Technical Contents

Engineering Guide: Aluminum Laser Cutting Service

Engineering Insight: Precision in Aluminum Laser Cutting Services

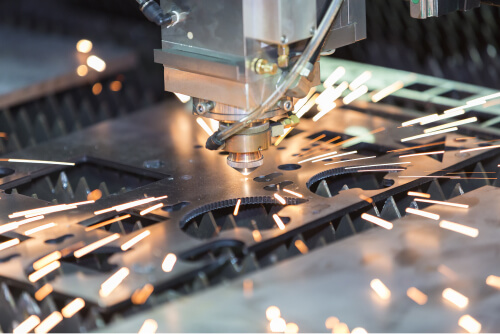

Aluminum laser cutting is a cornerstone of modern sheet metal fabrication, particularly in industries where dimensional accuracy, edge quality, and material integrity are non-negotiable. At Wuxi Lead Precision Machinery, we recognize that precision is not merely a performance metric—it is the foundation of reliability, repeatability, and long-term value in high-stakes manufacturing environments. Our advanced fiber laser technology, combined with decades of engineering expertise, ensures that every aluminum component we produce meets the most stringent tolerances demanded by aerospace, defense, and high-performance industrial sectors.

Aluminum, while highly machinable, presents unique challenges in laser processing. Its high thermal conductivity and reflectivity require precise control over laser parameters to avoid issues such as dross formation, warping, or inconsistent kerf widths. Standard cutting methods often fail to maintain edge squareness or surface consistency, especially in thin-gauge or complex geometries. At Lead Precision, our laser systems are calibrated for optimal beam focus, pulse frequency, and assist gas dynamics—specifically tuned for aluminum alloys such as 5052, 6061, and 7075. This ensures clean, burr-free cuts with minimal post-processing, reducing lead times and enhancing part functionality.

Precision extends beyond the cutting process. Our in-house quality assurance system incorporates real-time monitoring, automated inspection via CMM (Coordinate Measuring Machine), and strict adherence to ISO 9001 standards. Every job undergoes a full dimensional verification protocol, ensuring that tolerances are maintained within ±0.05 mm for critical features. This level of control is essential for clients in military and Olympic-grade equipment manufacturing, where our components have been trusted for structural integrity and performance under extreme conditions.

Our experience supplying precision parts for Olympic infrastructure projects and defense applications has reinforced the necessity of zero-defect manufacturing. These projects demand not only technical excellence but also full traceability, material certification, and rapid scalability—capabilities embedded in our operational DNA.

The following table outlines key technical specifications for our aluminum laser cutting services:

| Parameter | Specification |

|---|---|

| Laser Type | High-Power Fiber Laser (IPG Photonics) |

| Max Cutting Thickness | 25 mm (for aluminum) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Minimum Feature Size | 0.8 mm (holes, slots) |

| Edge Roughness (Ra) | ≤ 3.2 µm |

| Tolerance (Standard) | ±0.05 mm |

| Supported Alloys | 5052, 5083, 6061, 7075, etc. |

| Lead Time (Prototype) | 3–7 days |

| Quality Standard | ISO 9001:2015, MIL-STD-1312 (aerospace) |

At Wuxi Lead Precision Machinery, we do not simply cut aluminum—we engineer precision. Our commitment to excellence ensures that every component we deliver performs flawlessly in the field, meeting the exacting standards of the world’s most demanding industries.

Precision Specs & Tolerances

Technical Capabilities: Precision Aluminum Laser Cutting

Wuxi Lead Precision Machinery delivers exceptional aluminum laser cutting services engineered for the most demanding high-end manufacturing applications. Aluminum presents unique processing challenges due to its high thermal conductivity, reflectivity, and susceptibility to thermal distortion. Our advanced technical infrastructure is specifically optimized to overcome these hurdles, ensuring consistent part integrity, dimensional accuracy, and superior edge quality essential for aerospace, medical, and semiconductor industries.

Our core capability centers on state-of-the-art 5-axis CNC fiber laser cutting systems. These platforms provide unparalleled flexibility for processing complex 3D geometries and intricate contours directly from solid billet or pre-formed sheet, eliminating the need for multiple setups and minimizing cumulative error. The integrated 5-axis motion control precisely manages the laser head orientation relative to the workpiece surface across all angles, enabling accurate cutting of bevels, undercuts, and compound curves inherent in sophisticated aluminum components. High-power fiber lasers deliver exceptional energy density for clean, dross-free cuts even in thicker aluminum alloys, while advanced beam control and adaptive focus optics ensure high-fidelity edge quality and minimal heat-affected zones. Comprehensive thermal management protocols are rigorously applied to mitigate warpage and maintain material properties.

