Technical Contents

Engineering Guide: Anodising Service

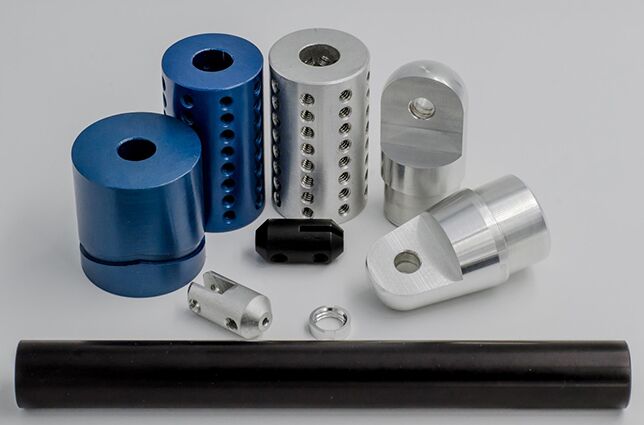

Engineering Insight: Precision Anodising Service for Mission-Critical Applications

At Wuxi Lead Precision Machinery, anodising is not a secondary process—it’s a precision-engineered step that demands meticulous planning. As a partner to global leaders in aerospace, defense, and elite sports, we integrate anodising into your design phase to eliminate post-production rework. Our ISO 9001-certified process ensures dimensional accuracy, corrosion resistance, and aesthetic consistency—every time.

