Technical Contents

Engineering Guide: Aluminum Vs Titanium Strength

Engineering Insight: Precision in Aluminum vs Titanium Strength Selection

Material choice fundamentally determines component performance in critical applications. While aluminum and titanium both serve high-strength requirements, their distinct mechanical behaviors under load demand rigorous engineering analysis and uncompromising manufacturing precision. Selecting between them isn’t merely about raw strength values; it hinges on understanding how machining processes interact with each material’s inherent properties to deliver the required structural integrity in service. At Wuxi Lead Precision Machinery, we recognize that sub-micron level control during CNC machining directly impacts the realized strength, fatigue life, and reliability of the final part—especially when pushing materials to their operational limits.

Aluminum alloys, particularly aerospace grades like 7075-T6, offer an exceptional strength-to-weight ratio and excellent machinability. However, their lower density comes with reduced absolute strength compared to titanium and greater susceptibility to fatigue crack propagation under cyclic loading. Titanium Grade 5 (Ti-6Al-4V), conversely, provides significantly higher ultimate and yield strength, superior corrosion resistance, and exceptional performance at elevated temperatures. Its higher density is often justified in mission-critical scenarios where failure is not an option. Crucially, titanium’s strength advantage is only fully realized when machined with extreme precision; improper cutting parameters or tooling can induce detrimental residual stresses or surface defects that compromise its fatigue resistance—a risk we mitigate through proprietary CNC protocols developed over decades.

The table below highlights key comparative mechanical properties essential for engineering decisions:

| Property | Aluminum 7075-T6 | Titanium Gr5 (Ti-6Al-4V) |

|---|---|---|

| Yield Strength (MPa) | 503 | 880 |

| Tensile Strength (MPa) | 572 | 900 |

| Density (g/cm³) | 2.81 | 4.43 |

| Fatigue Strength (MPa) | ~150 (10⁷ cycles) | ~250 (10⁷ cycles) |

| Modulus of Elasticity (GPa) | 71.7 | 114 |

Our experience machining both materials for Olympic-caliber sporting equipment and Tier-1 military contractors underscores a critical truth: theoretical material properties are irrelevant if manufacturing precision falters. On a recent defense project requiring titanium helicopter rotor components, maintaining tolerances within ±0.005mm was non-negotiable to prevent stress concentrations that could initiate fatigue failure under extreme vibrational loads. Similarly, for lightweight aluminum bicycle frames destined for Olympic competition, our controlled milling sequences minimized microstructural distortion, ensuring the predicted fatigue life matched rigorous track testing. These projects exemplify how Wuxi Lead’s mastery of precision CNC machining—spanning optimal toolpath strategies, thermal management, and in-process metrology—translates material potential into real-world performance. We don’t just cut metal; we engineer the integrity that defines success in the most demanding applications. Your component’s strength begins with our process control.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered aluminum and titanium components tailored to the demanding requirements of aerospace, medical, and high-performance industrial sectors. Our technical capabilities are anchored in advanced 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis platforms allow simultaneous movement across five planes, ensuring optimal tool engagement and access to intricate features that are unattainable with conventional 3-axis setups. This capability is particularly critical when machining high-strength materials like titanium, where precision and thermal management are paramount.

Our facility is equipped with state-of-the-art CNC centers featuring high-torque spindles, automated tool changers, and real-time monitoring systems. These machines are optimized for both aluminum and titanium, accommodating their distinct mechanical behaviors. Aluminum, with its lower density and superior machinability, allows for high-speed cutting and rapid material removal. Titanium, though more challenging due to its low thermal conductivity and high chemical reactivity, is processed using specialized toolpaths, coolant strategies, and cutting parameters developed in-house to prevent work hardening and tool wear. Our engineering team applies material-specific expertise to ensure dimensional stability and structural integrity in every component.

Quality control is integrated at every stage of production. All critical dimensions and geometries are verified using Coordinate Measuring Machines (CMM) with sub-micron resolution. These systems provide full traceability and compliance with ISO 10360 standards, ensuring repeatable accuracy across production runs. In addition to CMM inspection, we employ first-article inspection (FAI) reports, in-process checks, and final quality audits to maintain consistency and adherence to customer specifications.

The following table outlines our standard machining tolerances for aluminum and titanium components under normal production conditions. These values reflect our commitment to precision and are adjustable based on design requirements and application demands.

| Parameter | Aluminum Tolerance | Titanium Tolerance |

|---|---|---|

| Linear Dimensions (mm) | ±0.010 | ±0.012 |

| Hole Diameter (mm) | ±0.008 | ±0.010 |

| Positional Tolerance (mm) | ±0.015 | ±0.020 |

| Surface Roughness (Ra, µm) | 0.8 – 1.6 | 1.2 – 2.0 |

| Angular Tolerance (°) | ±0.1 | ±0.1 |

| Flatness (mm per 100 mm) | 0.015 | 0.020 |

All tolerances are achievable under controlled environmental conditions and may be tightened upon engineering review. Our technical team collaborates closely with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, material selection, and tolerance specifications. This proactive approach reduces lead times and enhances performance, ensuring that every machined component meets the highest standards of strength, reliability, and precision.

