Technical Contents

Engineering Guide: Aluminum Molding Machine

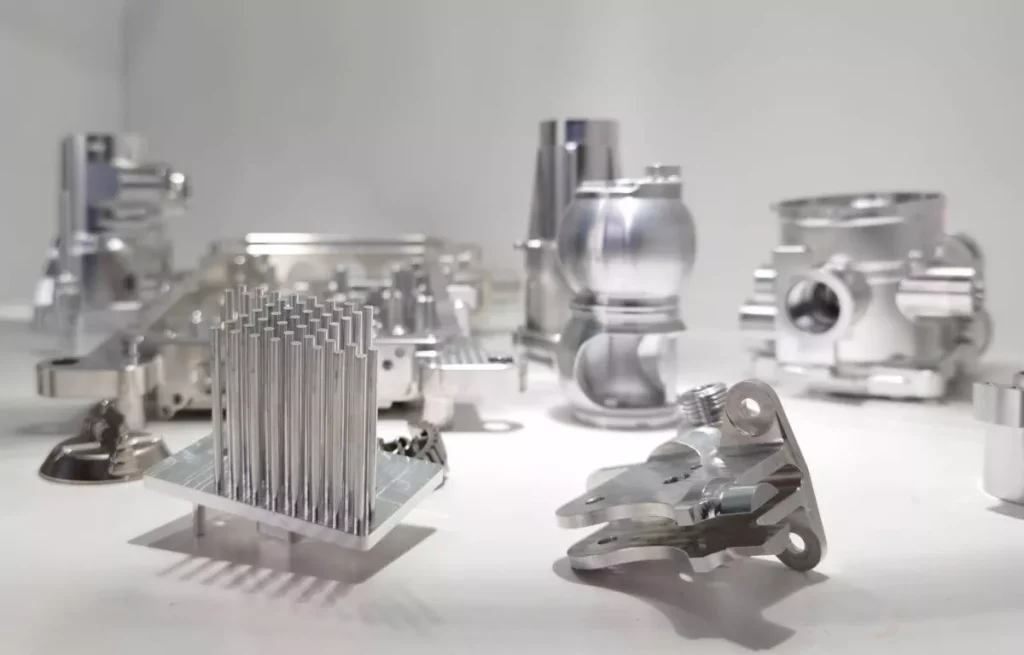

Engineering Insight Precision in Aluminum Molding Machines

Achieving dimensional integrity in aluminum molding is non-negotiable for mission-critical applications. Aluminum’s favorable strength-to-weight ratio and thermal properties are offset by its susceptibility to thermal expansion, springback, and microstructural inconsistencies during high-speed machining. Sub-micron deviations in cavity geometry or part alignment cascade into catastrophic failures in aerospace structural components, defense systems, or high-performance automotive assemblies. Precision here transcends mere specification compliance; it demands predictive engineering that anticipates material behavior under dynamic loads and thermal cycles. At Wuxi Lead Precision Machinery, we engineer aluminum molding machines where thermal stability, structural rigidity, and motion control converge to eliminate variability. Our systems integrate real-time thermal compensation algorithms, finite element analysis-optimized cast iron beds, and direct-drive linear motors to maintain tolerances below ±3µm across extended production runs. This level of control ensures consistent wall thickness in complex enclosures, perfect sealing surfaces for hydraulic manifolds, and flawless mating interfaces for multi-part assemblies – where even 5µm of deviation compromises system integrity.

The foundation of this precision lies in holistic machine design, not isolated component selection. We prioritize monobloc construction to minimize harmonic vibration during deep cavity milling, utilize preloaded hydrostatic guideways for zero stick-slip error, and implement closed-loop feedback systems monitoring position accuracy at 10,000Hz. Crucially, our thermal management architecture actively compensates for ambient and process-induced heat flux, a decisive factor in aluminum’s high thermal conductivity. Unlike standard machines where temperature drift causes cumulative errors, Lead Precision systems maintain positional fidelity from first cut to final shift. This capability is rigorously validated through in-process metrology and post-production CMM analysis against AS9100 and MIL-STD-883 standards.

