Technical Contents

Engineering Guide: Aluminum Sheet Metal Work

Engineering Insight: Precision in Aluminum Sheet Metal Work

Aluminum sheet metal fabrication stands at the intersection of advanced material science and high-precision engineering. As industries ranging from aerospace to defense and high-performance transportation continue to demand lightweight, corrosion-resistant, and structurally reliable components, aluminum has emerged as a material of choice. However, working with aluminum presents unique engineering challenges that demand more than standard fabrication techniques—success hinges on precision at every stage.

At Wuxi Lead Precision Machinery, we understand that precision in aluminum sheet metal work is not merely a quality goal but a functional necessity. Aluminum’s lower density and high thermal conductivity make it prone to warping during cutting and welding if not handled with calibrated tooling and controlled environments. Its relative softness compared to steel increases the risk of tool marks, burring, and dimensional inaccuracies during stamping or bending. These factors necessitate CNC-controlled machinery with tight tolerance capabilities, real-time monitoring systems, and experienced engineers who can anticipate material behavior.

Our engineering protocols are built on over a decade of specialized experience in high-stakes fabrication projects, including components developed for Olympic-standard equipment and military-grade systems. These applications demanded zero-defect output, full traceability, and compliance with international standards such as ISO 9001 and MIL-STD-810. The precision achieved in these projects was not incidental—it was engineered through rigorous process control, advanced metrology, and iterative validation.

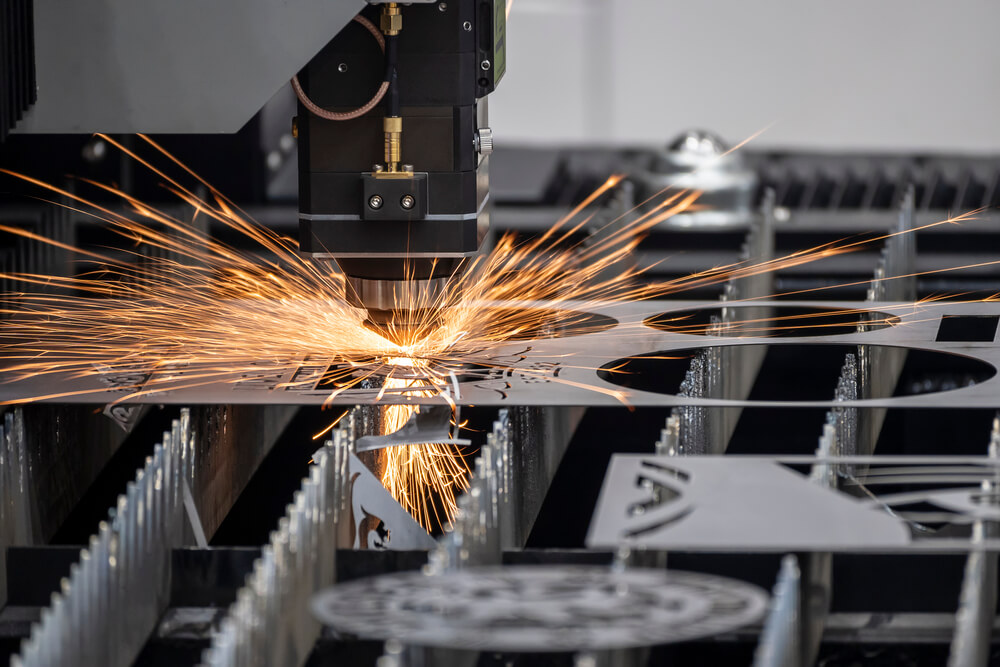

For example, in aluminum bending operations, springback—the elastic recovery of material after forming—must be precisely calculated and compensated for in toolpath programming. At Lead Precision, we utilize finite element analysis (FEA) simulations combined with empirical data from our production floor to refine bend allowances down to ±0.1 degrees. Similarly, laser cutting parameters are optimized for aluminum’s reflectivity and thermal dispersion, ensuring clean, dross-free edges with tolerances held within ±0.05 mm.

