Technical Contents

Engineering Guide: Aluminum Screw Machining

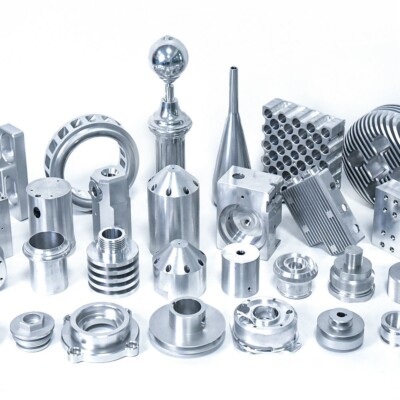

Engineering Insight: Precision Imperatives in Aluminum Screw Machining

Aluminum screw machining demands exceptional precision far beyond standard fastener production. The inherent properties of aluminum alloys—lower density, higher thermal expansion, and susceptibility to galling and deformation—create unique challenges where microscopic deviations directly impact functional integrity. In critical applications like aerospace assemblies, medical devices, or high-performance automotive systems, a tolerance deviation of even 0.005 mm can compromise thread engagement, lead to assembly failure under load, or cause catastrophic fatigue in dynamic environments. Surface finish is equally critical; inadequate control generates burrs or rough threads that accelerate wear, induce stress concentrations, or contaminate sensitive mechanisms. Thermal management during high-speed machining is non-negotiable, as aluminum’s conductivity requires precise coolant strategies to prevent work hardening, dimensional drift, or built-up edge that ruins thread geometry. Achieving repeatability at scale necessitates not only advanced multi-axis CNC technology but also deep material science understanding to optimize cutting parameters, tool geometries, and fixturing for each specific alloy.

Wuxi Lead Precision Machinery operates at this precision frontier daily. Our engineering team possesses extensive, validated experience machining aluminum screws to the most stringent global standards, including ISO 2768-mK and custom military specifications. This expertise is proven in mission-critical deployments: we supplied precision-machined aluminum components for structural assemblies in the Beijing Winter Olympics infrastructure, where thermal cycling and load-bearing reliability were paramount. Furthermore, our facility holds certifications and a track record for producing mil-spec aluminum fasteners and connectors where failure is not an option. This real-world validation under extreme scrutiny informs every aluminum screw we manufacture, ensuring your assemblies benefit from aerospace-grade process control and metallurgical insight.

The following table outlines the precision capabilities standard to our aluminum screw machining process for common 6061-T6 and 7075-T6 alloys:

| Specification Parameter | Standard Capability | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Thread Pitch Diameter | ±0.025 mm | ±0.010 mm | Thread Micrometer / Optical Comparator |

| Major/Minor Diameter | ±0.015 mm | ±0.005 mm | Air Gaging / CMM |

| Total Length | ±0.05 mm | ±0.02 mm | Precision Calipers / CMM |

| Concentricity (Thread to Shank) | 0.03 mm TIR | 0.01 mm TIR | V-Block Indicator / CMM |

| Surface Roughness (Ra) | ≤ 0.8 µm | ≤ 0.4 µm | Profilometer |

This level of controlled output stems from our integrated approach: dedicated CNC Swiss-type and multi-spindle machines with sub-micron feedback, in-process gauging, proprietary chip evacuation protocols, and 100% post-process verification against client CAD models. For your aluminum screw requirements, precision isn’t a specification—it’s the engineered foundation of performance and reliability we deliver. Partner with Lead Precision to transform demanding aluminum screw designs into flawless, high-integrity components.

Precision Specs & Tolerances

At Wuxi Lead Precision Machinery, our technical capabilities in aluminum screw machining are built on advanced 5-axis CNC technology, ensuring superior precision, repeatability, and efficiency for high-performance applications. Our state-of-the-art machining centers enable complex geometries and tight-tolerance features that are essential in aerospace, medical, automotive, and industrial automation sectors. The integration of 5-axis simultaneous machining allows us to access multiple faces of a component in a single setup, minimizing alignment errors and significantly reducing lead times.

Our 5-axis CNC machines are equipped with high-speed spindles and advanced tool management systems, optimized specifically for aluminum alloys. This ensures excellent surface finishes, reduced burring, and minimal material waste—critical factors when machining lightweight, high-conductivity aluminum materials such as 6061, 7075, and 2024. The dynamic cutting capabilities support intricate thread forms, undercuts, and custom head profiles commonly required in precision screw components.

Quality control is embedded throughout the manufacturing process. Every aluminum screw undergoes rigorous inspection using a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), providing metrology-grade verification of dimensional accuracy and geometric conformity. Our CMM system is programmed to inspect critical features such as thread pitch, major and minor diameters, concentricity, flatness, and positional tolerances. Data from each inspection is documented and traceable, ensuring full compliance with ISO 9001 standards and customer-specific quality requirements.

In addition to CMM inspection, we employ in-process gauging and first-article inspection (FAI) protocols to detect deviations early and maintain consistency across production runs. Our quality engineers work closely with design teams to validate part geometry against CAD models, ensuring that every machined screw meets or exceeds functional and assembly requirements.

