Technical Contents

Engineering Guide: Aluminum Printer

Engineering Insight Precision Imperatives for Aluminum Additive Manufacturing Systems

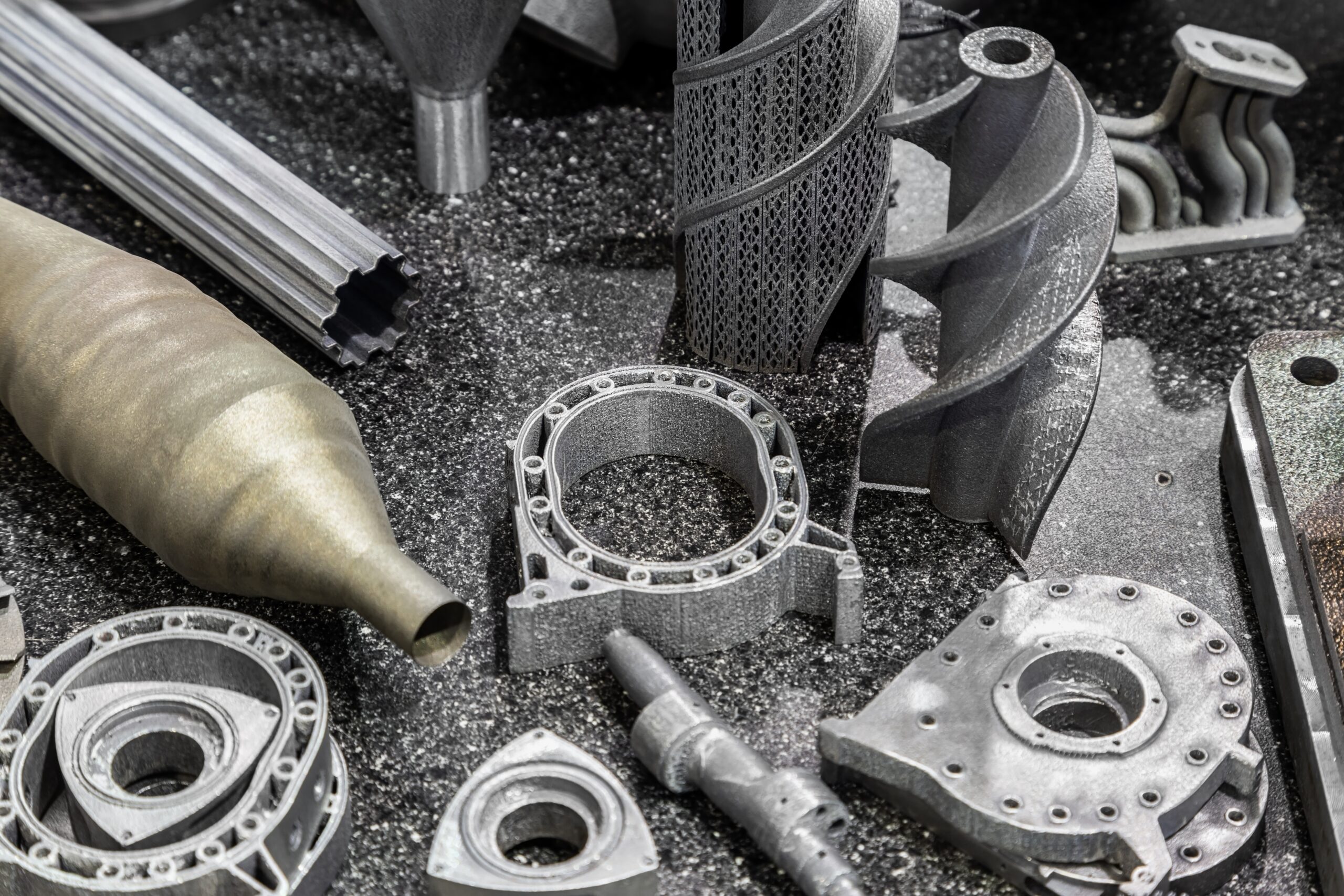

The term aluminum printer refers not to consumer-grade devices but to industrial additive manufacturing systems producing critical metal components. Within this high-stakes domain precision engineering is non-negotiable. Sub-micron deviations in structural frames thermal management components or motion control subsystems directly compromise print repeatability material integrity and final part performance. Aluminum alloys like 6061-T6 and 7075-T7351 dominate these systems due to their strength-to-weight ratio and thermal conductivity yet their machining demands extreme control. Micro-vibrations during multi-axis milling induce residual stresses causing post-machining dimensional drift; inconsistent surface finishes disrupt powder adhesion in laser beds; and thermal expansion miscalculations lead to catastrophic layer misalignment. At Wuxi Lead Precision Machinery we treat every component as a mission-critical element where 0.005mm tolerance is the baseline expectation not an aspiration.