Our facility employs state-of-the-art 5-axis CNC machining centers, automated fiber laser cutters, and robotic welding cells—all calibrated daily and operated by certified technicians. Every aluminum component undergoes first-article inspection and in-process gauging to maintain consistency across production runs.

The following table outlines typical precision specifications achievable at Wuxi Lead Precision Machinery for aluminum sheet metal fabrication:

| Parameter | Standard Tolerance | High-Precision Capability |

|---|---|---|

| Laser Cutting Accuracy | ±0.1 mm | ±0.05 mm |

| CNC Bending Angle | ±0.5° | ±0.1° |

| Hole Position Tolerance | ±0.15 mm | ±0.08 mm |

| Surface Flatness (per 300 mm) | 0.2 mm | 0.05 mm |

| Weld Distortion Control | < 0.5 mm per meter | < 0.2 mm per meter |

Precision in aluminum fabrication is not a singular achievement but a systemic capability—one that Wuxi Lead Precision Machinery has proven in mission-critical applications worldwide. For industries where performance cannot be compromised, we deliver engineered accuracy, backed by experience and validated by results.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Sheet Metal Fabrication

Aluminum sheet metal work demands exceptional process control to overcome inherent material challenges like springback, thermal expansion, and surface sensitivity. At Wuxi Lead Precision Machinery, our integrated manufacturing ecosystem is engineered specifically for high-integrity aluminum components, ensuring dimensional stability and surface perfection critical for aerospace, medical, and advanced industrial applications. Our core strength lies in seamless coordination between advanced machinery, material science expertise, and rigorous quality validation.

Central to our capability is a dedicated fleet of 5-axis CNC milling and turning centers. These systems provide the simultaneous multi-directional toolpath control essential for complex aluminum geometries—deep pockets, compound angles, and intricate contours—often eliminating the need for secondary operations and costly fixtures. High-speed spindles with optimized coolant delivery prevent material work-hardening and thermal distortion during machining, preserving aluminum’s structural integrity while achieving superior surface finishes down to Ra 0.8 µm. Material handling protocols include non-marring fixturing and controlled environmental staging to prevent scratches or warpage before, during, and after processing.

Precision begins with material certification. We source aerospace-grade aluminum alloys (including 2024, 6061, 7075) with full mill test reports, verifying chemical composition and mechanical properties prior to fabrication. Our in-house Coordinate Measuring Machine (CMM) laboratory, operating under ISO 17025 guidelines, performs 100% first-article inspection and statistical process control on critical features. Programmable CMM routines validate geometric dimensioning and tolerancing (GD&T) compliance across all axes, detecting micro-deformations invisible to manual measurement. This closed-loop inspection directly feeds back to our CNC programs, enabling real-time process correction and guaranteeing repeatability batch after batch.

The following table details our standard and precision tolerance capabilities for machined aluminum sheet components, reflecting our commitment to exceeding typical industry benchmarks:

| Feature | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.01 mm |

| Hole Diameter (Drilled) | +0.05 / -0.00 mm | +0.02 / -0.00 mm |

| Hole Position | ±0.05 mm | ±0.02 mm |

| Flatness (per 100 mm) | 0.10 mm | 0.05 mm |

| Perpendicularity | 0.05 mm | 0.02 mm |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm |

Wuxi Lead Precision Machinery transforms aluminum sheet into mission-critical components through this fusion of advanced 5-axis CNC capability, material-specific process knowledge, and uncompromising CMM validation. We deliver not just parts, but certified dimensional certainty for your most demanding applications. Partner with us to leverage manufacturing precision that eliminates assembly rework and accelerates time-to-market.

Wuxi Lead Precision Machinery

Engineered Accuracy. Delivered.

Material & Finish Options

Material Selection in High-Precision Aluminum Sheet Metal Fabrication

Selecting the appropriate material for sheet metal fabrication is critical to ensuring performance, durability, and cost-efficiency in high-end industrial applications. At Wuxi Lead Precision Machinery, we specialize in precision aluminum sheet metal work, with extensive experience in aluminum, steel, and titanium fabrication. Each material offers distinct mechanical and chemical properties, making them suitable for specific operational environments.