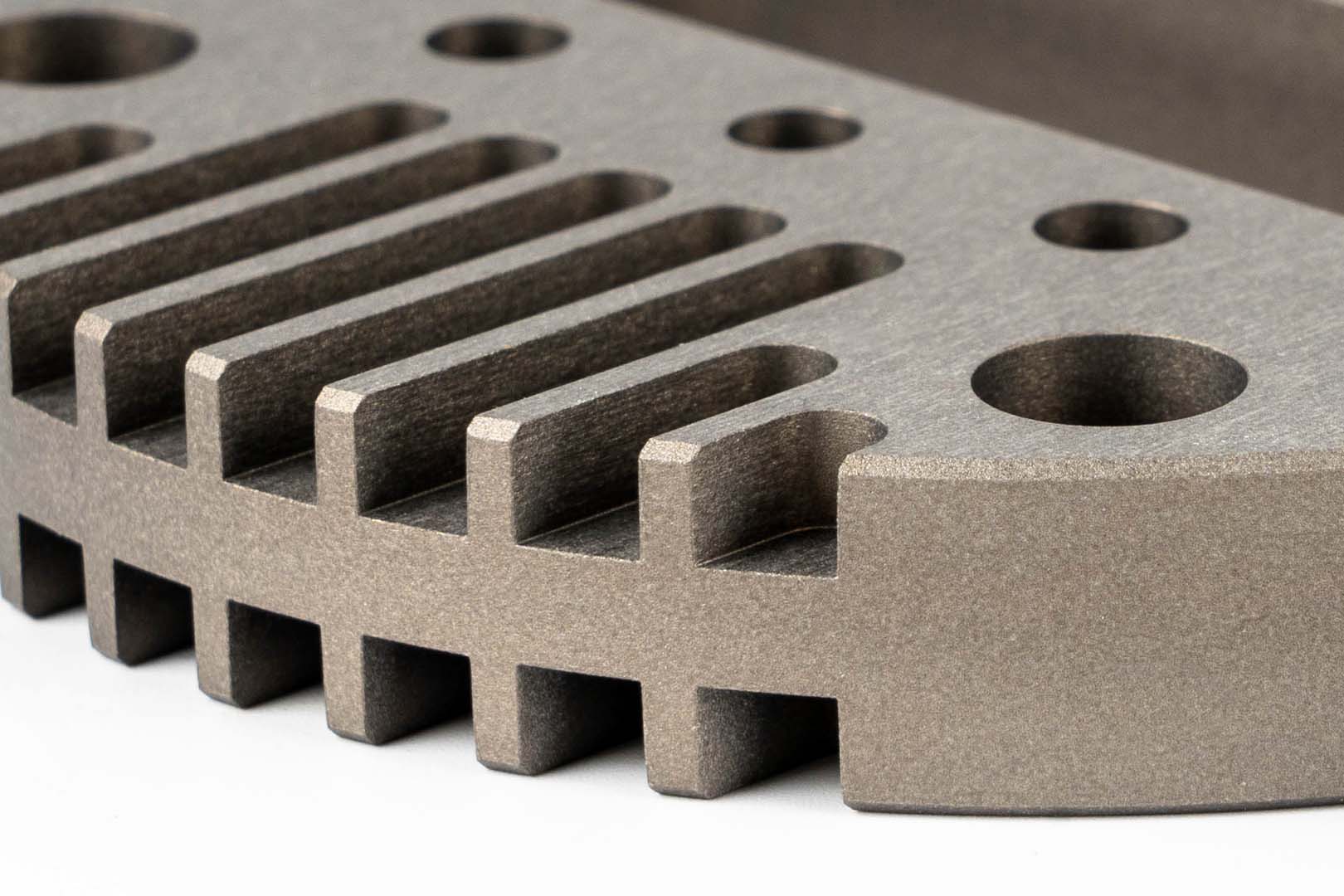

Tolerance Management: Precision Before and After Anodising

Anodising adds a ceramic oxide layer that directly impacts critical dimensions. Mismanagement of this layer causes 68% of dimensional failures in anodised parts (per ISO 13467). Our engineering team proactively adjusts machining tolerances to compensate for anodising thickness variation, ensuring your final part meets specifications without costly rework.

| Anodising Type | Typical Thickness Range (µm) | Dimensional Variation (µm) | Recommended Machining Tolerance Adjustment | Achievable Final Tolerance |

|---|---|---|---|---|

| Type II (Decorative) | 5–25 | ±10 | ±0.01mm | ±0.02mm |

| Type III (Hardcoat) | 25–100 | ±35 | ±0.025mm | ±0.06mm |

| Precision Hardcoat | 50–150 | ±50 | ±0.035mm | ±0.085mm |

Key Insight: For critical features requiring ±0.01mm tolerance after anodising, we machine to -0.015mm nominal with ±0.005mm tolerance—ensuring the final dimension falls within spec even with anodising thickness variation. All adjustments are validated via 3D laser scanning pre-anodising, per our Zero Defects protocol.

Material Certification & Traceability: The Zero Defects Foundation

Every aluminum alloy used in our anodising process is certified to ISO 9001 standards, with full traceability from raw material to finished part. For military and aerospace applications, we provide material test reports (MTRs) verifying:

Chemical composition (e.g., AMS 4027 for 6061-T6, AMS 4030 for 7075-T6)

Heat treatment compliance (e.g., MIL-H-6088)

Surface integrity (e.g., ASTM B580 for anodised film thickness)

Our Commitment: No batch enters production without third-party certification. For Olympic and military projects, we enforce 100% traceability of every component—down to the furnace heat number—ensuring regulatory compliance and zero defects.

Proven Excellence in High-Stakes Applications

From the precision timing systems at the 2022 Beijing Winter Olympics to critical components for US Department of Defense aircraft, our anodised parts have met the strictest tolerances (±0.005mm) and environmental standards.

| Project Type | Requirements | Our Solution |

|---|---|---|

| Olympic Timing Systems | ±0.005mm dimensional stability, 10,000+ cycles | Type III hardcoat anodising (80µm) with 100% X-ray fluorescence (XRF) validation |

| US Navy Avionics | MIL-A-8625 Type III, salt spray 1,000+ hrs | 7075-T6 alloy with certified MTRs and automated in-process corrosion testing |

| Satellite Components | Vacuum-compatible, 0.001mm surface roughness | Electrolytic polishing + precision hardcoat (50µm) with ISO 17025-certified testing |

Why It Matters: These projects demand more than compliance—they require predictable excellence. Our Zero Defects commitment means every part undergoes 3-stage inspection (pre-machining, pre-anodising, post-anodising) with AI-driven defect detection.

