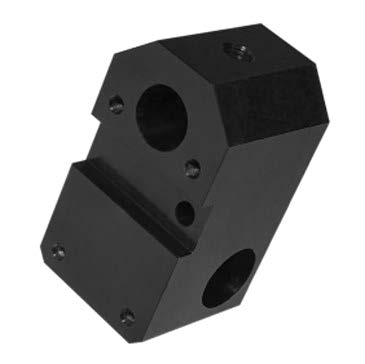

Engineering Insight: Precision in Anodized Aluminum Kits

In high-performance industries such as aerospace, defense, and advanced robotics, the integrity and consistency of materials are non-negotiable. Anodized aluminum kits represent a critical intersection of material science and precision engineering, where surface treatment enhances durability without compromising dimensional accuracy. At Wuxi Lead Precision Machinery, we understand that the success of these components hinges not only on the anodizing process itself but on the precision of the underlying machined parts.

Anodizing is an electrochemical process that converts the surface of aluminum into a durable, corrosion-resistant, and often decorative oxide layer. While the process adds functional value, it introduces variables that demand tight control—especially in custom applications. Dimensional stability, surface finish uniformity, and adhesion of secondary coatings all depend on the initial precision of the aluminum substrate. Even minor deviations in geometry or surface texture can result in inconsistent coating thickness, reduced fatigue strength, or rejection during final inspection.

This is where Wuxi Lead Precision Machinery distinguishes itself. With over 15 years of experience in custom metal manufacturing, we have engineered anodized aluminum components for mission-critical applications, including systems used in Olympic-grade sporting equipment and military-grade defense technology. These sectors demand zero tolerance for failure, and our track record reflects our commitment to precision at every stage—from CNC machining to post-treatment quality assurance.

Our process begins with high-grade aluminum alloys, selected based on the performance requirements of the end application. Using state-of-the-art 5-axis CNC machines and in-process metrology, we maintain tolerances as tight as ±0.005 mm. This precision ensures that parts arrive at the anodizing stage with exacting dimensional control, minimizing the risk of warping or coating irregularities. We collaborate closely with certified anodizing partners, specifying masking requirements, current density parameters, and sealing methods to align with MIL-A-8625 and other relevant standards.

Beyond compliance, we focus on repeatability. Every anodized aluminum kit we produce is backed by full inspection documentation, including first-article reports and batch traceability. This level of control is essential for clients integrating these components into larger assemblies, where interchangeability and long-term reliability are paramount.

The following table outlines typical specifications we achieve for anodized aluminum kits:

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Material Alloys | 6061, 7075, 2024, 5052 | Custom aerospace-grade alloys |

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm |

| Surface Finish (pre-anodize) | 3.2 μm Ra | 0.8 μm Ra or better |

| Anodizing Type | Type II (Sulfuric Acid) | Type III (Hardcoat), MIL-SPEC |

| Coating Thickness | 10–25 μm | 25–50 μm (hard anodizing) |

| Color Options | Clear, Black, Gold, Bronze | Custom dyed finishes |

| Quality Standards | ISO 9001, RoHS | MIL-STD, AS9100 (on request) |

Precision in anodized aluminum kits is not an optional upgrade—it is a foundational requirement. At Wuxi Lead Precision Machinery, we combine advanced manufacturing capabilities with deep industry experience to deliver components that perform under the most demanding conditions.

Precision Specs & Tolerances

Technical Capabilities for Precision Anodized Aluminum Components

Wuxi Lead Precision Machinery delivers the foundational precision required for high-performance anodized aluminum kits. Our core strength lies in producing geometrically complex, dimensionally stable aluminum substrates where surface integrity and exact form are non-negotiable prerequisites for successful anodizing. Inferior machining directly translates to visible defects in the final anodized finish, including uneven coating thickness, color variation, and compromised corrosion resistance. We eliminate this risk at the source through advanced CNC manufacturing and rigorous quality control, ensuring your anodized components meet the most demanding functional and aesthetic specifications.

Our dedicated fleet of 5-axis CNC machining centers forms the cornerstone of this capability. These systems enable the complete machining of intricate kit components in a single setup, critical for maintaining tight positional tolerances across multiple features and complex contours. Simultaneous multi-surface machining eliminates cumulative errors inherent in multi-setup processes, significantly reducing part handling and secondary operations. This capability is essential for producing the complex housings, brackets, and structural elements common in high-end anodized aluminum kits for aerospace, medical devices, and precision instrumentation. Advanced toolpath strategies and high-stability spindles ensure superior surface finishes directly off the machine, minimizing the need for labor-intensive pre-anodize polishing and providing an optimal base layer for uniform oxide growth.

