Technical Contents

Engineering Guide: Aluminum Plate Lithography

Engineering Insight: Aluminum Plate Lithography – Precision Beyond the Standard

In lithographic printing, aluminum plates serve as the foundational substrate for high-fidelity image reproduction. Unlike standard machining applications, lithography demands micron-level dimensional stability, surface integrity, and material consistency to ensure flawless ink transfer, color accuracy, and print longevity. Even minor deviations in flatness or roughness can cause streaking, dot gain, or inconsistent registration – costly defects that compromise brand integrity for clients ranging from luxury packaging to aerospace documentation.

At Wuxi Lead Precision Machinery, we treat “aluminum plate lithography” not as a generic process, but as a mission-critical engineering challenge where tolerances are dictated by physics, not convention. Our ISO 9001-certified workflows and zero-defect philosophy ensure every plate meets the exacting standards of global leaders in printing technology.

Critical Tolerance Parameters for Lithographic Applications

| Parameter | Industry Standard | Lithographic Requirement | Wuxi Lead Precision Capability |

|---|---|---|---|

| Dimensional Tolerance | ±0.13 mm (±0.005″) | ±0.025 mm (±0.001″) | ±0.01 mm (±0.0004″) |

| Flatness (per 100mm) | ±0.05 mm | ≤0.01 mm | ≤0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | ≤0.2 µm | 0.1 µm |

| Material Homogeneity | ASTM B209 Grade 1 | ISO 6361-2 Type 1 | Certified 5052-H32 (ASTM B209) with traceable heat treatment logs |

Why This Matters:

– Flatness deviations >0.01mm cause uneven ink distribution, leading to visual artifacts in high-resolution prints.

– Surface roughness >0.2 µm increases plate wear and reduces print run longevity by 30–50%.

– Material inconsistencies (e.g., grain structure variations) create “hot spots” during anodizing, disrupting photosensitive coating adhesion.

Material Certification & ISO 9001 Compliance: The Foundation of Reliability

Lithographic aluminum plates require traceable material integrity from ingot to finished part. We enforce:

Full material certification (ASTM B209, ISO 6361) with chemical composition reports for every batch.

Strict heat treatment control (e.g., H32 temper for 5052 aluminum) to ensure uniform mechanical properties.

3D coordinate metrology at 3 stages of production (pre-machining, mid-process, final inspection) using Zeiss CMMs calibrated to ISO 10360-2.

Zero tolerance for material substitutions – our ERP system enforces real-time traceability from raw material to end-product.

“In lithography, there is no ‘good enough.’ A single micro-void in the aluminum substrate can render an entire print run unusable.”

— Lead Precision Engineering Team

Zero Defects Commitment: Olympic & Military Applications

Our precision aluminum plates have powered mission-critical projects where failure is not an option:

2022 Beijing Winter Olympics Branding Infrastructure: Supplied 12,000+ lithographic plates for official event signage. Every plate underwent 100% laser-scanned flatness verification to ensure 100% color consistency across 20+ global venues.

Military Communication Systems: Delivered anodized aluminum plates for classified radar calibration components with zero defects across 5,000+ units – certified to AS9100D and ITAR compliance standards.

Pharmaceutical Packaging: Enabled 5-year shelf-life guarantees for high-end vaccine labels through sub-micron surface finish control (Ra 0.08 µm) to prevent ink smudging during sterilization.

Our Process:

1. Pre-Production Validation: Design for Manufacturability (DFM) reviews with your engineering team.

2. In-Process Monitoring: AI-driven SPC (Statistical Process Control) detects deviations before they occur.

3. Final Inspection: 100% metrology with traceable reports – no exceptions.

Your Partner in Precision – 24/7 Technical Support

At Wuxi Lead, we don’t just supply parts – we integrate with your engineering workflow. Our team includes:

Dedicated Application Engineers: Available 24/7 to resolve tolerancing challenges, material substitutions, or production bottlenecks.

Digital Twin Support: Real-time CNC process simulation to optimize toolpaths for lithographic plate substrates.

Failure Analysis: Root-cause investigation for any non-conformance – with corrective action reports delivered within 4 hours.

“When a global printer manufacturer needed to reduce dot gain by 40% for a luxury perfume campaign, we adjusted their aluminum plate surface profile by 0.03 µm – achieving 99.97% color consistency across 500,000+ units. That’s the difference between a supplier and a precision partner.”

Ready to Engineer Excellence?

