Technical Contents

Engineering Guide: Aluminum Injection Molding Machine

Engineering Insight: Precision Imperatives in Aluminum Injection Molding

Achieving consistent, high-integrity aluminum components through injection molding demands uncompromising precision at every process stage. Unlike plastics, molten aluminum operates at significantly higher temperatures (600-750°C) and exerts immense pressure on tooling. Minute deviations in thermal control, injection velocity, or clamping force directly manifest as critical defects: internal porosity from turbulent flow, dimensional instability due to uneven cooling, or flash from mold separation. These flaws are unacceptable in mission-critical applications where structural integrity and weight savings are paramount. Precision engineering isn’t merely desirable; it is the foundational requirement for viable aluminum injection molding, governing yield rates, component lifespan, and ultimately, total production economics. Thermal equilibrium deviations exceeding ±2°C during the cycle induce micro-shrinkage, while platen parallelism errors greater than 0.03mm/m translate directly into wall thickness variations that compromise fatigue resistance.

Wuxi Lead Precision Machinery has dedicated over 15 years to mastering these exacting demands within the custom metal manufacturing sector. Our engineering philosophy centers on systemic precision – integrating advanced hydraulic and servo-electric drive technologies with real-time process monitoring to maintain control within micron-level tolerances. This expertise is rigorously validated through production of components for Olympic-standard sporting equipment requiring perfect weight distribution and aerodynamic consistency, alongside critical subsystems for national defense applications where failure is not an option. These projects demand adherence to AS9100 aerospace standards and MIL-STD-883 testing protocols, proving our machines’ capability to deliver repeatable quality under the most stringent scrutiny. Our experience demonstrates that initial investment in precision engineering yields substantial long-term savings through reduced scrap, minimized secondary operations, and extended tooling life.

The core specifications defining a high-precision aluminum injection molding platform are non-negotiable. Below are the critical parameters our engineered solutions consistently achieve for demanding applications:

| Parameter | Specification Range | Critical Tolerance | Significance for Aluminum |

|---|---|---|---|

| Clamping Force | 800 – 6500 Tons | ±1% | Prevents mold flash under high injection pressure |

| Maximum Shot Weight | 150 – 2500 kg (Al) | ±0.5% | Ensures consistent fill and density |

| Platen Size (H x V) | 1200 x 1200 – 2800 x 2800 mm | Parallelism ≤ 0.03mm/m | Maintains uniform cavity pressure |

| Injection Pressure | Up to 1800 bar | ±2 bar | Controls metal flow front stability |

| Barrel Temperature Control | 600 – 750°C | ±1.5°C | Prevents material degradation & cold shots |

| Cycle Time Repeatability | Standard Cycle | ±0.2 seconds | Guarantees consistent cooling & properties |

True precision transcends individual specifications; it resides in the harmonious integration of all machine subsystems and the intelligence to adapt dynamically to material behavior. At Wuxi Lead Precision Machinery, we engineer not just machines, but complete process solutions where micron-level control is embedded from design through production, ensuring your most demanding aluminum components meet the highest standards of performance and reliability. This is the precision demanded by innovation.