Material & Finish Options

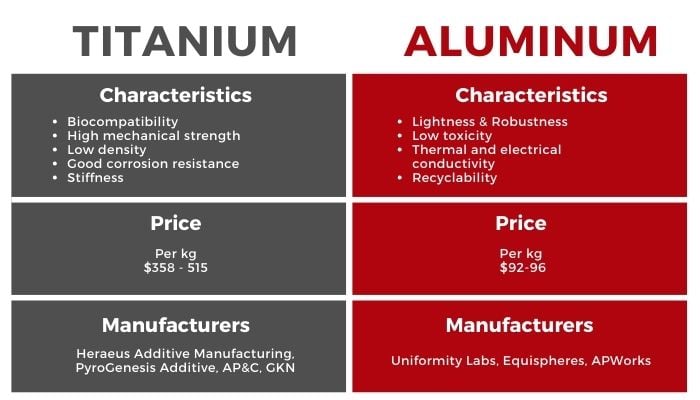

Strategic Material Selection for High-Performance Components

Choosing between aluminum, titanium, and steel demands precise analysis of mechanical requirements, environmental exposure, and lifecycle costs. At Wuxi Lead Precision Machinery, we prioritize engineering outcomes over material assumptions. Aluminum alloys like 6061-T6 offer exceptional strength-to-weight ratios and corrosion resistance, making them ideal for aerospace brackets and consumer electronics where weight savings are critical. Titanium Grade 5 (Ti-6Al-4V) provides superior tensile strength and fatigue resistance in extreme environments—such as marine or medical implants—but requires specialized CNC machining due to its low thermal conductivity and high reactivity. Steel remains indispensable for high-wear applications like tooling, though its density often negates strength advantages in weight-sensitive designs.

Material performance must be evaluated holistically. The following table compares key properties for common industrial grades:

| Property | Aluminum 6061-T6 | Titanium Grade 5 | Steel 4140 |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 4.43 | 7.85 |

| Yield Strength (MPa) | 276 | 880 | 655 |

| Tensile Strength (MPa) | 310 | 970 | 745 |

| Corrosion Resistance | High (anodized) | Exceptional | Moderate (coated) |

| Machinability Rating | Excellent | Poor | Good |

Titanium’s ultimate strength is nearly triple that of aluminum, but its density is 64% higher. This means aluminum often delivers better specific strength (strength per unit weight) for dynamic loads. Conversely, titanium’s fatigue strength excels in cyclic stress applications, such as aircraft landing gear, where longevity justifies its 3–5x material cost premium. Aluminum’s thermal conductivity also aids heat dissipation in electronics housings—a factor steel cannot match.

Anodizing transforms aluminum’s surface durability without altering core properties. Type II (sulfuric acid) anodizing provides standard corrosion resistance, while hardcoat (Type III) anodizing achieves 50–70 HRC surface hardness—comparable to some tool steels—ideal for hydraulic pistons or wear plates. Titanium cannot be anodized conventionally; its oxide layer forms naturally, but color anodizing for identification uses voltage-controlled electrolytic processes. Steel typically requires plating (e.g., zinc-nickel) or nitriding for equivalent protection.

Wuxi Lead Precision Machinery integrates material science with CNC expertise to optimize your selection. We simulate stress points using finite element analysis (FEA) to determine whether titanium’s raw strength or aluminum’s weight efficiency better serves your application. For instance, drone structural components often favor aluminum alloys with hardcoat anodizing, achieving 95% of titanium’s functional performance at half the cost. Our engineering team evaluates total cost of ownership—including machining time, secondary operations, and service life—to prevent over-engineering. Contact us for application-specific validation; we machine prototypes in all three materials to validate your design before full production.

Manufacturing Process & QC

Design Precision as the Foundation

At Wuxi Lead Precision Machinery, every high-performance component begins with rigorous design engineering. For applications comparing aluminum vs titanium strength, material behavior under load, thermal expansion, and fatigue resistance are modeled using advanced finite element analysis (FEA) software. Our engineering team evaluates stress distribution, weight targets, and environmental exposure to determine whether aluminum alloys such as 7075-T6 or titanium grades like Ti-6Al-4V are optimal. This phase integrates client specifications with manufacturing feasibility, ensuring geometric complexity, tolerances, and surface finishes are achievable at scale. Design for manufacturability (DFM) reviews eliminate costly iterations and set the benchmark for zero-defect production.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to precision prototyping using 5-axis CNC machining, which allows us to replicate exact production conditions on small batches. Prototypes are machined from the same certified raw materials intended for mass production, ensuring accurate evaluation of mechanical properties. Each prototype undergoes comprehensive metrology inspection via coordinate measuring machines (CMM) and 3D scanning to verify dimensional accuracy within ±0.005 mm. Mechanical testing, including tensile strength, hardness, and fatigue cycles, confirms whether the selected material—aluminum or titanium—meets structural requirements. This stage is critical for validating the strength-to-weight ratio, especially in aerospace, medical, and high-performance automotive applications where failure is not an option.