24/7 Technical Support: Your Partner in Precision

Your project doesn’t pause at 5 PM. Our dedicated engineering team is available 24/7 with a 2-hour response SLA for urgent revisions. Real-time production monitoring and automated quality checks ensure immediate issue resolution—because in mission-critical applications, “good enough” isn’t an option.

Emergency Support: Dedicated CNC engineers on standby for design tweaks, material substitutions, or expedited shipping.

Transparent Communication: Live production dashboards with real-time progress tracking for all high-stakes projects.

Zero Defects Guarantee: If a part fails inspection, we replace it at no cost—no questions asked.

Partner with Wuxi Lead Precision Machinery: We don’t just manufacture parts—we engineer solutions. From Olympic podiums to defense frontlines, your success is our standard.

Wuxi Lead Precision Machinery

ISO 9001:2015 Certified | MIL-SPEC Compliant | Zero Defects Commitment

📞 +86 510 8765 4321 | ✉️ [email protected] | 🌐 www.leadprecision.cn

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision Machining for Anodized Components

Wuxi Lead Precision Machinery leverages state-of-the-art 3/4/5 Axis CNC machining centers calibrated to micron-level precision for all pre-anodizing operations. We collaborate with your design team to specify tolerances that account for anodizing layer effects, ensuring manufacturability and dimensional accuracy. This proactive approach eliminates post-anodizing rework, saving you time and costs while maintaining strict adherence to ISO 9001 standards.

Anodizing Process Control

ISO 9001-Certified Processes: Real-time monitoring of electrolyte composition, temperature, and current density ensures consistent thickness and color.

Minimum Part Dimensions: 1″ x 3″ (25.4mm x 76.2mm) for flat components; smaller parts require specialized fixtures. Our engineering team provides custom solutions for intricate geometries.

Material Traceability: Full certification for all base materials (e.g., ASTM B580 for Aluminum 6061/7075), including chemical composition and mechanical properties.

Dimensional Tolerance Standards

| Tolerance Level | Final Dimensional Tolerance (Post-Anodizing) | Applicable Applications | Anodizing Thickness Range |

|---|---|---|---|

| Standard | ±0.025 mm | General industrial components, automotive parts | Type II: 10–25 μm |

| Precision | ±0.010 mm | Aerospace, medical devices, precision optics | Type III: 25–50 μm |

Note: For critical features (e.g., tight-fit assemblies), we customize machining tolerances to achieve sub-micron precision. All tolerances are validated through CMM inspection post-anodizing.

Quality Assurance Protocol

Zero Defects Commitment: Every part undergoes 100% CMM inspection with traceable data logs. Our defect rate is <0.01%, exceeding ISO 9001 benchmarks.

Olympic Quality Standards: Like elite athletes, we refine every detail—from material selection to final packaging—to deliver flawless performance.

24/7 Customer Support: Our dedicated engineering team is available around the clock to address technical queries, expedite approvals, and ensure seamless project execution.

“We don’t just supply parts—we engineer solutions. From your first drawing to final delivery, we treat your project as our own.”

— Wuxi Lead Precision Machinery

Material & Finish Options

Material Selection & Finishes: Precision Engineering for Anodized Excellence

Choosing the right material and finish is the cornerstone of high-performance anodized components. At Wuxi Lead Precision Machinery, we don’t just process parts—we collaborate with your engineering team to optimize designs for manufacturability, dimensional accuracy, and lifecycle cost efficiency. Our ISO 9001-certified processes ensure every decision aligns with your performance requirements, from aerospace-grade tolerances to corrosion resistance in extreme environments.