Precision Specs & Tolerances

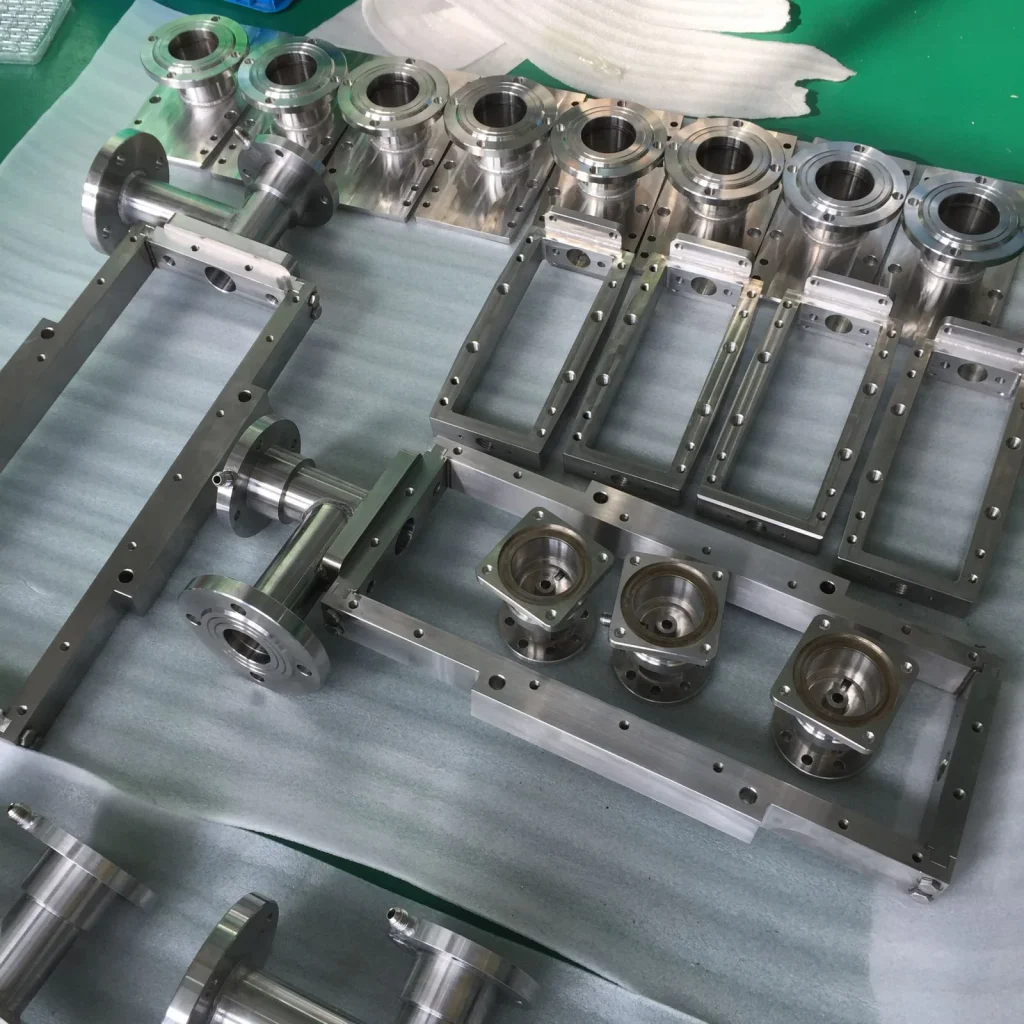

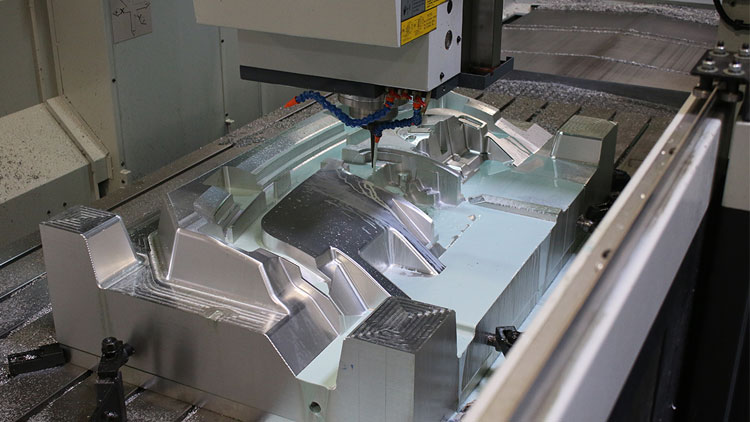

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision aluminum injection molding machine components. Our engineering expertise is built upon a foundation of state-of-the-art equipment, rigorous quality control, and a deep understanding of the demanding requirements in aerospace, automotive, and industrial automation sectors. At the core of our production capacity is our fleet of 5-axis CNC machining centers, which enable complex geometry processing with exceptional accuracy and surface finish. These machines support simultaneous multi-axis movement, allowing us to manufacture intricate molds, housings, and structural elements in a single setup, minimizing cumulative error and significantly reducing lead times.

Our 5-axis CNC systems are programmed using the latest CAM software, ensuring optimal toolpaths and material efficiency. This capability is particularly critical when machining aluminum alloys commonly used in injection molding applications, where thermal stability, dimensional consistency, and fatigue resistance are paramount. We handle a wide range of aluminum grades, including 6061, 7075, and A380, tailoring material selection and machining parameters to meet specific performance criteria. High-speed machining techniques combined with precision coolant delivery ensure minimal thermal distortion and superior edge definition, essential for mold components requiring fine detail and long service life.

Quality assurance is integral to every stage of production. Each component undergoes comprehensive inspection using a coordinate measuring machine (CMM) to verify dimensional accuracy against design specifications. Our CMM system operates with sub-micron resolution, capable of validating complex geometries, positional tolerances, and surface profiles with repeatable precision. All inspection data is documented and traceable, supporting full compliance with ISO 9001 standards and customer-specific quality requirements. In addition to CMM inspection, we employ surface roughness testers, optical comparators, and first-article inspection reports to ensure consistency across production runs.