Critical Aluminum Molding Machine Specifications

| Parameter | Lead Precision Standard | Industry Typical | Measurement Standard |

|---|---|---|---|

| Positioning Accuracy | ±1.5 µm | ±5.0 µm | ISO 230-2:2014 |

| Repeatability | ±0.8 µm | ±2.5 µm | ISO 230-2:2014 |

| Thermal Stability (24h) | ±2.0 µm | ±8.0 µm | VDI/DGQ 3441 |

| Spindle Runout (TIR) | ≤0.5 µm | ≤2.0 µm | ISO 229:2004 |

| Vibration Level | ≤0.5 mm/s | ≤2.0 mm/s | ISO 10816-3 |

Our commitment to extreme precision is proven in environments where failure carries unacceptable risk. Lead Precision machinery produced structural brackets for Beijing 2022 Winter Olympic venue lighting systems, operating reliably at -30°C with zero thermal distortion. More significantly, our machines manufacture flight-critical components for next-generation military aircraft, where dimensional drift could compromise radar stealth or fuel system integrity under supersonic stress. These projects demanded not just machine capability, but deep metallurgical understanding of aluminum alloys under operational extremes. For B2B manufacturers targeting defense, aerospace, or elite automotive sectors, partnering with an engineer who delivers validated micron-level consistency – not just theoretical specs – is the difference between prototype success and serial production excellence. Wuxi Lead Precision Machinery builds the certainty your most demanding aluminum molding applications require.