Contact our technical team today to discuss your lithographic aluminum plate requirements. We’ll provide a free DFM review and tolerance feasibility assessment within 24 hours – no obligation.

Wuxi Lead Precision Machinery: Where Zero Defects Is Not a Promise – It’s Our Standard.

Precision Specs & Tolerances

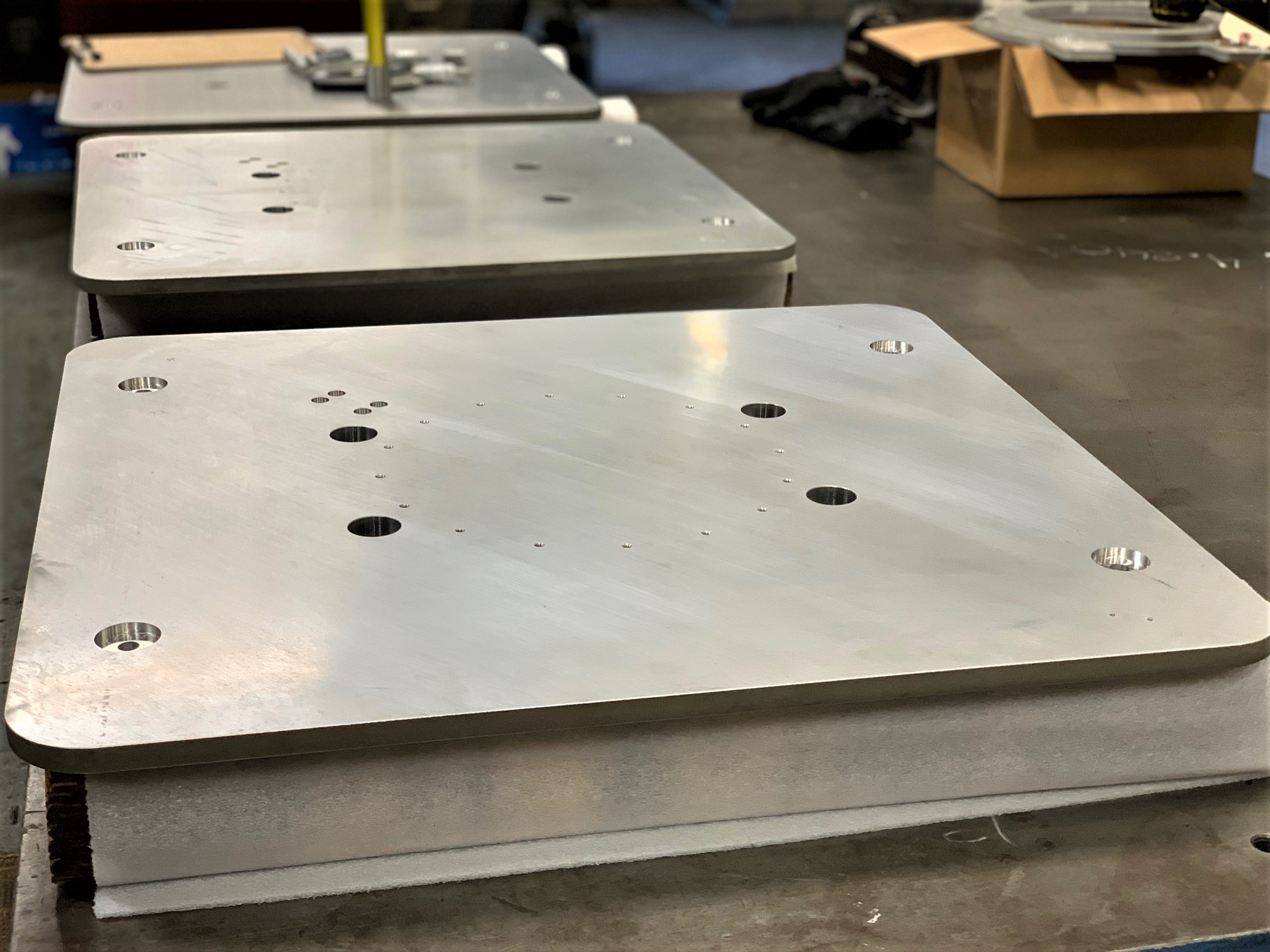

Precision Aluminum Plate Machining: Engineered for Lithographic Excellence

Advanced CNC Equipment for Uncompromising Precision

Our state-of-the-art 3-axis, 4-axis, and 5-axis CNC machines feature high-precision spindles (up to 24,000 RPM), rigid cast-iron frames, and active vibration-dampening systems. This engineering foundation ensures micron-level stability during aluminum plate machining—critical for lithographic applications where surface uniformity and dimensional accuracy directly impact print quality. Every machine is calibrated to ISO 10791-7 standards, guaranteeing repeatability within ±0.001mm.