Seamless Transition to Zero-Defect Mass Production

With prototype approval, we transition to full-scale production under a zero-defect manufacturing philosophy. Our CNC machining centers operate under strict ISO 9001 and IATF 16949 standards, with real-time tool wear monitoring, automated in-process inspections, and statistical process control (SPC) to maintain consistency. Each aluminum or titanium part is traceable through batch numbers and material certifications. Multi-stage quality gates ensure any deviation triggers immediate corrective action. For aluminum, we optimize cutting speeds and cooling strategies to prevent warping; for titanium, we use specialized tooling and controlled feeds to manage heat buildup and maintain integrity.

Material Performance Comparison

| Property | Aluminum 7075-T6 | Titanium Ti-6Al-4V |

|---|---|---|

| Tensile Strength (MPa) | 572 | 900 |

| Yield Strength (MPa) | 503 | 830 |

| Density (g/cm³) | 2.81 | 4.43 |

| Strength-to-Density Ratio | High | Exceptional |

| Machinability | Excellent | Moderate (heat-sensitive) |

| Corrosion Resistance | Good (anodized) | Outstanding |

| Typical Applications | Aerospace frames, drones | Medical implants, jet engines |

Final inspection includes non-destructive testing (NDT) where required, ensuring every component meets the highest reliability standards. At Wuxi Lead, precision is not achieved in stages—it is engineered into every phase from design to delivery.

Why Choose Wuxi Lead Precision

Material Selection Determines Performance: Partner with Lead Precision for Optimal Aluminum and Titanium Solutions

Choosing between aluminum and titanium is never merely a cost decision in mission-critical manufacturing. It is a fundamental engineering choice impacting structural integrity, service life, weight targets, and total lifecycle cost. At Wuxi Lead Precision Machinery, we understand that your application’s success hinges on selecting the precise material grade and executing flawless machining processes. Generic comparisons lack the context of your specific load conditions, environmental exposure, and performance tolerances. We move beyond basic strength metrics to deliver components where material science aligns perfectly with your operational reality. Our engineering team collaborates from the initial design phase, analyzing stress points, thermal dynamics, and fatigue requirements to determine whether the high strength-to-weight ratio of aluminum alloys like 7075-T6 or the unparalleled corrosion resistance and temperature stability of titanium Grade 5 (Ti-6Al-4V) best serves your project. We then leverage our advanced CNC capabilities to transform that material choice into a precision-engineered reality.

The following table highlights critical properties relevant to high-stress applications, emphasizing why context dictates the optimal choice:

| Property | Aluminum 7075-T6 | Titanium Grade 5 (Ti-6Al-4V) | Critical Application Impact |

|---|---|---|---|

| Yield Strength (MPa) | 469 – 524 | 827 – 896 | Titanium withstands significantly higher static loads before permanent deformation |

| Ultimate Tensile (MPa) | 542 – 593 | 895 – 965 | Titanium offers superior resistance to catastrophic failure under peak loads |

| Density (g/cm³) | 2.81 | 4.43 | Aluminum provides a decisive weight advantage where mass reduction is paramount |

| Fatigue Strength (MPa) | ~150 (at 500M cycles) | ~550 (at 10⁷ cycles) | Titanium excels in cyclic loading environments, critical for aerospace structures |

| Corrosion Resistance | Moderate (requires coating) | Exceptional (seawater, chemicals) | Titanium eliminates failure risk in aggressive environments, reducing maintenance |

| Machinability (Rating) | Excellent (100%) | Poor (22-35%) | Aluminum machines faster with lower tool wear; titanium demands specialized expertise |

Superior material properties are meaningless without precision manufacturing execution. Titanium’s low thermal conductivity and high chemical reactivity demand specialized toolpaths, rigid fixturing, and controlled coolant strategies to prevent work hardening and maintain dimensional accuracy. Aluminum’s softness requires meticulous parameter control to avoid burring and achieve critical surface finishes. Wuxi Lead Precision Machinery operates a certified AS9100D facility equipped with state-of-the-art 5-axis CNC machining centers, CMM inspection systems, and a team of engineers with 15+ years of experience machining both materials for aerospace, medical implant, and defense applications. We don’t just cut metal; we solve the complex interplay between material behavior, geometric complexity, and stringent quality requirements.

Stop compromising between performance and manufacturability. Let our engineering team analyze your specific load cases, environmental factors, and lifecycle goals to confirm the optimal material solution and validate the machining strategy upfront. We provide comprehensive DFM feedback, rigorous material certification, and full traceability to ensure your components meet the highest reliability standards. Partner with a manufacturer that treats material selection as the critical engineering decision it is. Contact us today for a confidential engineering consultation.

Contact Lead Precision Machinery: Email [email protected] to initiate your project review. Include your component specifications and performance requirements for a targeted material and process assessment within 24 business hours.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.