Quality assurance is integrated at every stage, not merely a final checkpoint. All critical dimensions and geometric features on components destined for anodizing undergo comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM). Our CMM inspection protocols are specifically calibrated to validate the tight tolerances required for successful anodizing, focusing on features where dimensional stability directly impacts coating performance and assembly fit. This includes precise measurement of hole positions, critical wall thicknesses, flatness of sealing surfaces, and the consistency of machined edges – all factors that influence anodize adhesion, coating thickness uniformity, and final part functionality. We provide full inspection reports traceable to national standards, offering complete transparency and confidence in the dimensional integrity of every component before it enters the surface treatment phase.

The following table details our standard machining tolerance capabilities for aluminum components, which form the essential substrate for high-quality anodized kits. These tolerances represent our typical production capability under controlled conditions for features critical to anodizing success and final assembly.

| Feature Type | Tolerance Range | Measurement Method | Applicable Standard |

|---|---|---|---|

| Critical Dimensions | ±0.005 mm | CMM | ISO 2768-fK |

| General Dimensions | ±0.02 mm | CMM / Micrometer | ISO 2768-mK |

| Hole Position (Ø) | ±0.01 mm | CMM | ISO 2768-fK |

| Flatness (per 100mm) | 0.01 mm | CMM / Surface Plate | ISO 2768-fK |

| Surface Roughness (Ra) | 0.8 µm | Profilometer | ISO 1302 |

This level of precision machining, validated by systematic CMM inspection, ensures your aluminum components arrive at the anodizing stage with the dimensional accuracy and surface quality necessary to achieve flawless, high-performance results. We provide the reliable, high-integrity substrate that makes exceptional anodized finishes achievable.

Material & Finish Options

Material Selection for High-Performance Anodized Aluminum Components

In precision manufacturing, selecting the right base material and surface treatment is critical to achieving optimal performance, durability, and aesthetic quality. For applications requiring lightweight strength, corrosion resistance, and excellent surface finish, anodized aluminum stands out as a premier choice. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing with a focus on engineered aluminum solutions tailored to aerospace, automotive, medical, and industrial sectors.

Aluminum, particularly grades 6061-T6 and 7075-T6, offers an exceptional strength-to-weight ratio, making it ideal for components where weight reduction is essential without compromising structural integrity. These alloys are highly machinable and respond exceptionally well to anodizing—a controlled electrochemical process that thickens the natural oxide layer on the surface. Anodizing enhances wear resistance, improves corrosion protection, and allows for color integration through dyeing, all while maintaining the material’s dimensional stability.

When comparing aluminum to steel and titanium, each material serves distinct purposes. Steel, such as 304 or 4140, provides superior hardness and load-bearing capacity but at the cost of increased weight and reduced corrosion resistance without plating. It is less suitable for anodizing, limiting finish options. Titanium, while offering excellent strength and corrosion resistance, is significantly more expensive and challenging to machine. Its use is typically reserved for extreme environments such as high-temperature aerospace or biomedical implants.

Anodizing is uniquely compatible with aluminum, providing functional and aesthetic advantages unmatched by other surface treatments. Type II (sulfuric acid) anodizing is commonly used for decorative and moderate-duty applications, offering a porous layer that accepts dyes. Type III, or hardcoat anodizing, produces a thicker, denser oxide layer suitable for high-wear environments, delivering surface hardness comparable to tool steel.

Below is a comparative overview of key materials and their compatibility with anodizing:

| Material | Typical Grades | Density (g/cm³) | Tensile Strength (MPa) | Anodizing Compatible | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310–570 | Yes | High (with anodizing) | Enclosures, heat sinks, UAVs |

| Steel | 304, 4140 | 7.8 | 500–1000 | No | Moderate (requires plating) | Structural, shafts, tooling |

| Titanium | Grade 5 (Ti-6Al-4V) | 4.4 | 900–1000 | Limited (not standard) | Excellent | Aerospace, medical implants |

For most high-end applications where weight, precision, and surface durability are critical, anodized aluminum provides the best balance. At Wuxi Lead, we integrate material science with advanced CNC machining and surface engineering to deliver custom kits that meet rigorous industry standards. Our expertise ensures that every anodized aluminum component is optimized for performance, longevity, and visual consistency.

Manufacturing Process & QC

Precision Anodized Aluminum Kit Production Process

At Wuxi Lead Precision Machinery, our anodized aluminum kit production integrates aerospace-grade discipline across three rigorously controlled phases to ensure zero defects. This methodology eliminates downstream failures while optimizing cost efficiency for high-volume industrial applications.

The Design phase begins with collaborative engineering using Siemens NX CAD/CAM software. We conduct comprehensive Design for Manufacturability (DFM) analysis to resolve geometric conflicts, thermal stress points, and anodizing uniformity risks before tooling. Critical features like thread tolerances, edge radii, and masking zones are validated against MIL-A-8625F standards. This upfront virtual prototyping reduces physical iterations by 70% and ensures dimensional tolerances are held to ±0.025mm at the CNC programming stage. Material selection prioritizes 6061-T6 and 7075-T6 aluminum alloys for optimal anodizing response and structural integrity in corrosive environments.