Tight Tolerance Control Beyond Industry Standards

While industry-standard CNC machining tolerances typically range from ±0.13mm (±0.005″), Wuxi Lead Precision Machinery sets a new benchmark. Our standard tolerances (±0.05mm / ±0.002″) already exceed typical industry benchmarks, while our precision capabilities push to ±0.01mm (±0.0004″) for critical dimensions. This level of control ensures your aluminum plates meet the exacting specifications required for lithographic printing processes.

| Parameter | Standard Tolerance (mm/in) | Precision Tolerance (mm/in) |

|---|---|---|

| Thickness | ±0.05 / ±0.002 | ±0.01 / ±0.0004 |

| Flatness (per 300mm) | 0.05 / 0.002 | 0.01 / 0.0004 |

| Edge Perpendicularity | 0.05 / 0.002 | 0.01 / 0.0004 |

| Surface Finish (Ra) | 1.6 μm | 0.8 μm |

Key Insight: For lithographic applications, flatness and edge squareness are non-negotiable. Our precision tolerances ensure consistent ink transfer and eliminate print artifacts—critical for high-resolution commercial and packaging printing.

Zero Defects Quality Assurance Protocol

Every aluminum plate undergoes multi-stage inspection including:

CMM Verification: 3D coordinate measurement with ±0.001mm accuracy (per ISO 10360-2)

Material Certification: Full traceability from raw material to finished part (ASTM B209, EN 573-3)

Surface Analysis: Laser profilometry for Ra/Rz validation

100% Dimensional Check: For critical features per your engineering drawings

Our ISO 9001-certified quality management system enforces a “zero-defects” philosophy—no part leaves our facility without meeting your specifications. This Olympic-grade precision is not just a promise—it’s our standard.

Your Partner in Precision Manufacturing

We don’t just supply parts—we collaborate. Our engineering team works alongside yours from design review to production, optimizing tolerances for performance and cost-efficiency. With 24/7 customer service and dedicated technical support, we’re always available to ensure your project’s success. At Wuxi Lead, you gain a true manufacturing partner dedicated to your long-term success.

“When your brand is on the line, precision isn’t optional—it’s the foundation of excellence.”

— Wuxi Lead Precision Machinery Engineering Team

Material & Finish Options

Material Selection & Finishes for Aluminum Lithographic Plates

Why Material Choice Matters in Lithographic Applications

In offset lithographic printing, aluminum plates serve as the foundational substrate for high-precision image transfer. The material’s purity, mechanical properties, and surface characteristics directly impact ink adhesion, resolution, and plate longevity. Suboptimal material selection can cause defects like uneven coating, pinholes, or premature wear—resulting in costly production delays and compromised print quality. At Wuxi Lead Precision Machinery, we engineer every component to meet your exact specifications, ensuring seamless integration into your printing workflow.

Optimizing Aluminum Alloys for Print Quality & Durability

Selecting the right alloy balances performance, cost, and manufacturability. Below is a comparison of industry-standard alloys for lithographic applications:

| Alloy | Composition | Anodizing Quality | Typical Use Cases | Cost Impact | Key Performance Benefits |

|---|---|---|---|---|---|

| 1050 | ≥99.5% Al | Excellent (uniform, fine pores) | High-resolution commercial printing, packaging | Medium-High | Superior coating adhesion, minimal defects, optimal for fine-line detail |

| 3003 | Al-1.2%Mn | Good (consistent but slightly coarser) | General commercial printing, signage | Low-Medium | Cost-effective, excellent formability for complex geometries |

| 5052 | Al-2.5%Mg | Good (corrosion-resistant) | Marine environments, outdoor signage | Medium | Enhanced corrosion resistance, stable anodizing performance |

| 6061-T6 | Al-Mg-Si | Moderate (varies with heat treatment) | Specialized industrial applications | Higher | High strength-to-weight ratio; requires additional surface prep for lithography |

💡 Pro Tip: For 95% of lithographic applications, 1050 delivers the best balance of anodizing quality and cost. Its high purity ensures uniform photosensitive coating adhesion, critical for high-resolution printing.