Quality assurance is non-negotiable. Every critical aluminum component undergoes 100% dimensional validation using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection process adheres strictly to ISO 10360 standards, utilizing certified probes and sophisticated metrology software to verify complex profiles, hole patterns, and critical features against the original CAD model. This generates fully traceable digital inspection reports, providing clients with unequivocal proof of conformance to specified tolerances. First-article inspection reports and in-process checks are standard practice for all production runs, ensuring continuous process stability and adherence to stringent quality requirements.

The following table details our standard achievable tolerances for aluminum laser cutting, reflecting our commitment to precision engineering. These values represent typical performance under controlled production conditions using optimized parameters for common aluminum alloys (e.g., 6061-T6, 5052-H32).

| Material Thickness Range | Linear Dimensional Tolerance | Angular Tolerance | Surface Roughness (Ra) |

|---|---|---|---|

| 0.5 mm – 3.0 mm | ± 0.05 mm | ± 0.1° | ≤ 1.6 μm |

| 3.1 mm – 6.0 mm | ± 0.08 mm | ± 0.15° | ≤ 2.5 μm |

| 6.1 mm – 12.0 mm | ± 0.10 mm | ± 0.2° | ≤ 3.2 μm |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis laser technology with rigorous, metrology-grade quality control to transform aluminum into precision components meeting the exacting demands of advanced manufacturing. Our process ensures repeatability, reliability, and full documentation for every part shipped.

Material & Finish Options

When selecting materials for precision laser cutting in sheet metal fabrication, understanding the mechanical, thermal, and chemical properties of aluminum, steel, and titanium is essential for achieving optimal performance, cost-efficiency, and longevity in end-use applications. Each material offers distinct advantages depending on the operational demands, environmental exposure, and design specifications of the final component.

Aluminum is a preferred choice in aerospace, electronics, and transportation industries due to its high strength-to-weight ratio, excellent thermal and electrical conductivity, and inherent corrosion resistance. Its non-magnetic nature makes it ideal for sensitive electronic enclosures and RF shielding applications. When processed using high-precision fiber laser cutting, aluminum sheets up to 25 mm in thickness can be cut with tight tolerances and clean edges, minimizing post-processing requirements. However, aluminum’s high reflectivity and thermal conductivity demand specialized laser parameters and assist gases to ensure consistent cut quality.

Steel, particularly low-carbon and stainless variants, remains a staple in industrial and structural applications. Mild steel offers high tensile strength and weldability, making it suitable for chassis, brackets, and machinery frames. Stainless steel, especially grades 304 and 316, provides superior corrosion resistance and aesthetic appeal, often used in medical devices and food processing equipment. Laser cutting steel allows for intricate geometries and burr-free edges, especially when using nitrogen or oxygen as assist gases depending on the desired surface finish.

Titanium is reserved for high-performance environments such as aerospace, defense, and medical implants. It exhibits exceptional strength-to-density ratio, outstanding corrosion resistance, and biocompatibility. While more challenging to laser cut due to its reactivity at high temperatures, modern CNC-controlled fiber lasers with inert gas shielding can produce precise cuts in titanium sheets up to 15 mm. Special handling and contamination control are required to maintain material integrity.

Post-processing finishes further enhance material performance, with anodizing being particularly critical for aluminum components. Anodizing creates a durable, non-conductive oxide layer that improves wear and corrosion resistance while allowing for color coding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are commonly specified, with Type III offering thicker, more abrasion-resistant coatings for demanding environments.

The following table summarizes key material specifications relevant to laser cutting:

| Material | Typical Thickness Range (mm) | Tensile Strength (MPa) | Common Grades | Max Cutting Power (kW) | Recommended Assist Gas |

|---|---|---|---|---|---|

| Aluminum | 0.5 – 25 | 70 – 570 | 5052, 6061, 7075 | 6 | Nitrogen |

| Mild Steel | 0.8 – 30 | 370 – 500 | Q235, SS400 | 8 | Oxygen / Nitrogen |

| Stainless Steel | 0.8 – 25 | 515 – 860 | 304, 316 | 6 | Nitrogen |

| Titanium | 0.8 – 15 | 900 – 1100 | Gr2, Gr5 (Ti-6Al-4V) | 6 | Argon (with shielding) |

Selecting the appropriate material and finish requires alignment between design intent, production capabilities, and environmental conditions. At Wuxi Lead Precision Machinery, our advanced laser systems and metallurgical expertise ensure precise, repeatable results across all major engineering metals.

Manufacturing Process & QC

Aluminum Laser Cutting: Precision Production Process from Design to Zero-Defect Delivery

Achieving flawless aluminum components demands a rigorously controlled production sequence, not merely machine operation. At Wuxi Lead Precision Machinery, our integrated process for aluminum laser cutting services begins with collaborative design validation. We conduct thorough Design for Manufacturability (DFM) analysis on client CAD files, identifying potential thermal distortion risks, kerf width implications, and optimal nesting strategies specific to aluminum alloys. This critical step ensures designs are not just feasible but inherently optimized for precision cutting, minimizing waste and maximizing structural integrity from the outset. Material certification verification is mandatory, confirming alloy grade, temper, and surface condition meet stringent aerospace or medical specifications before any laser engages the sheet.