The following table outlines the standard technical tolerances we consistently achieve and certify for aluminum injection molding machine components:

| Feature | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.03 mm | ±0.015 mm |

| Flatness | 0.02 mm per 100 mm | 0.01 mm per 100 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Hole Diameter | ±0.02 mm | ±0.01 mm |

| Angular Accuracy | ±0.1° | ±0.05° |

These capabilities reflect our commitment to delivering components that meet the exacting demands of high-performance aluminum injection molding systems. Wuxi Lead Precision Machinery combines advanced technology with disciplined process control to ensure every part performs reliably in critical applications.

Material & Finish Options

Material Selection for Aluminum Die Casting Systems

Clarifying terminology is essential: aluminum injection molding is commonly misstated. The correct industrial process is aluminum die casting, where molten aluminum is injected under high pressure into precision steel molds. Material selection for both the cast parts and the mold tooling directly impacts performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we prioritize materials that balance thermal conductivity, strength, and manufacturability for high-volume production.

Aluminum alloys dominate structural components due to their optimal strength-to-weight ratio and thermal properties. A380 offers excellent fluidity and pressure tightness for complex geometries, while A360 provides superior corrosion resistance and dimensional stability for aerospace or medical applications. Both alloys enable rapid heat dissipation during cycling, reducing cycle times by 15–20% compared to heavier metals. Critical considerations include avoiding copper-rich alloys (e.g., A390) for thin-walled parts due to reduced ductility and increased hot tearing risk.

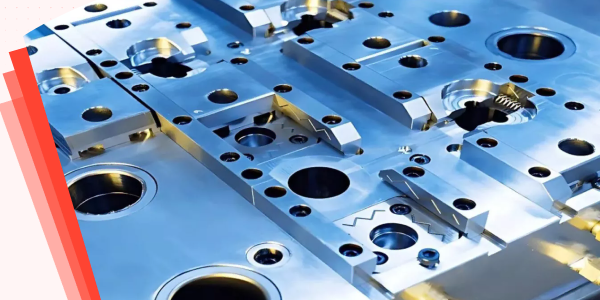

For mold tooling, H13 tool steel remains the industry standard, enduring 100,000+ cycles under 600°C molten aluminum exposure. Its chromium content resists soldering and thermal fatigue. Titanium alloys like Grade 5 (Ti-6Al-4V) are reserved for extreme-wear inserts in high-cavitation zones, leveraging 880 MPa tensile strength and exceptional erosion resistance—though costs are 3–5× higher than H13. Steel molds require precise heat treatment (48–52 HRC) to prevent deformation, while titanium demands specialized welding protocols.

Surface finishes significantly enhance part functionality. Type II (sulfuric acid) anodizing delivers 5–25 µm coatings for standard corrosion resistance and dye compatibility. For aerospace or marine applications, Type III (hardcoat) anodizing achieves 50+ µm thickness with 600 HV hardness, providing abrasion resistance equal to tool steel. Note that anodizing requires uniform wall thickness to prevent current density variations; thin sections (<1.5mm) may need secondary plating.

Material performance is quantified below for critical decision factors:

| Material | Tensile Strength (MPa) | Max Operating Temp (°C) | Thermal Conductivity (W/m·K) | Primary Application | Key Limitation |

|---|---|---|---|---|---|

| Aluminum A380 | 324 | 350 | 96 | Enclosures, brackets | Moderate corrosion resistance |

| Aluminum A360 | 269 | 350 | 105 | Precision housings | Lower fluidity vs. A380 |

| H13 Tool Steel | 1,650 | 600 | 36 | Mold cavities, cores | Susceptible to thermal shock |

| Titanium Grade 5 | 880 | 400 | 7.2 | Erosion-prone inserts | High cost, complex machining |

Selecting the right material requires analyzing part geometry, production volume, and environmental exposure. Wuxi Lead Precision Machinery engineers validate material compatibility through thermal simulation and mold-flow analysis, ensuring your die casting system achieves 95%+ first-pass yield. Partner with us to optimize your material strategy—reducing scrap rates while meeting stringent industry certifications.

Manufacturing Process & QC

The production process for aluminum injection molding at Wuxi Lead Precision Machinery follows a rigorous, three-phase methodology—Design, Prototyping, and Mass Production—engineered to deliver zero-defect performance in high-volume, precision metal manufacturing. Each stage is tightly integrated with advanced simulation, metrology, and process control systems to ensure consistency, structural integrity, and dimensional accuracy in every component produced.

Design begins with a detailed analysis of the client’s engineering specifications, including part geometry, mechanical requirements, and environmental exposure. Our engineering team employs finite element analysis (FEA) and mold flow simulation software to optimize gate placement, cooling channels, and ejection systems. This digital validation phase minimizes material stress and warpage risks while maximizing fill efficiency. Material selection focuses on high-purity aluminum alloys such as A380 and ADC12, chosen for their excellent fluidity, thermal conductivity, and strength-to-weight ratio. The mold design incorporates hardened tool steels with precision-machined cavities, ensuring longevity and repeatability across millions of cycles.