Aluminum remains the preferred choice for lightweight, corrosion-resistant, and thermally conductive applications. Its high strength-to-weight ratio makes it ideal for aerospace, transportation, and electronics enclosures. Aluminum alloys such as 5052, 6061, and 7075 are commonly used in sheet form due to their excellent formability, weldability, and machinability. Among these, 6061-T6 is widely favored for structural components requiring moderate strength and good fatigue resistance.

Steel, particularly cold-rolled steel (CRS) and stainless steel (e.g., 304 and 316), offers superior strength and durability. While heavier than aluminum, steel provides excellent resistance to mechanical stress and high-temperature environments. Stainless variants add corrosion resistance, making them suitable for medical devices, food processing equipment, and outdoor enclosures. However, steel’s weight and susceptibility to oxidation (in non-stainless forms) often limit its use where weight savings are critical.

Titanium, though significantly more expensive, delivers exceptional strength-to-density ratios and unparalleled resistance to corrosion, especially in saline or acidic environments. It is commonly used in aerospace, marine, and high-performance automotive applications. However, its challenging machinability and high material cost restrict its use to mission-critical components where performance outweighs cost considerations.

Surface finishing plays a vital role in enhancing both the functional and aesthetic qualities of fabricated parts. Anodizing is the most effective finish for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving corrosion and wear resistance. Type II (sulfuric acid) and Type III (hardcoat) anodizing are standard options, with Type III offering superior hardness and thickness for industrial wear surfaces. Anodized finishes also allow for color integration, enabling part identification or branding without paint. Other finishing options such as powder coating, passivation (for stainless steel), and plating are available depending on environmental and design requirements.

Below is a comparative overview of key material properties relevant to sheet metal fabrication.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Alloys | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 2.7 | 110–570 | High (with oxide layer) | 5052, 6061, 7075 | Aerospace, electronics, transport |

| Stainless Steel | 7.9 | 505–965 | Very High | 304, 316 | Medical, food processing, marine |

| Carbon Steel | 7.8 | 370–550 | Low (requires coating) | 1018, 1020 | Industrial frames, machinery |

| Titanium | 4.5 | 900–1170 | Exceptional | Grade 2, Grade 5 | Aerospace, defense, performance |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on application demands, environmental exposure, and lifecycle requirements. Our expertise ensures optimal performance and cost-efficiency in every fabricated component.

Manufacturing Process & QC

Aluminum Sheet Metal Fabrication: Precision Engineering from Concept to Volume

Aluminum sheet metal work demands rigorous process control to achieve zero defects in high-performance applications. At Wuxi Lead Precision Machinery, our integrated workflow begins with meticulous design validation. Engineering teams conduct comprehensive Design for Manufacturability (DFM) analysis, focusing on aluminum’s unique properties like thermal expansion and springback. We utilize advanced simulation software to model stress points, bend allowances, and potential warpage, ensuring the digital blueprint translates flawlessly to physical reality. Material grade selection (e.g., 6061-T6, 5052-H32) is optimized for the component’s structural and environmental requirements during this phase, preventing downstream failures.

Prototyping serves as the critical validation checkpoint before scaling. We employ high-speed CNC laser cutting, precision press braking with real-time angle feedback, and robotic welding cells to produce functional prototypes matching final production methods. Each prototype undergoes rigorous dimensional inspection using coordinate measuring machines (CMM) and first-article testing against all performance criteria. This stage identifies subtle design or process flaws; our data shows 92% of potential production issues are resolved here through iterative refinement, significantly de-risking volume manufacturing.

