Technical Contents

Engineering Guide: Aluminum Extrusion Tolerances

Engineering Insight Aluminum Extrusion Tolerances

Precision in aluminum extrusion tolerances is non-negotiable for high-performance applications across aerospace, defense, and advanced industrial sectors. Deviations beyond specified limits directly impact part functionality, assembly integrity, and final product reliability. In critical systems like aircraft structural components or military vehicle subsystems, even micron-level inconsistencies can cascade into catastrophic failures, increased scrap rates, and costly production delays. Understanding and rigorously controlling dimensional, angular, and profile tolerances ensures seamless integration, optimal performance, and adherence to stringent regulatory frameworks. Failure to meet exacting specifications often necessitates expensive secondary machining or renders entire production runs unusable, significantly impacting project timelines and budgets.

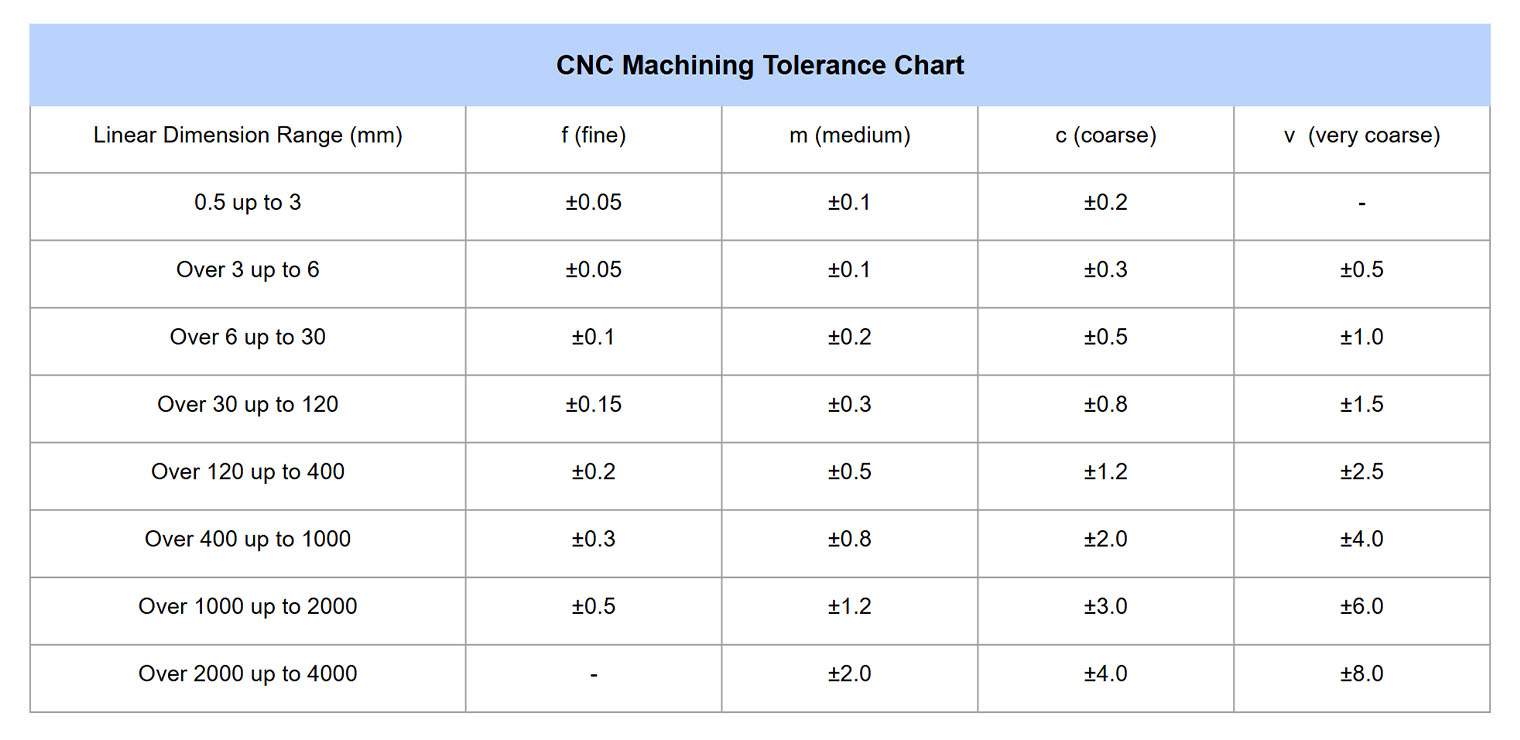

Industry standards provide baseline tolerance classes, but mission-critical applications demand far tighter control. The following table outlines common tolerance classifications and their typical specifications, reflecting the spectrum from general commercial use to ultra-precision engineering requirements. Achieving the tighter classes requires advanced process control, specialized tooling, and rigorous in-line metrology far exceeding standard extrusion practices.