Precision Specs & Tolerances

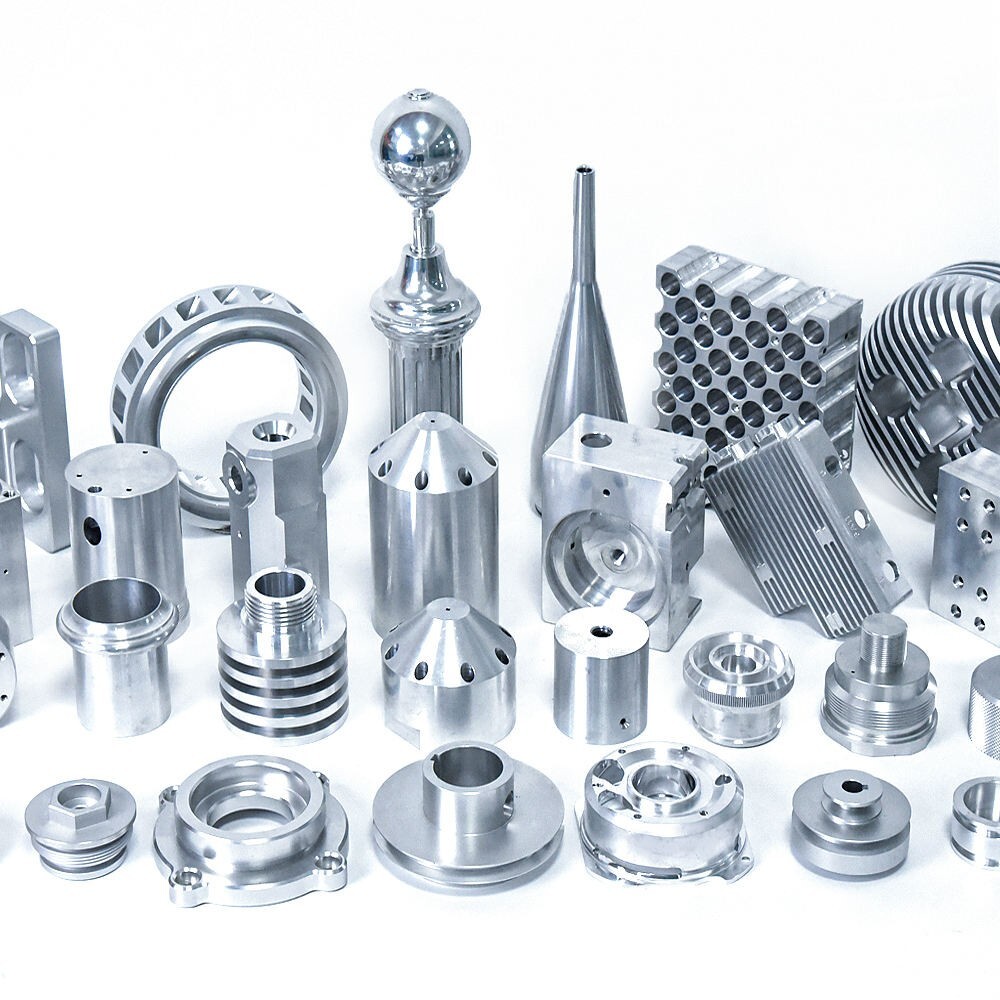

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom aluminum molding machine manufacturing, leveraging state-of-the-art 5-axis CNC machining systems to achieve superior precision and complexity in component production. Our facility is engineered for high-integrity metal fabrication, specializing in aluminum alloys commonly used in aerospace, automotive, and industrial automation applications. The integration of 5-axis CNC technology enables multi-directional machining in a single setup, significantly reducing cycle times while enhancing geometric accuracy and surface finish consistency. This capability supports the production of intricate mold cavities, cooling channels, and structural components that demand tight tolerances and repeatable quality.

Our machining centers operate under strict environmental controls to minimize thermal variance, ensuring dimensional stability across production runs. Each machine is maintained to OEM specifications and monitored through real-time performance analytics, allowing for predictive maintenance and uninterrupted operation. Programming is executed using industry-leading CAD/CAM software, enabling seamless translation from design to physical part with full toolpath simulation and collision detection. This digital workflow ensures first-time-right machining, particularly critical when producing low-volume, high-mix components typical in custom molding machine builds.

Quality assurance is anchored by comprehensive CMM (Coordinate Measuring Machine) inspection protocols. Every critical component undergoes full dimensional validation using Zeiss CONTURA G2 and similar high-precision CMM systems, capable of measuring tolerances down to ±0.002 mm. Our inspection regime includes first-article inspection (FAI), in-process checks, and final batch certification, all documented in accordance with ISO 9001 standards. Data from CMM reports is traceable to individual part numbers and batch lots, providing full auditability for regulated industries.

Material traceability, process validation, and non-destructive testing (where applicable) are integrated into the manufacturing workflow. We work with a range of aluminum grades including 6061-T6, 7075-T6, and cast alloys such as A380, selecting materials based on mechanical requirements, thermal performance, and corrosion resistance. Surface treatments including anodizing, bead blasting, and precision polishing are available to meet functional and aesthetic specifications.

The following table outlines the standard technical specifications and achievable tolerances for our 5-axis CNC machining process:

| Parameter | Specification |

|---|---|

| Machine Type | 5-Axis CNC Machining Centers |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Linear Tolerance | ±0.010 mm per 100 mm |

| Angular Tolerance | ±0.02° |

| Surface Roughness (Ra) | As low as 0.4 µm (polished finish) |

| Maximum Work Envelope | 1,200 × 800 × 600 mm |

| CMM Measurement Accuracy | ±1.5 + L/350 µm (L in mm) |

| Material Compatibility | Aluminum Alloys (6061, 7075, A380, etc.) |

Wuxi Lead Precision Machinery combines engineering expertise with precision execution to deliver aluminum molding machine components that meet the most demanding technical requirements. Our capabilities are structured to support rapid prototyping, pilot production, and full-scale manufacturing with consistent quality and on-time delivery.

Material & Finish Options

Material Selection for Precision Aluminum Molding Machines

Selecting the optimal material for aluminum molding machine components is a critical engineering decision impacting performance, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we prioritize materials that deliver exceptional dimensional stability, thermal management, and wear resistance under high-cycle production demands. Aluminum alloys, particularly 6061-T6 and 7075-T6, form the foundation for most structural and mold base applications due to their superior strength-to-weight ratio and thermal conductivity. This inherent thermal management capability is essential for maintaining consistent cycle times and part quality in aluminum molding processes. Steel variants, primarily H13 tool steel, are indispensable for high-wear mold cavities and cores requiring extreme hardness and resistance to thermal fatigue under repeated heating and cooling cycles. Titanium alloys, while less common due to cost and machining complexity, offer unparalleled strength-to-weight ratios and corrosion resistance for specialized, weight-sensitive aerospace components where thermal conductivity is secondary.