Prototyping transitions digital models into physical validation through our 5-axis CNC milling center. Each prototype undergoes coordinate measuring machine (CMM) inspection against the original CAD file, with deviations tracked via SPC charts. Anodizing trials follow on dedicated racks to verify color consistency, coating thickness, and adhesion per ASTM B117 salt-spray testing. Clients receive full metrology reports and functional test data within 72 hours, enabling design lock with zero ambiguity before mass production.

Mass production leverages our integrated facility where CNC machining, anodizing, and quality control operate under one roof. Aluminum components move through automated CNC cells with real-time tool wear monitoring, followed by a 12-stage anodizing line featuring temperature-stabilized electrolytes and digital color calibration. Every part undergoes 100% post-anodization inspection: coating thickness is verified via eddy current gauges, surface roughness measured to Ra ≤ 0.8μm, and critical dimensions rechecked on CMMs. Statistical Process Control (SPC) data from all stations feeds into our central quality dashboard, triggering automatic line halts if any parameter breaches control limits. This closed-loop system achieves <50 PPM defect rates consistently.

Key anodizing specifications maintained throughout production:

| Parameter | Specification Range | Standard Compliance |

|---|---|---|

| Coating Thickness | 8μm to 25μm | MIL-A-8625F Type II |

| Color Consistency | ΔE ≤ 0.5 | ASTM D2244 |

| Surface Hardness | 250-350 HV | ASTM B244 |

| Salt Spray Resistance | 1000+ hours | ASTM B117 |

| Dimensional Tolerance | ±0.025mm | ISO 2768-mK |

Wuxi Lead’s end-to-end ownership of the production chain—from alloy sourcing to final packaging—ensures traceability for every component. Our zero-defect commitment is not a target but a baseline requirement, delivering anodized aluminum kits that perform reliably in aerospace, medical, and defense applications where failure is not an option. Partner with us to convert complex designs into flawless production reality.

Why Choose Wuxi Lead Precision

When it comes to high-performance, precision-engineered components, an anodized aluminum kit is more than just a part—it’s a critical element in the reliability, durability, and functionality of advanced industrial systems. At Wuxi Lead Precision Machinery, we understand that your manufacturing demands require more than standard solutions. We deliver fully customized anodized aluminum kits engineered to meet the exact mechanical, thermal, and aesthetic requirements of your application.

Partnering with Lead Precision means aligning with a team that combines decades of CNC machining expertise with a deep commitment to quality and innovation. Our in-house capabilities span precision milling, turning, surface treatment, and full QA inspection—ensuring every anodized aluminum component we produce meets international standards for dimensional accuracy and surface integrity. From prototype to high-volume production, we maintain tight control over every phase of manufacturing, delivering parts that perform consistently in demanding environments.

Our anodizing process is optimized for both protection and performance. We utilize Type II (sulfuric acid) and Type III (hardcoat) anodizing techniques, tailored to your project’s needs. Whether you require enhanced corrosion resistance, improved wear performance, or specific color matching for branding and identification, our surface treatment specialists ensure consistent, high-quality results across every batch.

We serve industries where failure is not an option—automotive, aerospace, medical devices, robotics, and industrial automation. Our clients rely on us not just for precision, but for partnership. We work closely with your engineering team to review designs, suggest manufacturability improvements, and accelerate time-to-market without compromising quality.

Below are key specifications for our anodized aluminum kit production:

| Specification | Detail |

|---|---|

| Material Compatibility | 6061, 7075, 5052, 2024, and custom aluminum alloys |

| Tolerance | Up to ±0.005 mm |

| Anodizing Types | Type II (Standard) and Type III (Hard Anodizing) |

| Coating Thickness | 12–25 µm (Type II), 25–100 µm (Type III) |

| Color Options | Clear, Black, Red, Blue, Gold, and custom colors |

| Surface Finish | Matte, Satin, or Polished (pre-anodize) |

| Quality Standards | ISO 9001:2015, RoHS compliant, full inspection reports |

| Lead Time | 10–25 days (varies by complexity and volume) |

| Finishing Add-ons | Laser engraving, masking, sealing, and chromate conversion |

Every project begins with a technical consultation. We believe that clear communication and engineering collaboration are the foundations of successful manufacturing partnerships. When you contact us, you’re not just sending an RFQ—you’re starting a dialogue with engineers who are invested in your success.

For custom anodized aluminum kits that meet the highest standards in precision and performance, reach out to our team today. Email us at [email protected] to discuss your project, request a quote, or receive design for manufacturability feedback. Let Wuxi Lead Precision Machinery be your trusted partner in advanced metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.