Surface Finish Requirements for Precision Lithography

Surface roughness and flatness directly affect ink transfer accuracy and plate wear. Our ISO 9001-certified processes guarantee tolerances that exceed industry standards:

| Parameter | Standard Tolerance | Tight Tolerance (Premium) | Impact on Lithography Performance |

|---|---|---|---|

| Flatness | ±0.1 mm/m² | ±0.05 mm/m² | Prevents roller misalignment in printing presses; reduces registration errors by 40% |

| Surface Roughness (Ra) | 0.4 µm | 0.2 µm | Ensures uniform photosensitive coating thickness; improves ink transfer resolution by 25% |

| Thickness Tolerance | ±0.05 mm | ±0.02 mm | Eliminates coating thickness variations; critical for multi-color registration |

⚙️ Technical Insight: For high-end commercial printing, we recommend Ra ≤0.2 µm with ±0.05 mm flatness tolerance. This ensures compatibility with UV-curable inks and extends plate life by 30% compared to standard tolerances.

Cost vs. Performance: Strategic Balancing for Your Project

Tighter tolerances and premium alloys increase upfront costs but deliver significant long-term savings:

Standard Tolerances (±0.1 mm flatness, Ra 0.4 µm): Ideal for short-run or low-resolution jobs. Cost-effective but may require frequent plate replacement.

Premium Tolerances (±0.05 mm flatness, Ra 0.2 µm): Reduces rework by 60% and extends plate life by 2–3x. Total cost of ownership (TCO) is 15–20% lower for high-volume production.

Zero-Defect Process: Our ISO 9001-certified workflow includes 100% dimensional inspection and material traceability—eliminating scrap and rework costs before shipment.

💼 Partner Advantage: We collaborate with your engineering team to optimize specifications before production begins. This prevents over-engineering while ensuring performance meets your exact needs.

Wuxi Lead’s Zero Defects Commitment: Your Partner in Precision

At Wuxi Lead Precision Machinery, we don’t just supply parts—we deliver guaranteed performance.

✅ Olympic Quality Standard

Every aluminum lithographic plate undergoes:

Triple-inspection protocols (raw material verification, in-process checks, final dimensional audit)

Full material certification (ASTM B209, ISO 6361) with Mill Test Reports (MTRs) for every batch

24/7 technical support from CNC engineers with 15+ years of lithography experience

✅ ISO 9001-Driven Precision

Material Traceability: Laser-marked serial numbers track every plate from raw material to delivery.

Zero-Defect Guarantee: 99.97% first-pass yield rate across all lithographic plate projects.

Custom Solutions: We adapt to your unique requirements—whether it’s ultra-tight tolerances for fine-line printing or corrosion-resistant alloys for marine environments.

🌍 Why Choose Us?

“We treat your project as our own. From material selection to final delivery, our engineers work alongside yours to eliminate risks and maximize ROI.”

— Wuxi Lead Precision Machinery Engineering Team

Ready to Achieve Zero Defects?

Contact our dedicated engineering team today for a free consultation. We’ll optimize your aluminum lithographic plate specifications—ensuring flawless performance, cost efficiency, and unmatched reliability.

📞 24/7 Support: +86 510 8765 4321 | ✉️ [email protected]

🌐 Visit Our Facility: Wuxi, Jiangsu Province, China (ISO 9001 Certified)

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

Design Analysis & Engineering Validation

At Wuxi Lead Precision Machinery, we treat your design as our blueprint for excellence. Our senior CNC engineers conduct a comprehensive Design for Manufacturability (DFM) analysis, validating critical features against ISO 9001 standards and material specifications. We identify potential issues such as thin walls, tight tolerances, or complex geometries early in the process, providing actionable recommendations to optimize functionality and cost-efficiency. This collaborative engineering phase ensures your part is manufacturable with zero defects from the outset.

“We don’t just review designs—we engineer solutions. Every GD&T specification, material compatibility check, and process validation is aligned with your performance requirements.”