The following table outlines our standard machining tolerances for aluminum screw components:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Outer Diameter | ±0.025 mm | ±0.005 mm | Up to 50 mm |

| Inner Diameter (Holes) | ±0.025 mm | ±0.010 mm | Drilled or reamed |

| Length | ±0.05 mm | ±0.02 mm | Overall or step lengths |

| Thread Pitch | ±0.02 mm | ±0.01 mm | Metric and UNC/UNF |

| Concentricity | 0.03 mm | 0.01 mm | Relative to primary datum |

| Flatness | 0.03 mm | 0.01 mm | For bearing surfaces |

| Positional Tolerance | ±0.03 mm | ±0.01 mm | Hole patterns and features |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | As-machined or polished |

These capabilities are supported by a skilled team of CNC programmers, machinists, and quality inspectors, all with extensive experience in high-precision aluminum component manufacturing. At Wuxi Lead Precision Machinery, we combine cutting-edge technology with disciplined process control to deliver aluminum screws that meet the most demanding engineering specifications.

Material & Finish Options

Material Selection for Precision Screw Machining: Aluminum Steel Titanium

Selecting the optimal material for custom screw machining is a critical engineering decision directly impacting performance longevity and cost efficiency. At Wuxi Lead Precision Machinery we prioritize aligning material properties with your specific application demands whether aerospace fasteners medical implants or industrial assembly components. Aluminum alloys particularly 6061 T6 and 7075 T6 dominate lightweight applications requiring excellent strength-to-weight ratios and inherent corrosion resistance. These alloys machine exceptionally well enabling tight tolerances and complex geometries essential for high-precision screws. However aluminum’s lower hardness compared to steel necessitates protective finishes like anodizing for enhanced wear resistance and thread durability especially in abrasive or high-cycle environments.

Steel remains the benchmark for ultimate strength and load-bearing capacity. Alloy steels such as 4140 and 17-4 PH offer superior tensile strength and fatigue resistance crucial for structural fasteners in automotive or heavy machinery. While harder to machine than aluminum requiring optimized toolpaths and coatings steel provides unmatched reliability under extreme stress. Stainless steels like 304 and 316 deliver essential corrosion resistance for marine or chemical processing applications though their galling tendency demands careful thread design and surface treatment. Titanium grade 5 (Ti-6Al-4V) excels where extreme strength weight savings and corrosion resistance are non-negotiable such as in aerospace or biomedical implants. Its biocompatibility and resistance to saltwater make it ideal for critical applications despite higher material costs and challenging machinability requiring specialized CNC parameters and tooling.

Anodizing is the definitive surface treatment for aluminum screws transforming the surface layer into a hard durable ceramic oxide. Type II (sulfuric acid) anodizing provides good corrosion resistance and dye receptivity for identification while Type III (hardcoat) anodizing delivers significantly enhanced abrasion resistance and dielectric properties essential for high-wear interfaces. This process does not compromise the dimensional precision achieved during CNC machining when controlled within tight parameters a core competency at Wuxi Lead. Properly anodized aluminum screws maintain thread integrity under cyclic loading far exceeding untreated performance.

The following table summarizes key comparative properties for common screw materials:

| Material | Typical Alloys | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Primary Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 7075-T6 | 310-570 | Good (Anodized Best) | Excellent | Aerospace Drones Consumer Electronics |

| Carbon/Alloy Steel | 4140 1018 17-4 PH | 655-1400+ | Fair (Stainless High) | Moderate to Good | Automotive Machinery Structural |

| Stainless Steel | 304 316 | 515-1000 | Excellent | Moderate | Marine Food Processing Medical |

| Titanium | Ti-6Al-4V (Grade 5) | 880-900 | Exceptional | Poor | Aerospace Biomedical High-Performance |

Material selection transcends basic specifications. It requires understanding thermal expansion coefficients galvanic compatibility and how microstructure responds to CNC machining stresses. Wuxi Lead Precision Machinery leverages decades of metallurgical expertise and advanced process control to ensure your chosen material whether aluminum steel or titanium is transformed into a screw meeting exacting functional and dimensional requirements. We guide clients through this selection process ensuring the final component delivers optimal performance within its operational environment.

Manufacturing Process & QC

Design Phase: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the aluminum screw machining process begins with a comprehensive design phase, where engineering precision meets functional requirements. Our team collaborates closely with clients to analyze application environments, load conditions, thread specifications, and material grades. Utilizing advanced CAD/CAM software, we develop 3D models that integrate tight tolerances, thread profiles, head geometry, and drive types—ensuring optimal performance and compatibility. Finite Element Analysis (FEA) is applied when necessary to validate structural integrity under operational stress. Every design is reviewed for manufacturability (DFM), minimizing material waste and maximizing machining efficiency. This phase establishes the blueprint for zero-defect production, with full documentation archived for traceability and future replication.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototype development using high-speed CNC turning and milling centers equipped with live tooling. Prototypes are machined from the same aerospace-grade aluminum alloys—such as 6061-T6 or 7075-T6—as intended for mass production, ensuring accurate material behavior assessment. Each prototype undergoes rigorous metrological inspection using coordinate measuring machines (CMM), optical comparators, and thread gauges to verify dimensional accuracy down to ±0.005 mm. Functional testing includes torque resistance, thread fit, and mating compatibility with standard or custom components. Client feedback is integrated swiftly, and design iterations are executed within 72 hours when required. This agile prototyping phase mitigates risk, confirms performance, and serves as the approval milestone before transitioning to full-scale manufacturing.