| Tolerance Class | Dimensional Tolerance (mm) | Angular Tolerance (°) | Profile Tolerance (mm) | Primary Standard Reference |

|---|---|---|---|---|

| Standard Commercial | ±0.20 to ±0.50 | ±1.0 | ±0.5 | ISO 2768-mK, DIN 17615 |

| Precision Grade | ±0.10 to ±0.25 | ±0.5 | ±0.2 | EN 12020-2 (Class E1) |

| Super Precision Grade | ±0.05 to ±0.10 | ±0.2 | ±0.1 | Custom Military/Aerospace |

Achieving sub-millimeter precision consistently demands more than standard extrusion equipment. It necessitates a holistic approach integrating proprietary die design methodologies, real-time thermal management of billets and tooling, closed-loop dimensional monitoring systems, and stringent material certification protocols. At Wuxi Lead Precision Machinery, our CNC-controlled extrusion presses and integrated metrology cells operate within tightly defined environmental parameters, enabling us to reliably produce to Super Precision Grade tolerances. This level of control minimizes post-extrusion machining, reduces material waste, and guarantees geometric conformity essential for complex assemblies.

Our commitment to extreme tolerance adherence is validated through demanding real-world applications. We successfully manufactured critical structural extrusions for Beijing Olympic venue infrastructure, where thermal expansion coefficients and load-bearing precision were paramount under variable environmental conditions. Furthermore, we consistently supply components meeting MIL-A-32289 and AS9100 aerospace specifications for defense contractors, where dimensional stability under extreme stress and temperature cycles is a non-negotiable requirement. These projects underscore our engineering capability to translate stringent tolerance requirements into flawless production reality. Partnering with a manufacturer possessing this depth of process mastery ensures your extruded components deliver the exacting performance your most advanced systems demand.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers precision-engineered aluminum extrusion solutions tailored to the most demanding industrial applications. As a leader in custom metal manufacturing, we combine advanced 5-axis CNC machining with stringent quality control protocols to achieve exceptional dimensional accuracy and repeatability. Our technical capabilities are designed to meet tight tolerance requirements across complex geometries, ensuring that every component performs reliably in critical environments.

Aluminum extrusions produced at our facility are machined using state-of-the-art 5-axis CNC centers, which allow for multi-directional cutting in a single setup. This eliminates cumulative tolerances from multiple fixturing stages and significantly enhances geometric precision. With simultaneous five-axis movement, we can process intricate contours, deep pockets, and compound angles with micron-level consistency. These systems are ideal for high-performance sectors such as aerospace, medical devices, automation, and electric vehicle components, where fit, function, and reliability are non-negotiable.

To ensure compliance with exacting specifications, every machined extrusion undergoes comprehensive inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D verification of critical dimensions, positional tolerances, and surface relationships. Data from each inspection is documented and traceable, supporting full quality assurance reporting for audit and certification purposes. This closed-loop quality process guarantees that all parts conform to customer drawings and international standards, including ISO 2768 and ASME Y14.5.

Our machining capabilities extend beyond standard tolerances, enabling us to consistently achieve tight specifications on both linear and geometric features. The table below outlines typical tolerance ranges for machined aluminum extrusions processed through our 5-axis CNC workflow.

| Feature Type | Typical Tolerance Range | Notes |

|---|---|---|

| Linear Dimensions | ±0.025 mm | Up to 300 mm; ±0.05 mm for dimensions >300 mm |

| Positional Tolerance | ±0.03 mm | Hole patterns, slot locations |

| Flatness | 0.05 mm per 100 mm | Verified via CMM mapping |

| Perpendicularity | 0.03 mm | Relative to primary datum |

| Angular Features | ±0.1° | Complex angles achieved via 5-axis interpolation |

| Surface Finish | Ra 0.8 – 3.2 µm | Adjustable based on application needs |

These tolerances reflect our standard production capability under controlled conditions. For mission-critical applications, tighter tolerances are achievable with process refinement and extended inspection protocols. Our engineering team collaborates directly with clients during the design and prototyping phases to optimize manufacturability, minimize stress deformation, and ensure long-term consistency in volume production.