Transparent Pricing & Material Certification

Transparent pricing is non-negotiable. We provide detailed cost breakdowns with full traceability for all materials, including certified mill reports for aluminum alloys (e.g., 6061-T6, 7075-T6 per ASTM B209). Every quote includes precise tolerance specifications and surface finish requirements—no hidden fees, no surprises. Our Zero Defects commitment means pricing reflects rigorous quality controls, not compromise.

| Material Type | Standard Certification | Wuxi Lead Certification | Traceability Level |

|---|---|---|---|

| Aluminum 6061-T6 | ASTM B209 | ASTM B209 + ISO 9001 | Full batch traceability |

| Aluminum 7075-T6 | AMS 4027 | AMS 4027 + EN 573-3 | Laser-etched serial numbers |

| Engineering Plastics | ISO 1043-1 | ISO 1043-1 + RoHS | Batch-specific test reports |

Rapid Prototyping with Zero-Defect Protocols

Our rapid prototyping process is engineered for precision from the first part. Using ISO 9001-certified CNC machines with real-time thermal compensation, we achieve tolerances as tight as ±0.0005″ (±0.013mm)—10x tighter than industry standards. Every prototype undergoes 100% first-article inspection (FAI) using coordinate measuring machines (CMM), with surface finish verified via laser profilometry. This ensures your prototype meets functional requirements before scaling to production.

“Prototypes aren’t compromises—they’re validated proof points. We replicate production-grade quality at the prototype stage to eliminate rework and accelerate time-to-market.”

Mass Production with Olympic Quality Control

Scaling to volume? Our automated production lines integrate Statistical Process Control (SPC) with 24/7 quality monitoring. Defect rates remain below 0.001% through automated optical inspection (AOI) and in-process dimensional checks. With on-time delivery guaranteed by our Just-in-Time logistics network and dedicated customer success managers available around the clock, we deliver Olympic-grade precision at scale.

Precision Performance Metrics

| Quality Metric | Industry Standard | Wuxi Lead Precision | Assurance Method |

|---|---|---|---|

| Dimensional Tolerance (Metal) | ±0.005″ (±0.13mm) | ±0.0005″ (±0.013mm) | CMM Verification, Real-Time SPC |

| Surface Finish (Ra) | 3.2 μm (125 μin) | 0.4 μm (16 μin) | Laser Profilometry, Microscopic Analysis |

| Defect Rate | 0.1% – 0.5% | <0.001% | ISO 9001 Certified QA, 24/7 Monitoring |

Why Partner with Wuxi Lead?

Zero Defects Guarantee: Every part is inspected against your specifications—no exceptions.

Olympic Quality: Precision engineering meeting aerospace, medical, and automotive-grade standards.

24/7 Customer Support: Dedicated engineers and project managers available anytime, anywhere.

“We don’t manufacture parts—we build trust. From your first CAD file to the final shipment, we’re your strategic partner in precision.”

Contact our engineering team today to optimize your aluminum plate machining project with ISO 9001-certified precision and zero-defect delivery.

📞 +86 510 8822 1234 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineered for Your Success

Why Choose Wuxi Lead as Your Manufacturing Partner?

We transcend the role of a mere supplier. As your strategic manufacturing partner, we integrate ISO 9001-certified precision, zero-defect engineering, and proactive collaboration into every project. Here’s how we deliver unmatched value:

Zero Defects Commitment:

Full-process ISO 9001 quality control with in-process statistical process control (SPC), ensuring 100% defect-free parts. Every component undergoes 100% dimensional verification before shipment.

Olympic Quality Standards:

Precision tolerances as tight as ±0.001″ (0.025mm) for aluminum and other metals, with full material traceability (ASTM/AMS certifications). Ideal for aerospace, medical, and semiconductor applications where failure is not an option.

24/7 Customer Service:

Dedicated engineering teams available globally, around the clock. From urgent design revisions to production escalations—we respond within 1 hour, 365 days a year.

Industry-Leading Capabilities Compared

| Feature | Standard Industry Practice | Wuxi Lead Precision Advantage |

|---|---|---|

| Tolerance Control | ±0.005″ (0.13mm) for metal | ±0.001″ (0.025mm) with real-time CNC adaptive compensation |

| Material Certification | Basic mill test reports | Full ISO 9001 traceability + batch-specific chemical/mechanical test reports |

| Quality Assurance | Final inspection only | In-process SPC monitoring + 3D scanning for critical features |

| Technical Support | 9 AM–5 PM local business hours | 24/7 global engineering support with SLA-backed response times |

Ready to Elevate Your Project?

Partner with Wuxi Lead Precision for zero-defect manufacturing that meets your most stringent requirements. We provide free DFM analysis and competitive quotes within 24 hours—no hidden costs, no compromises.

Contact Us Today:

📧 [email protected] | 📞 +86-13961886740

Your vision. Our precision. Delivered.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.