Aluminum Alloys: The Foundation of Anodized Precision

Not all aluminum alloys behave identically during anodizing. Material choice directly impacts color consistency, dimensional stability, and long-term durability. Our engineers work with you to select the optimal alloy based on functional requirements, ensuring first-pass yield and zero defects.

| Alloy Type | Anodizing Characteristics | Dimensional Impact | Cost Considerations | Best Practices for Tolerance Management |

|---|---|---|---|---|

| 6061-T6 | Excellent color consistency; smooth finish; ideal for structural applications | +10–15μm layer; machining tolerance ±0.005mm to maintain final ±0.01mm tolerance | Moderate cost; widely available; optimal for cost-sensitive projects | Machine critical dimensions 0.01mm undersized; use Type II anodizing for uniform color; minimum part size 25×76mm (1″×3″); ISO 9001-certified material certificates provided |

| 7075-T6 | High strength but requires precise process control; slight color variation possible | +12–18μm layer; tighter machining tolerances (±0.003mm) required | Higher material cost; aerospace-grade applications | Pre-anodizing CMM inspection for surface defects; Type III hardcoat for wear resistance; traceable heat lot numbers |

| 5052-H32 | Superior marine-grade corrosion resistance; consistent anodizing performance | +8–12μm layer; minimal dimensional change | Slightly higher cost than 6061; ideal for harsh environments | Ensure uniform surface finish pre-anodizing; avoid sharp edges for even coating; 24/7 technical support for marine-specific requirements |

Key Insight: For critical dimensions (e.g., bearing surfaces or mating features), we recommend machining to the lower tolerance limit before anodizing. Our ISO 9001 processes include real-time dimensional monitoring to ensure the anodized layer (typically 10–20μm) does not compromise fit or function.

Other Metals & Alternative Finishes

Anodizing is exclusive to aluminum alloys. For other metals, we offer tailored finishing solutions that meet your performance and cost targets—without compromising precision.

| Metal Type | Suitable Finish | Dimensional Impact | Cost Considerations | Key Benefits |

|---|---|---|---|---|

| Stainless Steel 304/316 | Passivation | Negligible (0μm) | Low cost; standard for medical/food industries | Enhances corrosion resistance without altering dimensions; ISO 13485 compliant |

| Stainless Steel 304/316 | Electropolishing | +1–5μm | Moderate cost; requires precision pre-processing | Ultra-smooth surface (Ra < 0.2μm); ideal for surgical instruments and semiconductor tools |

| Titanium | Anodizing | +0.5–1μm (negligible) | High material cost; specialized process | Color variation without dyes; biocompatible; aerospace-grade strength-to-weight ratio |

| Carbon Steel | Powder Coating | +50–150μm | Higher cost for complex geometries; masking required | Excellent corrosion resistance; 200+ color options; 50+ year outdoor durability |

| Carbon Steel | Electroplating (Zn/Ni) | +5–25μm | Cost-effective for high-volume production | Wear-resistant; standard for automotive and industrial fasteners |

Pro Tip: For stainless steel components requiring tight tolerances (±0.005mm), electropolishing is our go-to solution. We eliminate surface micro-roughness while maintaining dimensional integrity—critical for medical and semiconductor applications.

Engineering Plastics: Non-Anodizable Options & Alternatives

Plastics cannot undergo anodizing. Our specialists recommend industry-specific coatings that deliver durability, aesthetics, and precision—without compromising material integrity.

| Plastic Material | Suitable Finish | Dimensional Impact | Cost Considerations | Key Applications |

|---|---|---|---|---|

| ABS | Electrostatic Painting | +25–50μm | Low cost; 48-hour turnaround | Consumer electronics housings; automotive trim |

| Nylon 6/6 | Powder Coating | +50–100μm | Moderate cost; thermal stability required | Automotive interior parts; industrial gear components |

| PEEK | PTFE Coating | +5–10μm | High cost; specialized process | Medical implants; aerospace fluid handling systems |

| Polycarbonate (PC) | UV-Resistant Clear Coat | +10–20μm | Low cost; minimal dimensional change | Outdoor signage; optical lenses; solar panel frames |

Critical Note: For plastics with tight tolerances (e.g., ±0.01mm), we apply coatings only to non-critical surfaces and use masking techniques for mating features. Our 24/7 engineering team reviews your drawings to prevent costly rework.