Our CNC protocols integrate in-process metrology with environmental compensation algorithms. Temperature-stabilized machining cells maintain ±0.5°C variance while real-time laser interferometry corrects for tool deflection during deep cavity milling. This rigor stems from direct experience supplying structural chassis and beam delivery optics mounts for Olympic-grade timing systems where 2μm positional error would invalidate world records. Similarly our work on classified military drone propulsion housings demanded hermetic sealing under 15,000 RPM centrifugal loads—requiring coaxiality tolerances of 0.003mm across 450mm spans. Such projects forged our understanding that aluminum printer components fail not from gross errors but accumulated micro-irregularities. A 1.2μm surface roughness deviation on a build plate interface can propagate into 50μm layer distortion over 100mm prints; a 0.01° angular error in gantry rails compounds to 175μm positional drift at print volume extremities.

The following specifications represent our standard deliverables for aluminum printer subsystems—exceeding ISO 2768-mK and AS9100 aerospace benchmarks:

| Parameter | Standard Tolerance | Verified Method | Application Impact |

|---|---|---|---|

| Positional Accuracy | ±0.005 mm | CMM with thermal mapping | Ensures layer alignment fidelity |

| Surface Roughness (Ra) | 0.8 μm max | Profilometry | Prevents powder adhesion defects |

| Flatness | 0.01 mm/m | Laser interferometer | Critical for build plate sealing |

| Thermal Stability | 0.000023 mm/mm/°C | Dilatometer validation | Minimizes thermal warpage |

| Residual Stress | < 20 MPa | XRD analysis | Eliminates post-machining drift |

This precision translates directly to client ROI. A European medical device manufacturer reduced failed titanium builds by 37% after implementing our stress-relieved aluminum support structures—proving that component-level accuracy dictates system-wide success. For aluminum printer manufacturers Wuxi Lead delivers not just parts but engineered certainty. Every machined surface embeds decades of lessons from environments where perfection isn’t optional; it’s the price of entry. Partner with us to transform aluminum from a structural material into a precision instrument.

Precision Specs & Tolerances

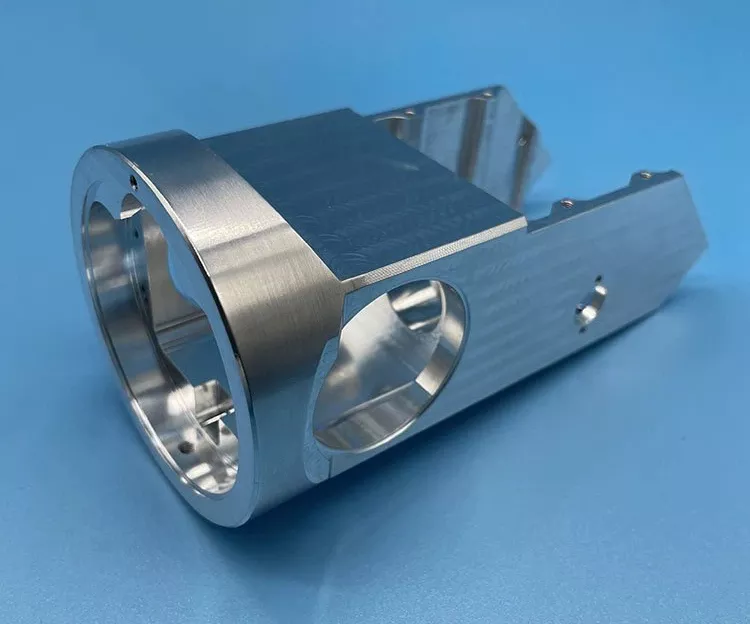

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications. At the core of our production floor is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with exceptional accuracy and surface finish. These machines allow simultaneous multi-axis movement, significantly reducing setup times and enhancing part consistency. Our expertise in aluminum machining is particularly suited for industries such as aerospace, medical equipment, and high-performance industrial printing—where lightweight, durable, and thermally efficient components are critical.

Our 5-axis CNC systems are operated by certified engineers with over a decade of experience in precision machining. Each program is optimized using the latest CAM software to ensure toolpath efficiency, minimal material waste, and maximum repeatability. We work with a wide range of aluminum alloys, including 6061, 7075, and 2024, tailoring material selection to the functional requirements of the final component. Whether producing intricate housings, structural frames, or precision nozzles for aluminum printers, our machining process ensures tight tolerances and superior dimensional stability.

To maintain the highest quality standards, every production run undergoes rigorous quality control protocols. Our metrology lab is equipped with a Zeiss DuraMax Bridge-type Coordinate Measuring Machine (CMM), capable of micron-level inspection. This allows us to verify critical features such as positional accuracy, flatness, concentricity, and profile tolerances on complex 3D surfaces. All inspection reports are documented and available to clients, ensuring full traceability and compliance with ISO 9001 standards.