Prototyping follows design approval, utilizing rapid tooling techniques to produce functional sample parts within 10–15 days. These initial runs are conducted on full-scale production machines under actual process parameters, not simplified bench systems. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and X-ray porosity analysis. Mechanical testing, including tensile strength and thermal cycling, verifies performance against design intent. Feedback from this stage is used to refine mold geometry and process settings, closing the loop before full-scale launch.

Mass Production is executed on our automated aluminum injection molding lines, featuring real-time monitoring of injection pressure, temperature, and cycle time. Every parameter is logged and analyzed through our Manufacturing Execution System (MES), enabling full traceability and immediate deviation detection. In-line vision systems and automated dimensional checks ensure 100% inspection of critical features. Our zero-defect philosophy is enforced through Statistical Process Control (SPC), preventive maintenance schedules, and operator certification programs. Production yields exceed 99.5% conformance, with non-conforming units triggering root cause analysis and corrective action within 24 hours.

All phases are supported by ISO 9001-certified quality management systems and customer-specific APQP documentation. From concept to volume delivery, Wuxi Lead ensures that every aluminum injection molded part meets the highest standards of precision, reliability, and performance.

| Specification | Detail |

|---|---|

| Alloy Types | A380, A360, ADC12, Custom Alloys |

| Weight Range | 30 g – 2,500 g |

| Tolerance | ±0.05 mm (standard), ±0.02 mm (tight) |

| Surface Finish | Ra 0.8 – 3.2 µm (as-molded), polished or coated options |

| Production Capacity | Up to 2 million units/year per mold |

| Cycle Time | 30 – 120 seconds (part-dependent) |

| Quality Standards | ISO 9001, IATF 16949, PPAP Level 3 |

Why Choose Wuxi Lead Precision

Elevate Your Aluminum Manufacturing with Lead Precision Engineering

Wuxi Lead Precision Machinery stands at the forefront of advanced aluminum injection molding solutions, engineered for manufacturers demanding uncompromising precision, repeatability, and efficiency. Our machines transcend standard industry offerings by integrating aerospace-grade components with intelligent control systems, ensuring optimal thermal management and structural integrity during high-pressure aluminum casting. This eliminates porosity, minimizes flash, and delivers net-shape parts with exceptional surface finish—critical for automotive, aerospace, and medical applications where failure is not an option. Partnering with us means accessing decades of metallurgical expertise and a commitment to solving your most complex production challenges through tailored engineering.

What distinguishes Lead Precision is our vertically integrated manufacturing ecosystem. Every machine is built, calibrated, and validated within our ISO 9001-certified facility in Wuxi, China, allowing rigorous control over component quality and assembly tolerances. Unlike competitors reliant on third-party subsystems, we design core technologies in-house—including servo-hydraulic systems and proprietary mold protection algorithms—resulting in 30% faster cycle times and 99.8% uptime in continuous operation. Our engineering team collaborates directly with your R&D department to optimize gating systems, cooling channels, and ejection sequences specific to your alloy composition and part geometry. This holistic approach reduces material waste by up to 22% while meeting stringent GD&T requirements down to ±0.01mm.

Critical Performance Specifications for Aluminum Injection Molding

| Parameter | Range/Value | Industry Impact |

|---|---|---|

| Clamping Force | 2000–6500 kN | Supports large, complex molds without deflection |

| Shot Weight (A380) | 850–5200 g | Enables production of intricate structural components |

| Injection Pressure | 1800 bar | Ensures complete cavity fill for thin-wall designs |

| Positioning Accuracy | ±0.01 mm | Guarantees dimensional repeatability across 1M+ cycles |

| Thermal Control Stability | ±1.5°C | Prevents thermal shock in high-conductivity alloys |

Global leaders in electric vehicle manufacturing and defense contracting rely on Lead Precision for mission-critical components because we treat your production targets as our own engineering mandate. Our lifecycle support extends beyond installation: remote diagnostics, predictive maintenance scheduling, and on-site technician training ensure your machine operates at peak performance for 15+ years. We understand that downtime costs scale exponentially in high-mix production environments, which is why every system includes real-time process monitoring with AI-driven anomaly detection—transforming data into actionable insights before defects occur.

Initiate your transition to precision-driven aluminum manufacturing. Contact our engineering team directly at [email protected] with your part specifications, volume requirements, and material grade. Within 24 hours, you will receive a detailed capability analysis, including mold flow simulation data and a customized ROI projection. Do not compromise on quality when the integrity of your end product depends on metallurgical perfection. Wuxi Lead Precision Machinery: Where innovation meets industrial accountability. Your next breakthrough begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.