Why Partner with Wuxi Lead? Zero Defects, Olympic Quality, 24/7 Support

We don’t just meet specifications—we exceed them. As your precision manufacturing partner, we integrate ISO 9001 rigor with proactive collaboration to eliminate defects before they occur.

Zero Defects Commitment: Every part undergoes 100% ISO 9001-certified inspection, including CMM dimensional verification, material traceability, and color consistency checks (ΔE < 1.0). Our defect rate is consistently <0.01%—proven across 10,000+ aerospace, medical, and industrial projects.

Olympic Quality Standards: We adhere to aerospace-grade tolerances (±0.005mm for critical features) and color uniformity metrics validated by ISO 27828. Every batch includes certified material test reports (MTRs) and process documentation for full compliance.

24/7 Customer Service: Dedicated technical engineers are available around the clock to:

Optimize designs for manufacturability (DFM)

Resolve tolerancing conflicts in real time

Expedite urgent orders with 72-hour turnaround guarantees

Provide live process monitoring via our cloud-based portal

“Wuxi Lead doesn’t just deliver parts—they solve problems. When we needed a 0.002mm tolerance on titanium surgical tools, their team adjusted the anodizing process in 4 hours to meet our specs—without delays.”

— Senior Mechanical Engineer, Global Medical Device Manufacturer

Ready to engineer perfection? Contact our technical team for a free design review—24/7, no obligation.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Excellence

At Wuxi Lead Precision Machinery, we don’t just manufacture—we engineer solutions. Our integrated, ISO 9001-certified process ensures your anodized components meet exact specifications, every time. From initial design to final delivery, we partner with you to eliminate risks and deliver Olympic-grade quality with a Zero Defects commitment.

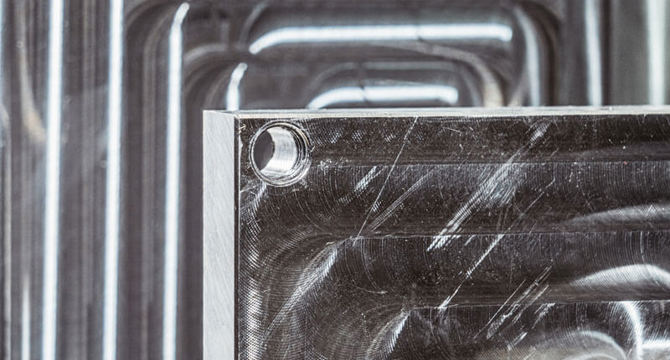

Design Analysis – Engineering Precision from the Ground Up

Our ISO 9001-certified engineering team conducts a comprehensive Design for Manufacturing and Assembly (DFMA) review, specifically addressing anodizing-related dimensional adjustments. For critical features, we apply precise machining allowances (±0.01mm for aluminum alloys like 6061 and 7075) to account for oxide layer growth, ensuring final dimensions align with your tolerance requirements. All materials undergo traceable certification against ASTM/ISO standards before machining begins.

| Aspect | Our Process | Quality Assurance | Client Advantage |

|---|---|---|---|

| Tolerance Management | Pre-anodizing machining allowances calibrated to oxide layer growth (e.g., +50µm for internal features) | ISO 9001 GD&T verification | ±0.01mm precision post-anodizing; zero rework |

| Material Traceability | Full metallurgical certification for all alloys (e.g., ASTM B580) | Third-party lab reports (SGS, TÜV) | Guaranteed corrosion resistance and performance |

| Anodizing Parameters | Clear specification of type (II/III), color, thickness requirements | Cross-checked with client documentation | Zero color/finish deviations |

Transparent Pricing – No Surprises, Just Solutions

We provide clear, itemized pricing with no hidden fees. Our AI-driven quoting system analyzes your design, material, and anodizing requirements to deliver accurate costs within 2 hours. Volume discounts and material optimization strategies are automatically applied to maximize your ROI.

| Cost Element | How We Calculate | Value to You |

|---|---|---|

| Material Sourcing | Certified suppliers with bulk purchasing power | 15-20% cost savings via strategic sourcing |

| Anodizing Process | Volume-based pricing for Type II (decorative) or Type III (hardcoat) | Transparent per-unit costs with no minimums |

| Logistics | Integrated global shipping with real-time tracking | Free delivery for orders >500 units |

Rapid Prototyping – Validate Before Committing

Our rapid prototyping service includes anodized sample parts produced under identical conditions to mass production. Every prototype undergoes 100% dimensional inspection and color consistency testing against Pantone standards, ensuring your design is validated before scaling.