We understand that precision in aluminum components directly impacts performance in high-end applications. That is why we maintain strict environmental controls in both machining and inspection areas to minimize thermal drift and ensure measurement reliability. Our facility also integrates first-article inspection (FAI) and in-process checks to catch deviations early and maintain consistency across batch production.

The following table outlines the standard tolerances we consistently achieve through our 5-axis CNC and quality assurance processes:

| Feature Type | Standard Tolerance | Capability Range | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | Down to ±0.005 mm | CMM, Micrometers |

| Hole Diameter | ±0.01 mm | ±0.005 mm (reamed) | CMM, Air Probes |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | CMM |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate |

| Surface Finish (Ra) | 0.8 µm | Down to 0.2 µm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.02° | CMM, Optical Comparator |

| Profile of Surface | 0.03 mm | 0.01 mm | CMM |

Wuxi Lead Precision Machinery combines cutting-edge technology, expert engineering, and uncompromising quality control to deliver aluminum components that meet the most stringent performance criteria. Our capabilities are engineered to support high-end manufacturing clients who demand precision, reliability, and repeatability in every part.

Material & Finish Options

Material Selection for Precision Aluminum Printers

Selecting optimal materials is critical for aluminum printer components requiring dimensional stability, thermal management, and longevity. At Wuxi Lead Precision Machinery, we prioritize aluminum alloys as the foundation for extrusion systems, structural frames, and thermal cores due to their exceptional strength-to-weight ratio and machinability. Aluminum 6061-T6 and 7075-T6 dominate our builds, balancing weldability, corrosion resistance, and fatigue performance under cyclic thermal loads. While steel offers higher rigidity for base plates, its density increases inertia and energy consumption. Titanium excels in extreme environments but incurs prohibitive costs and machining complexity for most printer applications. Material choice directly impacts print accuracy, maintenance cycles, and total operational expenditure.

Anodizing: The Essential Protective Finish

Anodizing is non-negotiable for aluminum printer parts exposed to abrasion, chemicals, or humidity. This electrochemical process converts the surface into a durable, non-conductive aluminum oxide layer. We specify Type II (sulfuric acid) anodizing at 25–30 µm thickness for standard wear resistance, with dye options including matte black for thermal absorption or clear for dimensional precision. For critical motion components like linear rails or lead screws, Type III (hardcoat) anodizing at 50–75 µm provides superior hardness (60–70 HRC) and extended service life. Avoid powder coating—it delaminates under thermal cycling and introduces particulate contamination risks in cleanroom printer environments.

Comparative Material Specifications

| Material | Density (g/cm³) | Tensile Strength (MPa) | Cost Factor | Key Applications in Printers |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 1.0 | Frames, heat sinks, extrusion mounts |

| Aluminum 7075-T6 | 2.8 | 570 | 1.8 | High-stress brackets, couplings |

| Stainless Steel 304 | 8.0 | 515 | 2.5 | Base plates, fasteners |

| Titanium Grade 5 | 4.4 | 900 | 8.0 | Specialized nozzles, aerospace builds |

Strategic Implementation Guidance

Prioritize 6061-T6 for 80% of structural printer components—it machines efficiently, minimizes thermal distortion, and anodizes uniformly. Reserve 7075-T6 for high-load zones like motor mounts where yield strength exceeds 450 MPa. Steel bases must be isolated from aluminum frames using insulating polymers to prevent galvanic corrosion. All anodized surfaces require precise masking of threaded holes and bearing seats to maintain critical tolerances. Wuxi Lead’s CNC processes achieve ±0.005 mm accuracy on anodized parts, ensuring seamless integration with printer subsystems. Remember: material and finish selection is not merely cost-driven—it defines system reliability over 10,000+ operational hours. Consult our engineering team to validate thermal expansion coefficients against your printer’s operating range.

Manufacturing Process & QC

From Concept to Consistency: The Precision Manufacturing Process for Aluminum Printers

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision aluminum components tailored for advanced applications such as aluminum printers used in industrial additive manufacturing. Our end-to-end production process is engineered for excellence, ensuring every part meets the highest standards of accuracy, durability, and performance. From initial design to full-scale mass production, our Zero Defects philosophy drives every stage of manufacturing.

The process begins with collaborative design engineering. Our team works closely with clients to analyze technical requirements, material behavior, and functional constraints. Using advanced CAD/CAM software and finite element analysis (FEA), we optimize component geometry for structural integrity, thermal stability, and manufacturability. This stage includes tolerance stack-up analysis and Design for Manufacturing (DFM) reviews to preempt potential issues before any metal is cut.