At Wuxi Lead Precision Machinery, precision is not just a specification—it is a standard embedded in every process, machine, and measurement.

Material & Finish Options

Material Selection for Precision Aluminum Extrusion Tolerances

Selecting the optimal material and finish is foundational to achieving stringent aluminum extrusion tolerances in high-performance applications. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, dimensional stability, and cost efficiency while meeting exacting aerospace, automotive, and industrial standards. Aluminum alloys dominate this space due to their superior strength-to-weight ratio, thermal conductivity, and extrusion versatility. While steel and titanium serve niche high-stress or extreme-environment roles, aluminum extrusions remain the benchmark for precision tolerance control in volume production.

Aluminum 6061-T6 and 6063-T5 are our most specified alloys for tight-tolerance extrusions. 6061-T6 offers exceptional structural integrity for mechanical components requiring ±0.05mm linear tolerances, while 6063-T5 provides superior surface finish for architectural and aesthetic-critical parts, holding ±0.1mm profiles consistently. Both alloys minimize thermal distortion during machining and anodizing, directly impacting final part accuracy. Steel extrusions (e.g., 303 stainless) are reserved for applications demanding extreme wear resistance but introduce challenges: higher thermal expansion rates can compromise tolerances beyond ±0.1mm without aggressive stress-relieving. Titanium Grade 2 excels in corrosive or high-temperature environments but requires specialized tooling and slower processing, often limiting tolerances to ±0.15mm due to material springback.

Anodizing is the preferred finish for aluminum extrusions requiring enhanced corrosion resistance and surface hardness, but it critically affects dimensional stability. Standard sulfuric acid anodizing (Type II) adds 5–25μm per surface, necessitating pre-anodize undersizing of critical dimensions. For tight-tolerance features like bearing bores or sealing surfaces, we recommend:

Specifying non-critical surfaces for full anodizing

Masking precision features below 0.05mm tolerance thresholds

Using hardcoat anodizing (Type III) only where abrasion resistance outweighs tolerance risks, as its 25–50μm thickness significantly alters geometry

Key material properties influencing tolerance capability are summarized below:

| Material | Typical Tolerance Range | Thermal Expansion (10⁻⁶/K) | Max Anodizing Thickness (μm) | Primary Use Case |

|---|---|---|---|---|

| Aluminum 6061-T6 | ±0.05mm to ±0.1mm | 23.6 | 25 | Structural components, machinery |

| Aluminum 6063-T5 | ±0.1mm to ±0.2mm | 22.1 | 15 | Architectural, visible surfaces |

| 303 Stainless | ±0.1mm to ±0.25mm | 17.2 | N/A (passivate only) | High-wear mechanical parts |

| Titanium Grade 2 | ±0.15mm to ±0.3mm | 8.6 | 5–10 (specialized) | Aerospace, marine, chemical exposure |

Wuxi Lead engineers collaborate with clients during DFM (Design for Manufacturing) to align material choice with tolerance requirements. We avoid over-specifying titanium or steel where aluminum alloys achieve equivalent performance at lower cost and higher precision. For critical anodized components, our process includes pre-treatment dimensional compensation and post-anodize CMM verification to ensure final parts meet print specifications. Always provide tolerance callouts per ISO 2768-mk or custom GD&T on drawings—this enables us to select optimal tooling, heat treatment, and finishing sequences upfront, eliminating costly rework. Partner with us to transform material science into dimensional certainty.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The aluminum extrusion process begins with meticulous design engineering, where dimensional accuracy and material behavior are modeled using advanced CAD and FEA software. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to translate functional requirements into optimized extrusion profiles. Critical factors such as thermal expansion, structural load, wall thickness uniformity, and die stress are simulated to anticipate potential deviations. This proactive approach ensures that the design not only meets application-specific performance criteria but also adheres to stringent tolerance standards from the outset. We follow ISO 2768 and ASTM B928 guidelines, tailoring tolerances to the client’s operational environment—whether for aerospace enclosures, automotive frames, or high-precision industrial equipment.