Prototyping serves as the definitive process validation phase, not merely a sample run. Utilizing the exact production-grade fiber laser systems and identical material batches intended for volume, we produce functional prototypes under full production parameters. Every cut edge undergoes microscopic inspection for dross formation, heat-affected zone (HAZ) control, and dimensional fidelity against the validated CAD model using CMM and optical comparators. Any deviation triggers immediate root cause analysis and parameter refinement. This phase is non-negotiable for complex geometries or tight-tolerance applications, proving the process capability before committing to mass production.

Mass production executes under our Zero Defects Manufacturing (ZDM) framework. Real-time process monitoring tracks laser power, gas pressure, focus position, and cutting speed for every contour, with AI-driven analytics flagging micro-variations before they impact quality. Automated in-process inspection stations verify critical dimensions at predefined intervals, feeding data directly into our Statistical Process Control (SPC) system. Material handling utilizes non-marring fixtures to prevent surface scratches, while climate-controlled environments stabilize the aluminum substrate. Final inspection is 100% dimensional verification against the original CAD, coupled with rigorous first-article reporting and full traceability from raw material heat number to finished part. Defects are not corrected; they are prevented through systemic control.

Our technical capabilities for aluminum laser cutting are engineered to support this uncompromising process:

| Parameter | Capability | Typical Tolerance |

|---|---|---|

| Material Thickness | 0.5 mm – 12 mm | ±0.05 mm |

| Laser Type | IPG Photonics Fiber Laser | |

| Max. Work Area | 3000 mm x 1500 mm | |

| Positioning Acc. | ±0.03 mm/m | |

| Edge Quality | Burr-free, minimal HAZ (Ra < 3.2 µm) | |

| Nesting Efficiency | > 95% material utilization |

This seamless transition from validated design through rigorously proven prototyping to monitored mass production, governed by ZDM principles, is how Wuxi Lead delivers production-ready aluminum components with absolute reliability. We transform specifications into guaranteed outcomes, eliminating rework and supply chain disruption for your critical applications.

Why Choose Wuxi Lead Precision

When it comes to precision manufacturing in the modern industrial landscape, the integration of advanced technology and engineering expertise defines success. At Wuxi Lead Precision Machinery, we specialize in high-accuracy aluminum laser cutting services tailored for industries demanding uncompromised quality, repeatability, and speed. As a trusted partner in sheet metal fabrication, we combine state-of-the-art fiber laser systems with decades of engineering experience to deliver components that meet exacting specifications.

Our facility in Wuxi, China, is equipped with high-power laser cutting platforms capable of processing aluminum sheets with exceptional edge quality and dimensional accuracy. Whether you require intricate geometries for aerospace components, enclosures for high-end electronics, or structural elements for transportation systems, our process ensures clean cuts, minimal thermal distortion, and superior surface finish—critical for downstream operations such as welding, anodizing, or assembly.

Partnering with Wuxi Lead Precision Machinery means gaining access to a vertically integrated manufacturing ecosystem. From initial design consultation and material sourcing to precision cutting, bending, welding, and finishing, we manage every stage under one roof. This integrated approach reduces lead times, enhances quality control, and provides full traceability—essential for clients in regulated industries such as medical devices, renewable energy, and advanced automation.

Our commitment to operational excellence is reflected in our certifications and process controls. We adhere to international quality standards, with rigorous in-process inspections and final product validation using coordinate measuring machines (CMM) and optical profiling systems. Every aluminum component we produce is verified for conformance to your technical drawings and tolerance requirements.

Below are the key technical specifications of our aluminum laser cutting service:

| Parameter | Specification |

|---|---|

| Material | Aluminum Alloys (e.g., 5052, 6061, 7075) |

| Thickness Range | 0.5 mm – 25 mm |

| Maximum Cutting Area | 1500 mm × 3000 mm |

| Laser Source | IPG/Trumpf Fiber Laser, up to 12 kW |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Edge Quality | Burr-free, minimal dross, Ra < 6.3 μm |

| Lead Time (Standard) | 5–10 working days (varies by order complexity) |

| Finishing Options | Deburring, cleaning, protective film application |

We understand that your projects demand more than just cutting—they require a strategic manufacturing partner who anticipates challenges, ensures scalability, and maintains consistent quality across production runs. Our engineering team works closely with clients worldwide to optimize designs for manufacturability, reduce material waste, and accelerate time-to-market.

For precision you can rely on and service you can trust, contact us today. Send your drawings and project requirements to [email protected] and let Wuxi Lead Precision Machinery become your preferred partner in aluminum fabrication.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.