Once the design is finalized, we proceed to precision prototyping. Utilizing 5-axis CNC machining centers with sub-micron repeatability, we produce functional prototypes from high-grade aluminum alloys such as 6061-T6 and 7075-T6. These prototypes undergo rigorous validation, including dimensional inspection via coordinate measuring machines (CMM), surface finish analysis, and fit-function testing within simulated printer environments. Feedback from this phase informs final design refinements, ensuring optimal performance under real-world operating conditions.

With prototype approval, we transition seamlessly into mass production. Our automated production lines integrate high-speed CNC machining, robotic material handling, and in-process quality monitoring. Each operation is governed by standardized work instructions and statistical process control (SPC) protocols. We employ real-time tool wear compensation and automated defect detection systems to maintain consistency across batches of any size.

Throughout the entire process, quality is not inspected in — it is built in. Our ISO 9001-certified quality management system enforces traceability at the lot and serial level. Every component is subject to first-article inspection, ongoing sampling checks, and final audit before shipment. This disciplined approach ensures a defect rate consistently below 50 PPM (parts per million), aligning with the most demanding industrial standards.

| Specification | Detail |

|---|---|

| Material Options | 6061-T6, 7075-T6, 5052, 2024 (custom alloys available) |

| Tolerance Capability | ±0.005 mm (standard), ±0.001 mm (tight-tolerance features) |

| Surface Finish | Ra 0.8 μm (machined), down to Ra 0.2 μm (polished) |

| Max Work Envelope | 1200 × 800 × 600 mm (custom fixturing available) |

| Production Capacity | 50,000+ units/month (scalable with demand) |

| Quality Standards | ISO 9001, IATF 16949, GD&T compliant, full CMM reporting |

By integrating precision engineering, advanced manufacturing technology, and an uncompromising commitment to quality, Wuxi Lead delivers aluminum components that power reliable, high-performance printers. Our process doesn’t just meet specifications — it ensures trust in every part.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Aluminum Component Excellence

In the demanding realm of precision aluminum manufacturing, component integrity directly impacts your product’s performance, longevity, and market success. Standard machining processes often fail to address aluminum’s unique challenges: thermal expansion during cutting, microstructural inconsistencies, and stringent surface finish requirements for critical applications. At Wuxi Lead Precision Machinery, we engineer solutions where others see limitations. Our integrated approach combines aerospace-grade CNC infrastructure with material science expertise, ensuring every aluminum component meets micron-level tolerances while maintaining structural integrity. We don’t just machine parts—we validate metallurgical consistency, optimize chip evacuation for burr-free edges, and implement real-time thermal compensation to eliminate dimensional drift. This rigor transforms aluminum from a challenging material into your competitive advantage, whether for aerospace actuators, medical device housings, or semiconductor tooling.

Our technical capabilities are built on purpose-configured equipment and relentless process validation. The table below details our core specifications for aluminum machining, reflecting our commitment to exceeding industry benchmarks:

| Parameter | Capability | Relevance to Aluminum Manufacturing |

|---|---|---|

| Machine Accuracy | ±0.002 mm | Ensures fit-for-function in multi-part assemblies |

| Surface Finish | Ra 0.4 µm (achievable) | Critical for sealing surfaces and fatigue resistance |

| Spindle Speed Range | 20,000 RPM (HSK-A63 interface) | Prevents work hardening and thermal distortion |

| In-Process Metrology | On-machine probing with temperature compensation | Guarantees dimensional stability across batches |

| Material Certification | Full traceability to mill certs (6061-T6, 7075-T7351, etc.) | Meets AS9100 and ISO 13485 compliance needs |

Choosing a manufacturing partner is a strategic decision that affects time-to-market, total cost of ownership, and end-product reliability. Lead Precision operates as your embedded engineering extension, not merely a vendor. We initiate every project with a Design for Manufacturability (DFM) review, identifying potential aluminum-specific risks—such as stress concentration zones or suboptimal grain flow orientation—before a single chip is produced. Our facility runs 24/7 with dedicated cells for aluminum, featuring oil mist collection systems and humidity-controlled environments to prevent oxidation during extended runs. This operational discipline delivers zero-defect delivery records for Tier-1 clients in aerospace and life sciences, where failure is not an option.

The next step requires no lengthy RFQ process or generic sales pitch. Forward your CAD model or engineering drawing to [email protected] with a brief statement of functional requirements. Within 24 business hours, our application engineering team will provide a validated manufacturability assessment, including material utilization optimization and a timeline for first-article submission. We handle NDA-protected data with military-grade cybersecurity protocols, ensuring your intellectual property remains secure. For high-mix, low-volume aluminum components demanding uncompromised precision, Lead Precision is the engineered solution. Initiate your project today—your timeline starts when we receive your files.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.