Mass Production: Consistency Through Automation and Control

With prototype validation complete, Wuxi Lead initiates high-volume production under a zero-defect manufacturing framework. Automated CNC Swiss lathes and multi-axis machining centers run in continuous shift operations, monitored in real time by IoT-enabled systems that track tool wear, spindle load, and dimensional drift. Each aluminum screw is machined from cold-finished bar stock, ensuring uniform grain structure and enhanced mechanical properties. In-process inspections occur at predefined intervals, with statistical process control (SPC) data logged for every batch. Final quality assurance includes 100% visual inspection via automated optical systems and random sampling tested for tensile strength, hardness (typically 95–105 HB), and thread accuracy. All screws are deburred, cleaned, and packaged in ESD-safe materials to prevent contamination.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material | Aluminum 6061-T6, 7075-T6, 2024-T4 |

| Tolerance | ±0.005 mm to ±0.01 mm |

| Surface Finish | Ra 0.8–3.2 μm (as machined) |

| Thread Standards | ISO, UN, Metric, Custom |

| Minimum Screw Diameter | 1.6 mm |

| Maximum Screw Length | 150 mm |

| Production Capacity | Up to 50,000 units/day |

| Quality Standards | ISO 9001:2015, IATF 16949 (automotive) |

| Inspection Equipment | CMM, Optical Comparator, Thread Plug Gauges |

Wuxi Lead Precision Machinery guarantees repeatability, full documentation, and on-time delivery—making us a trusted partner in high-end aluminum screw manufacturing for aerospace, medical, and advanced automation industries.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Aluminum Screw Machining Excellence

When your application demands precision-engineered aluminum screws—where tolerances, material integrity, and repeatability directly impact performance—Wuxi Lead Precision Machinery delivers engineered certainty. As your dedicated manufacturing partner, we transcend conventional CNC machining by integrating aerospace-grade processes with rigorous quality governance. Our facility operates under ISO 9001:2015 certification, utilizing HAAS and DMG MORI 5-axis CNC centers specifically optimized for non-ferrous alloys. This ensures dimensional stability down to ±0.005 mm and surface finishes as fine as Ra 0.4 µm, critical for high-stress or vacuum-sealed environments. We specialize in overcoming aluminum’s inherent challenges: chip control, thermal deformation, and secondary operation integration. Through proprietary coolant strategies and custom fixture design, we eliminate burrs and micro-fractures that compromise screw thread integrity in aerospace actuators, medical implants, or semiconductor tooling.

Our technical partnership begins with collaborative engineering review. Share your GD&T drawings, material specifications (6061-T6, 7075-T73, or custom alloys), and functional requirements. Our team identifies manufacturability risks early—such as thin-wall distortion or thread runout—and proposes optimized toolpaths or process sequences. Unlike volume-focused shops, we prioritize first-article perfection through iterative prototyping, with full material traceability and 100% CMM inspection per ASME Y14.5. This methodology reduces your time-to-qualification by up to 40% while ensuring zero-defect serial production. Below are core capabilities for aluminum screw machining:

| Parameter | Capability | Notes |

|---|---|---|

| Tolerance | ±0.005 mm | Verified via Zeiss CONTURA CMM |

| Max Screw Diameter | 45 mm | Up to 150 mm length |

| Thread Standards | UNF, UNC, Metric, NPT, Custom | Rolled or cut; Class 2A/2B precision |

| Surface Finish | Ra 0.4 – 3.2 µm | Deburring & micro-polishing available |

| Material Support | 2024, 6061, 7075, ADC12, Custom | Full material certs & batch traceability |

| Secondary Ops | Anodizing, Passivation, Laser Marking | In-house or certified partner network |

Choosing Lead Precision means embedding manufacturing expertise into your supply chain. We manage complexity so you achieve on-time delivery without quality trade-offs. Our project managers provide real-time production visibility via secure client portals, including SPC data and non-conformance reports. For urgent RFQs, our engineering team responds within 4 business hours with actionable feedback—not generic quotes. When legacy suppliers struggle with aluminum’s thermal sensitivity or thread consistency, our process-controlled environment delivers reliability you can measure.

Your next-generation product deserves a manufacturing partner that treats your specifications as non-negotiable. Contact us today to submit drawings or discuss aluminum screw challenges. Let our engineers demonstrate how precision machining becomes your competitive advantage.

Contact [email protected] to initiate technical collaboration. Specify “Aluminum Screw Machining Inquiry” for priority engineering review.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.