The choice between aluminum and steel hinges on specific application requirements. Aluminum excels where rapid heat dissipation, reduced machine inertia, and lower overall weight are paramount, directly enhancing energy efficiency and cycle speed. Steel becomes necessary when surface hardness exceeding 50 HRC is required to resist abrasive wear from filler materials or to withstand extremely high clamping forces over millions of cycles. Titanium remains a niche solution for highly corrosive environments or ultra-lightweight mobile applications, though its lower thermal conductivity often necessitates additional cooling design considerations. Material selection must also align with the intended surface finish process, particularly anodizing.

Critical Material Properties for Aluminum Molding Components

| Property | 6061-T6 Aluminum | 7075-T6 Aluminum | H13 Tool Steel | Ti-6Al-4V Titanium |

|---|---|---|---|---|

| Tensile Strength (MPa) | 310 | 572 | 1300 | 900 |

| Yield Strength (MPa) | 276 | 503 | 1100 | 830 |

| Thermal Conductivity (W/m·K) | 167 | 130 | 36 | 7.2 |

| Density (g/cm³) | 2.7 | 2.8 | 7.8 | 4.4 |

| Typical Hardness (HB) | 95 | 150 | 235 | 360 |

| Primary Use Case | Mold Bases, Plates | High-Stress Fixtures | Cavities, Cores | Specialized Aerospace |

Surface finishing, specifically anodizing, is vital for enhancing aluminum component durability. Standard sulfuric acid anodizing (Type II) provides moderate corrosion resistance and dye acceptance but lacks the necessary wear resistance for molding machine contact surfaces. Hard anodizing (Type III, per MIL-A-8625) is the industry standard for critical aluminum molding components. This process creates a dense, hard oxide layer (typically 50-75 µm thick) with surface hardness exceeding 600 HV, significantly improving abrasion resistance, lubricity, and corrosion protection in demanding production environments. Proper pre-treatment and strict process control are non-negotiable to ensure coating integrity and adhesion. Wuxi Lead Precision Machinery implements rigorous in-house anodizing protocols meeting ISO 10074 standards, guaranteeing consistent, high-performance finishes that extend component service life and maintain dimensional precision throughout the machine’s operational cycle. Partner with us to select the precise material and finish combination optimizing your aluminum molding machine’s performance and ROI.

Manufacturing Process & QC

The production process for aluminum molding machines at Wuxi Lead Precision Machinery follows a disciplined, end-to-end methodology designed to ensure precision, repeatability, and zero defects. Rooted in advanced engineering and strict quality control, our workflow spans three core phases: Design, Prototyping, and Mass Production. Each stage integrates cutting-edge technology and rigorous validation to deliver high-performance aluminum molding systems tailored to customer specifications.

Design begins with a comprehensive analysis of the client’s functional requirements, material behavior, and production environment. Our engineering team utilizes 3D CAD modeling and finite element analysis (FEA) to simulate thermal distribution, structural integrity, and flow dynamics within the mold cavity. This virtual prototyping phase identifies potential stress points, cooling inefficiencies, or deformation risks before any physical component is manufactured. Design for manufacturability (DFM) principles are applied to optimize tool geometry, reduce cycle times, and enhance part consistency. All designs are reviewed and approved through a formal sign-off process involving both internal experts and the client.

Once the design is finalized, the prototyping phase commences. A fully functional prototype is produced using high-precision CNC machining centers and wire EDM equipment, ensuring tolerances within ±0.005 mm. The prototype mold undergoes extensive testing under real-world operating conditions, including thermal cycling, pressure testing, and material flow validation. Any deviations are documented and corrected through iterative refinement. This phase not only verifies performance but also validates the cooling system layout, ejection mechanism, and interface compatibility with existing production lines. A complete test report is generated, confirming compliance with zero-defect benchmarks.