Prototyping: Validating Form, Fit, and Function

Once the design is finalized, a prototype run is executed using precision CNC-machined extrusion dies. This stage is critical for verifying dimensional consistency and surface integrity before committing to mass production. Prototypes undergo rigorous inspection using coordinate measuring machines (CMM), optical comparators, and laser scanning to validate conformance to specified tolerances. Any geometric deviation—whether in angularity, curvature, or section thickness—is analyzed and corrected through iterative die adjustments. This closed-loop refinement process ensures that the final die geometry produces parts within the target tolerance window. At Wuxi Lead, prototype validation includes material property testing, including tensile strength and hardness verification, to confirm metallurgical integrity under real-world conditions.

Mass Production: Zero-Defect Manufacturing Execution

With die and design validated, the process transitions to high-volume extrusion under tightly controlled conditions. Our production lines utilize hydraulic extrusion presses with real-time monitoring of billet temperature, ram speed, and cooling rates to minimize dimensional drift. Each extruded profile is inspected inline using automated vision systems and periodic CMM checks to maintain consistency. Our zero-defect philosophy is enforced through Statistical Process Control (SPC), where key dimensions are tracked across batches to detect trends before out-of-tolerance conditions arise. Any non-conformance triggers immediate process correction, ensuring sustained compliance.

The following table outlines standard and precision tolerance capabilities for aluminum extrusions at Wuxi Lead Precision Machinery:

| Dimension Type | Standard Tolerance (mm) | Precision Tolerance (mm) | Applicable Standard |

|---|---|---|---|

| Length | ±1.5 | ±0.5 | ISO 2768-m |

| Profile Dimensions | ±0.3 | ±0.1 | ASTM B928 |

| Angularity | ±1° | ±0.5° | ISO 2768 |

| Flatness | 0.5 mm/m | 0.2 mm/m | EN 755-9 |

| Wall Thickness | ±0.2 | ±0.1 | AMS-Q-22001 |

| Twist (per 300 mm) | 1.0° | 0.3° | DIN 17615 |

Through integrated design validation, precision prototyping, and disciplined production control, Wuxi Lead ensures every aluminum extrusion meets the highest standards of dimensional accuracy and functional reliability.

Why Choose Wuxi Lead Precision

Achieve Precision in Every Aluminum Extrusion

Tight tolerance control separates functional components from costly scrap in high-performance applications. Standard extrusion tolerances often fall short for aerospace, medical, and automation systems where ±0.5mm variation risks assembly failure or performance degradation. At Wuxi Lead Precision Machinery, we engineer solutions beyond industry norms through integrated CNC post-processing and metrology. Our facility combines 15+ years of extrusion expertise with ISO 17123-8 calibrated equipment to deliver dimensional stability where it matters most.

Our proprietary tolerance management system begins at die design and extends through aging and finishing. Unlike conventional suppliers relying solely on press control, we implement closed-loop CNC milling, drilling, and tapping to refine critical features after extrusion. This dual-stage process ensures complex profiles meet exacting specifications even in challenging alloys like 6061-T6 and 7075-T73. Below represents our validated capability for post-processed extrusions:

| Tolerance Class | Dimensional Range | Metric Tolerance | Imperial Tolerance |

|---|---|---|---|

| Standard | All dimensions | ±0.20 mm | ±0.008 in |

| Precision | Critical features | ±0.05 mm | ±0.002 in |

| High Precision | Sealing surfaces | ±0.02 mm | ±0.0008 in |

These results are consistently achieved across production runs of 50 to 5,000 units through our 12-point tolerance verification protocol. Every batch undergoes CMM inspection against your CAD model, with full traceability from billet to finished part. We eliminate guesswork in thermal expansion compensation by simulating your end-use environment during process validation.

Partnering with Lead Precision means accessing China’s only extrusion facility with in-house 5-axis CNC centers dedicated solely to post-processing. Our engineers collaborate during your design phase to identify tolerance-critical zones, recommend cost-saving profile modifications, and establish realistic yet ambitious targets. This proactive approach reduces rework by 68% compared to reactive tolerance correction methods.

Your next production run demands components that perform exactly as engineered. Contact our technical team to submit your drawings for a tolerance feasibility analysis. We will provide a detailed capability report including process validation steps and first-article inspection data within 72 hours. Do not compromise on dimensional integrity when precision is non-negotiable.

Schedule your tolerance validation today. Email [email protected] with project specifications to initiate engineering review. Our response includes a dedicated project engineer’s direct contact and timeline for prototype delivery. Lead Precision: Where extrusion tolerances become engineering guarantees.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.