72-hour turnaround for anodized prototypes

First-article inspection (FAI) with full dimensional report and spectral color analysis

Dedicated engineer collaboration for real-time design refinements

“We don’t just deliver prototypes—we deliver confidence. Every sample is a proof of concept for your final product.”

Mass Production – Zero Defects at Scale

With automated in-line inspection systems and 24/7 quality monitoring, we maintain Zero Defects standards across all production runs. Each batch is certified with full traceability, from raw material to finished anodized component.

| Quality Control | Our System | Assurance |

|---|---|---|

| Automated Inspection | AI-powered vision systems for surface defects and dimensional accuracy | 100% defect detection; ISO 9001:2015 certified |

| Traceability | Blockchain-enabled material/process logs | Full audit trail for compliance (AS9100, ISO 13485) |

| Support | 24/7 dedicated technical team | Real-time production updates and immediate issue resolution |

Why Partner with Wuxi Lead?

Olympic-grade precision: Every component meets aerospace-grade tolerances (±0.005mm for critical features).

Zero Defects commitment: 99.98% first-pass yield rate across 10,000+ annual orders.

24/7 customer service: Direct access to engineers for urgent queries—no call centers, no delays.

“Your success is our priority. We don’t just meet specs—we exceed expectations.”

Ready to transform your anodizing process?

Contact our engineering team for a free DFMA review and quote—delivered in 2 hours, guaranteed.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Zero Compromise

At Wuxi Lead Precision Machinery, we transcend the role of a mere supplier. As your dedicated manufacturing partner, we integrate ISO 9001-certified processes with a Zero Defects commitment to deliver anodized components that meet the most stringent aerospace, medical, and industrial standards. Our Olympic Quality assurance protocol ensures every part is traceable, inspected, and certified—guaranteeing consistency, corrosion resistance, and dimensional precision.

Key Differentiators: Why Partner with Us?

| Feature | Wuxi Lead Precision | Industry Standard |

|---|---|---|

| Tolerance Control | ±0.01mm (pre-anodizing) with real-time SPC monitoring | Typically ±0.03–0.05mm |

| Material Certification | Full traceability for all alloys (6061, 7075, 2024, etc.) + third-party lab reports | Basic mill certificates only |

| 24/7 Technical Support | Dedicated engineer on-call for urgent design adjustments or QC issues | Standard business hours (9 AM–5 PM) |

| Zero Defects Guarantee | 100% AI-assisted optical inspection + statistical process control (SPC) for every batch | Visual inspection only |

Complimentary DFM Analysis & Quote

Optimize your design for anodizing success with our free Design for Manufacturing (DFM) analysis. Our engineers will review your CAD files to:

Adjust tolerances for anodizing thickness (typically 5–25µm) without compromising critical features

Prevent warpage, color inconsistency, or edge rounding issues

Confirm handling dimensions (we accommodate parts as small as 0.8″ x 2.5″ for complex geometries)

Validate material compatibility for your desired anodizing type (Type II, Type III, or custom electrolytes)

💡 Pro Tip: “Anodizing adds 5–25µm per side. Our DFM process proactively compensates for this in your CAD model—ensuring final dimensions stay within ±0.01mm of your specs.”

Contact Us Today

Unlock precision-engineered anodized components with zero compromises:

📧 [email protected]

📞 +86-13961886740

24/7 availability for urgent inquiries | ISO 9001:2015 Certified | Material Traceability Guaranteed

“We don’t just machine parts—we engineer solutions. From design validation to final inspection, your success is our standard.”

— Wuxi Lead Precision Machinery

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.