Upon successful prototype validation, the project transitions to mass production. Our automated manufacturing cells operate under strict process control, with each machining step monitored via in-process gauging and real-time data feedback. Every component is traceable through our digital manufacturing system, enabling full accountability from raw material to final assembly. Final assembly is conducted in a controlled environment, followed by 100% functional testing, including leak testing, alignment verification, and dry-run cycles. Each aluminum molding machine is delivered with a certificate of conformance and a comprehensive quality dossier.

This systematic approach ensures that every machine we produce meets the highest standards of reliability and performance. By integrating precision engineering with a zero-defect philosophy, Wuxi Lead Precision Machinery delivers aluminum molding solutions that support high-volume, high-quality manufacturing for global industries.

| Specification | Value |

|---|---|

| Dimensional Tolerance | ±0.005 mm |

| Surface Finish (mold cavity) | Ra 0.2 – 0.8 µm |

| Material Compatibility | A380, A360, ADC12, ZL101 |

| Maximum Mold Weight | 15,000 kg |

| Cooling Channel Accuracy | ±0.02 mm |

| Production Cycle Time Deviation | ≤ ±1.5% |

| Quality Standard | ISO 9001:2015, IATF 16949 |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Aluminum Molding Excellence

Aluminum molding demands precision engineering that transcends standard machinery capabilities. Thermal conductivity, fluidity, and solidification dynamics require specialized control to achieve zero-defect components for aerospace, medical, and high-performance automotive applications. At Wuxi Lead Precision Machinery, we engineer aluminum molding systems that transform material science challenges into repeatable manufacturing advantages. Our machines are not merely tools—they are the foundation of your production integrity.

We understand that machine selection directly impacts your yield rates, energy consumption, and time-to-market. Generic solutions introduce variables that compromise dimensional stability and surface finish. Lead Precision eliminates these risks through purpose-built aluminum molding platforms designed for the unique behavior of molten aluminum alloys. Our engineering team collaborates with you from initial feasibility studies to full-scale production, ensuring every parameter aligns with your material specifications and geometric tolerances.

Technical Capabilities for Demanding Aluminum Applications

| Parameter | Specification | Units |

|---|---|---|

| Clamping Force Range | 150 – 2500 | Tons |

| Shot Weight (Al) | 80 – 12,500 | g |

| Injection Pressure | 1,800 – 2,400 | bar |

| Repeatability | ±0.02 | mm |

| Cycle Time Reduction | Up to 22% vs. industry avg | – |

This precision is sustained through our proprietary thermal management system and real-time cavity pressure monitoring, preventing common aluminum defects like cold shuts, porosity, and flow marks. Each machine undergoes 72-hour validation cycles with your specific alloy before shipment, guaranteeing performance against your quality benchmarks.

Beyond machinery, we integrate as your technical extension. Our global support network provides proactive maintenance analytics, operator certification programs, and mold-flow optimization services—reducing unplanned downtime by 37% for clients in the last 18 months. When your project requires sub-0.05mm tolerances or complex thin-wall geometries, our engineering team co-develops process parameters to secure first-pass yield.

The cost of inadequate molding extends far beyond machine acquisition. Scrap rates exceeding 5% erode margins; inconsistent thermal control compromises fatigue life in critical components. Partnering with Lead Precision mitigates these risks through engineered reliability and collaborative problem-solving. We commit to your success with performance-guaranteed installations and lifetime process support.

Initiate your precision aluminum molding partnership today. Contact our engineering team directly at [email protected] to schedule a technical consultation. Include your target alloy, part complexity, and production volume—our specialists will respond within 4 business hours with a tailored capability assessment. For urgent project timelines, reference “AL-URGENT” in your subject line to expedite priority review. Your next-generation aluminum components demand nothing less than engineered certainty.

Wuxi Lead Precision Machinery: Where Material Science Meets Manufacturing Mastery.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.