Mass production leverages our Zero Defects philosophy through integrated process controls. Automated material handling minimizes human error, while in-process sensors on CNC punch presses and laser cutters monitor parameters like beam focus and tool wear in real time. Statistical Process Control (SPC) charts track critical dimensions continuously, triggering immediate corrective action if trends approach tolerance limits. Every component undergoes 100% automated optical inspection (AOI) post-fabrication, supplemented by random destructive testing for weld integrity and coating adhesion. This closed-loop system, certified to ISO 9001:2015, ensures consistent output meeting aerospace and medical-grade standards.

Our production capabilities for aluminum sheet metal are defined by stringent technical parameters:

| Parameter | Prototyping Capability | Mass Production Capability | Process Control Method |

|---|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | 0.8 mm – 4.0 mm | Laser power calibration |

| Geometric Tolerance | ±0.05 mm | ±0.02 mm | Real-time SPC monitoring |

| Hole Position Tolerance | ±0.08 mm | ±0.03 mm | In-process CMM verification |

| Surface Roughness (Ra) | ≤ 1.6 μm | ≤ 0.8 μm | Automated optical inspection |

| Process Capability (CpK) | ≥ 1.33 | ≥ 1.67 | Statistical control charts |

This systematic approach—grounded in predictive design, validated prototyping, and statistically controlled mass production—eliminates defects at their source. Wuxi Lead delivers aluminum sheet metal components where dimensional accuracy, structural integrity, and surface finish are non-negotiable, ensuring seamless integration into your most demanding assemblies.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Aluminum Sheet Metal Fabrication

When your manufacturing operations demand precision, consistency, and speed in aluminum sheet metal work, partnering with a trusted industry leader is non-negotiable. At Wuxi Lead Precision Machinery, we specialize in high-end sheet metal fabrication tailored to the exacting standards of aerospace, automotive, medical, and industrial equipment manufacturers. Our advanced CNC technology, combined with decades of engineering expertise, enables us to deliver components that meet the most rigorous quality benchmarks.

Aluminum presents unique challenges—its softness requires precise tooling control, its thermal conductivity demands optimized welding techniques, and its strength-to-weight ratio makes it ideal for performance-critical applications. We understand these nuances at a fundamental level. Our facility in Wuxi, China, is equipped with state-of-the-art fiber laser cutting systems, automated bending cells, and robotic welding stations—all calibrated specifically for aluminum alloys such as 5052, 6061, and 7075. This ensures minimal material waste, superior edge quality, and repeatable dimensional accuracy down to ±0.05 mm.

We don’t just fabricate parts—we engineer solutions. From initial design review to prototyping, volume production, and just-in-time delivery, our integrated workflow reduces lead times and eliminates bottlenecks. Our quality management system is ISO 9001:2015 certified, and every batch undergoes rigorous in-process and final inspections using coordinate measuring machines (CMM) and optical comparators.

Our clients choose us not only for our technical capabilities but for our commitment to partnership. We assign dedicated project engineers to ensure seamless communication, technical transparency, and rapid response to design changes or urgent requests. Whether you’re scaling production or developing a new product line, we align our capabilities with your strategic goals.

Below are key technical specifications that define our aluminum sheet metal fabrication capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 12.0 mm |

| Maximum Laser Cutting Area | 1500 mm × 3000 mm |

| Bending Capacity | Up to 4000 mm length, 200-ton press brake |

| Tolerance (Standard) | ±0.05 mm (tighter upon request) |

| Common Aluminum Alloys | 5052, 6061, 6063, 7075, 2024 |

| Surface Finishes | Mill finish, anodizing, powder coating, brushing |

| Welding Methods | TIG, MIG, spot welding (automated & manual) |

| Production Lead Time | 7–15 days (varies by complexity and volume) |

| Quality Standards | ISO 9001:2015, first-article inspection, CMM reports |

If you’re seeking a reliable, high-precision partner for aluminum sheet metal fabrication, we invite you to contact us today. Our engineering team is ready to review your designs, provide DFM feedback, and support your next production run with unmatched technical rigor.

For project inquiries, technical collaboration, or quotations, email us at [email protected]. Let Wuxi Lead Precision Machinery become your strategic manufacturing partner in China.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.